Clamping mechanism for cable through-going device

A clamping mechanism and cable technology, applied to electrical components, mechanical equipment, pipes, etc., can solve the problems of increased production costs, complexity and inconvenient, complicated manufacturing process, etc., and achieve the effect of saving materials and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

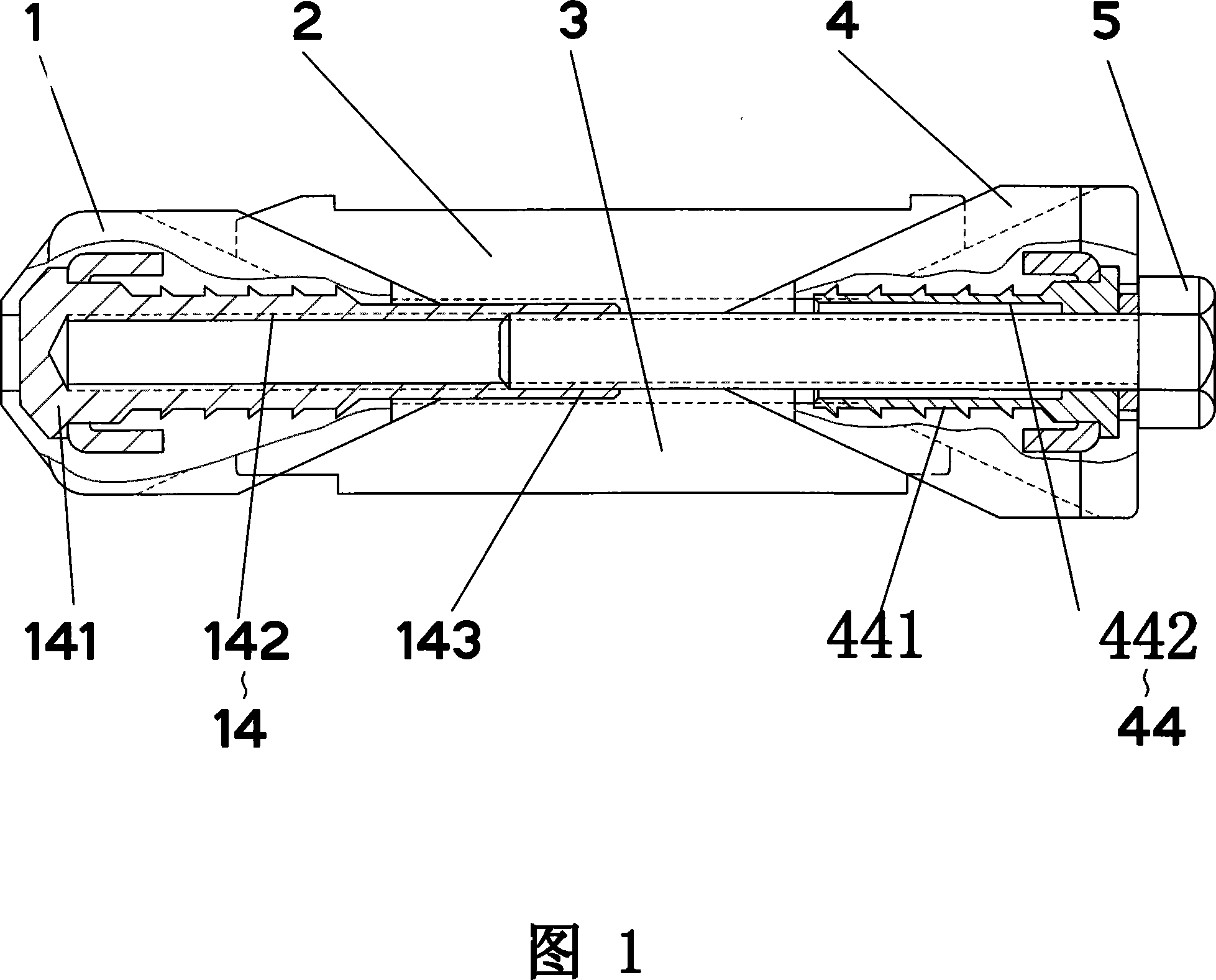

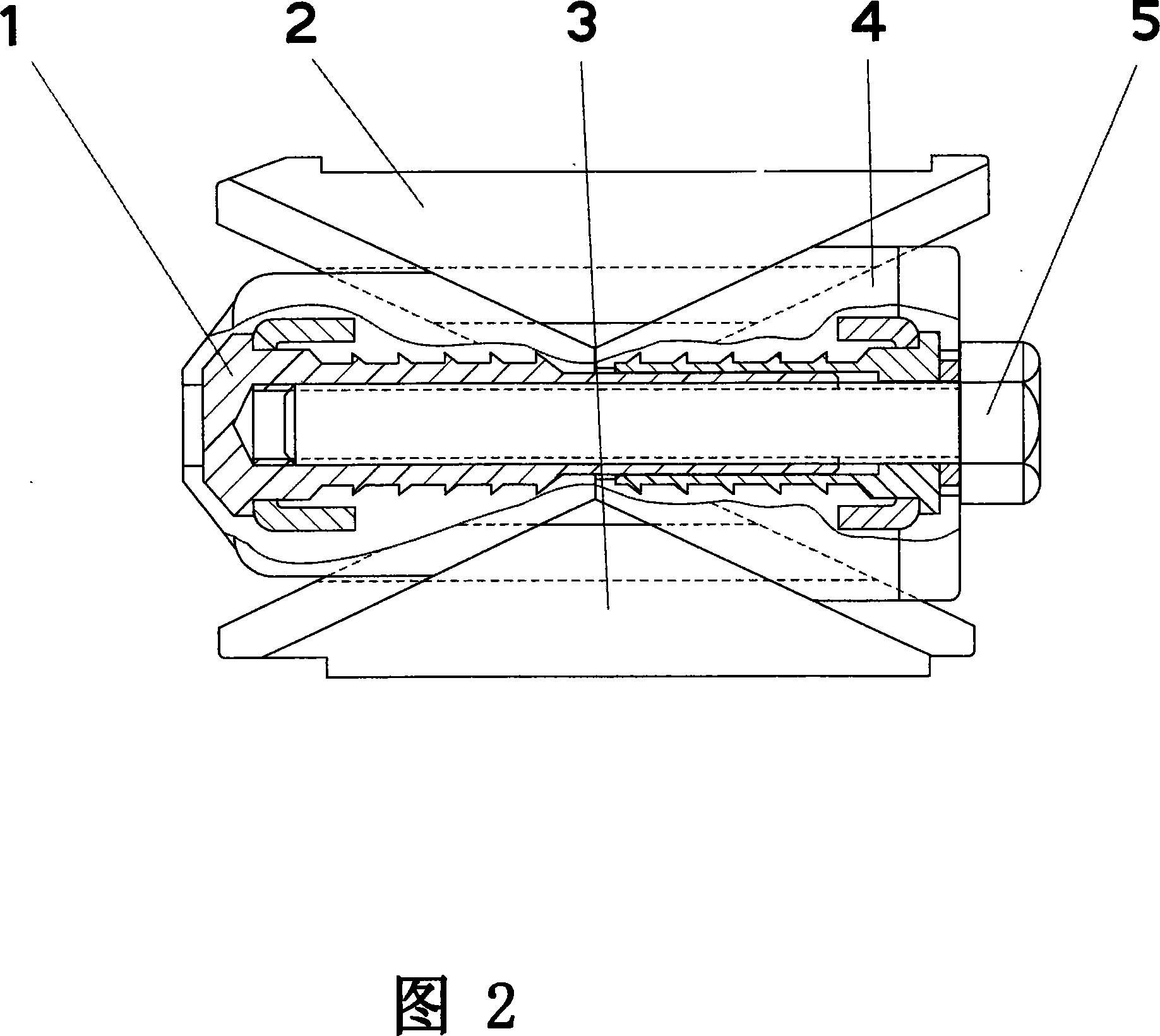

[0018] Referring to Figures 1 and 2, the clamping mechanism of the cable penetration device includes a left wedge 1 , an upper wedge 2 , a lower wedge 3 , a left wedge 4 and a long screw 5 .

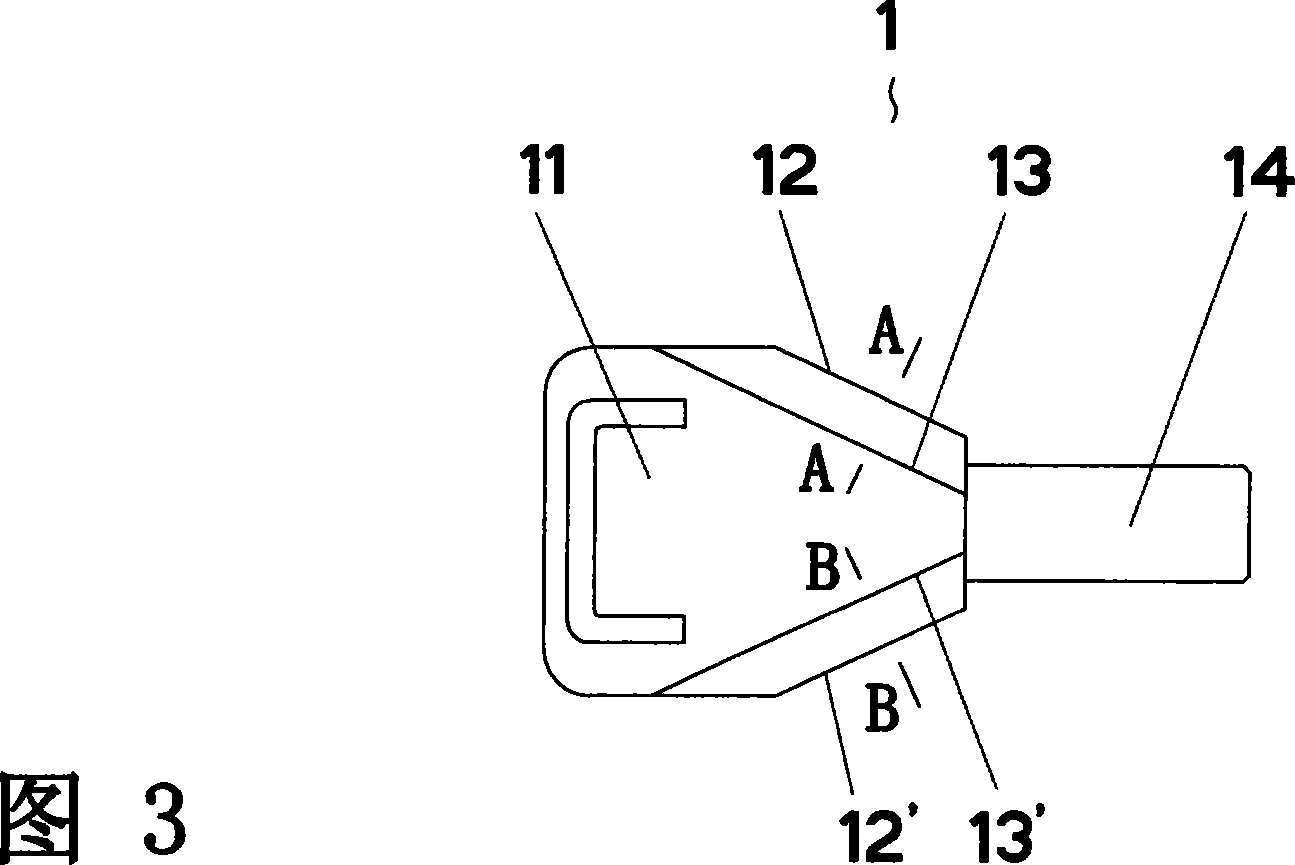

[0019] Left wedge 1, its main structure and material are all the same or similar to the existing structure, on the left upper slope 12, there is a left upper card slot 13 (shown in Figures 3 and 4), on the left lower slope 12', there is a left lower card Groove 13 ', the length of above-mentioned draw-in groove 13,13' is the full length of slope 12,12', the width of draw-in groove 13,13' can be 1 / 5 to 1 / 3 of the width of slope 12,12', draw-in groove 13. The depth of 13' is at least 3mm;

[0020] A threaded sleeve 14 is integrally vulcanized on the left wedge 1, and the threaded sleeve 14 is made of metal, and the structure of the joint part with the left wedge body 11 is the same or similar to the prior art.

[0021] Right wedge 4, its main body structure and material are all the same o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com