Laser diode drive circuit

A laser diode and driving circuit technology, applied in circuits, lasers, laser parts and other directions, can solve the problems of long feedback path, large time constant, difficult circuit matching, etc., to eliminate the response speed, easy circuit design, and time constant. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

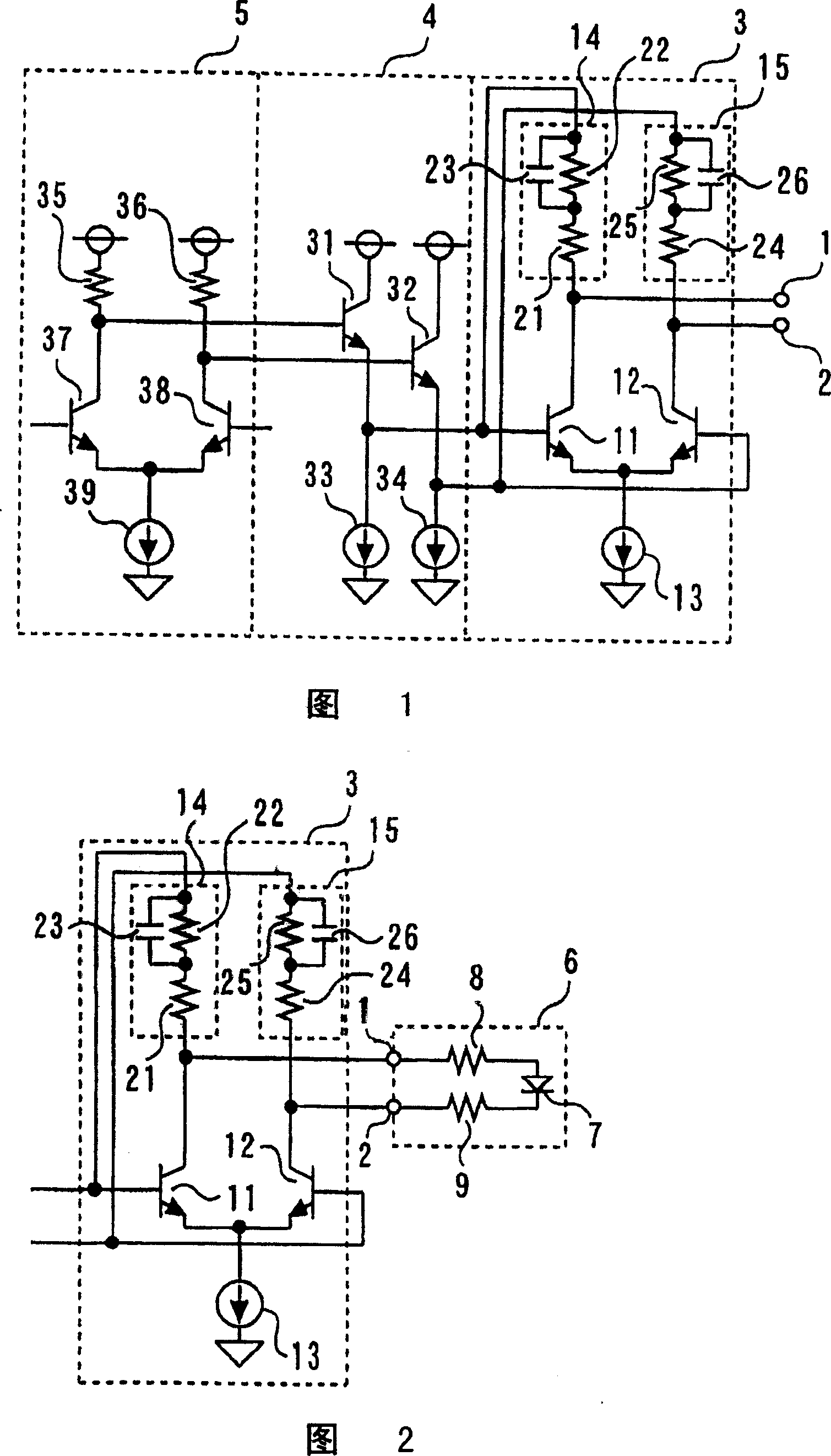

[0023] Fig. 1 is a circuit diagram showing a driving circuit according to a first embodiment of the present invention. In addition, FIG. 2 is a circuit diagram showing a TOSA to which the driving circuit of FIG. 1 is connected.

[0024] A drive circuit having output terminals 1, 2, a final stage amplifying circuit 3, a first emitter follower circuit 4 arranged in a preceding stage of the final stage amplifying circuit 3, and an amplifier arranged in a preceding stage of the first emitter follower circuit 4 Circuit 5.

[0025] On the other hand, TOSA 6 has laser diode 7 , matching resistor 8 connected to the anode of laser diode 7 , and matching resistor 9 connected to the cathode of laser diode 7 .

[0026] The final stage amplifier circuit 3 has: a first transistor 11 , a second transistor 12 , a constant current circuit 13 , a first high-pass filter 14 , and a second high-pass filter 15 . Then, the collector of the first transistor 11 is connected to the anode of the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com