Multifunctional cup accepting and inspecting machine

A cup inspection machine and multi-functional technology, which can be applied to cardboard items and other directions, can solve problems such as affecting work efficiency, laborious and time-consuming, and easy to burn the face, and achieve the effects of reducing labor intensity, ensuring hygienic quality, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

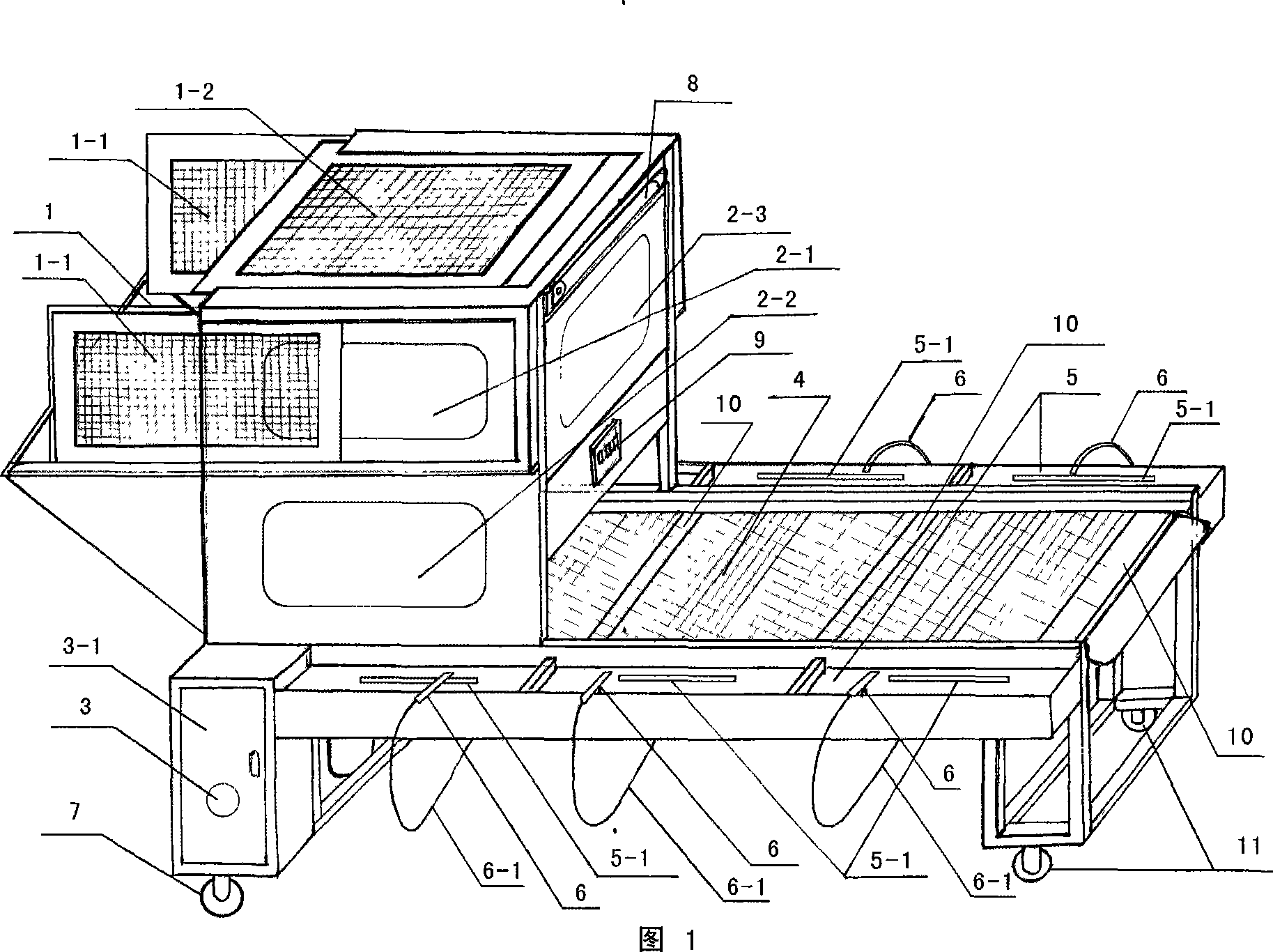

[0013] As shown in Figure 1, the multi-functional cup receiving and picking cup inspection machine mainly consists of a cup receiving and dropping bucket 1, a cup storage chamber 2, a transmission motor 3, a transmission roller 10, a transmission mesh belt 4, a light box 5, an air gun 6, Pulley 11, universal pulley 7 form. The cup receiving and dropping bucket 1 is composed of two left and right push-pull nets 1-1 and a top cup retaining net 1-2, which plays the role of receiving cups. The cup storage chamber 2 is surrounded by two left and right upper glass windows 2-1, two left and right lower glass windows 2-2, a front glass window 2-3 and a conveying mesh belt 4. When the cup is blown out from the forming machine mold, the cup is received The cup drop hopper 1 catches it and stores it in the cup storage chamber 2, and the cup receiving drop hopper 1 and the cup storage chamber 2 also block the blown hot air, forcing the hot air to disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com