Processing method for superimposed riveting pressing pieces automatically

A processing method and technology of stamping parts, applied in the field of metal stamping processing, can solve the problems of wasting man-hours, quality cannot meet the technical index requirements of supporting products, and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

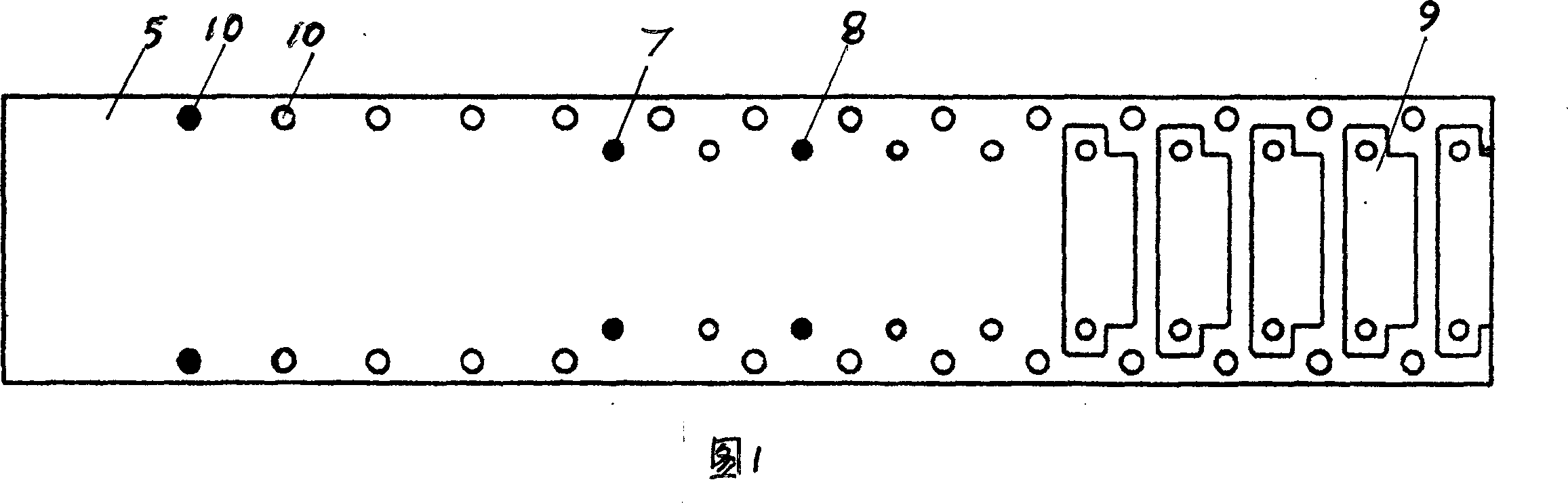

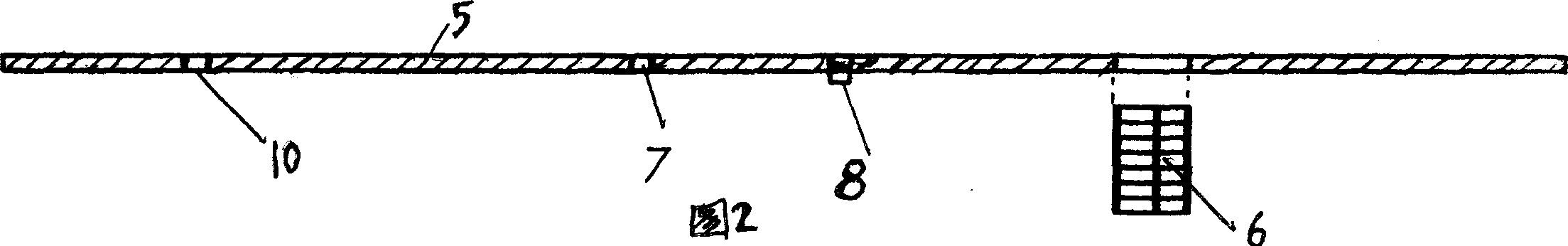

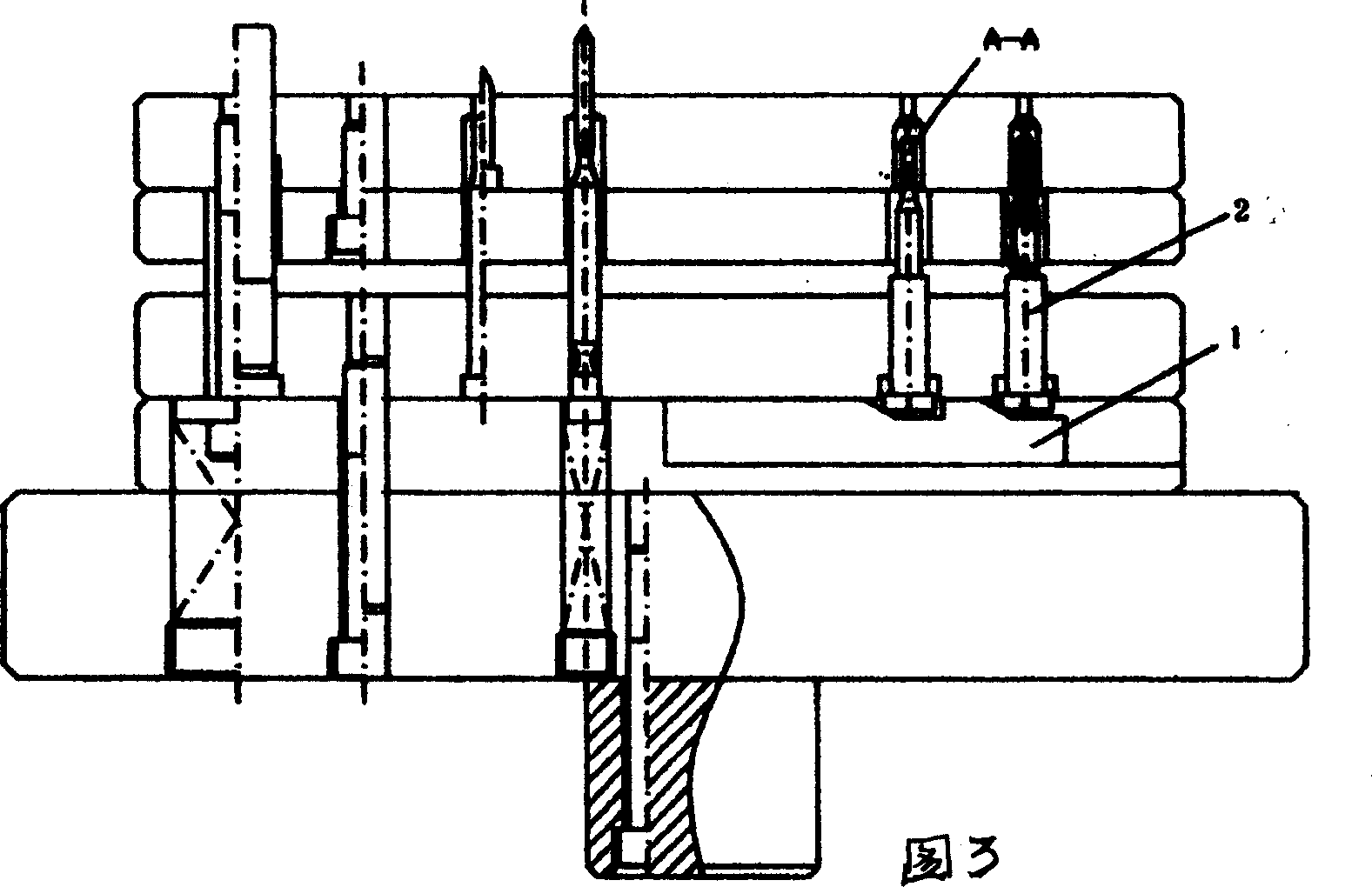

[0017] Figures 1 and 2 are the layout of the parts on the material belt and the side view of the formed stacked riveting workpiece. Figures 3 and 4 are the general assembly drawings of the upper mold, and Figures 5 and 6 are the general assembly drawings of the lower mold. The mold adopts two-way guide pillars for precise guidance , the stepping direction is the guiding and positioning of the guiding nail, which creates conditions for correct riveting. The specific structure is: the cylinder is connected to the mold, a relay is installed on the punching machine, the punching machine works eight times as a cycle, the first stamping, the cylinder works once to push the wedge-shaped slider to work to achieve punching, and pull the wedge-shaped slider to quickly return to its original position . The last seven stamping cylinders do not work, which is the stamping and convex process, and the eight parts are completed in the cavity of the three-punch concave model shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com