Diffraction device

A diffraction element and diffraction pattern technology, applied in the field of diffraction elements, can solve the problems of high production cost, difficulty in making diffraction elements, fluctuations in diffraction efficiency, etc., and achieve the effect of less wavelength dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

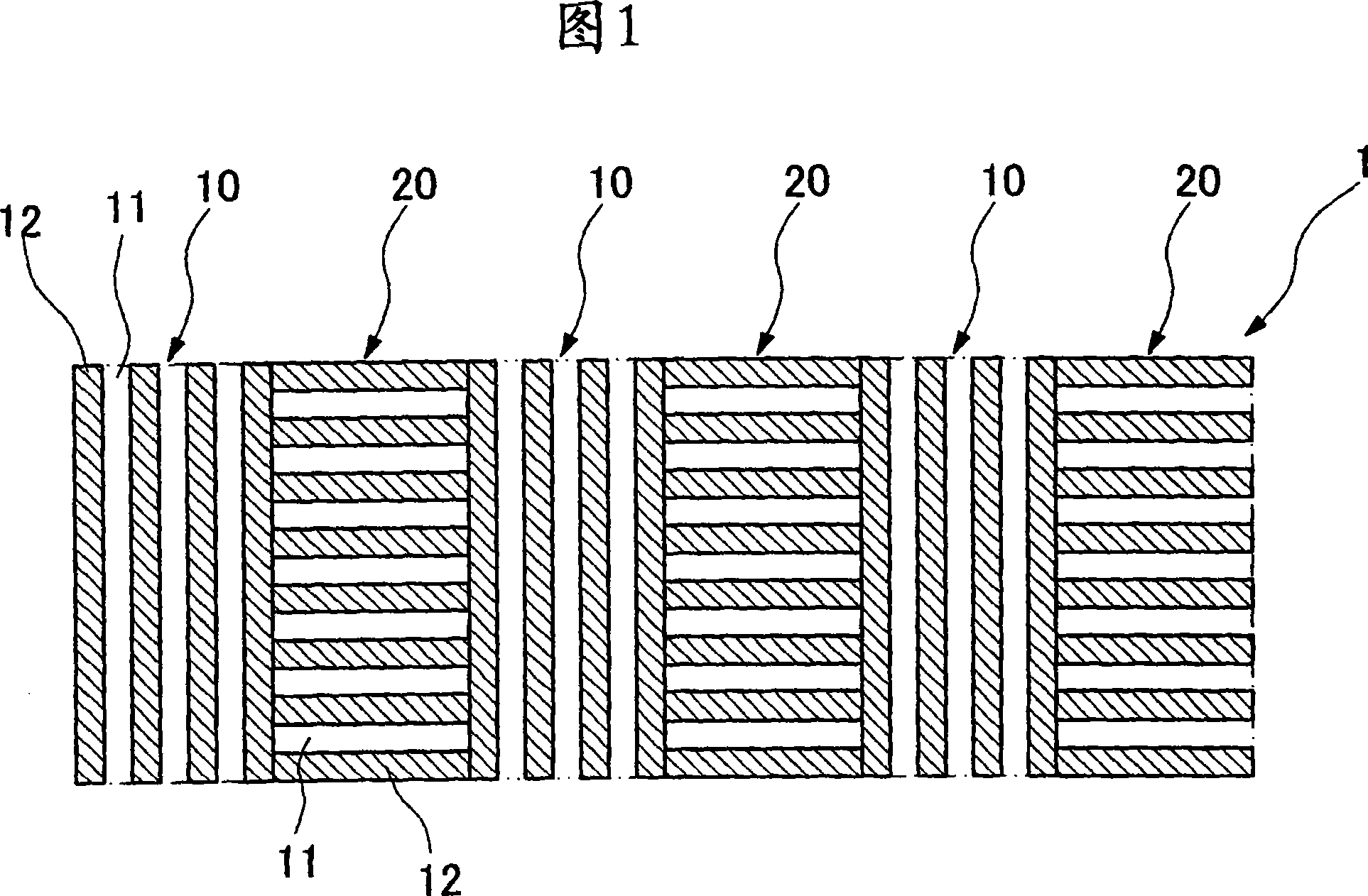

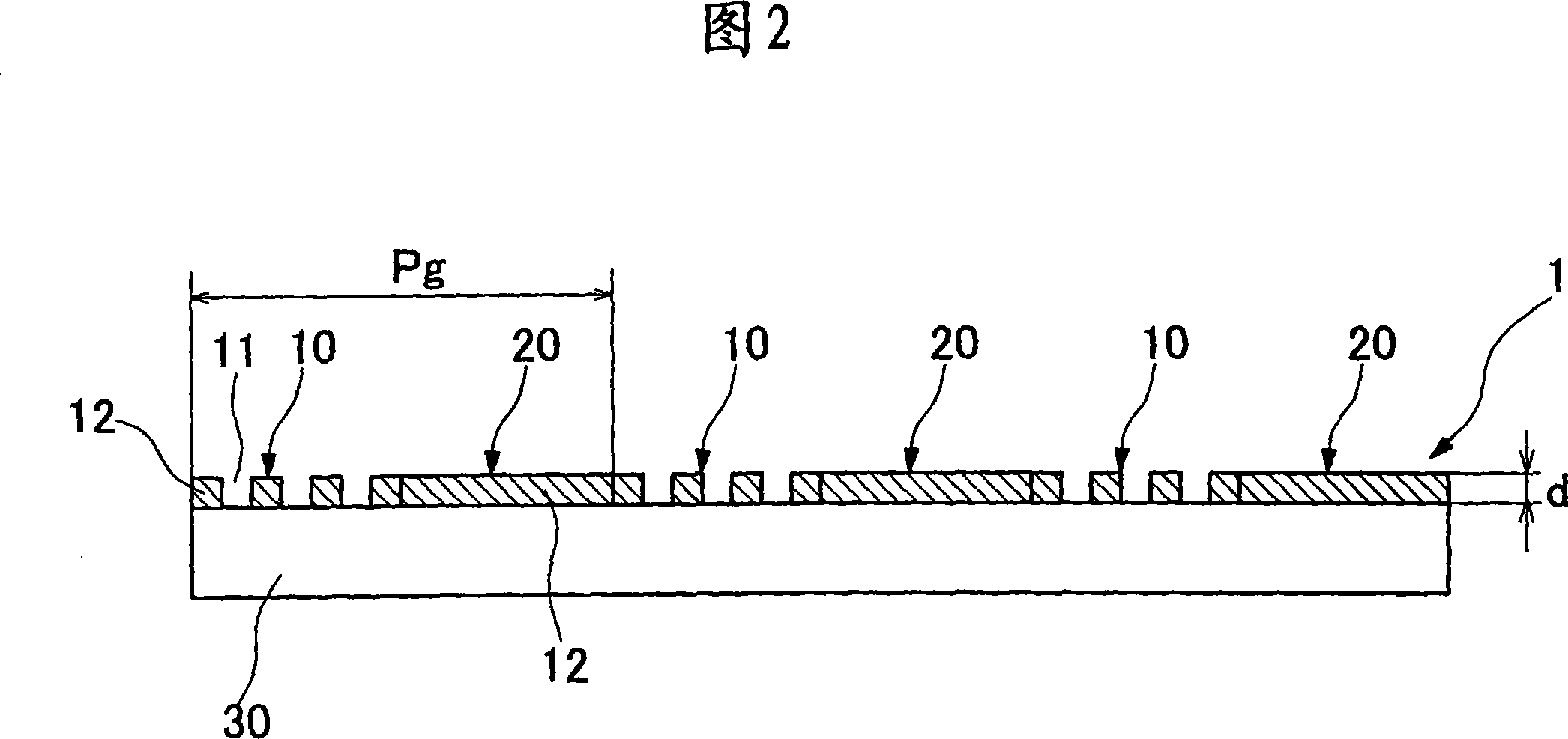

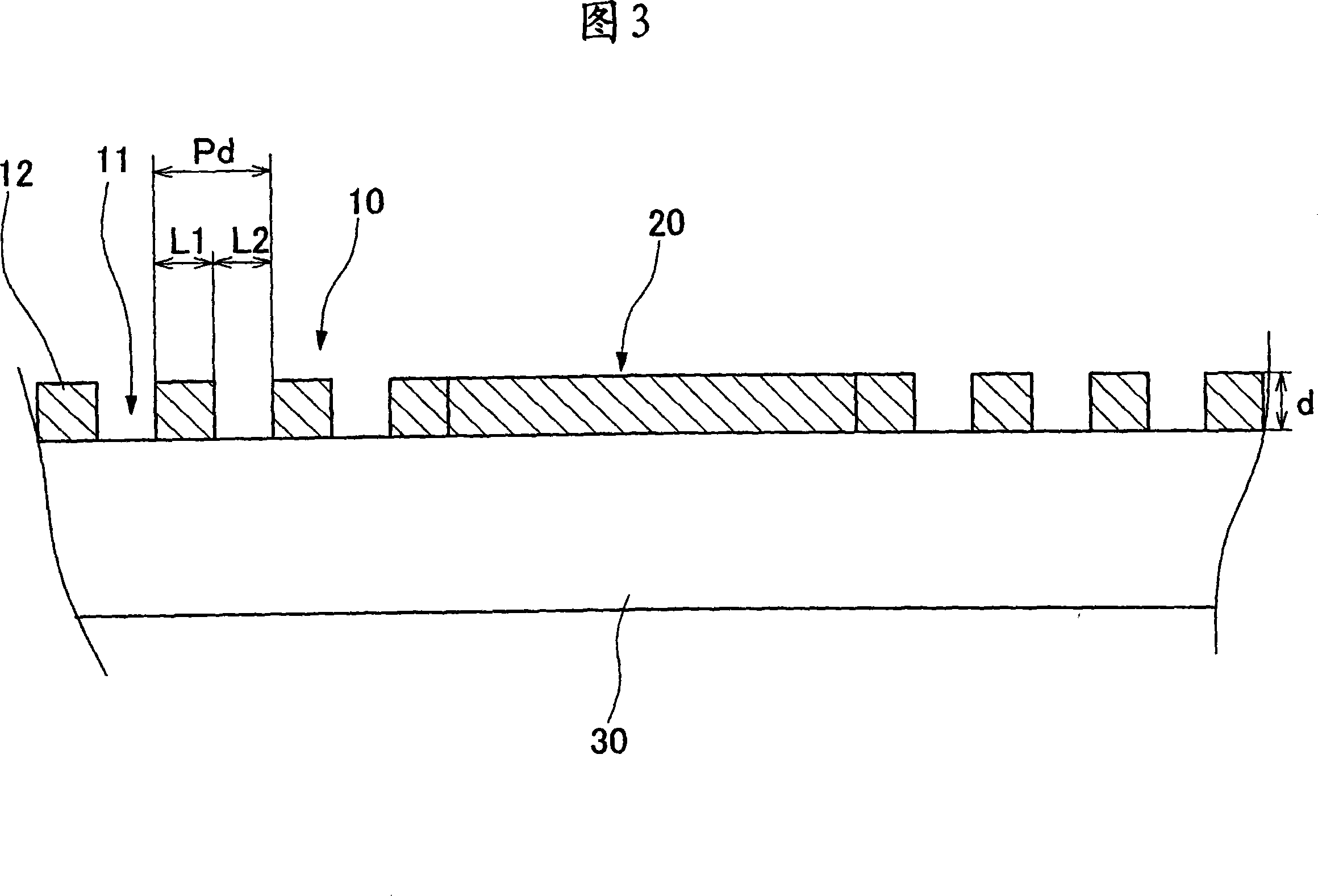

[0032] A. Description of the diffraction element of the present invention

[0033] Embodiments of the present invention will be described below with reference to the accompanying drawings. As shown in FIGS. 1 and 2 , the first phase difference region 10 and the second phase difference region 20 of the diffraction element 1 of the present invention are formed on one side of a transparent substrate 30 such as a glass substrate. As shown in FIG. 1 , the first phase difference regions 10 and the second phase difference regions 20 are arranged in a periodic structure alternately. In the first phase difference region 10 and the second phase difference region 20 , as shown in FIG. 3 , a concave-convex structure with a fine pitch is formed. Such a micro-pitch concave-convex structure is formed by duplicating the concave-convex structure on resin or the like or by digging grooves on the transparent substrate 30 itself. Accordingly, the concave portion (below as concave portion 11) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com