Planar display device with explosive star-typed cathode structure and its production

A flat-panel display and cathode structure technology, which is applied in the field of flat-panel display technology, and can solve the problems of failing to meet the quality system requirements of low-voltage flat-panel display devices and maintaining a high grid operating voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

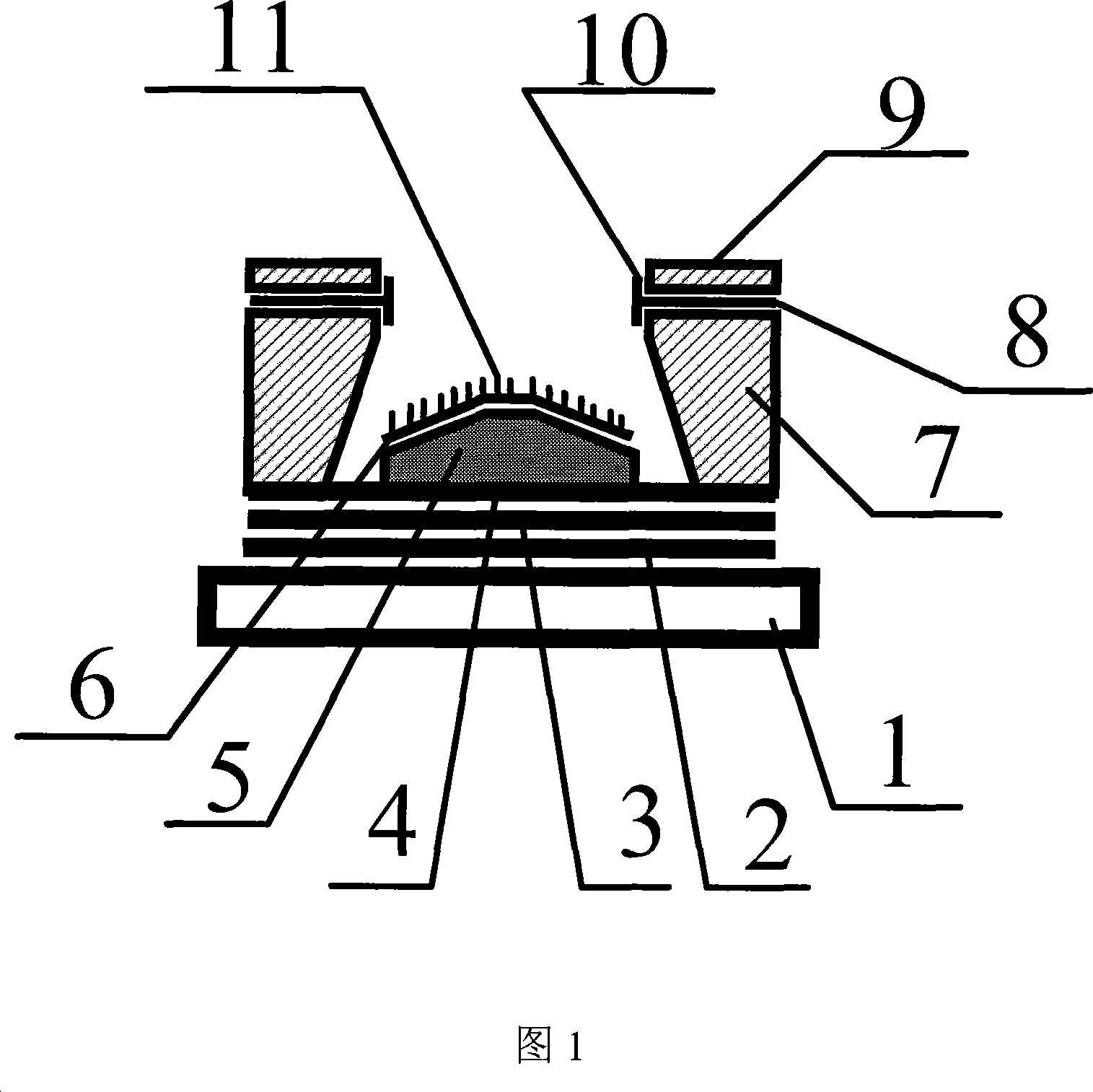

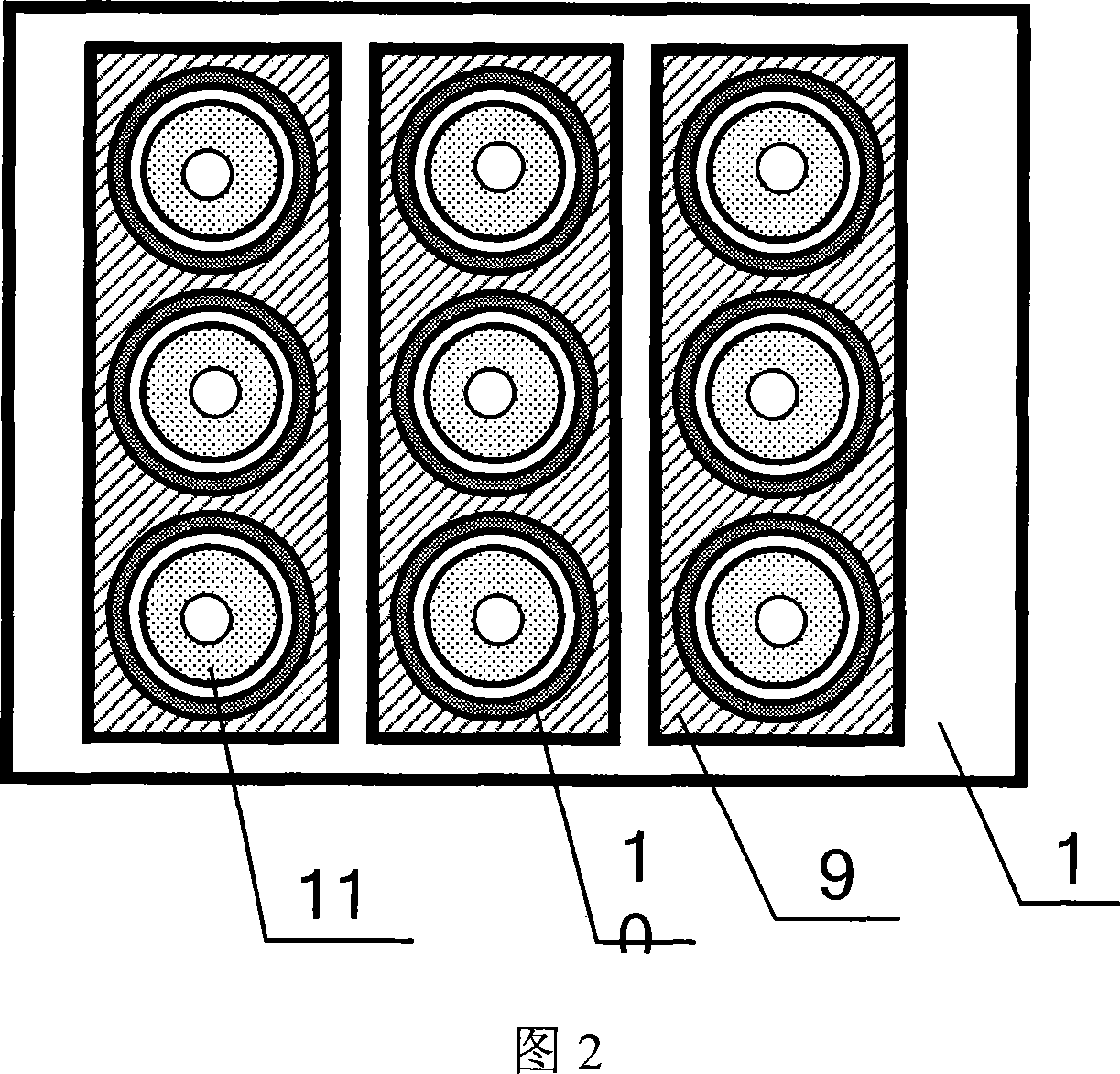

[0040] Described a kind of flat-panel display with explosive star cathode structure, comprises the airtight vacuum cavity that is made of anode glass panel [12], cathode glass panel [1] and surrounding glass frame [17]; There is an anode conductive layer [13] and a phosphor layer [15] prepared on the anode conductive layer; there are grid lead layers [8], carbon nanotubes [11] and an explosive star cathode structure on the cathode glass panel; Supporting wall structure [16] and getter [18] accessory elements located between the anodic glass panel and the cathodic glass panel.

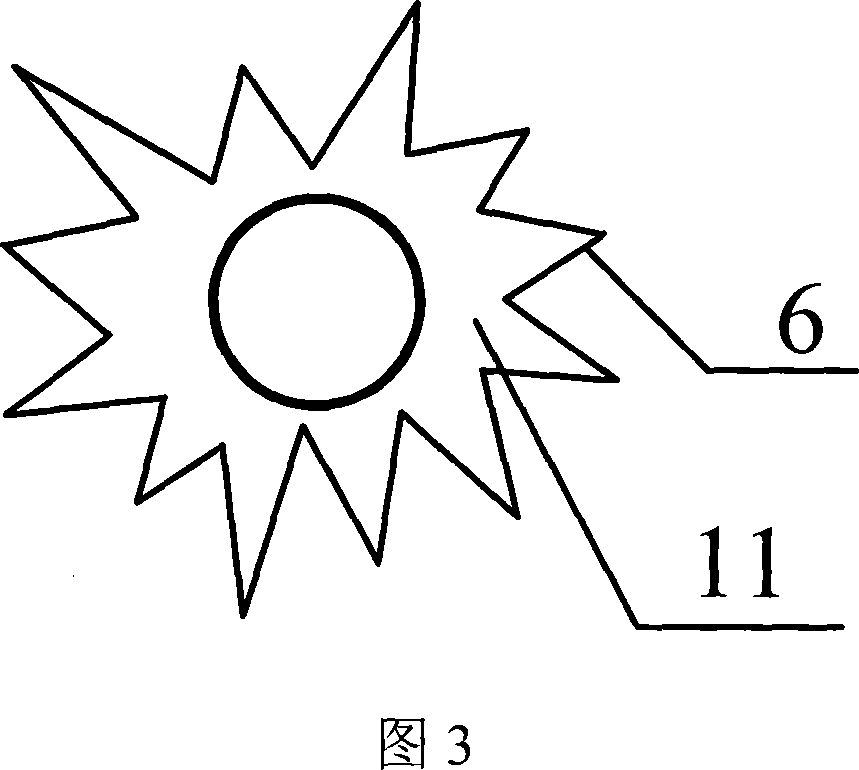

[0041] The explosive star cathode structure includes a cathode glass panel [1], a retardation layer [2], a cathode lead layer [3], a cathode transition layer [4], a cathode lifting layer [5], and a cathode conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com