Pitch storage tank with heat preserved by heating medium oil

A technology of heat medium oil and asphalt, which is applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve the problems of complex structure and operation, inaccurate measurement, etc., and achieve simple structure and operation, low energy consumption, and no energy consumption. The effect of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

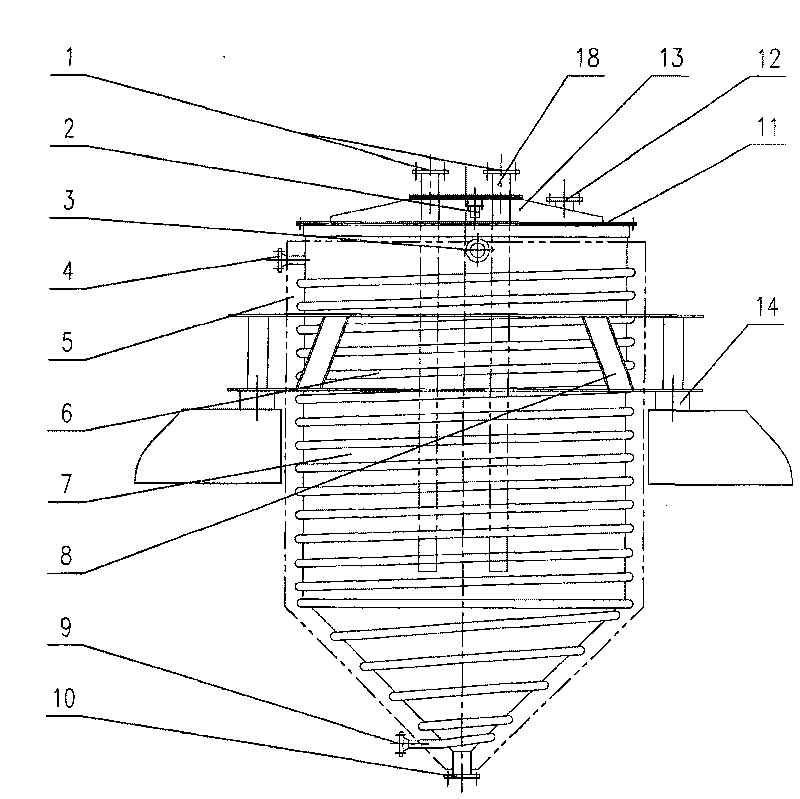

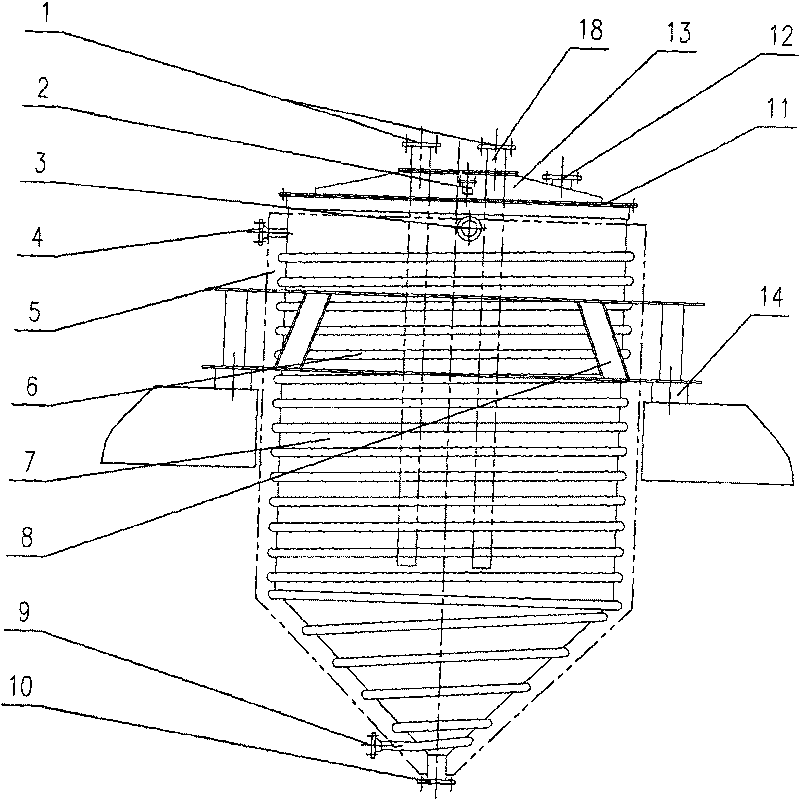

[0025] Such as figure 1 As shown, a sealing gasket 11 is provided between the upper cover 13 and the cylinder 7 and is connected together by fasteners for easy maintenance. The bracket 8 is welded on the outer circle of the cylinder 7, and a thermal The medium pipe 6, the heat medium pipe 6 is spirally arranged outside the cylinder body 7, the two ends of the heat medium pipe 6 are the heat medium oil inlet 9 and the heat medium oil outlet 4, the lower end of the bracket 8 is placed on the upper end of the electronic scale 14, and the electronic scale 14 lower ends are placed on the foundation.

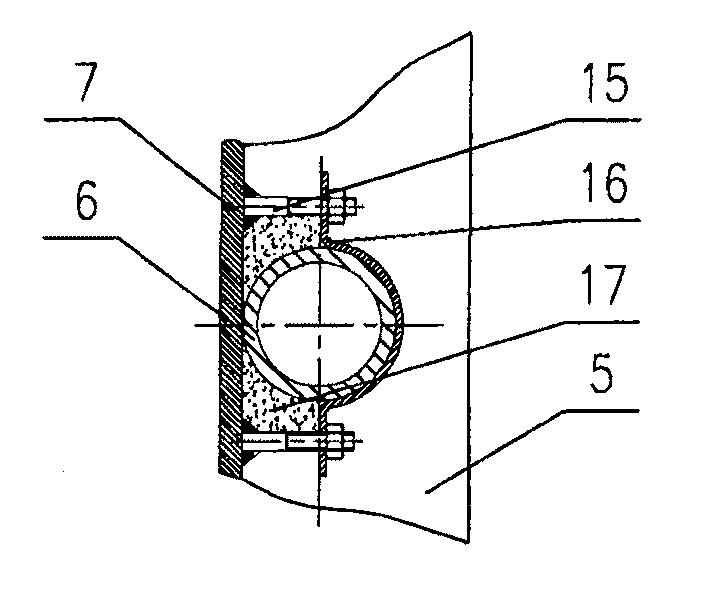

[0026] Such as figure 2 As shown, one end of the bolt 15 is welded on the outer circle of the cylinder body 7, and the other end presses the heat medium pipe 6 with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com