Heat pipe

A heat pipe and heat transfer technology applied to heat pipes. It can solve the problems of unfavorable heat transfer of heat pipes, hinder the return of condensed liquid, and slow down the response time of heat pipes to temperature, so as to achieve the effect of enhancing heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

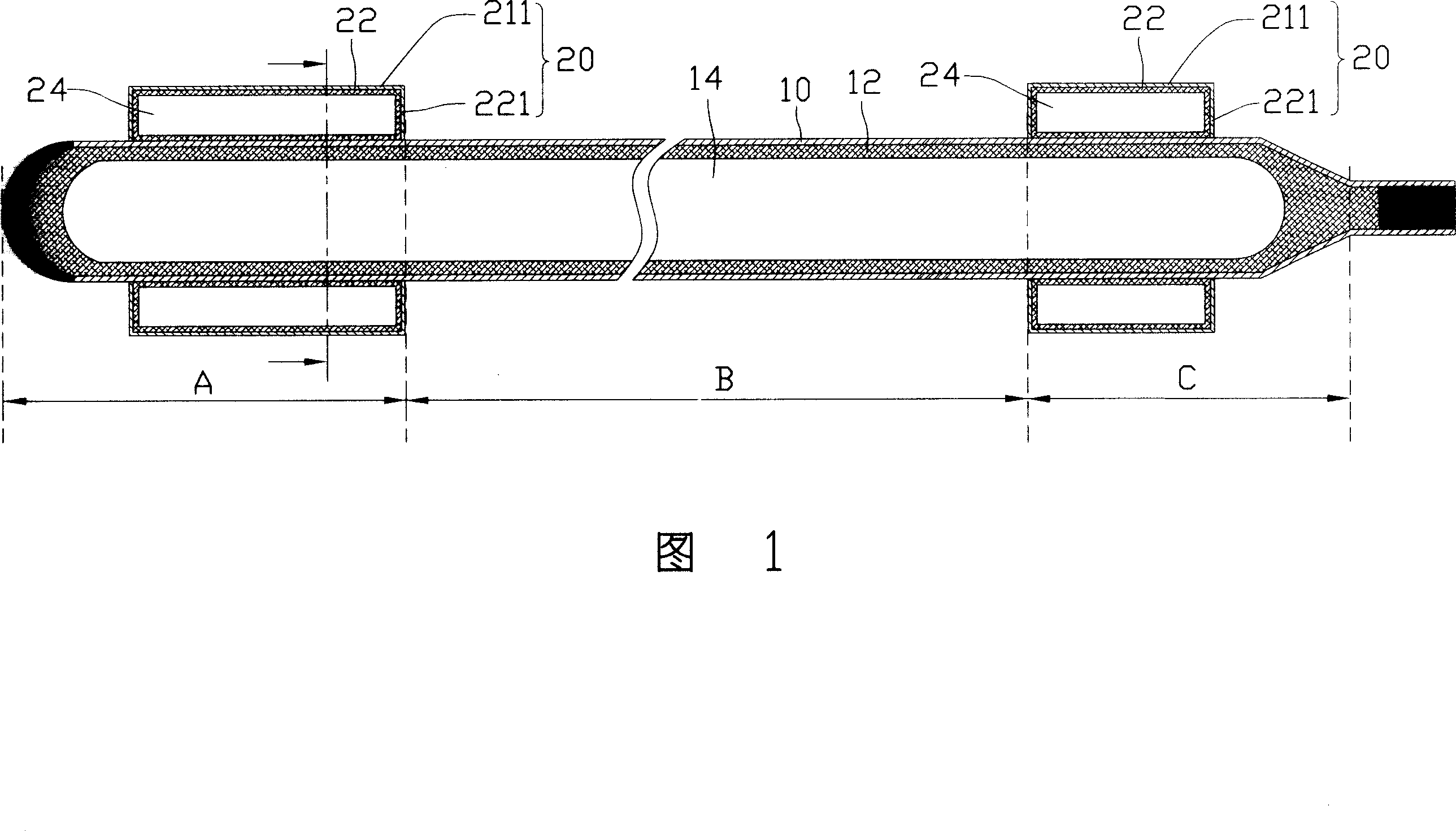

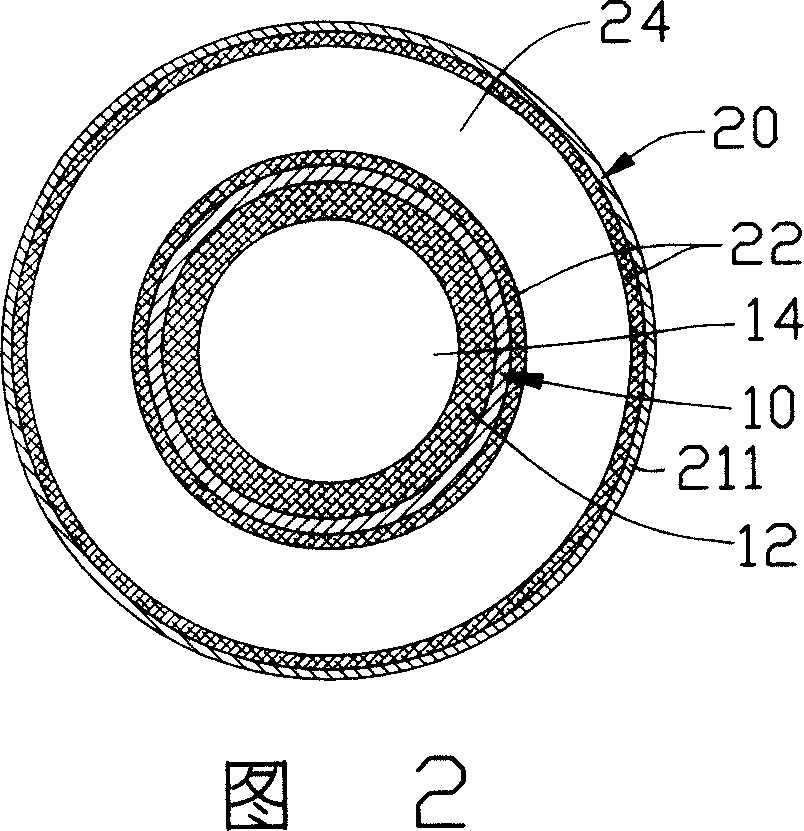

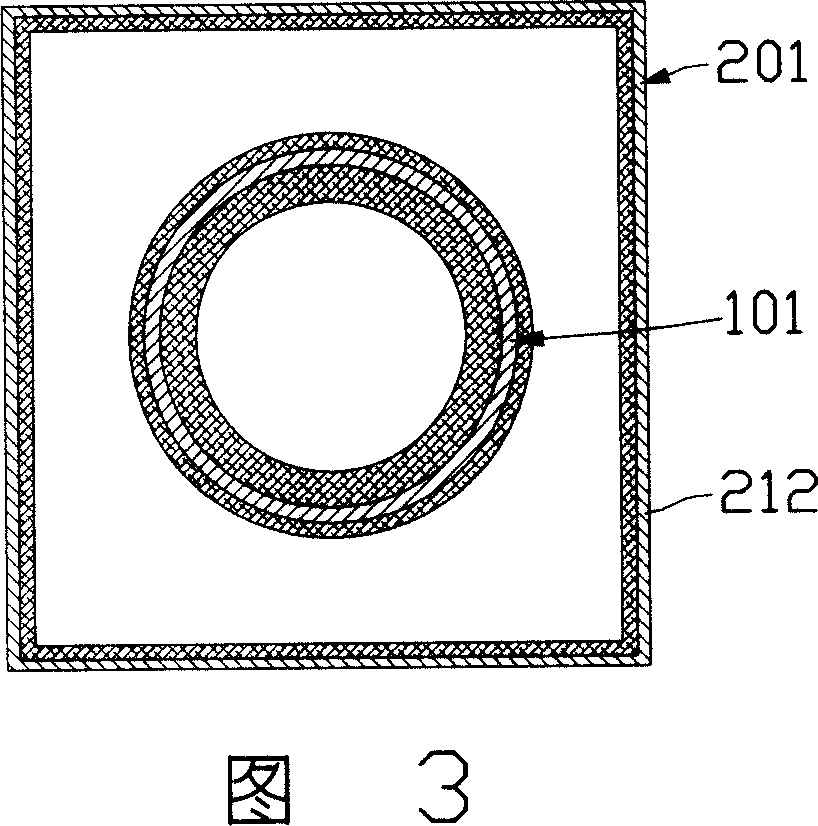

[0016] Please refer to FIG. 1, which is a longitudinal cross-sectional view of the first embodiment of the heat pipe of the present invention; the heat pipe shown includes a sealed heat transfer cavity 10, the inner wall of which is provided with a capillary structure 12 for reflux of condensate, and the capillary structure 12 The space in the center of the inner side is the steam channel 14, and the heat transfer cavity 10 is enclosed with a proper amount of working fluid and can be properly pumped to a certain degree of vacuum; the heat transfer cavity 10 along the length of the cavity is based on the function of each section It can be divided into a condensing section A, an evaporation section C and an adiabatic section B located between the two; the outer walls of the corresponding condensation section A and the evaporation section C of the heat transfer cavity 10 are respectively sealed with a heat storage cavity 20. Wherein, the heat transfer cavity 10 and the heat storage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com