Electromotor safety valve

A safety valve and motor technology, applied in the direction of engine components, lift valves, electromagnets, etc., can solve the problems of reduced battery life, rising cost, installation space limitation, etc., and achieve the effect of preventing cost rise, preventing stall, and increasing degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

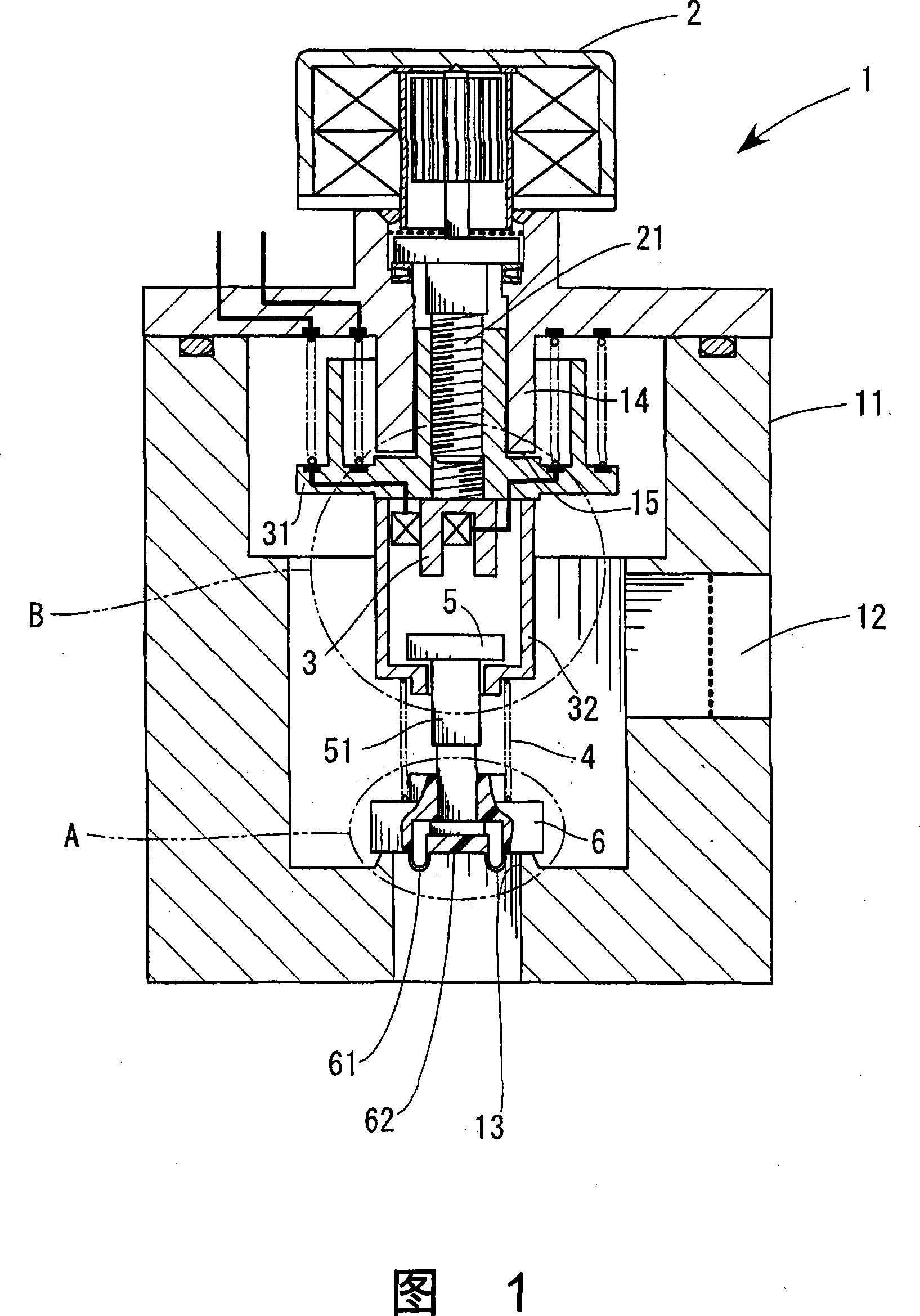

[0021] Referring to Fig. 1, 1 is an example of a motor safety valve of the present invention. An inlet 12 for inflowing gas and a valve port 13 for outflowing gas are provided on the housing 11 of the motor safety valve. The stepping motor 2 is mounted on the upper part of the casing 11 . The stepping motor 2 rotates at a rotation angle proportional to the number of input drive pulses, and can freely switch between forward and reverse rotation.

[0022] An external thread 21 is provided on the rotating shaft of the stepping motor 2 . On the other hand, 3 is a movable electromagnet held by a holder 31 screwed to the external thread 21 . The retainer 31 is inserted into the anti-rotation portion 14 to be able to move forward and backward. In addition, the lower end of the anti-rotation portion 14 functions as a stopper for the upward movement of the holder 31 . The movable electromagnet 3 is enclosed by a housing 32 fixed on a holder 31 .

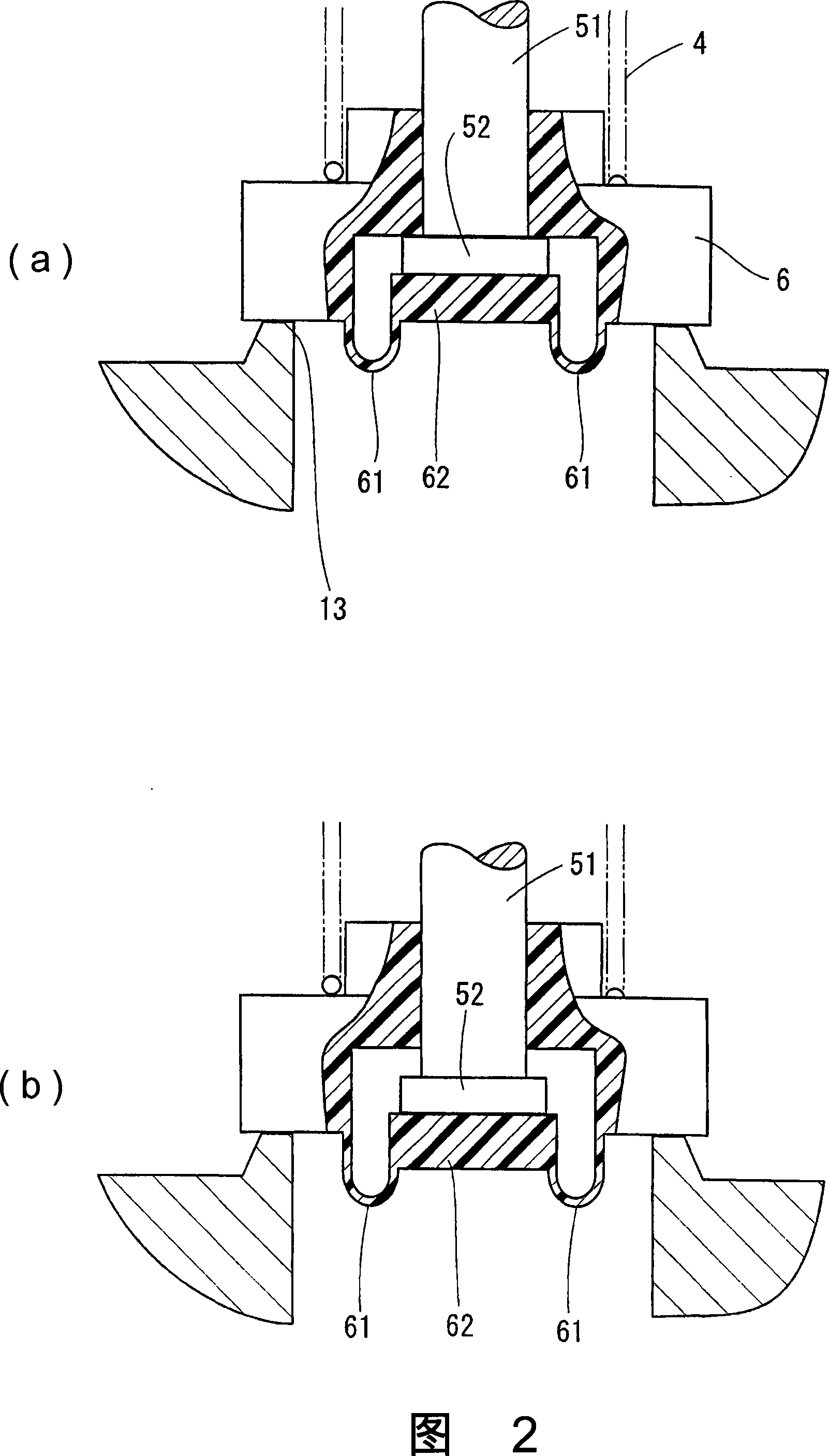

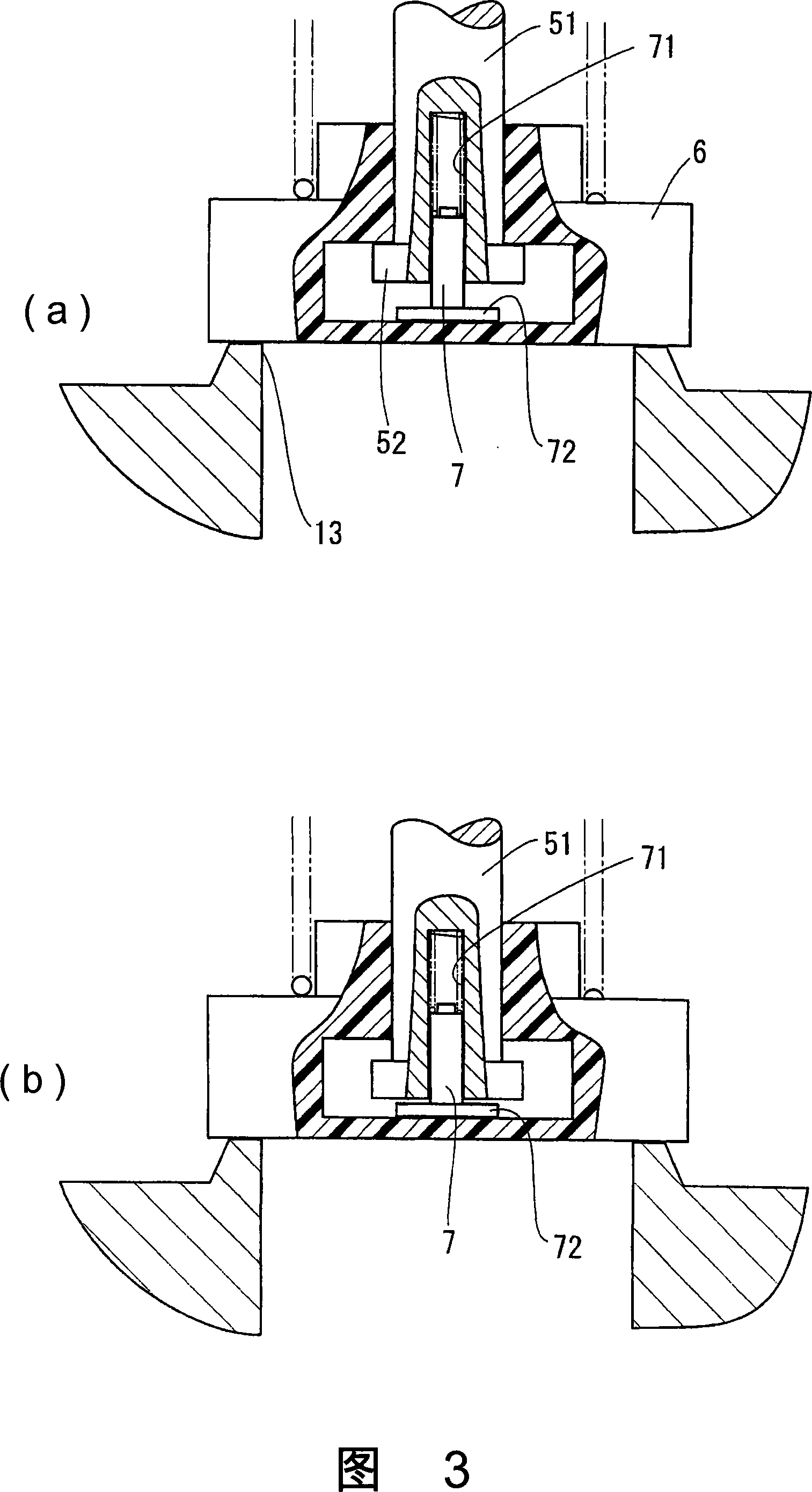

[0023] The movable iron piece 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com