Automatic measuring equipment for volume density of ceramic test sample

An automatic measurement and tile technology, applied in the direction of material analysis by measuring buoyancy, can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

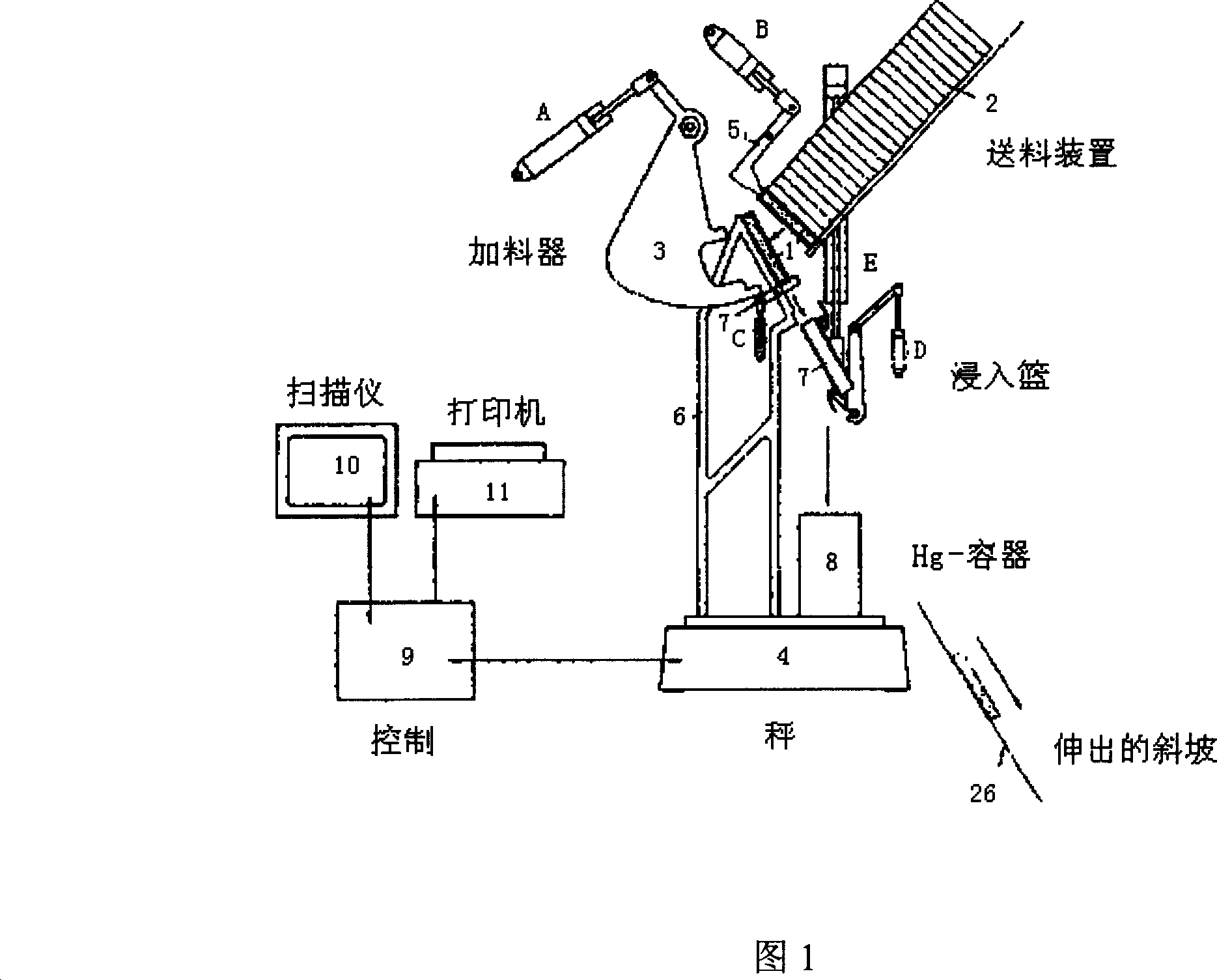

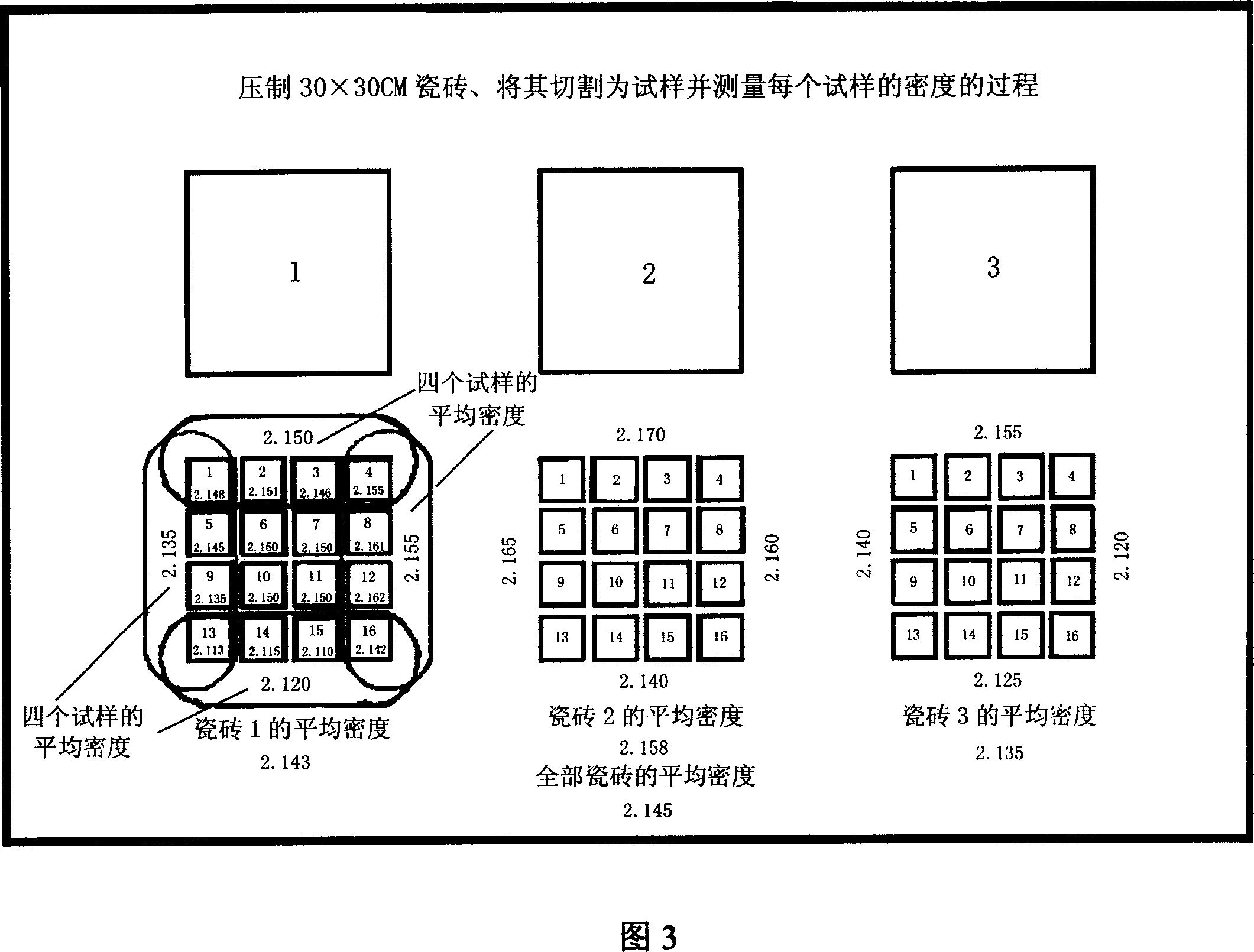

[0017] The device shown in Figure 1 is capable of determining the density of a sample and determining the density distribution in the following manner:

[0018] The first test sample 1 is transferred from the feeding device 2 onto the scale 4 by a transfer mechanism comprising a swivel arm 3 and actuated by a hydraulic or pneumatic cylinder A. Stopper 5 holds the other test samples in the feeder. The stand 6 on the scale provides the best position for the test sample on the scale. Scale 4 is used to determine the weight of the test sample. After weighing, a further conveyor mechanism 7 comprising baskets for picking up test samples dips the test sample 1 into a container 8 containing pure liquid mercury. This container 8 is preferably placed on the same scale 4 used to determine the weight of the test sample.

[0019] When the test sample is immersed in the mercury and the mercury is at rest, the scale 4 measures the buoyancy of the submerged basket with the test sample in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com