Circulation pump for auto

A circulating pump and automobile technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of fast wear, short life, difficulties, etc., and achieve the effects of reduced energy consumption, low noise, and long product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

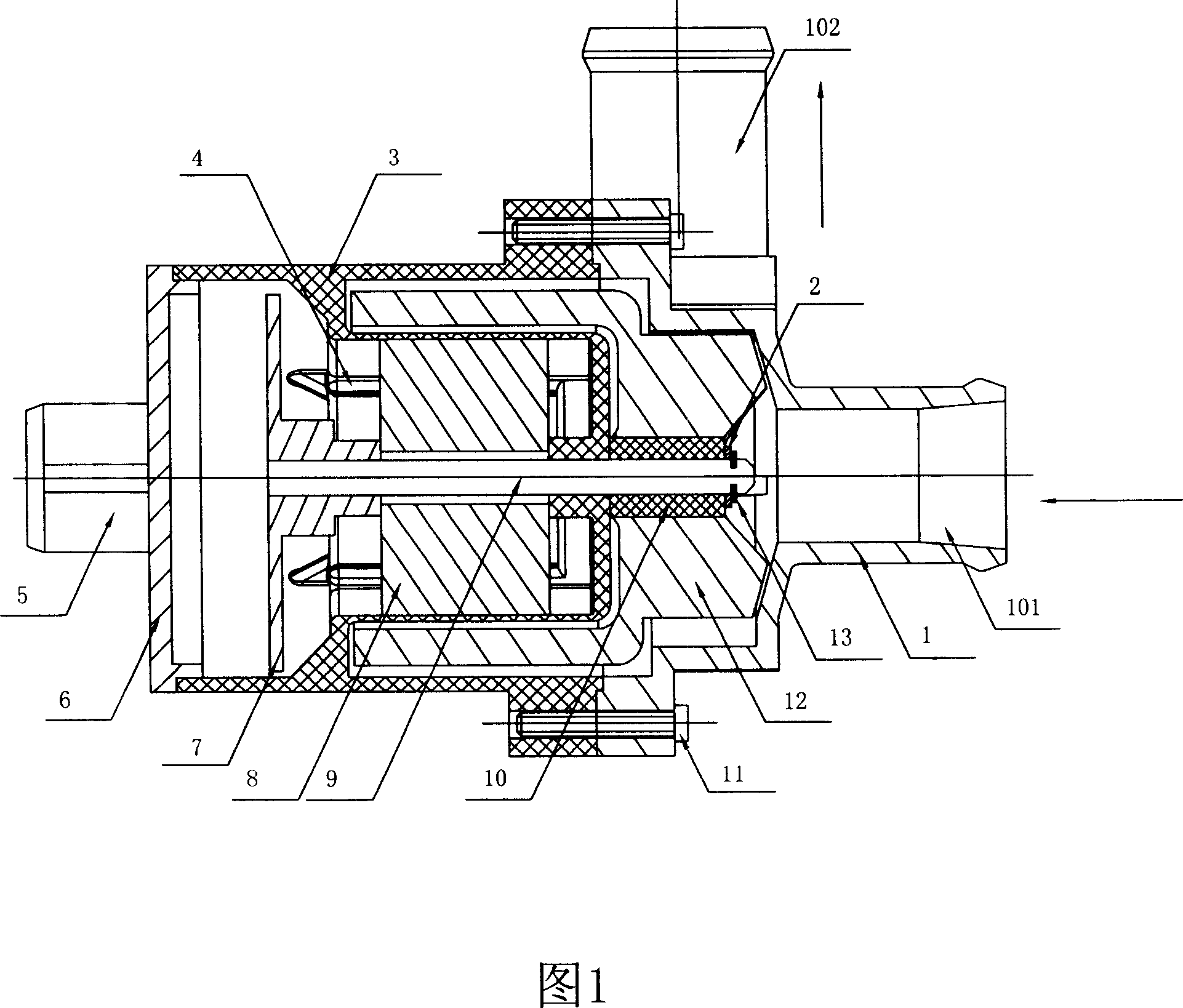

[0020] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0021] As shown in Figure 1, the automobile circulation pump includes an electromagnetic drive mechanism and an impeller rotor 12. The impeller rotor 12 is placed in the space composed of the pump casing and the pump cover. The pump casing 3 and the pump cover 1 are fixed by screws 11. On the pump cover 1 With a water inlet 101 and a water outlet 102, the impeller rotor 12 is supported on the pump casing 3 by the shaft 9 through the bearing 10, and the outer end of the shaft 9 is limited by the gasket 2 and the circlip 13.

[0022] The electromagnetic drive mechanism includes a silicon steel sheet 8 wound on a coil 4 and supported by a shaft 9 in the center of the pump casing 3 .

[0023] The impeller rotor 12 is made of magnetic material, and its main body is a cylinder, which is sleeved outside the pump casing 3, and the corresponding silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com