Line focusing metal flow passage solar vacuum heat-collecting tube and fabrication technology thereof

A vacuum heat collector tube and metal flow channel technology, applied in the field of solar thermal utilization, can solve the problems of limited use range, low sealing temperature and high heat loss probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

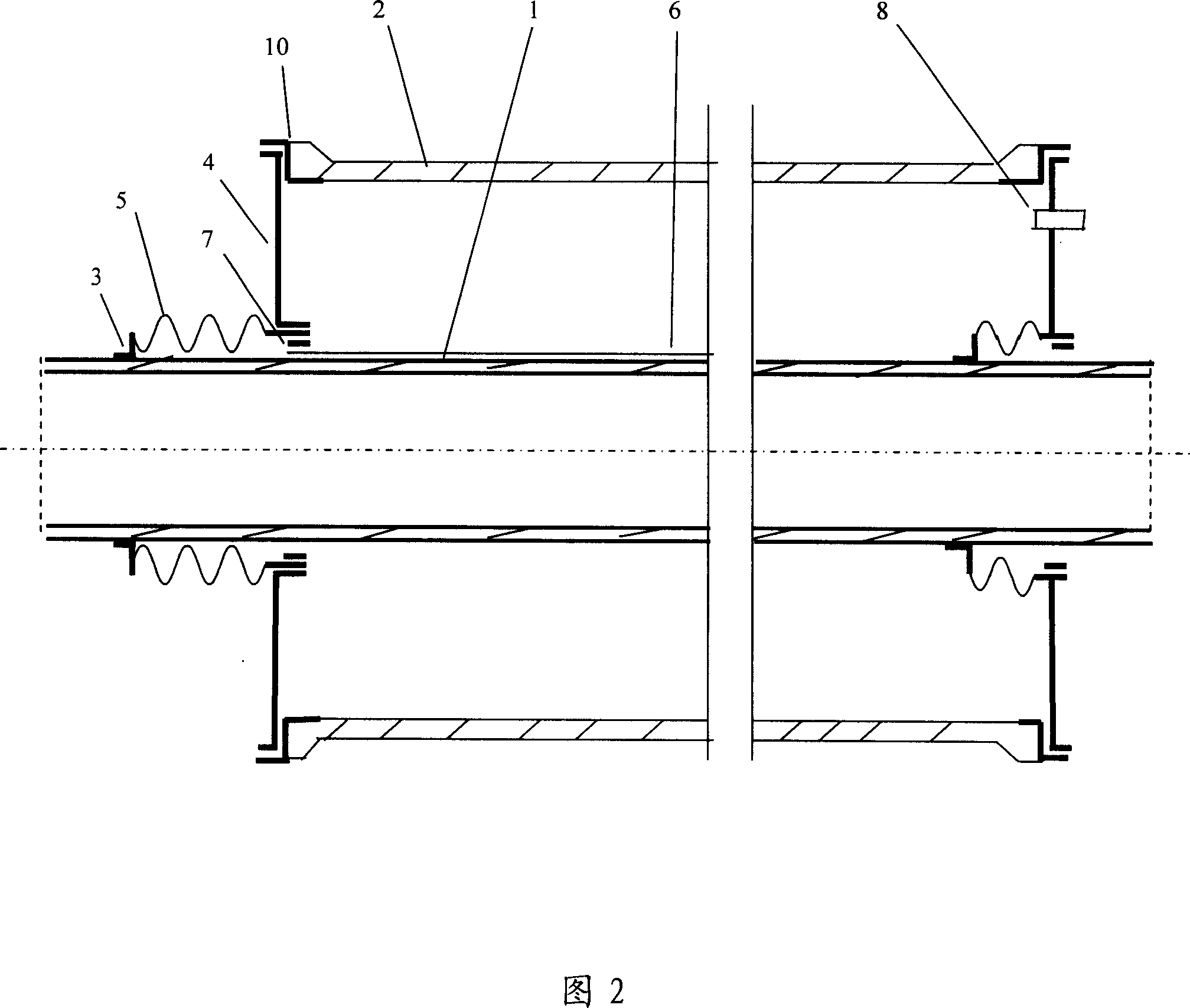

[0031] 1) The iron-nickel alloy kovar process ring and the glass outer tube are welded and sealed into a single component by indirect fusion sealing process, that is, component 1: firstly, the iron-nickel kovar alloy plate is stamped and stretched to make convex rings with different inner circles Its convex top is turned outward by 1-3mm, and the ring surface and elevation are indirectly sealed with the inner wall of the glass tube and the plane of the glass flange to ensure that the depth of the seal and the width of the plane seal are each 10mm. The coefficient of linear expansion is less than 48×10 -7 / °C.

[0032] 2) In order to prevent harmful air bubbles from appearing at the interface between the kovaring part 6 and the glass during sealing, the iron-nickel kovaring part is degassed and decarburized in high temperature and wet hydrogen according to the conventional process, that is, heat treatment by burning hydrogen;

[0033] 3) Atomization is carried out after servin...

Embodiment 2

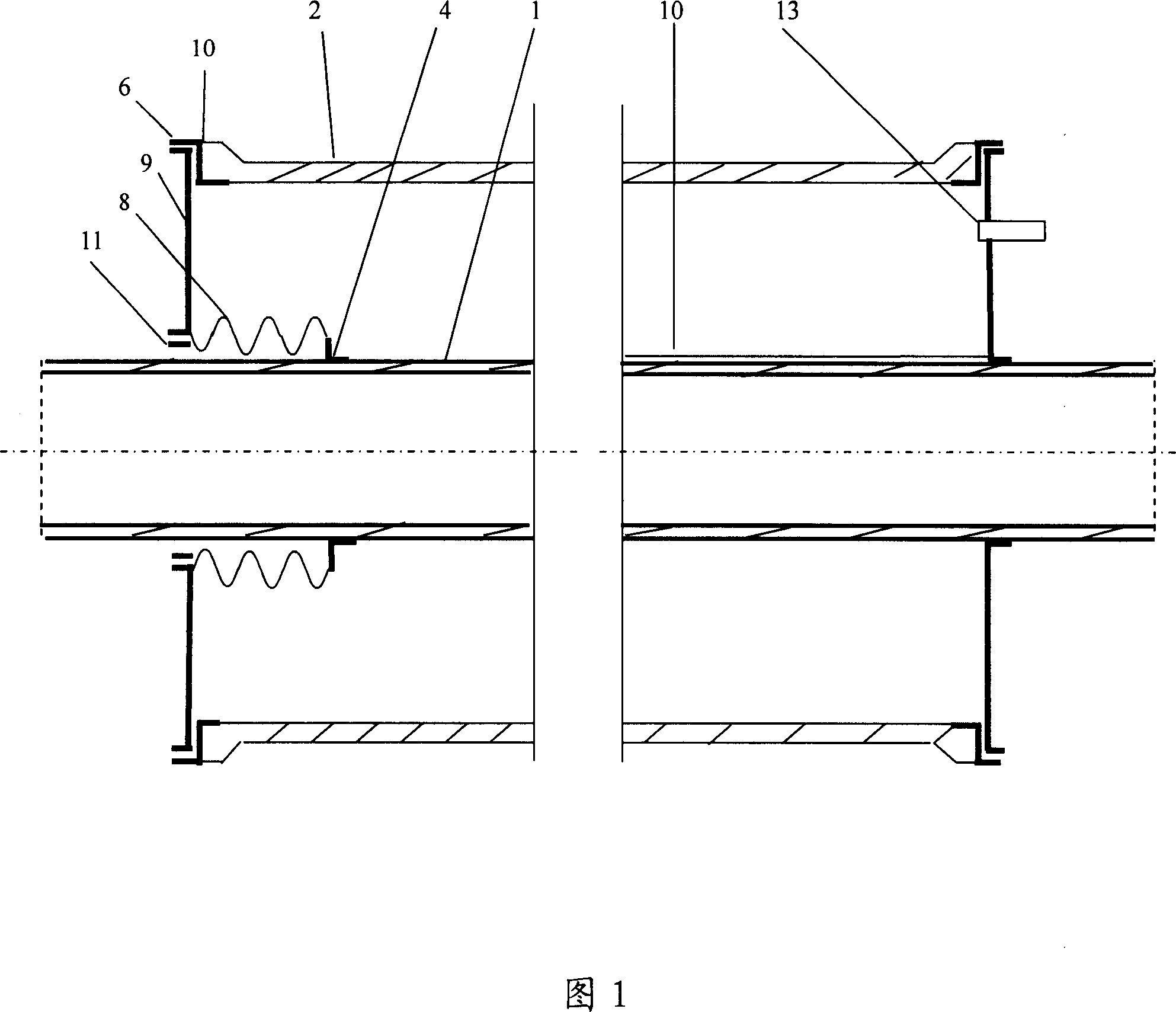

[0045] 1) The bellows 8 of the external unloading device are arranged at both ends. Turn the inner circles of the two metal end caps 9 inwardly and outwardly.

[0046] 2) According to the unloading absorption of the bellows 8, the wave number is divided into two sections, one section is set inside the metal end cap 9 and the glass tube 2, and the other section is set outside the metal end cap 9 and the glass tube 2.

[0047] 3) One end of the bellows 8 of the external unloading device is welded with the inner circle of the metal end cover 9 that is flanging outward and the heat insulation process ring 11 that is close to the inner wall of one end of the bellows 8 to form the external unloading device component 2A .

[0048] 4) One end of the bellows 8 of the built-in external unloading device is welded with the inner circle of the metal end cap 9 flanging inward and the heat insulation process ring 11 close to the inner wall of one end of the bellows 8 to form the external ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com