Glass hood cooking fume exhauster

A range hood and glass cover technology, which is applied in the field of kitchen range hoods, can solve problems such as difficult disassembly and cleaning, poor ventilation, and shortened service life of impellers, so as to prevent oil fume from polluting the environment, improve the efficiency of range hood, and reduce the entry of oil fume mouth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

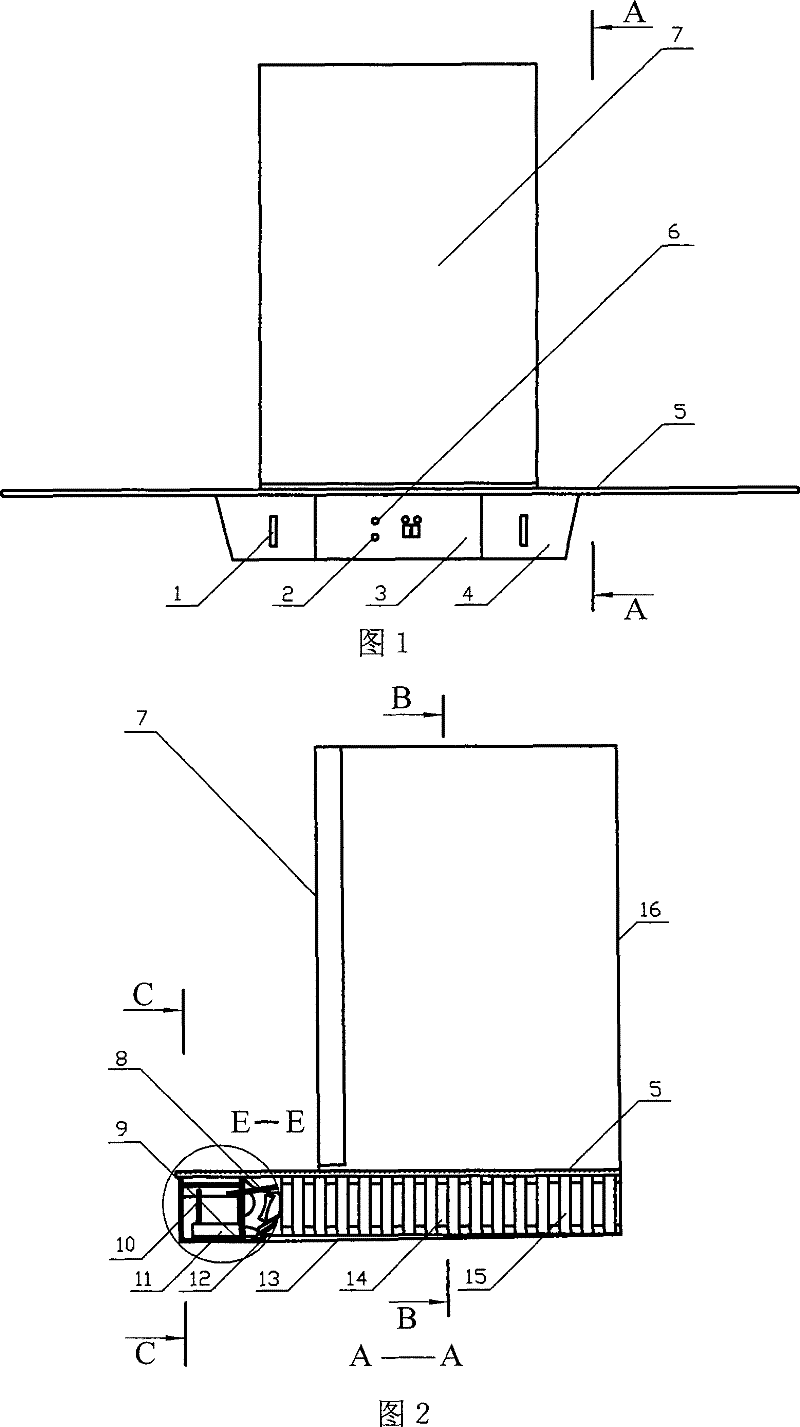

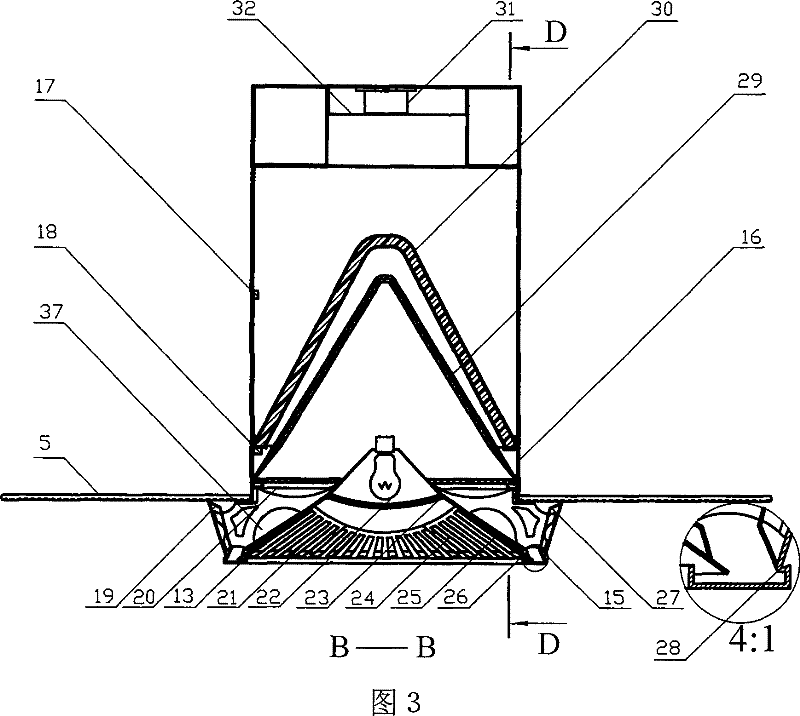

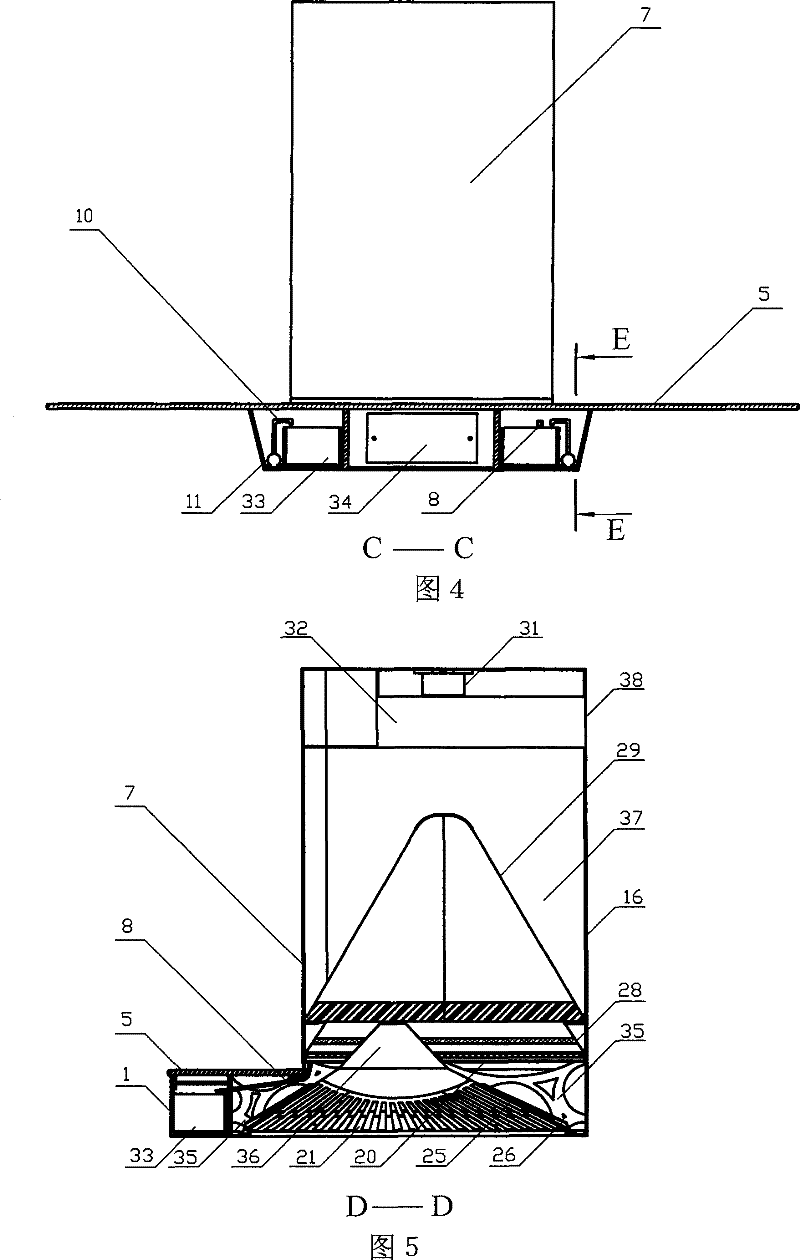

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025]With reference to the accompanying drawings, the present invention is provided with a smoke collecting chamber 16, the lower end of the smoke collecting chamber 16 has an outward turning edge before and on the left and right sides, the glass cover 5 is hung on the turning edge of the lower end of the smoke collecting chamber 16 and fixed, 5. The lower smoke collection cavity 16 is turned over and fixed with more than six fixed plates 35 around the upper periphery. The side ventilation inner wall 21 is installed on the inner side between the fixed plates 35. The vertical slot air inlet 24 at the bottom of the side ventilation inner wall 21 can be disassembled in pieces. An illuminating lamp 22 and a lampshade 23 are disposed in the middle of the reflector 36 . The left and right outer sides of fixed plate 35 are fixed two side air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com