Anti-freezing pressure reducing device for natural gas

A pressure reducer and natural gas technology, which is applied in the field of balance valves, can solve the problems of increasing management workload and achieve low cost, improve environmental conditions, and overcome the effects of frosting and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

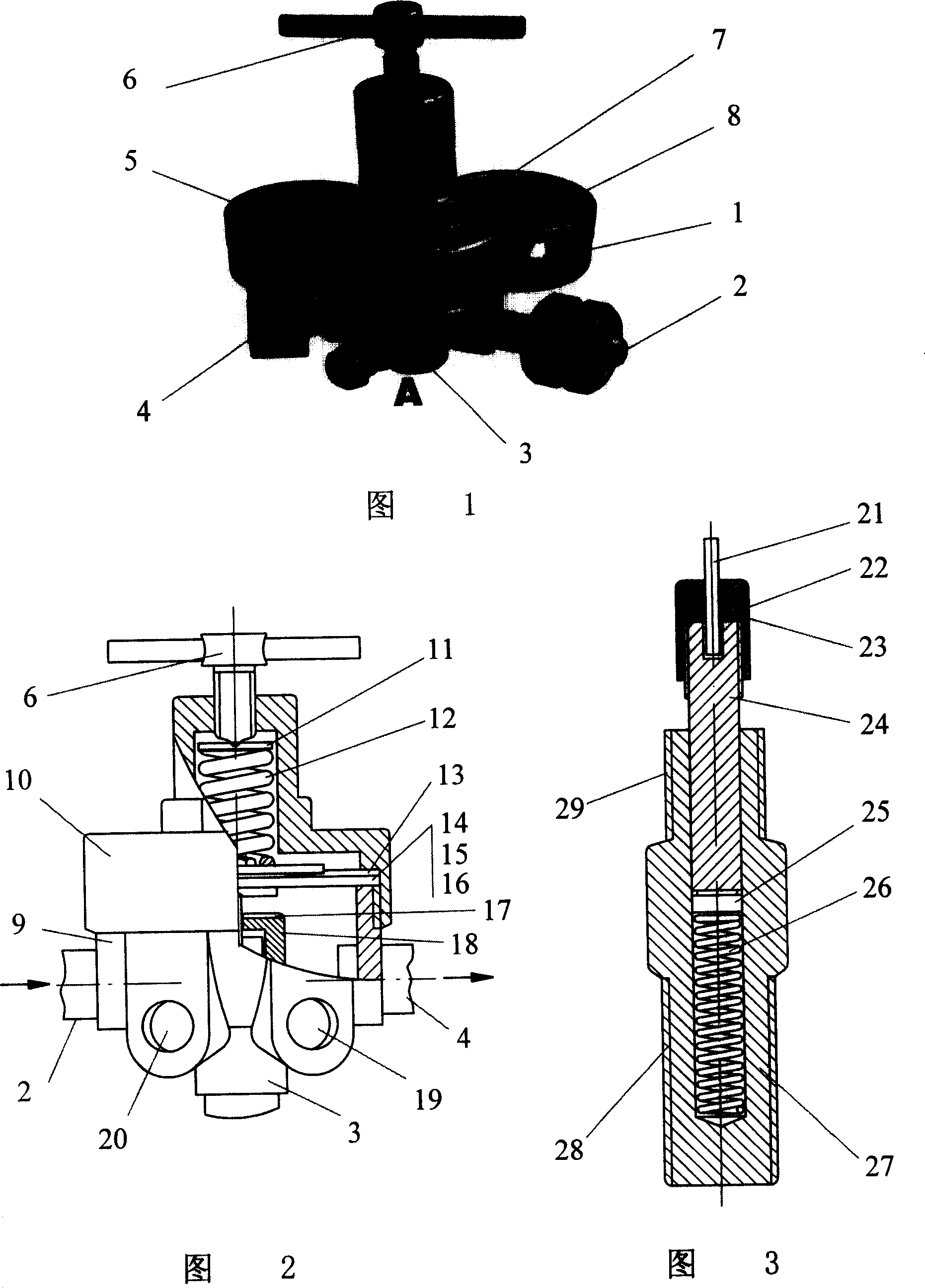

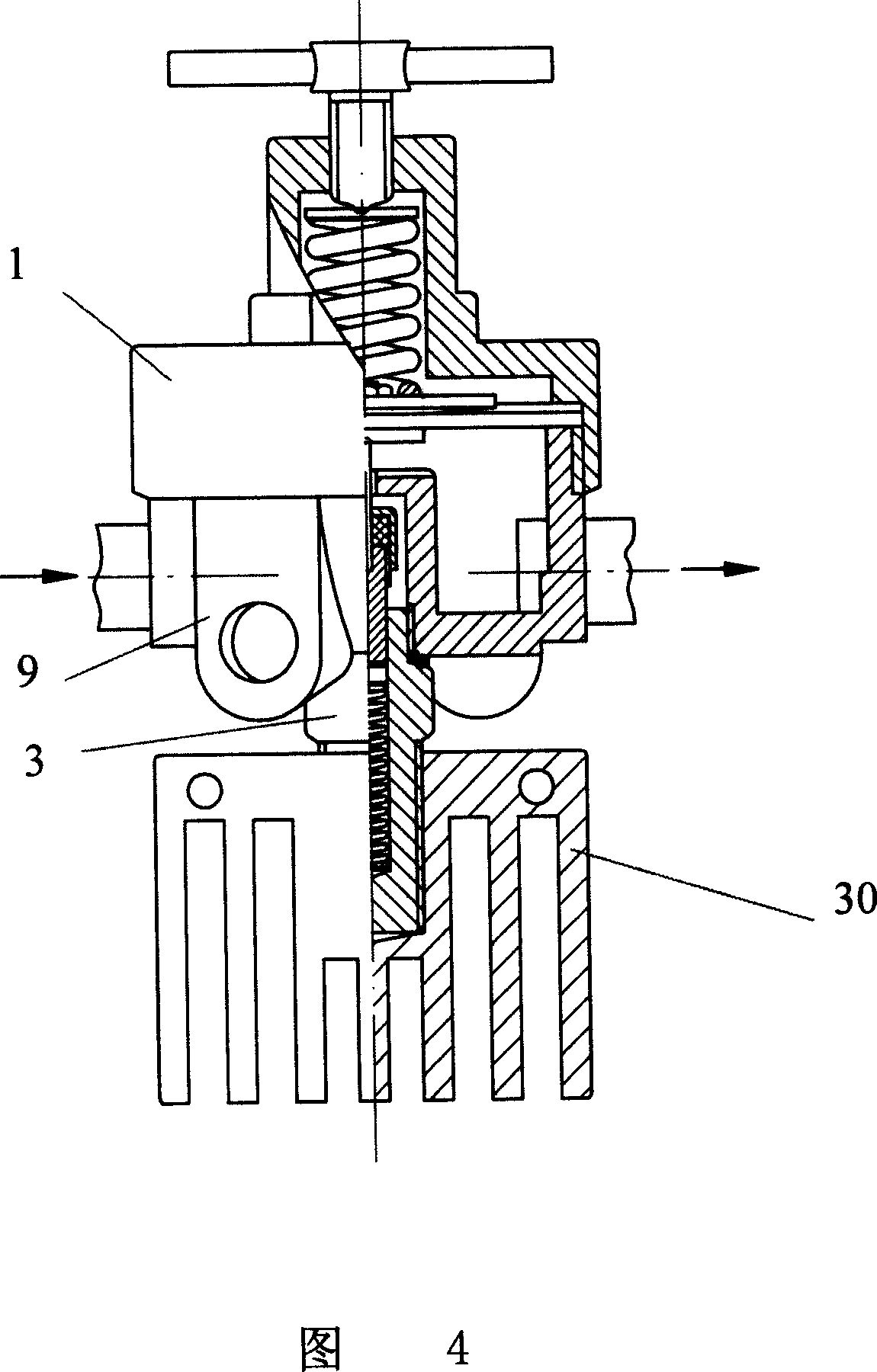

[0025] Further description will be given below in conjunction with the implementation examples and accompanying drawings.

[0026] As shown in Figure 1: Natural gas and gas pressure reducing valves are often used in pipelines, gas cylinders and busbars. It is mainly composed of valve body 1, air inlet and outlet ports 2 and 4, air pressure gauges 5 and 8, regulating device 6 and thimble device 3. The thimble device is located at part A, and the thimble and pressure spring are directly installed on the valve body wall by plugging screws. Due to the compact structure, the influence of temperature drop during operation is great, and the pressure change when single-stage is used is small, and 2 to 3 more stages are needed to achieve the decompression target from 25MPa to 0.8MPa. The air intake hole and the diaphragm assembly on the air intake platform can seal off the air during adjustment. When used in a single stage with a large load, it will be frozen soon. The 7th, communic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com