Production of micro-solid phase extraction chip based on micro-processing method and using method

An extraction and chip technology, applied in the fields of analytical chemistry and biological analysis and detection, can solve the problems of integration limitations, difficult rough processing detection integration, limiting analysis process automation and portability, and achieve the effect of improving feasibility and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate substantive characteristics and remarkable progress of the present invention below in conjunction with accompanying drawing.

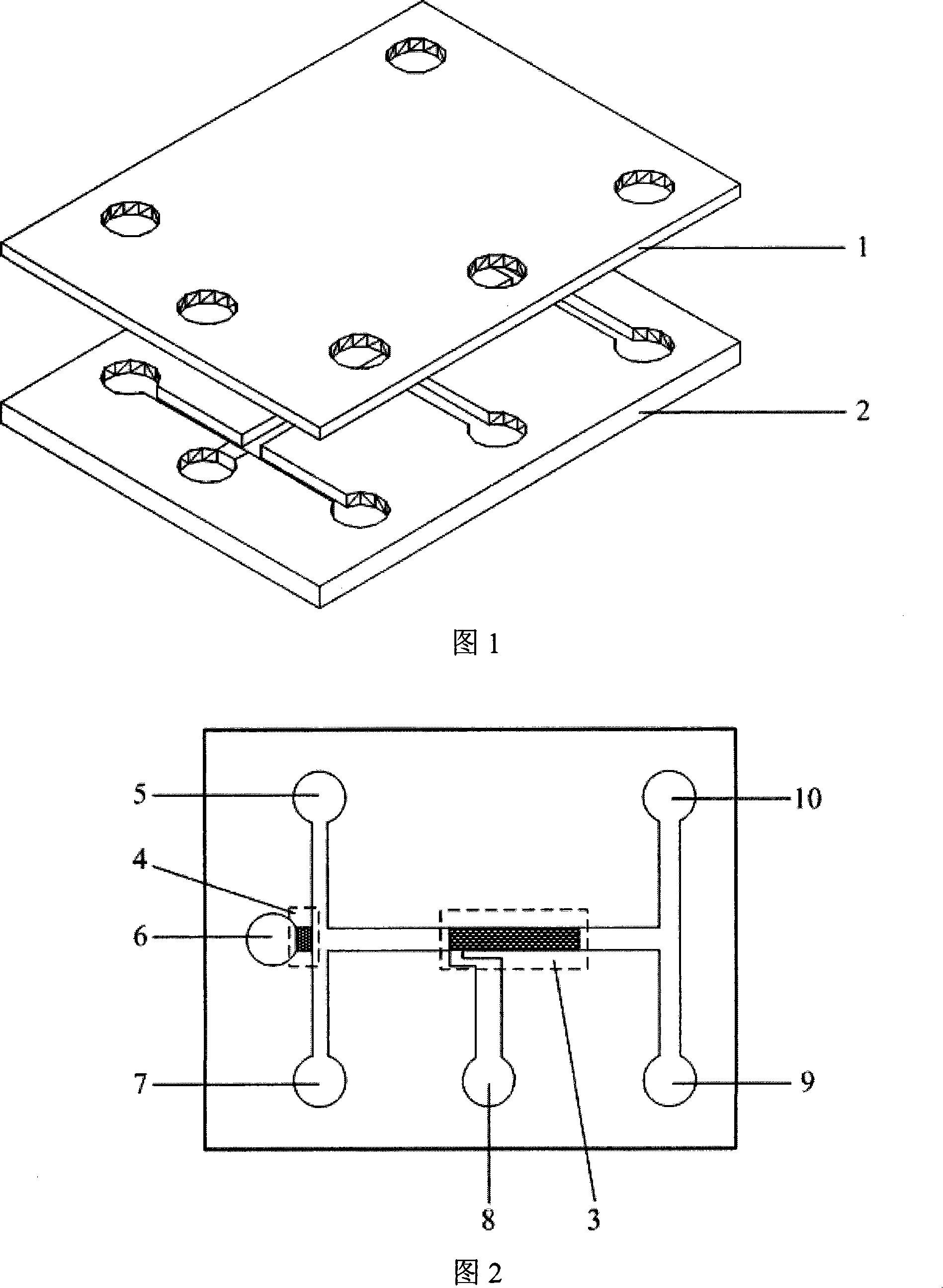

[0014] FIG. 1 is a schematic diagram of the structure of the solid phase extraction chip of the present invention, and the chip includes a cover layer 1 and a pipeline layer 2 . Among them, the pipe layer is processed with the micropipe and micro-pool structure as shown in Figure 2 by means of micro-machining, and the cover layer is processed with small holes corresponding to the micro-pools of the pipe layer.

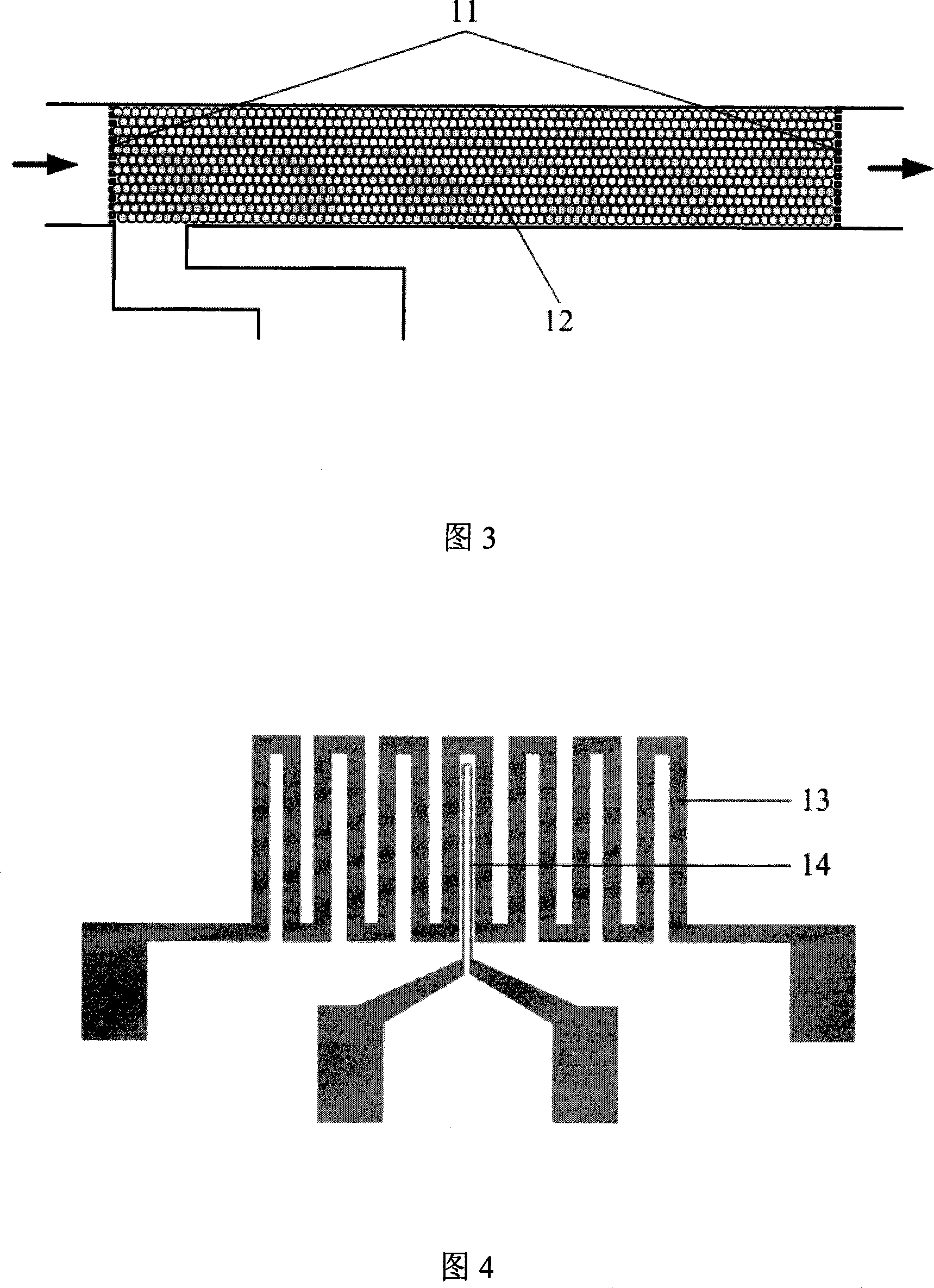

[0015] Fig. 2 is a schematic diagram of the planar structure of the pipe layer of the solid phase extraction chip of the present invention, comprising at least one section of solid phase extraction filler filling pipe 3, filter pipe 4 and a series of micro pools: an activation reagent pool 5, a sample pool 6, and a eluent Reservoir 7, an extraction packing-filled reservoir 8, a waste reservoir 9 and a sample collection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com