Sewing machine

A sewing machine and sewing needle technology, which is applied in the direction of sewing machine components, sewing machine thread take-up devices, sewing equipment, etc., to improve reliability and achieve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

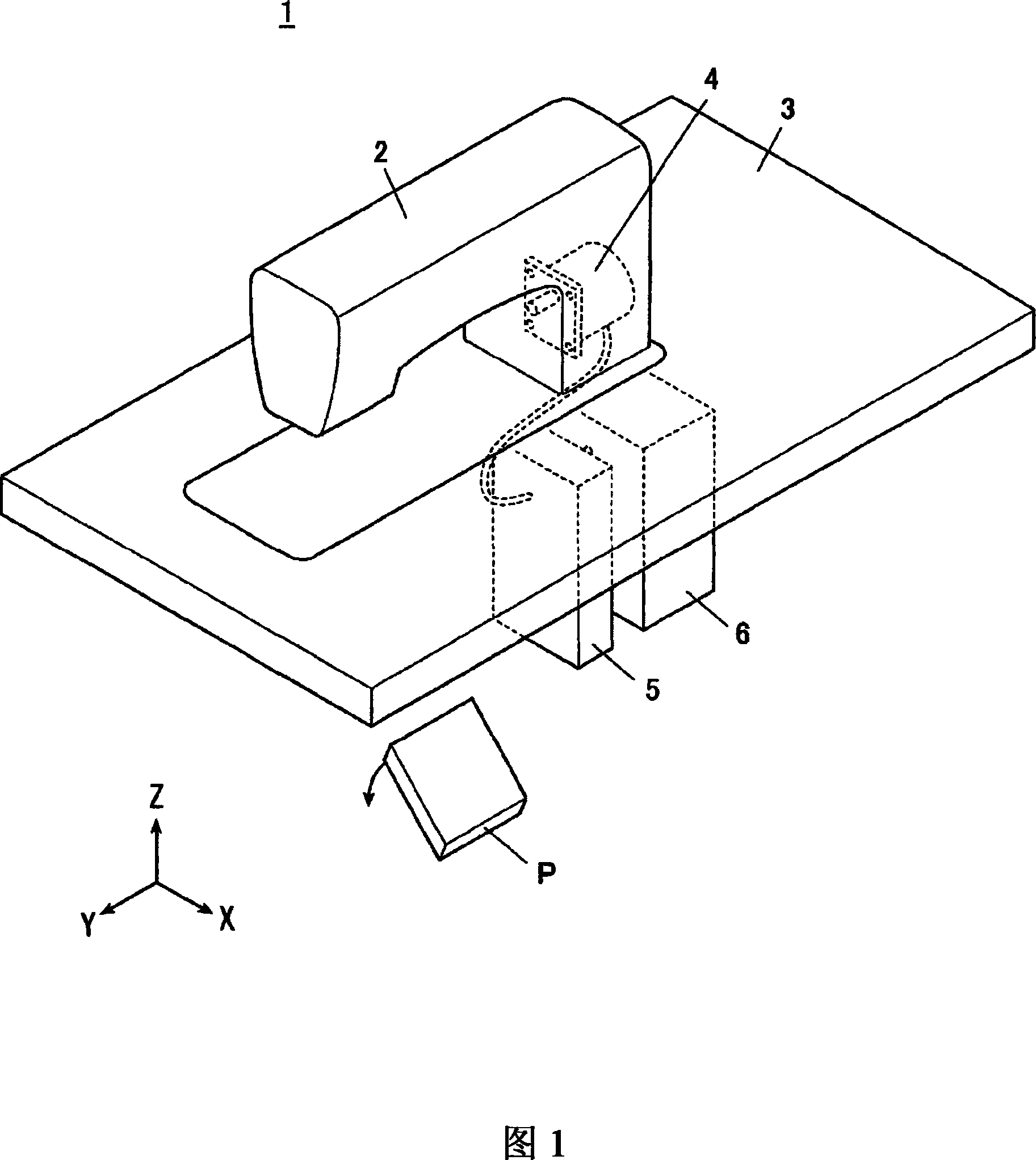

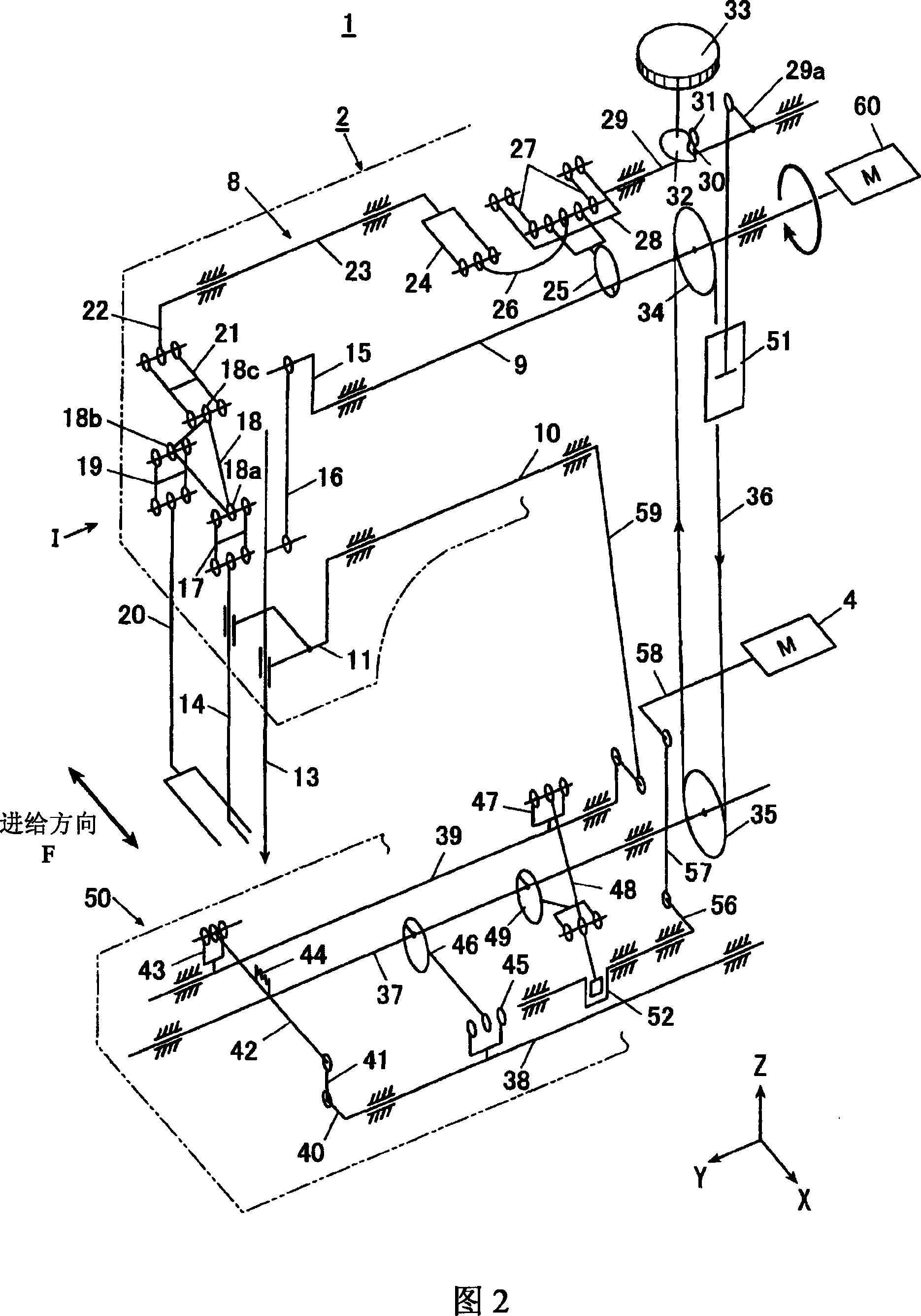

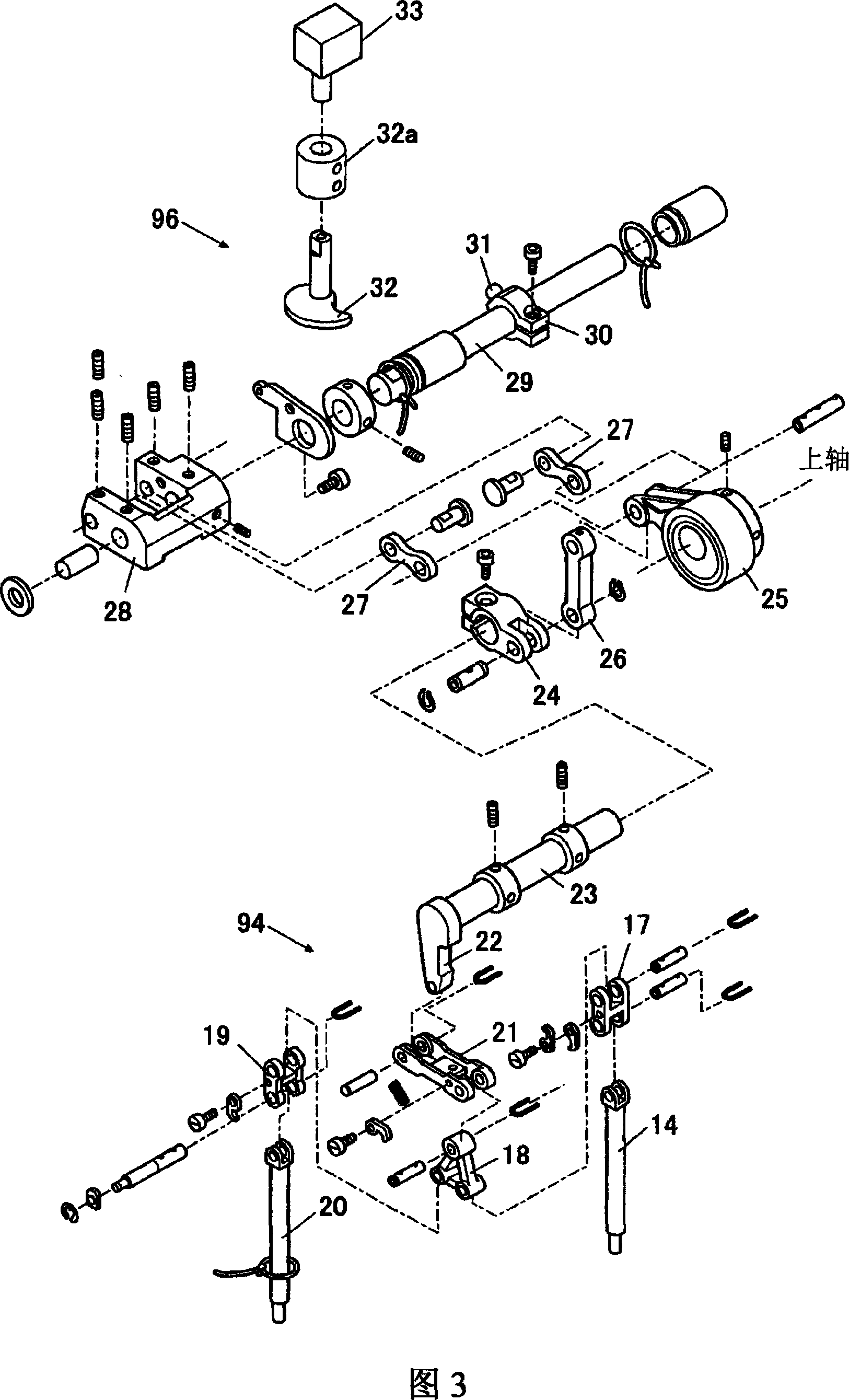

[0028] Hereinafter, the embodiments of the present invention will be described in detail according to the accompanying drawings 1 to 11 .

[0029] In this embodiment, as a sewing machine, a combined feed sewing machine will be described as an example. The combined feed sewing machine is, for example, a sewing machine as follows: in order to prevent the object to be sewn from shifting along with the feeding action, the sewing needle is moved up and down by a needle up and down movement mechanism, the needle is wobbled by a needle oscillating mechanism, And the feeding action that is produced by the upper feeding mechanism and the lower feeding mechanism is synchronized, and the sewing needle is inserted into a thicker sewing object (for example, leather goods) to feed. Here, in the following description, the direction along the feed direction (arrow F) is defined as the X-axis direction (front-rear direction), and the longitudinal direction of the sewing machine arm 8 perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com