Method for producing metal

A technology of metal and cooling section, applied to the equipment for manufacturing metal, and the metal produced. In the field, it can solve the problem of insufficient reliable characteristics or material characteristics of thermoformed metals, and achieve the effect of improved accuracy and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

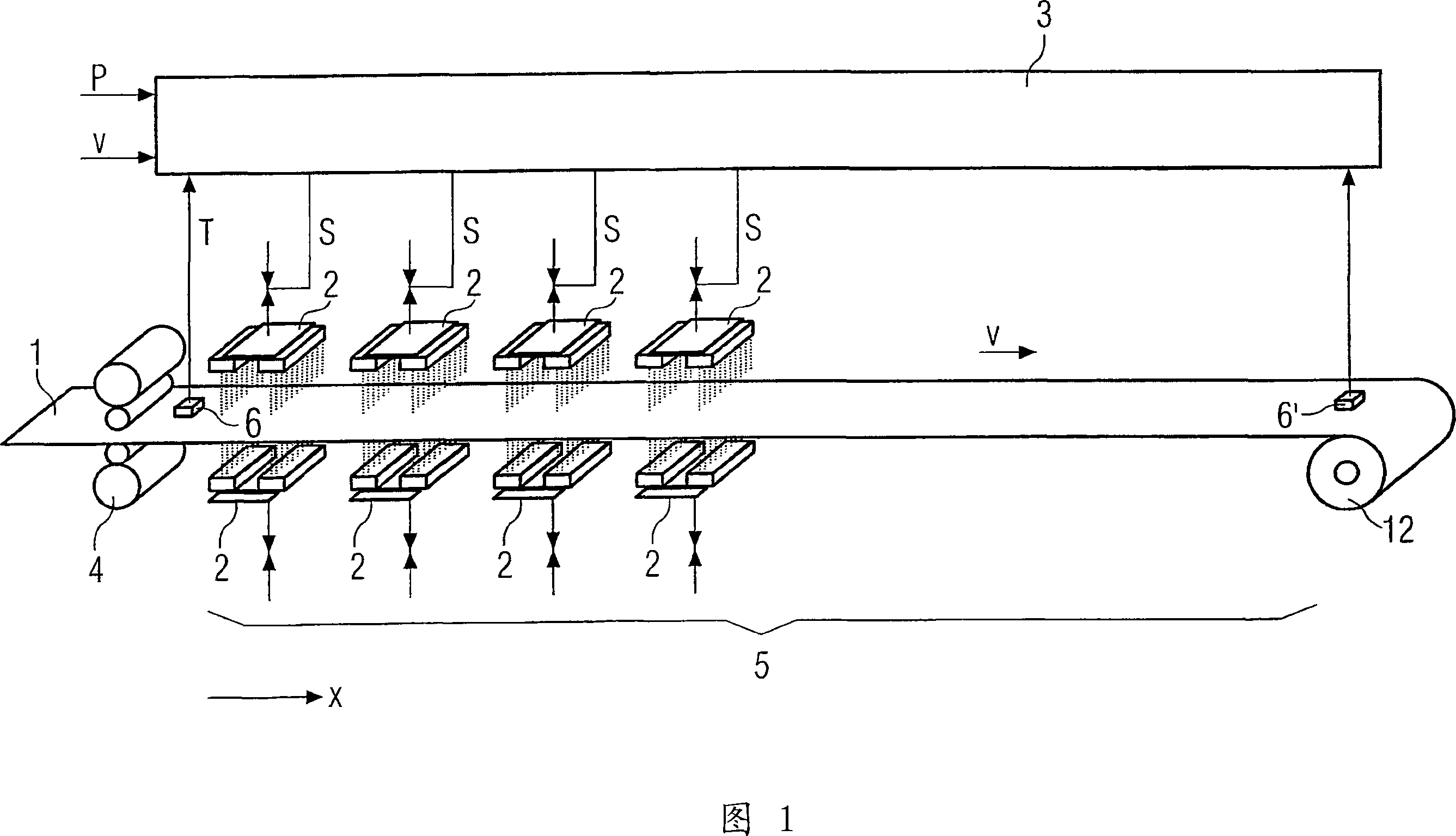

[0030] FIG. 1 shows a cooling section 5 and a computing device 3 for controlling or regulating and modeling the cooling section 5 . In the exemplary embodiment shown, the hot-formed metal 1 is removed from the rolling mill stand 4 at a velocity v in the direction of movement x of the strip. The rolling stand 4 is, for example, the last rolling stand of a so-called finishing train. However, other different deformation or processing devices for the metal 11 can also be arranged upstream of the cooling section 5 . The cooling section 5 and possibly also one or more devices for deforming or processing the metal 11 arranged upstream and possibly downstream of the cooling section form the plant for producing the metal 11 . In the exemplary embodiment shown, a coiling device 12 is arranged after the cooling section 5 , by means of which coiling device 12 the cooled metal 1 is wound into coils. However, it is also possible to arrange other different devices for the treatment and / or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com