Reinforcing bar cage hoisting process for canal wall construction

A steel cage hoisting and construction technology, which is applied in the tunnel field, can solve the problems of a large number of electric welding electrodes, increase the labor intensity of welders, and prolong the construction period, so as to reduce the waste of steel bars, speed up the production progress, and ensure safety. Lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

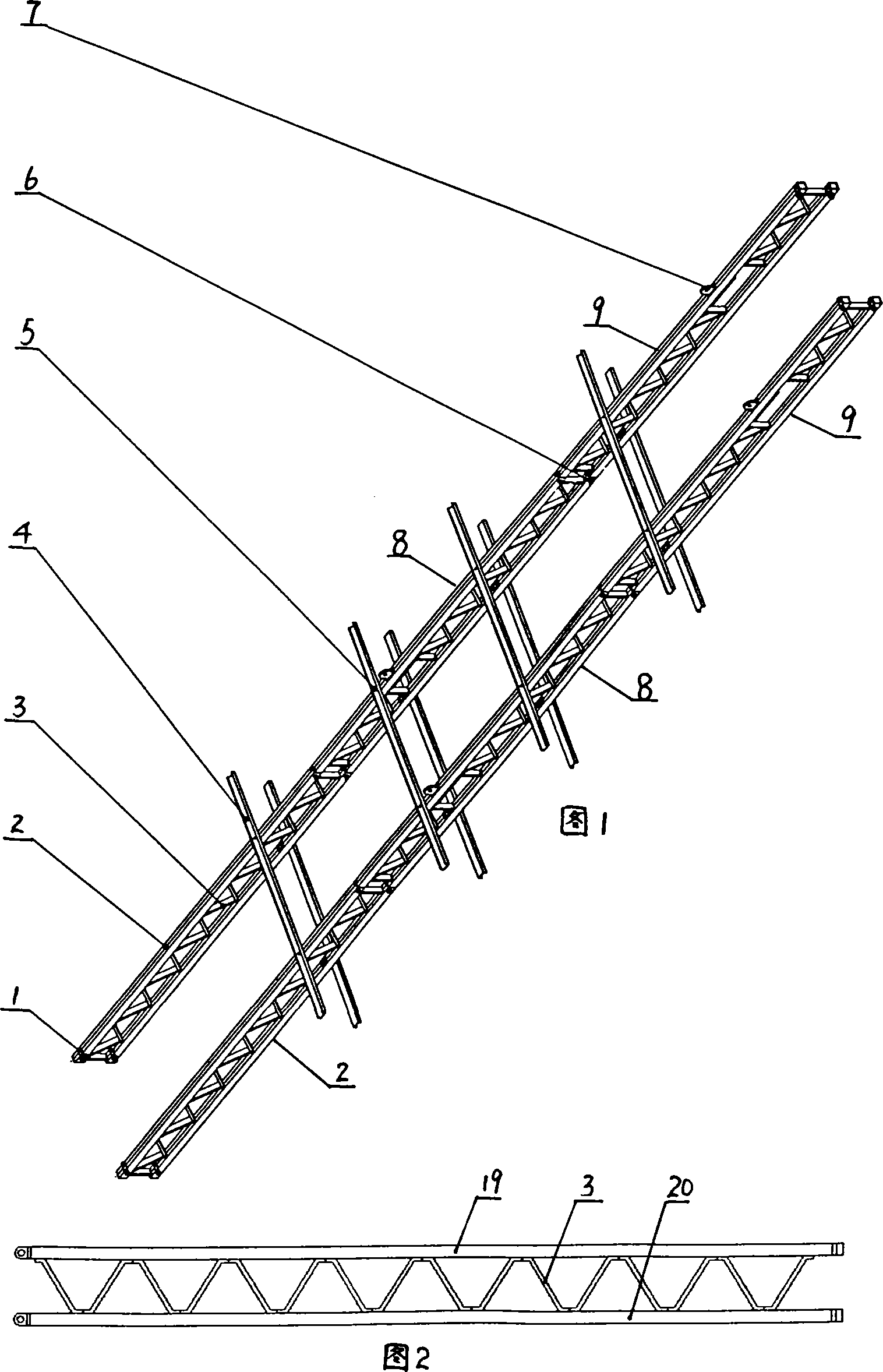

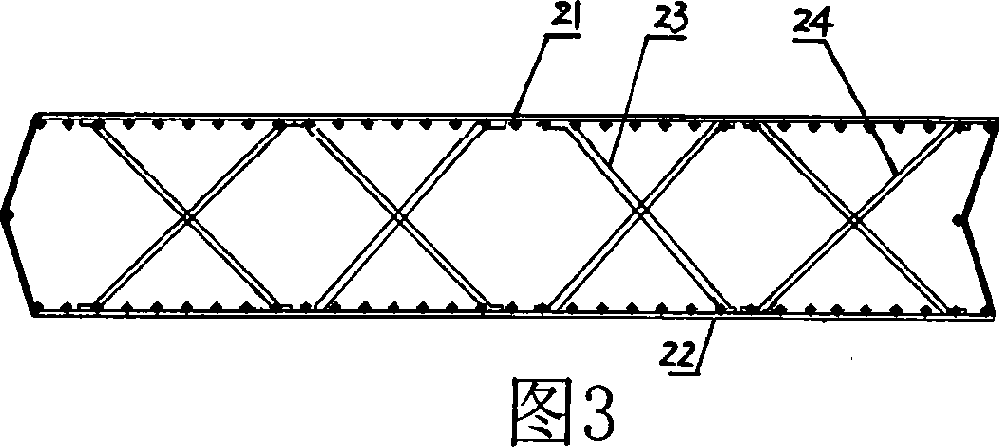

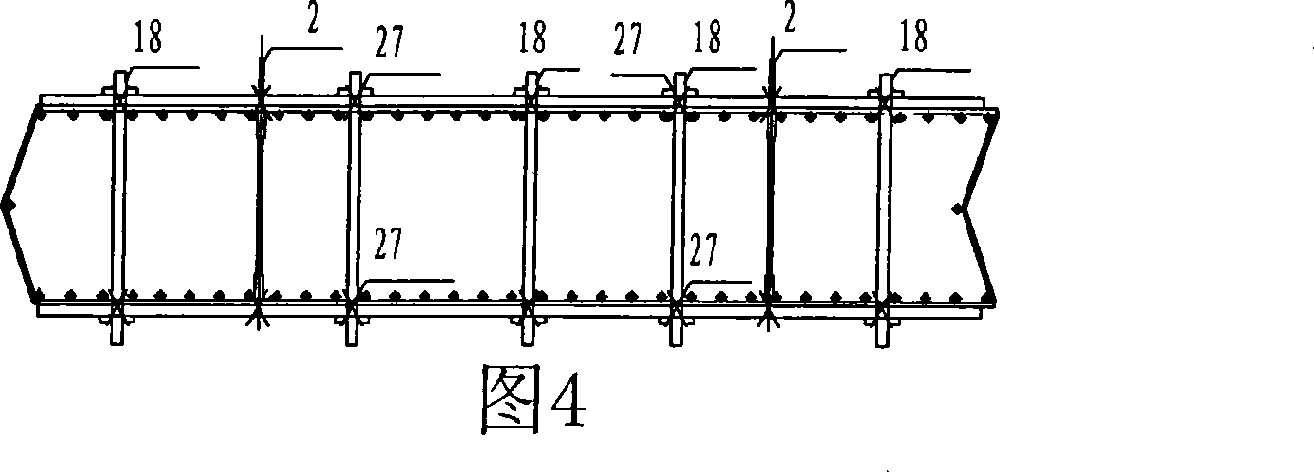

[0025] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0026] As shown in Figure 1-9, the labels 1-27 respectively represent: connecting steel bolt 1, longitudinal truss 2, wave channel steel 3, transverse truss 4, transverse truss fastening bolt 5, connecting steel pin between trusses 6, movable crane Point 7, longitudinal truss 8, longitudinal truss 9, pulley 10, truss hoisting structure 11, steel cage 12, transverse truss I13, transverse truss II14, transverse truss III15, transverse truss IV16, transverse truss V17, fastening screw 18, upper slot Steel 19, lower channel steel 20, channel steel I21, channel steel II22, channel steel 23, channel steel 24, steel pin connection hole 25, longitudinal truss protruding tongue 26, No. 8 iron wire 27.

[0027] What this embodiment relates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com