Valve core

A technology of the main body and sealing components, which is applied in the direction of lifting valves, valve details, control valves, etc. It can solve the problems of gas leakage, metal components meshing with each other, and metal sealing parts not functioning, so as to achieve high elastic deformation rate and improve tightness Degree, the effect of reducing the amount of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

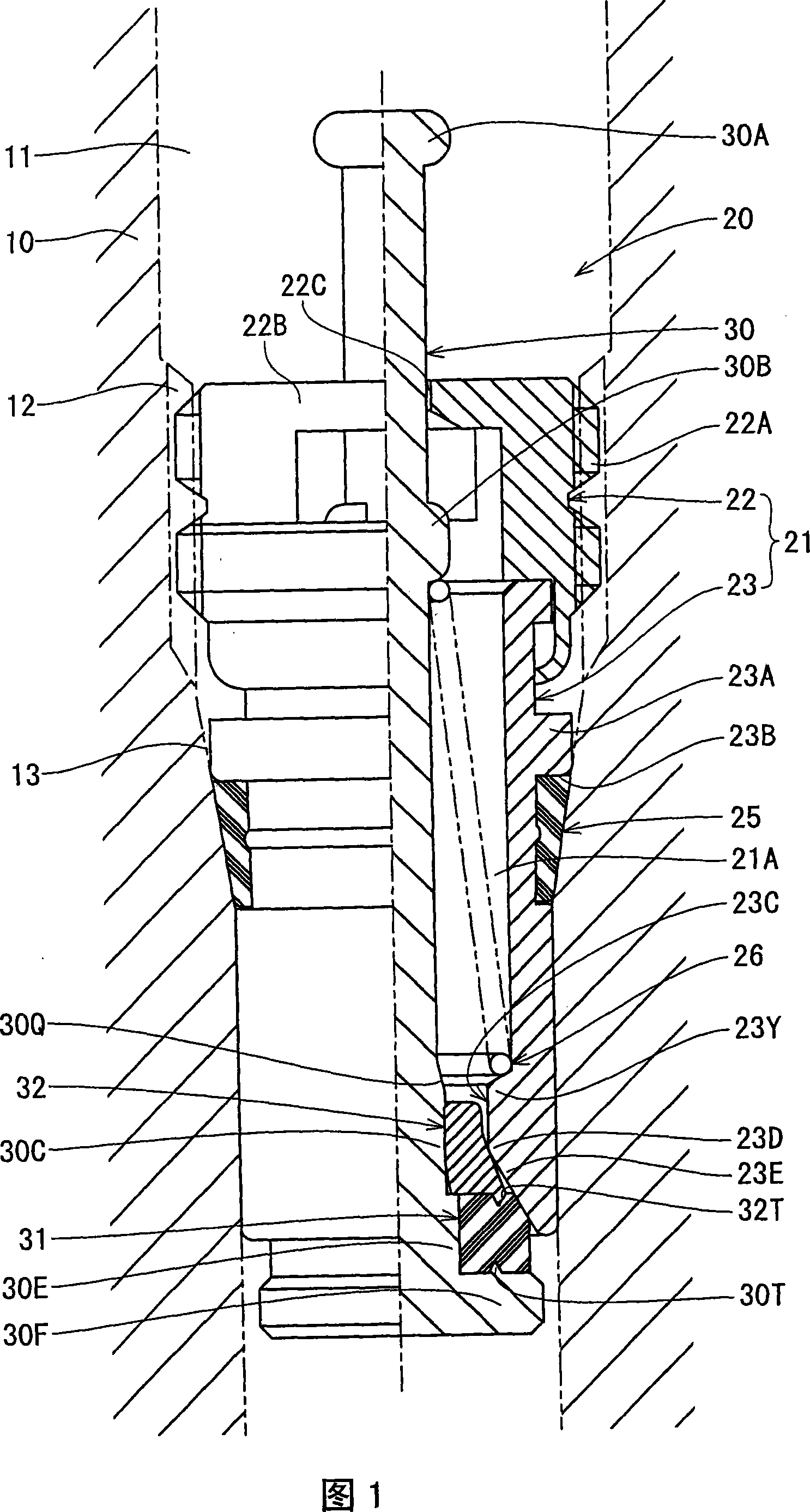

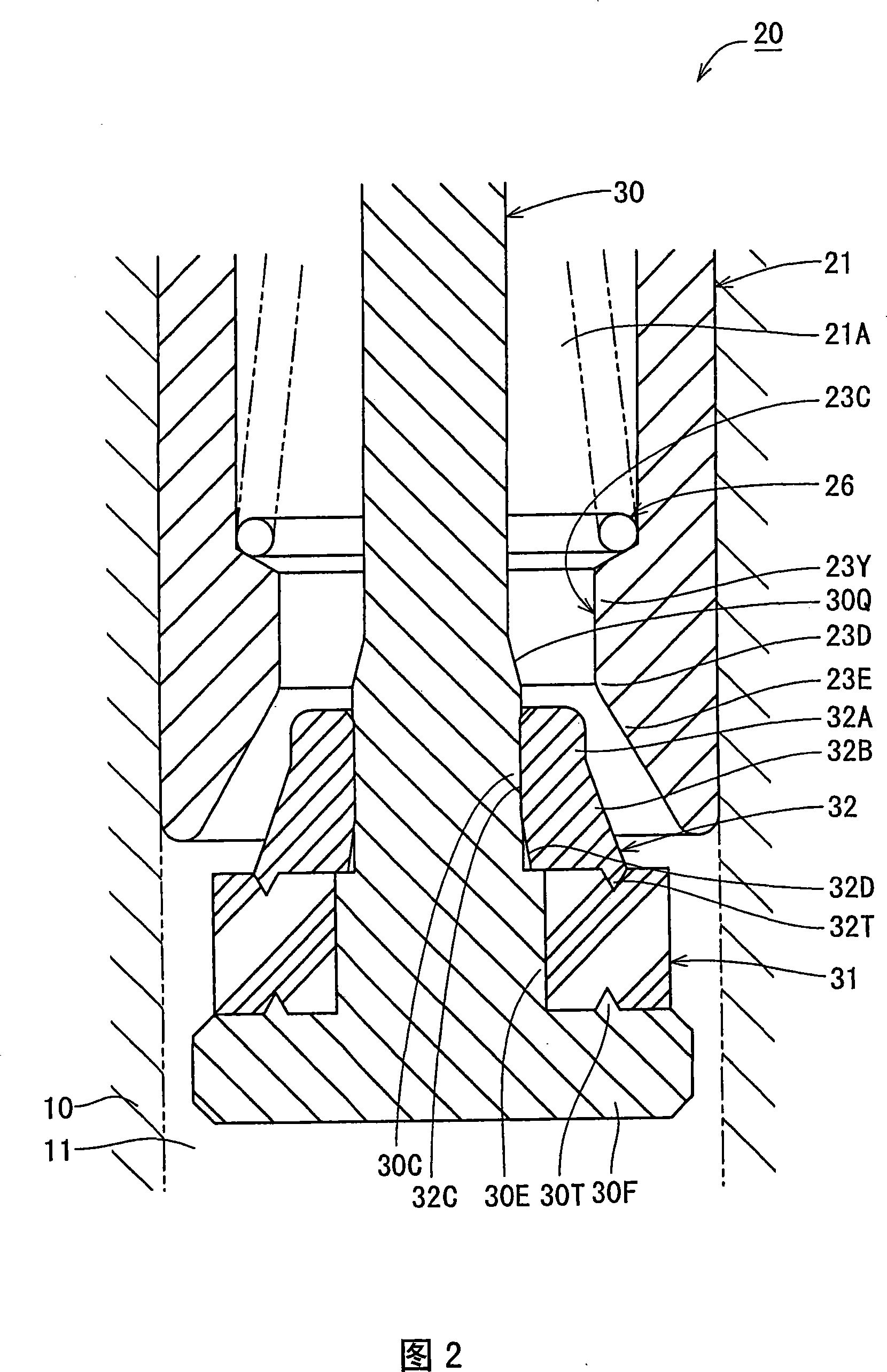

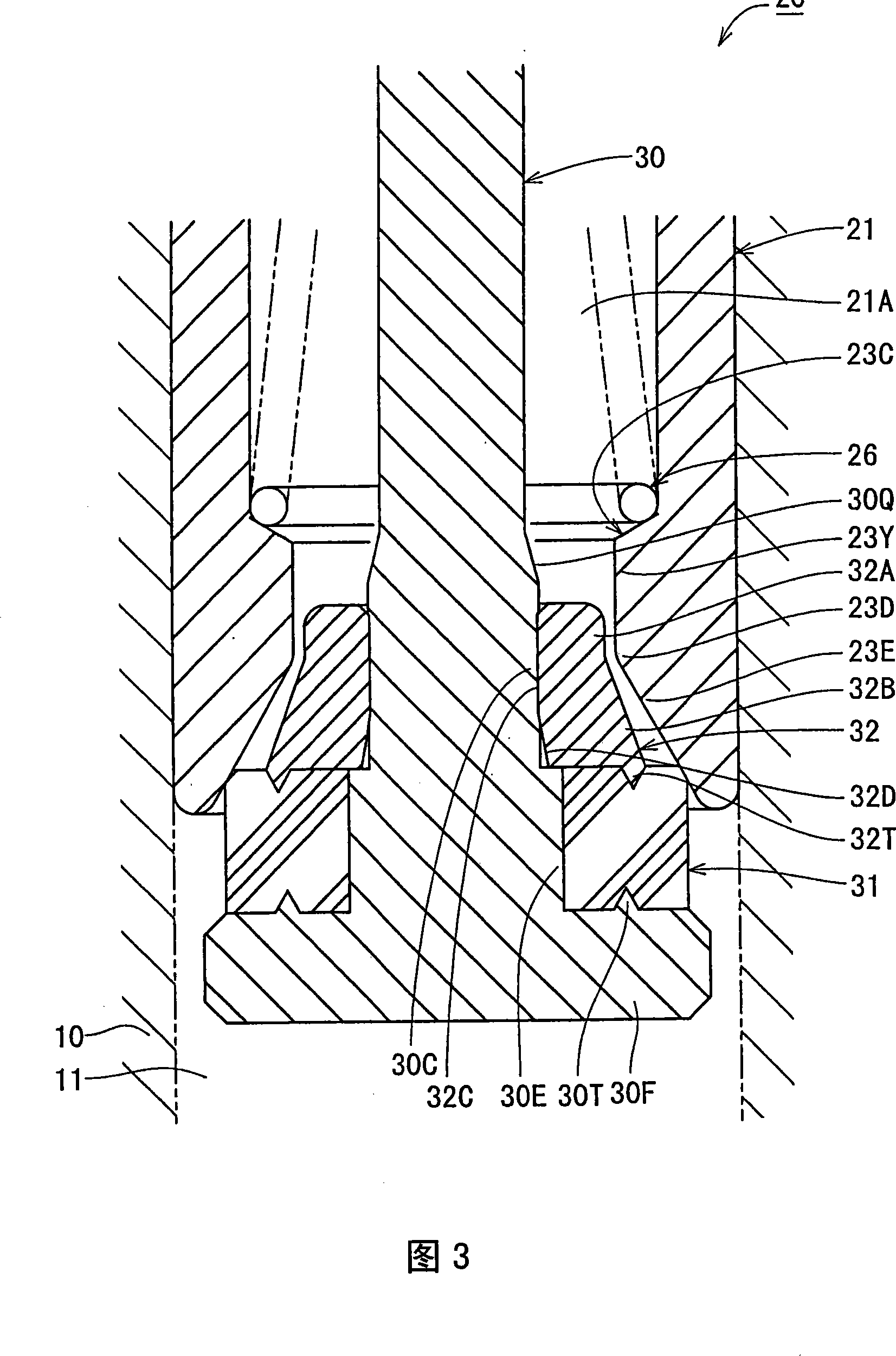

[0020] Hereinafter, a first embodiment of the present invention will be described based on FIGS. 1 to 4 . Reference numeral 10 in FIG. 1 is a valve main body corresponding to the "core holding member" of the present invention, which is, for example, in the shape of a nozzle and has a core fitting hole 11 in the axial center. In addition, a female thread portion 12 is provided in the middle of the core fitting hole 11, and a tapered portion 13 whose inner diameter gradually decreases is provided on the inner side (lower side in FIG. 1 ) of the female thread portion 12 .

[0021] In addition, the "core holding member" of the present invention is not limited to a nozzle shape as described for the valve main body 10, and may be, for example, a wall member constituting a container case as long as it has a core fitting hole 11.

[0022] The valve core 20 of the present invention includes a cylindrical core body 21 , and the movable shaft 30 is inserted through an insertion hole 21A ...

no. 2 approach

[0040] As shown in FIG. 5 , the valve core 20 of this embodiment differs from the first embodiment only in the structure of the contact portion between the metallic glass sealing member 32 and the core main body 21 . Hereinafter, the same reference numerals as those in the first embodiment are assigned to the same configurations as those of the first embodiment, overlapping descriptions will be omitted, and only configurations different from those of the first embodiment will be described.

[0041] The sealing member 33 made of metallic glass according to the present embodiment has a first flat surface 33A facing the base end side of the movable shaft 30 at an intermediate portion in the axial direction, and an annular protrusion 33B protrudes from the first flat surface 33A. In addition, the first flat surface 33A and the annular protrusion 33B are continuously formed over the entire circumference of the sealing member 32 made of metallic glass.

[0042] On the other hand, on...

no. 3 approach

[0045] In this embodiment, as shown in FIG. 6 , instead of the annular protrusion 33B included in the metallic glass sealing member 33 of the second embodiment, an annular protrusion is formed protruding from the second flat surface 23F of the core body 21 . 23G structure. This configuration also provides the same operational effects as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com