Energy-saving method for stainless strip sulfuric acid refining continuous annealing production line hydraulic stations

A technology of stainless steel belt and hydraulic station, which is applied in the direction of liquid variable capacity machinery, pump control, machine/engine, etc., which can solve the problems of high proportion of no-load energy consumption and slow production rhythm of stainless steel pickling production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

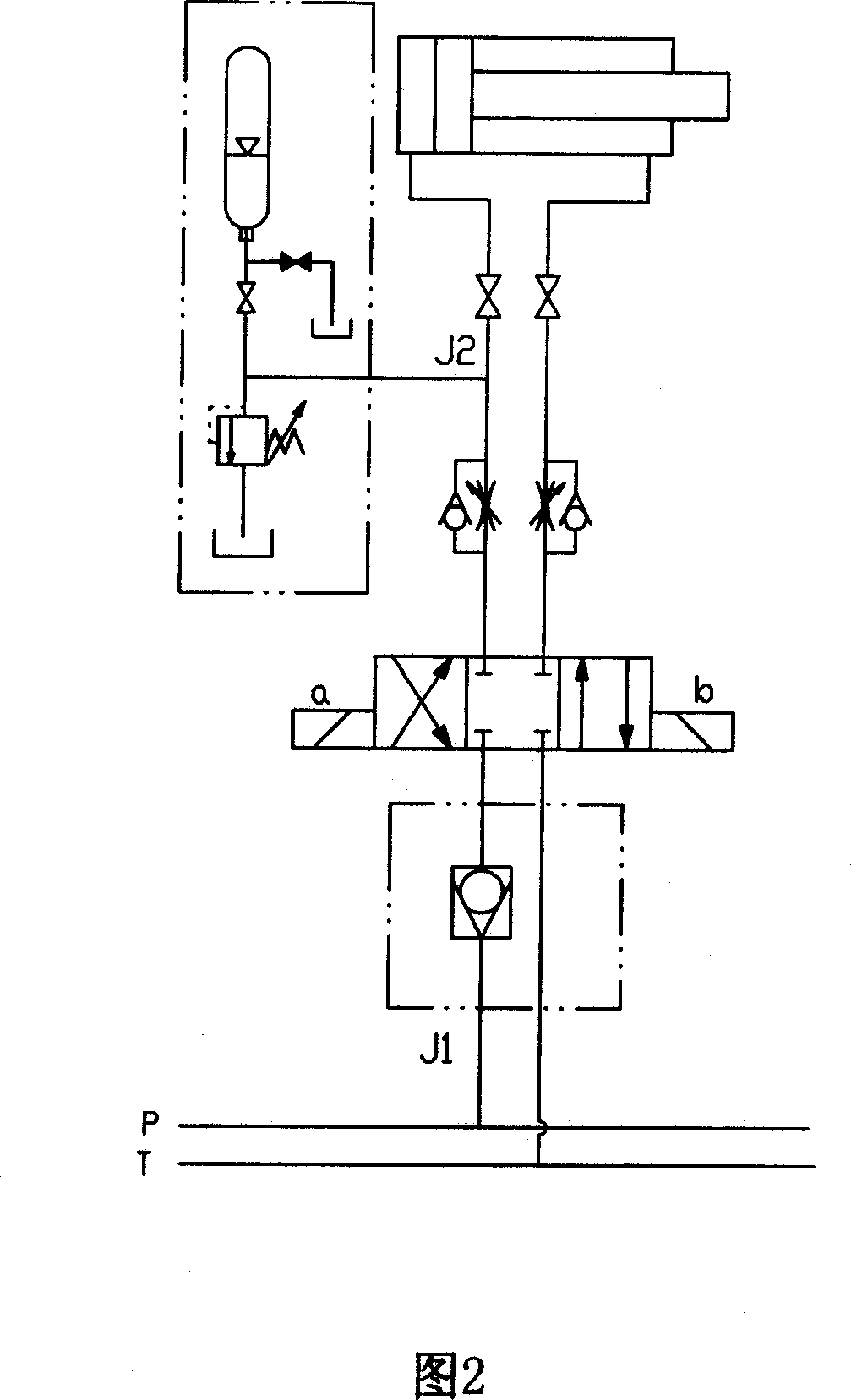

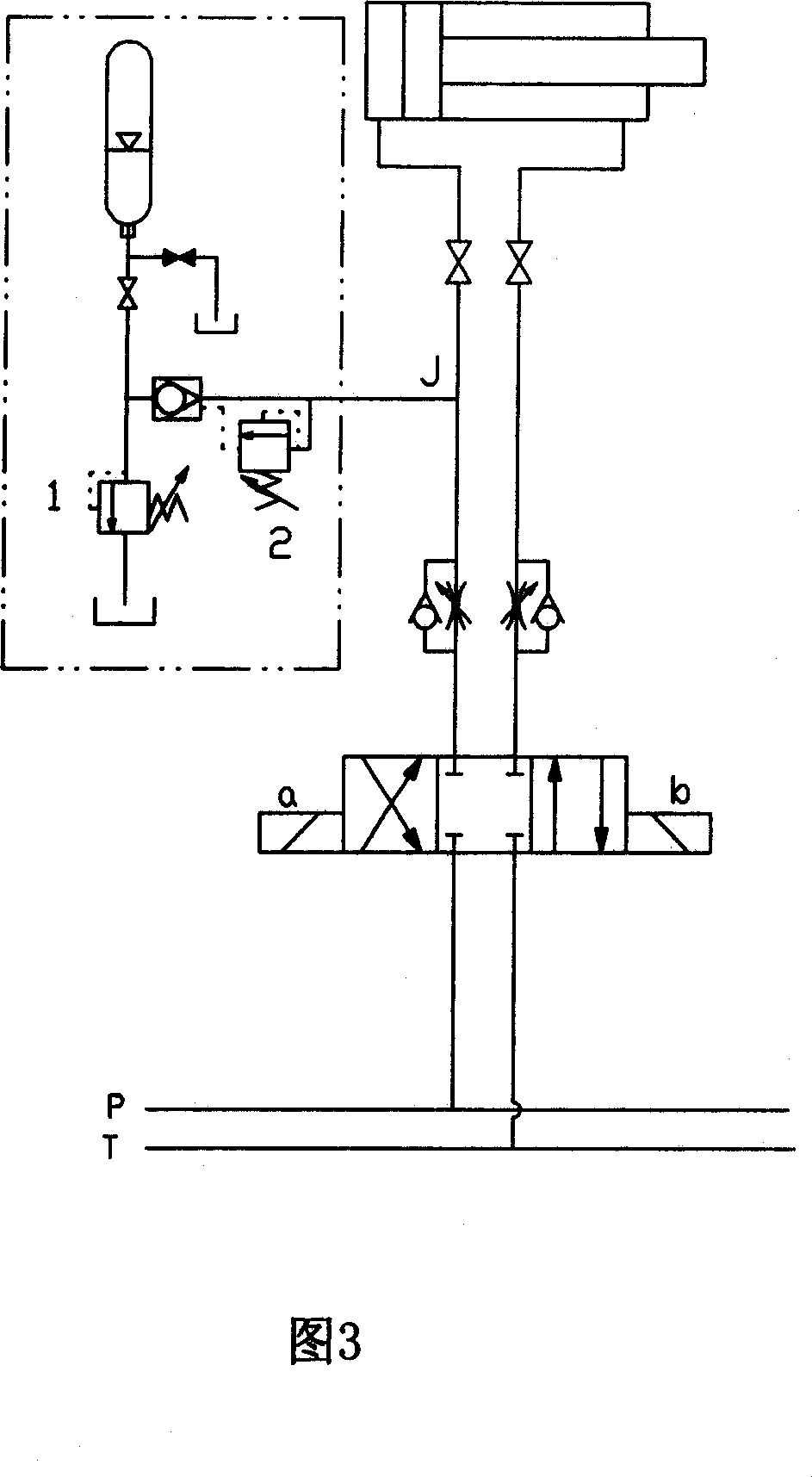

[0024] The invention will be described in further detail below with reference to the embodiments of the accompanying drawings.

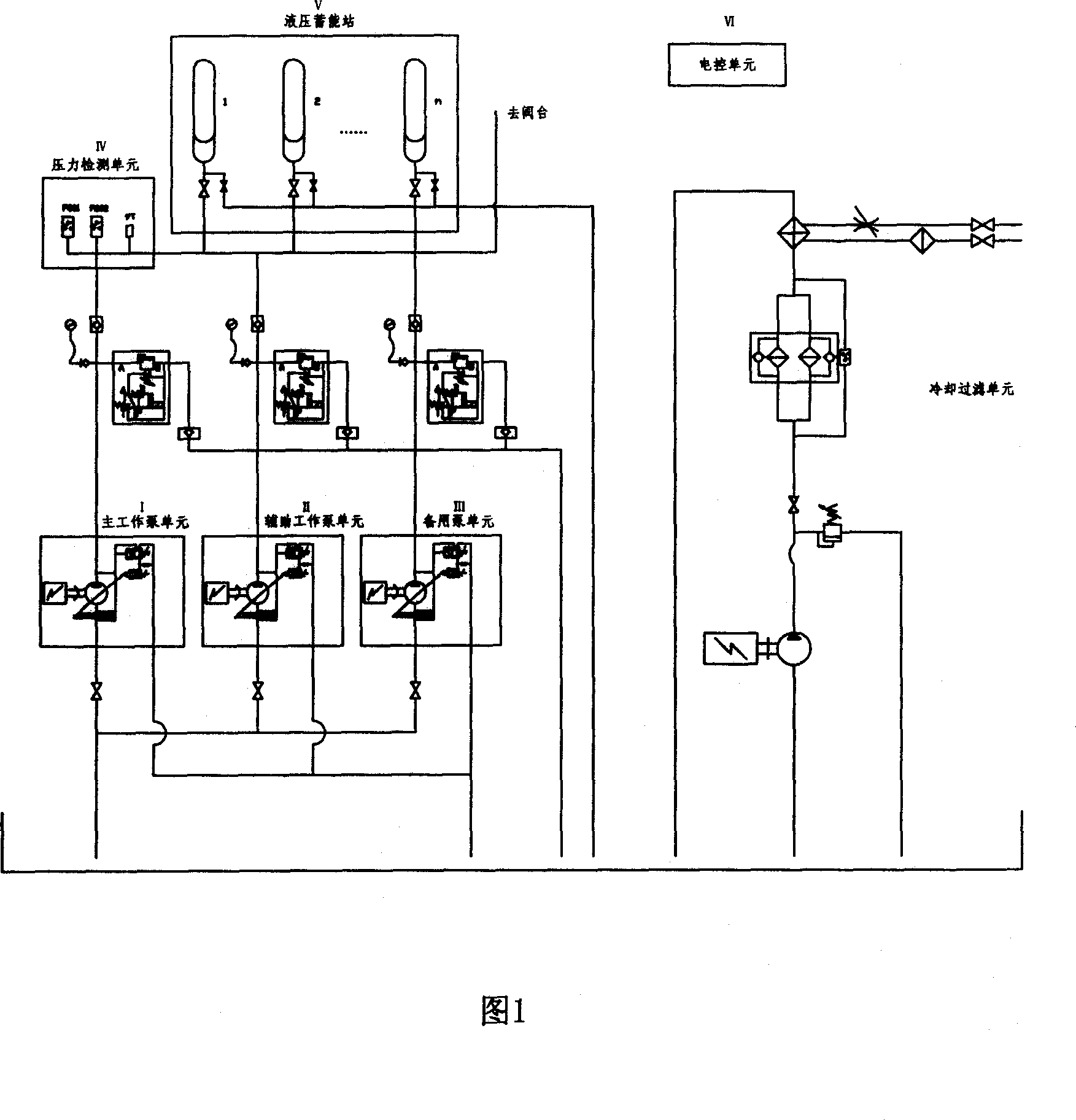

[0025] The basic component of the new hydraulic station. As shown in Figure 1, the energy-saving hydraulic station consists of the main working pump unit I, the auxiliary working pump unit II, the system pressure detection unit IV, the hydraulic energy storage station unit V and the system electronic control unit VI and other basic units; Optional on-machine spare pump unit III and circulating filter unit.

[0026] The main working pump unit I, the auxiliary working pump unit II, and the standby pump unit III are connected in parallel, and the output pipeline is connected to the control valve table, and the detection point of the pressure detection unit IV is connected to the output pressure pipeline, and the output control signal is used to directly or indirectly control the auxiliary pump. Working pump unit II, a large-capacity hydraulic energy st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com