Integral forming method for overlay film powder in complex shape of geometrical body of disabled laser selection

A technology of complex shape and integral molding, which is applied in the direction of laser welding equipment, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of difficult to manufacture complex parts, low strength, and inability to process powder materials, etc., and achieve the effect of detail protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

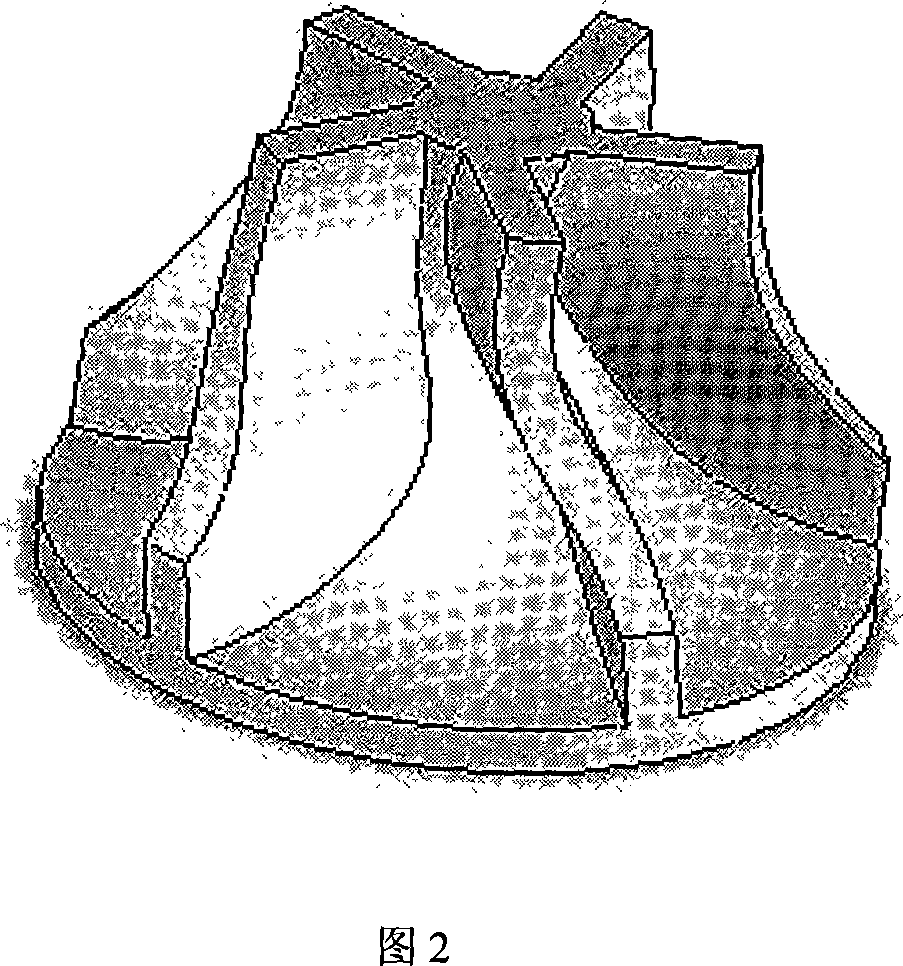

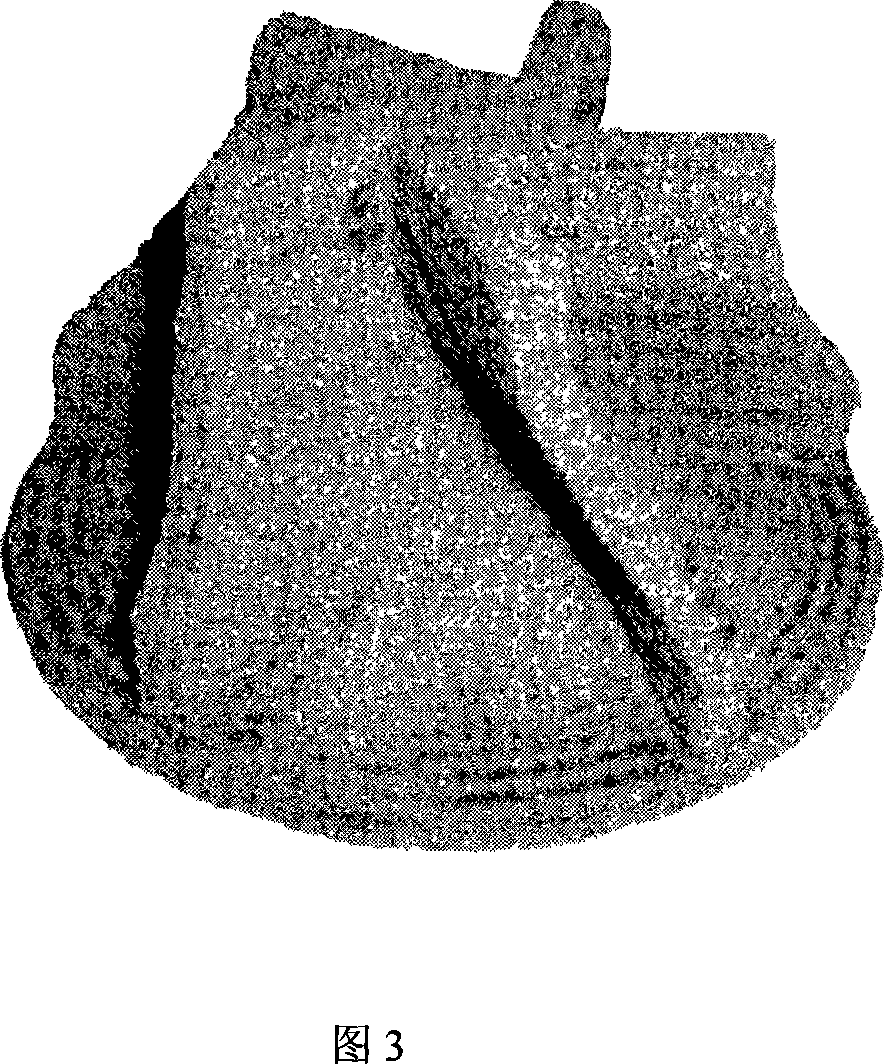

[0044] Embodiment: Manufacture "impeller" solid part

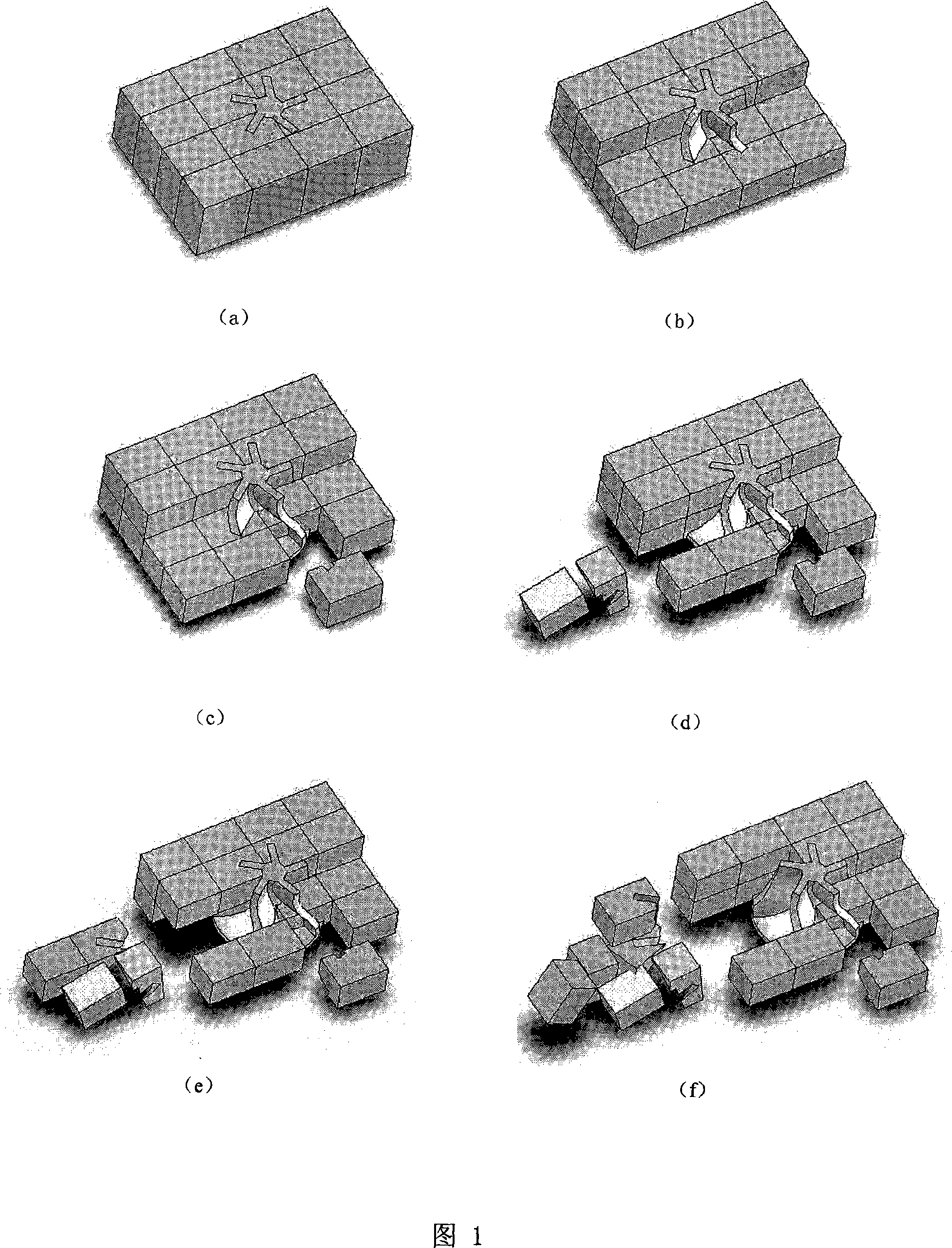

[0045] Firstly, the modeling design of the three-dimensional CAD model of the "impeller" and the solid modeling design of the sand box are completed in the computer, and the "impeller" entity is subtracted from the solid model of the sand box through the integrated operation function of the CAD software system, and the "impeller as the Cavity" sand mold three-dimensional geometric model. At this time, there are two solid models of the "impeller" solid model and the sand mold with the "impeller as a cavity" in the computer system, and the union of these two solid models is the entire sand box. According to the needs, select the "impeller" as the target entity of rapid integral molding, and take the sand mold with "the impeller as the cavity" as the object to be broken, and then regularly break the sand mold with the "impeller" as the cavity" into a series of The small stripped body is in the shape of a small cuboid or an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com