Automatic soil eliminating construction apparatus for deep foundation groove

A technology for construction devices and deep foundation pits, which is applied in infrastructure engineering, earth movers/excavators, excavation, etc., which can solve problems such as difficulties in safe construction management, low construction efficiency, and partial under-excavation, and achieve benefits to the site Construction management, high construction efficiency, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

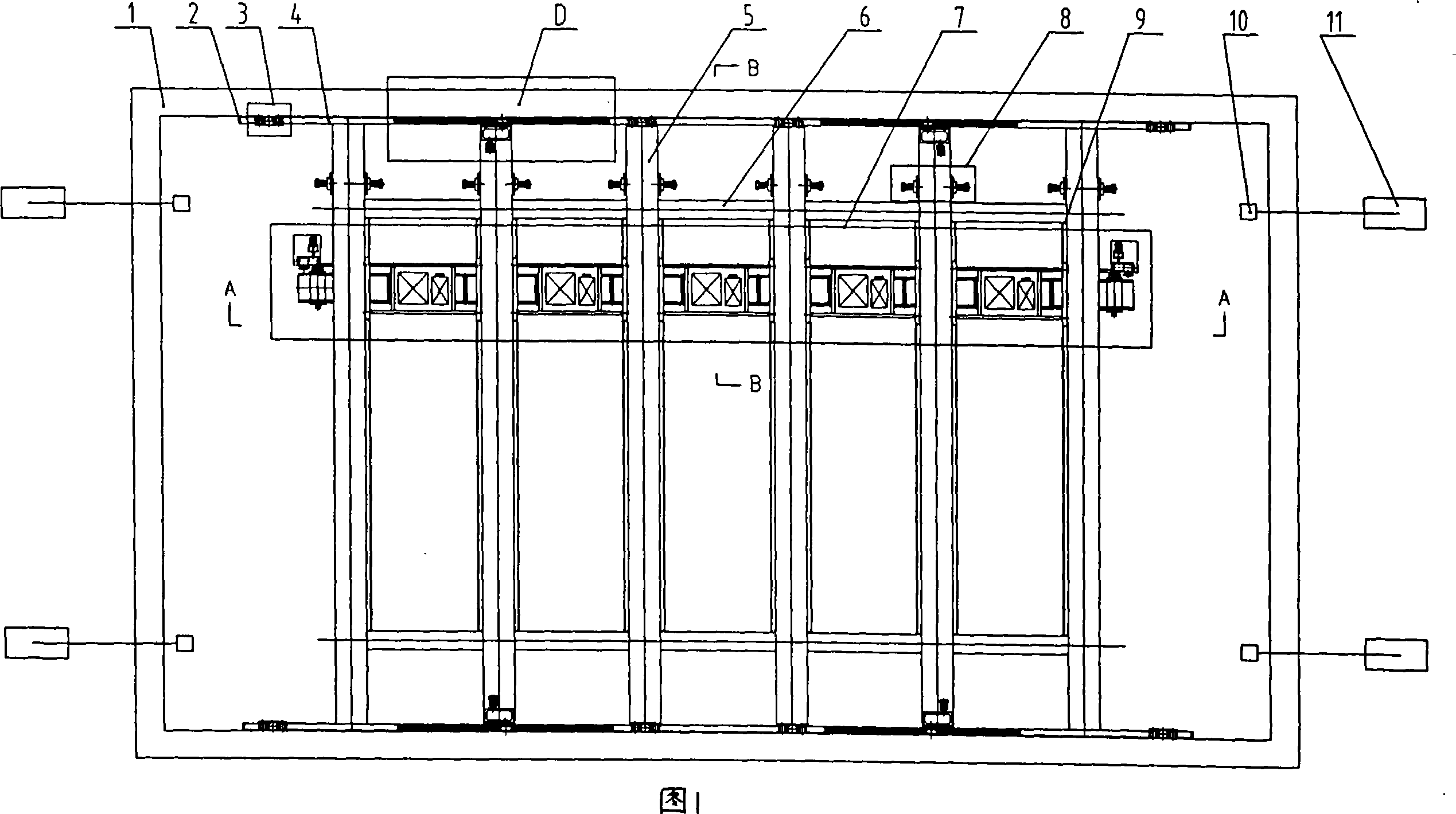

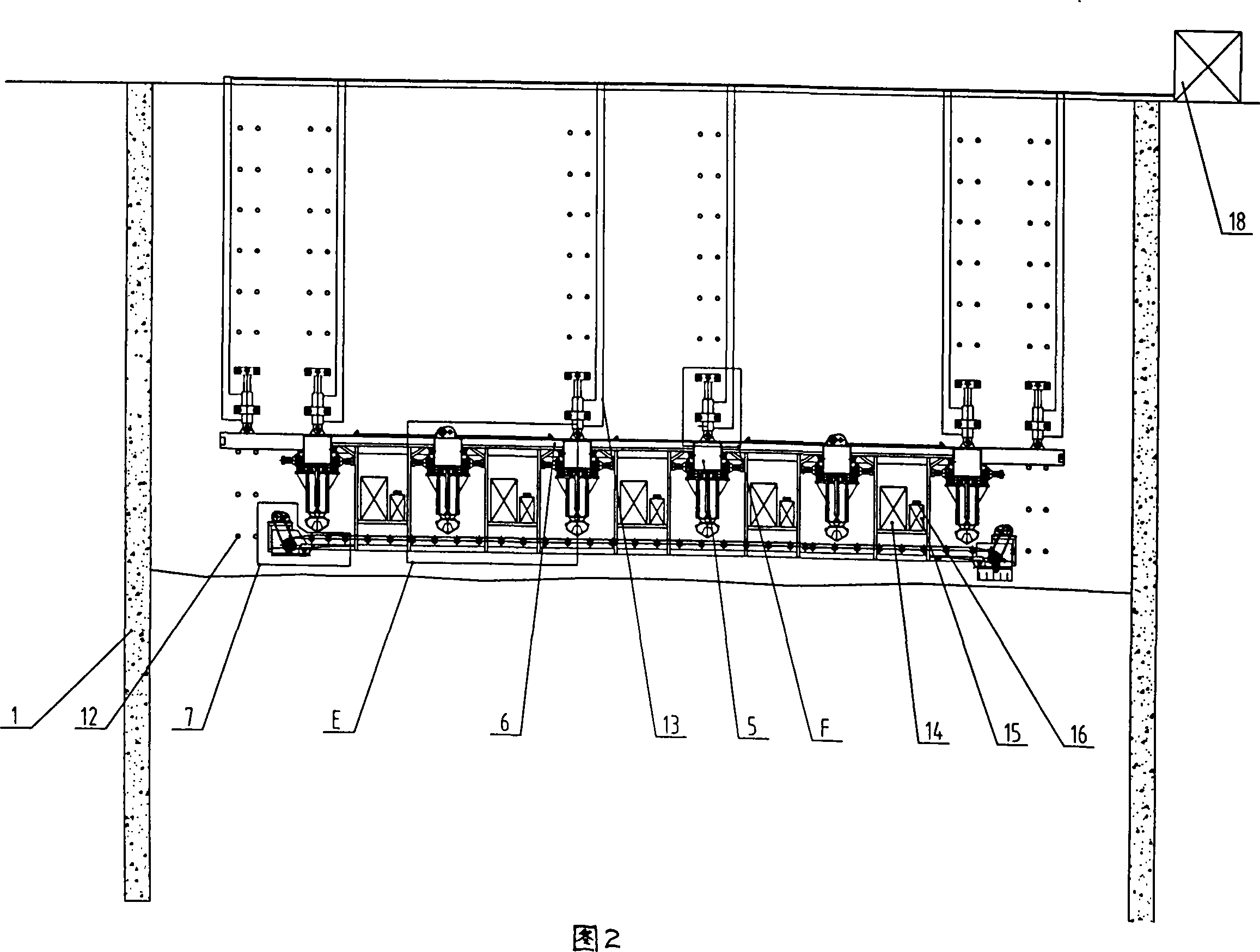

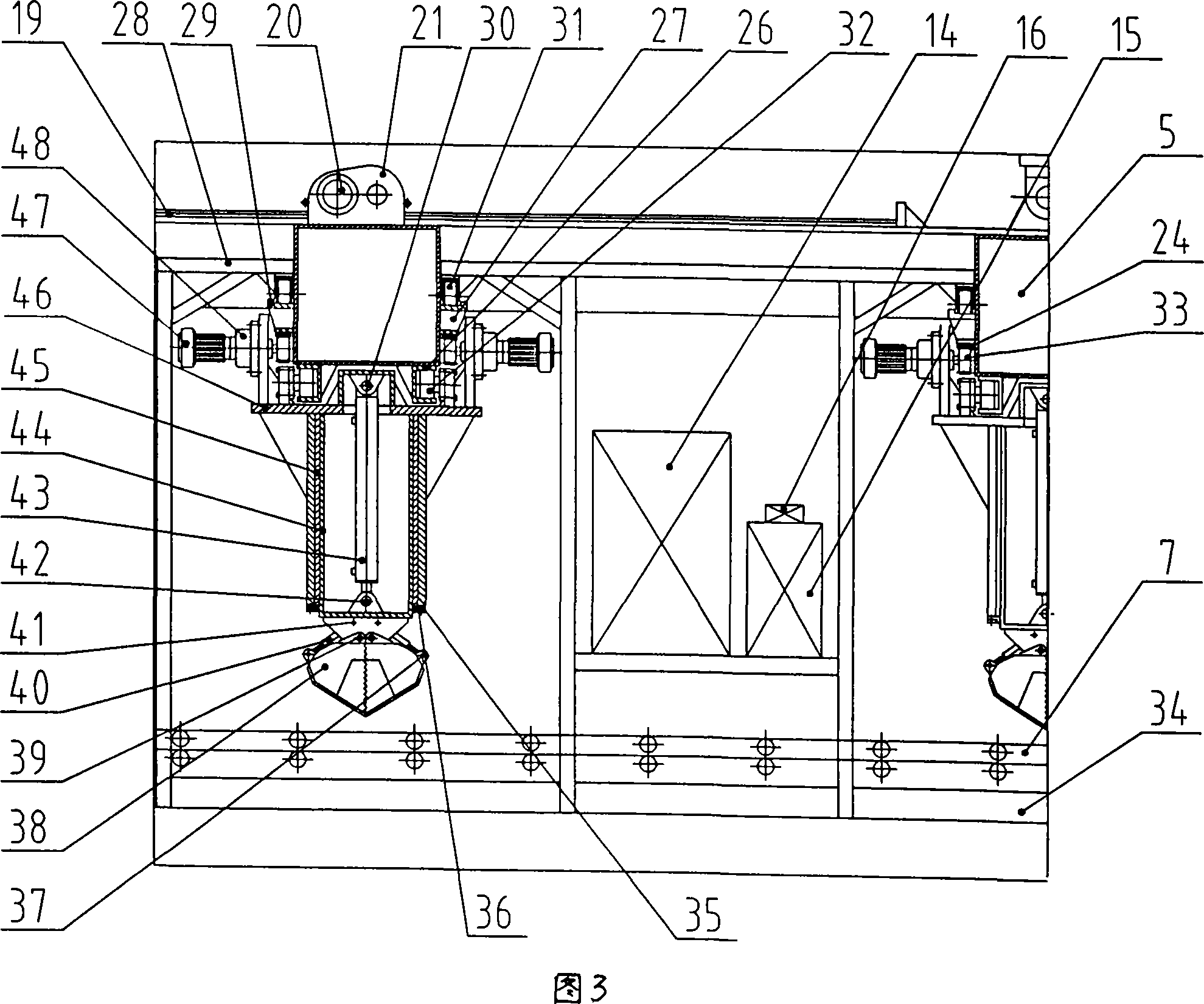

[0020] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0021] As shown in Figure 1-9, the labels 1-57 respectively represent: underground diaphragm wall 1, elastic limit block 2, self-climbing and descending device 3, track beam 4, walking beam 5, connecting beam 6, belt conveyor 7, hydraulic Grab excavation device 8, elastic limit block 9, mechanical grab 10, crawler crane 11, embedded pin seat 12, hydraulic hose 13, hydraulic power equipment 14, electrical control box 15, wireless remote control receiving device 16 , hinge seat 17, hydraulic power unit 18, rack 19, motor 20, reducer 21, gear 22, elastic limit block 23, rack 24, traveling wheel 25, track 26, rib plate 27, equipment frame 28, Track 29, pin 30, road wheel 31, road wheel 32, gear 33, connecting beam 34, dustproof rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com