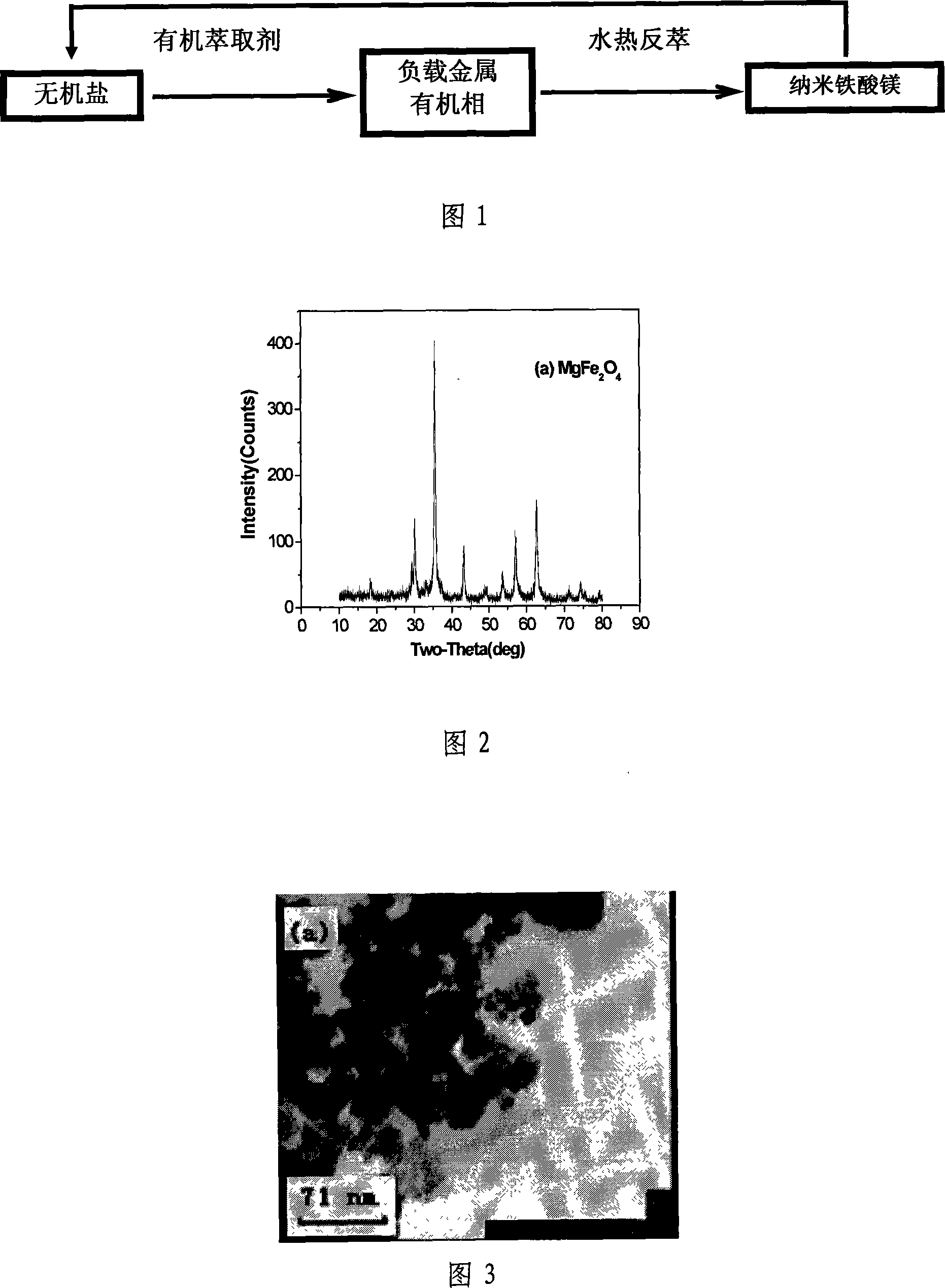

Method for synthesizing spinel structure magnesium frrite nano particles

A technology of magnesium ferrite and nano-powder, applied in magnesium compounds, iron compounds, chemical instruments and methods, etc., can solve problems such as environmental pollution, ensure product purity, reduce consumption and waste water discharge, and overcome difficulties in controlling precipitation. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Extract Mg with naphthenic acid 2+ and Fe 3+ Preparation of Mg- and Fe-loaded organic phases

[0052] Under magnetic stirring, add an appropriate amount of ammonia water with a volume ratio of 1:1 to naphthenic acid (commercially available) for saponification, control the pH of the solution=10, and then add MgSO with a concentration of 0.2mol / L 4 solution, magnetically stirred for 0.5 h, and the organic phase was separated, washed with distilled water for 3 times to obtain a pure organic phase loaded with magnesium metal.

[0053] By controlling the pH of the solution to 3, the iron-loaded organic phase can also be prepared.

[0054] (2) Hydrothermal stripping of loaded metal-organic phase

[0055] by Mg 2+ : Fe 3+ =1:2 molar ratio Mix the organic phase loaded with metal magnesium and iron evenly, introduce it into the autoclave, add distilled water according to the volume ratio of the water phase and the organic phase as 1:4, adjust to 210°C after sealing, and...

Embodiment 2

[0060] (1) Extract Mg with naphthenic acid 2+ and Fe 3+ Preparation of magnesium- and iron-loaded organic phases: the same as in Example 1.

[0061] (2) Hydrothermal stripping of the metal-organic phase: the same as in Example 1 except that the temperature is 220°C.

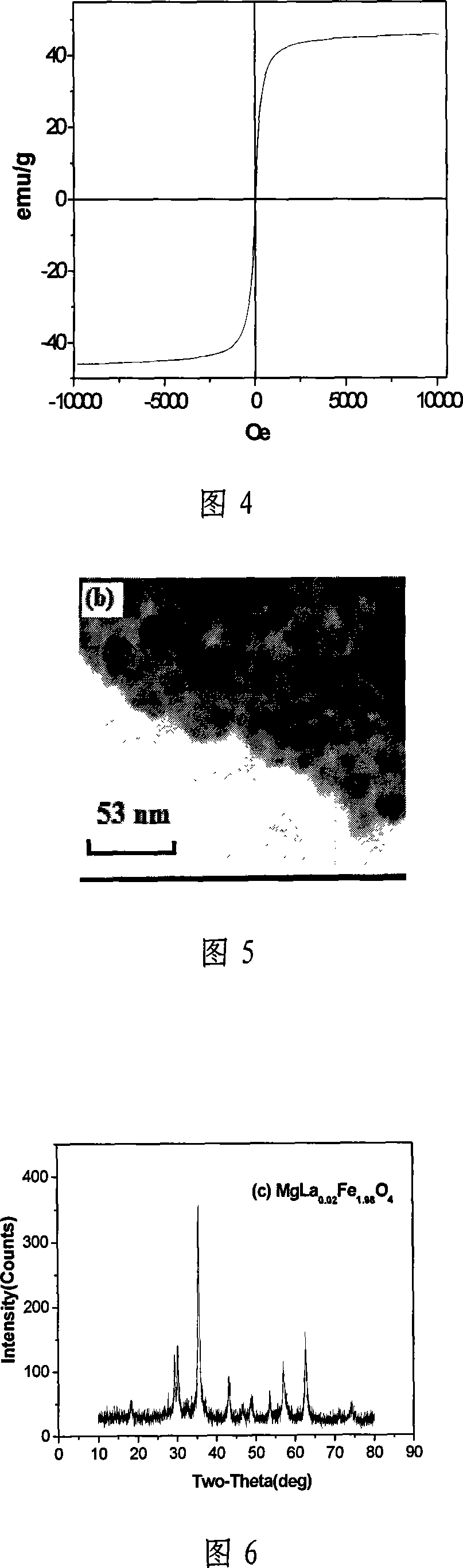

[0062] (3) Product characterization

[0063] The transmission electron microscope photograph of the product is shown in Figure 5, and the test results obtained from the transmission electron microscope photograph are listed in Table 1.

Embodiment 3

[0065] (1) Extract Mg with naphthenic acid 2+ , Fe 3+ and La 3+ Preparation of the organic phase loaded with magnesium, iron and lanthanum is the same as in Example 1, and the pH of the solution is controlled to be 5, and the organic phase loaded with lanthanum can also be prepared.

[0066] (2) Hydrothermal stripping of the loaded metal-organic phase: the same as in Example 1, except that the temperature is 220° C., and the organic phases are mixed in a ratio of 1: 1.98: 0.02 in a molar ratio of magnesium, iron and lanthanum to obtain Lanthanum doped magnesium ferrite (MgLa 0.02 Fe 1.98 o 4 )product.

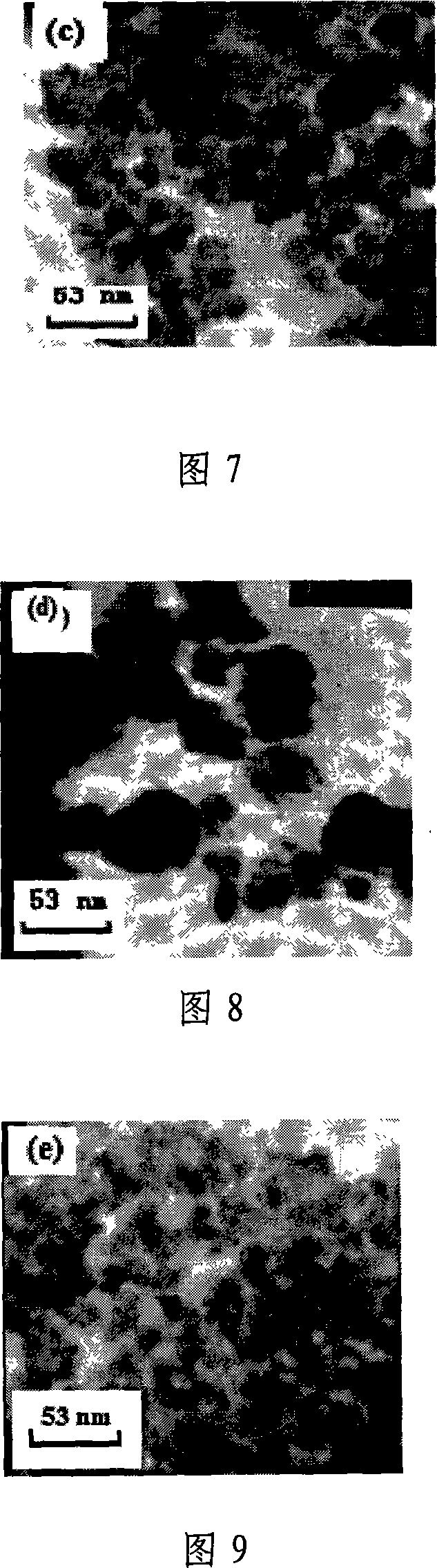

[0067] (3) Characterization of the product:

[0068] The XRD pattern measurement result of the product is shown in Figure 6. The transmission electron microscope photograph of the product is shown in Figure 7, and the test results obtained from the transmission electron microscope photograph are listed in Table 1. The hysteresis loop of the product is shown in Figure 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com