Fire resistant anaerobic adhesive with low dismounting force moment and preparation method thereof

A high-temperature-resistant, anaerobic adhesive technology, applied in adhesives, non-polymer organic compound adhesives, etc., can solve the problems of poor maintainability of high-temperature-resistant anaerobic adhesives, difficult disassembly of bonded parts, and low-strength products. Overcoming the effects of low breaking torque at high temperature, low cost, and adjustable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

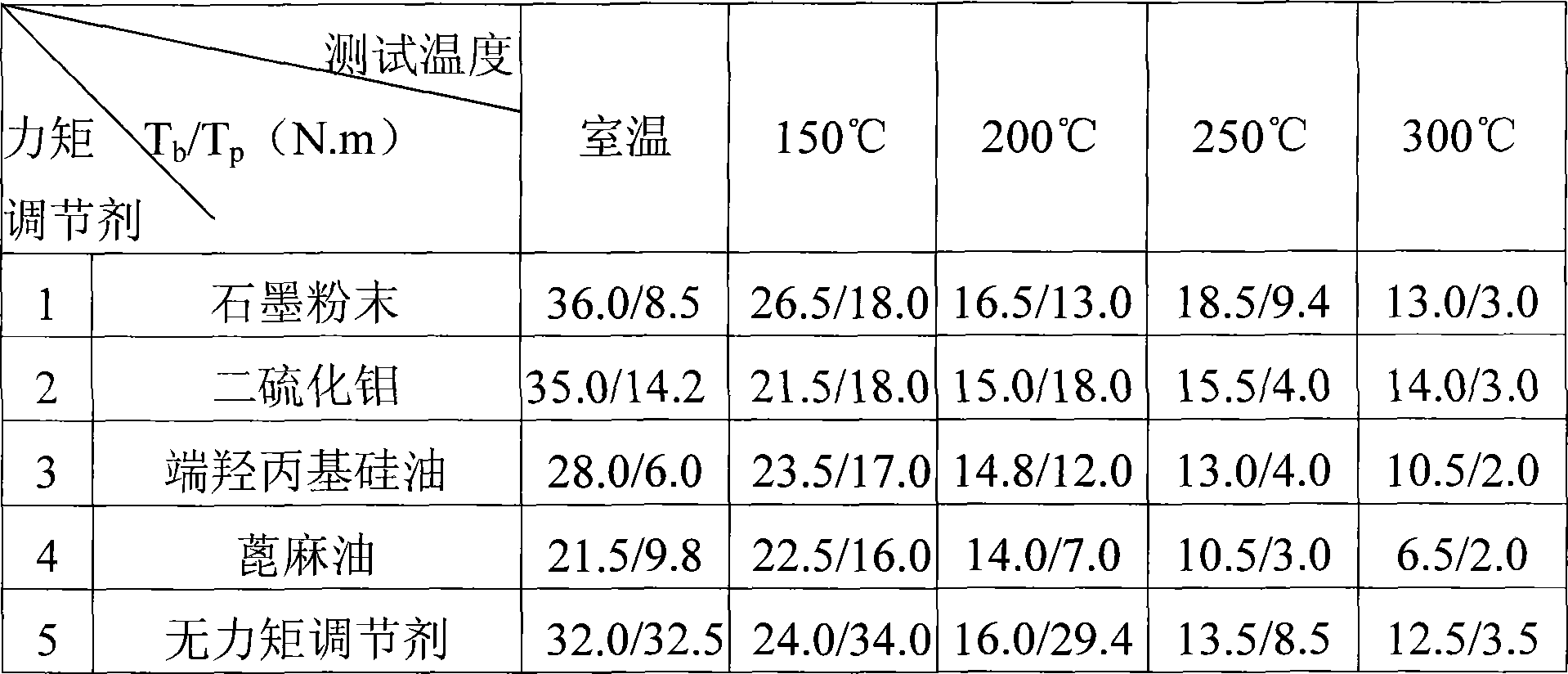

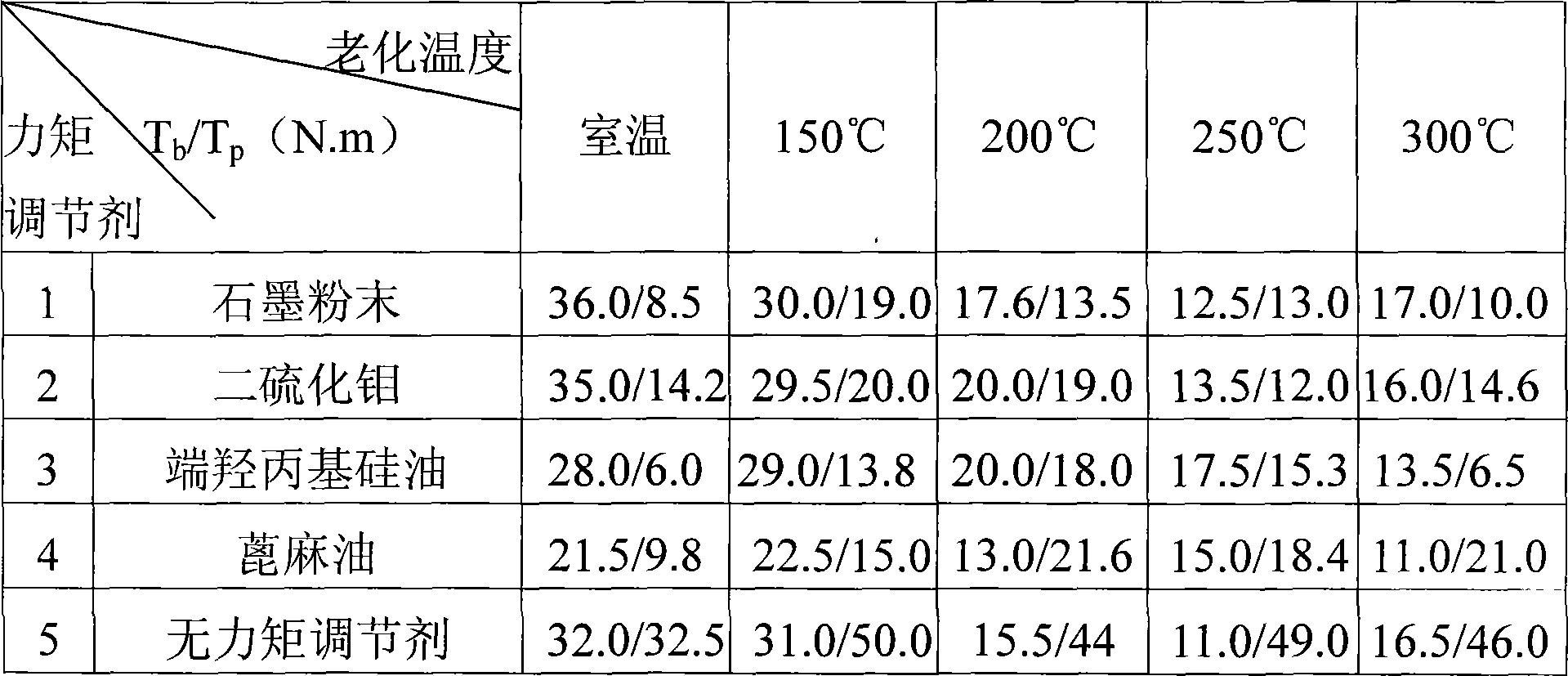

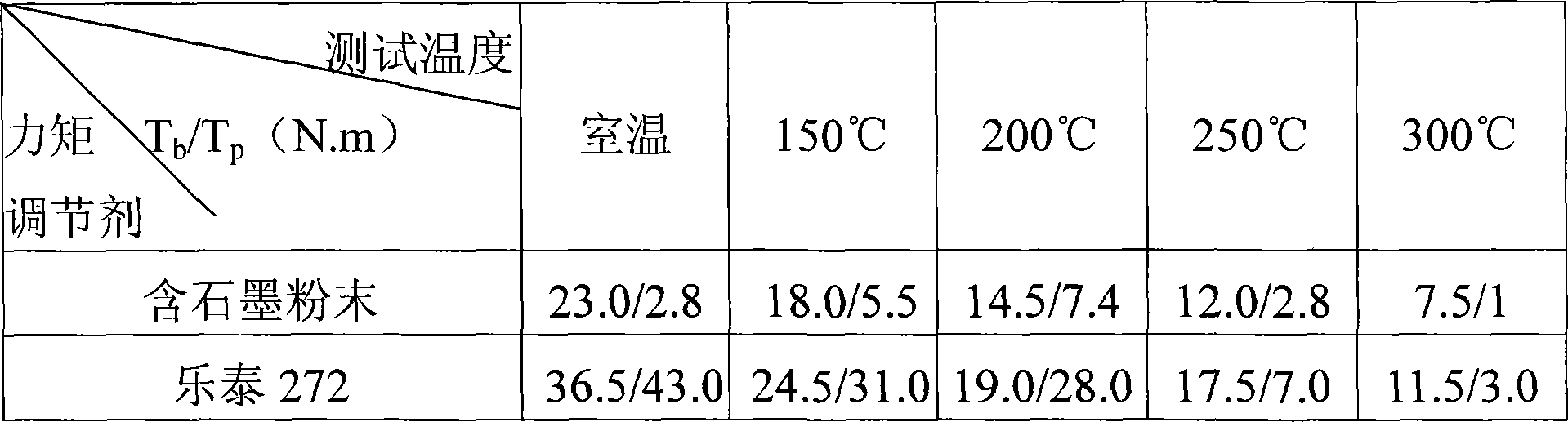

[0015] Specific embodiment 1: In this embodiment, the high temperature resistant anaerobic adhesive with low disassembly torque consists of 50-95 parts by weight of diester methacrylate monomer, 10-40 parts of heat-resistant additive, 0.1-5 parts of accelerator, It is prepared by 0.1-5 parts of o-benzenesulfonimide, 0.01-2 parts of stabilizer, 5-40 parts of high temperature resistant torque regulator, 0.1-5 parts of fumed silicon dioxide and 1-10 parts of organic peroxide.

specific Embodiment approach 2

[0016] Specific embodiment two: In this embodiment, the low disassembly torque high temperature resistant anaerobic adhesive consists of 60-80 parts by weight of diester methacrylate monomer, 15-30 parts of heat-resistant additive, 2-4 parts of accelerator, and It is prepared by 1-3 parts of benzenesulfonimide, 0.1-1 part of stabilizer, 10-35 parts of high temperature resistant torque regulator, 1-4 parts of fumed silicon dioxide and 2-8 parts of organic peroxide.

specific Embodiment approach 3

[0017] Specific embodiment three: In this embodiment, the low disassembly torque high temperature resistant anaerobic adhesive consists of 70 parts by weight of diester methacrylate monomer, 20 parts of heat-resistant additive, 3 parts of accelerator, and 3 parts of o-benzenesulfonimide. 1 part, 1 part of stabilizer, 20 parts of high temperature resistant torque regulator, 3 parts of fumed silica and 6 parts of organic peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com