Patents

Literature

40results about How to "Increased electron emission area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

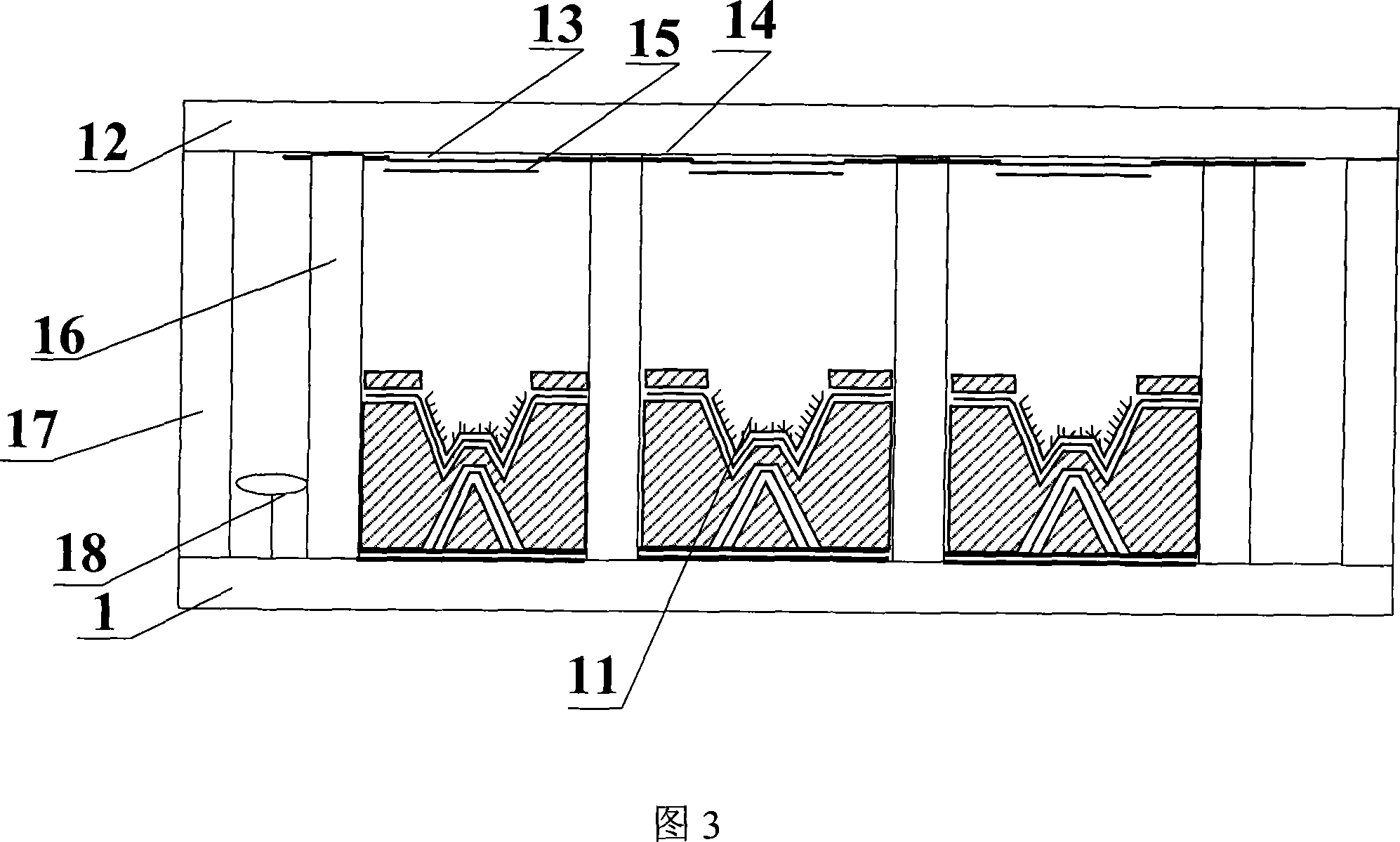

Flat board display of splayed inclined bar control structure and its making process

InactiveCN101080123AImprove control efficiencyStrong electric field strengthElectrical apparatusElectroluminescent light sourcesImaging qualityCarbon nanotube

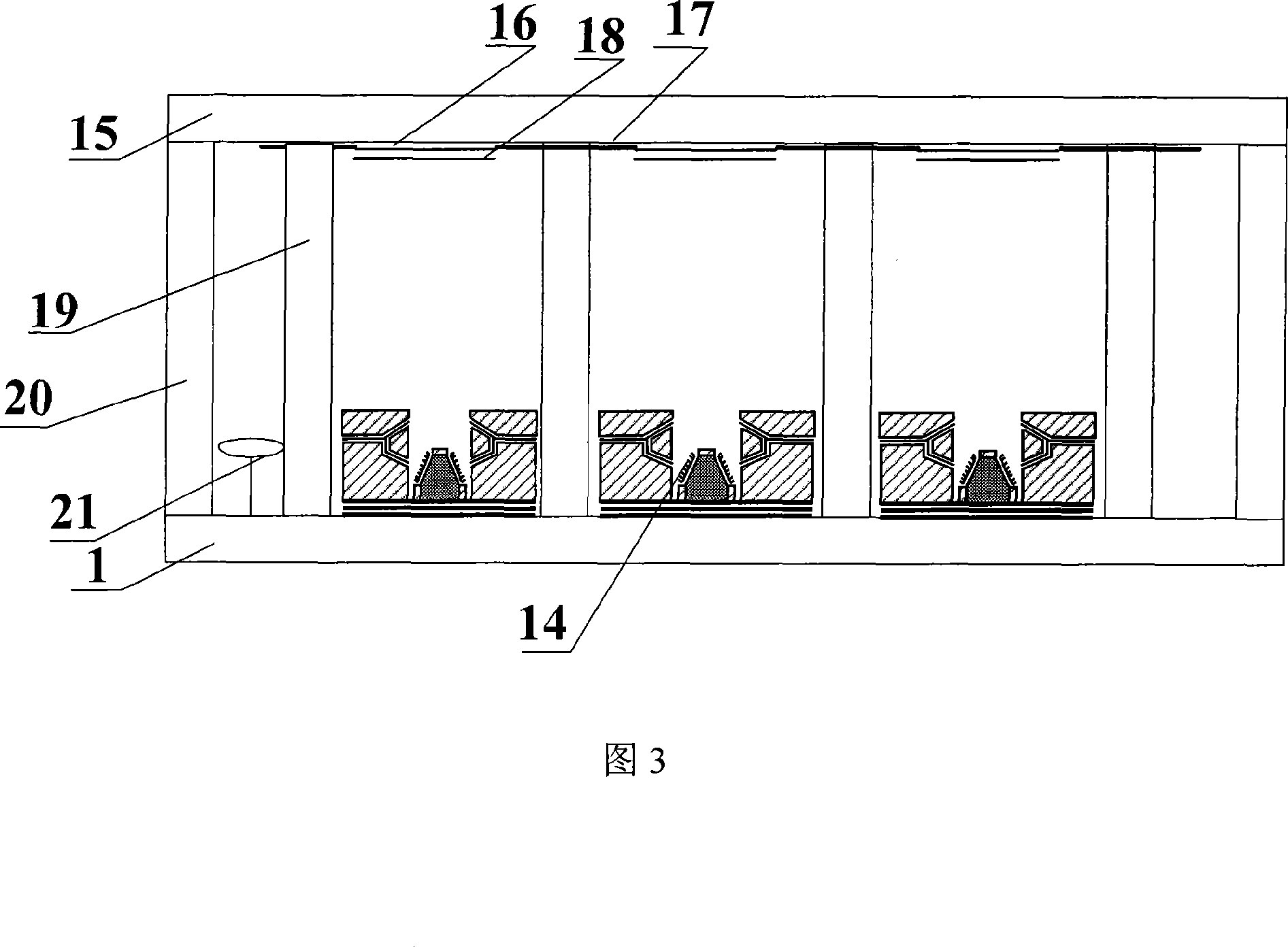

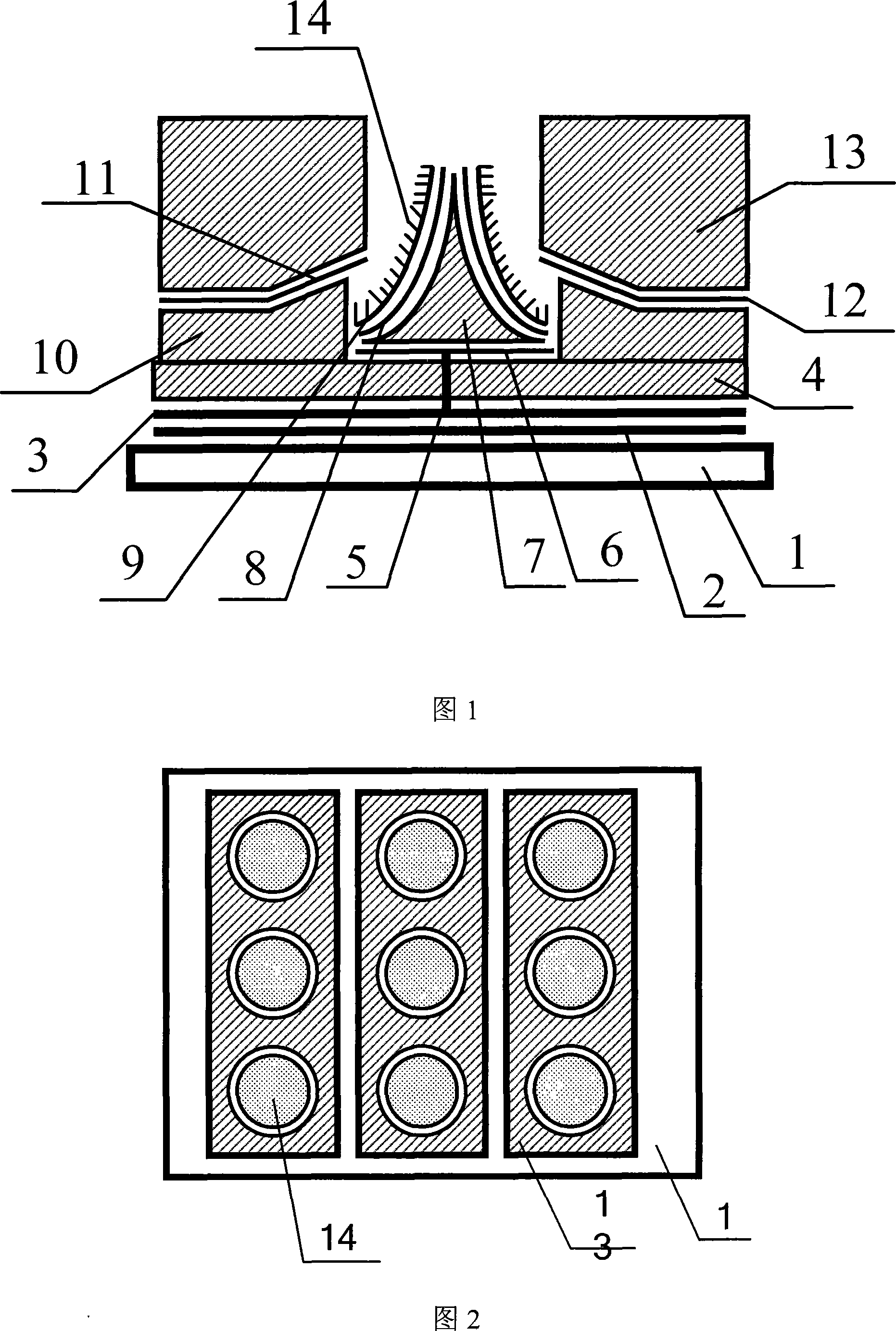

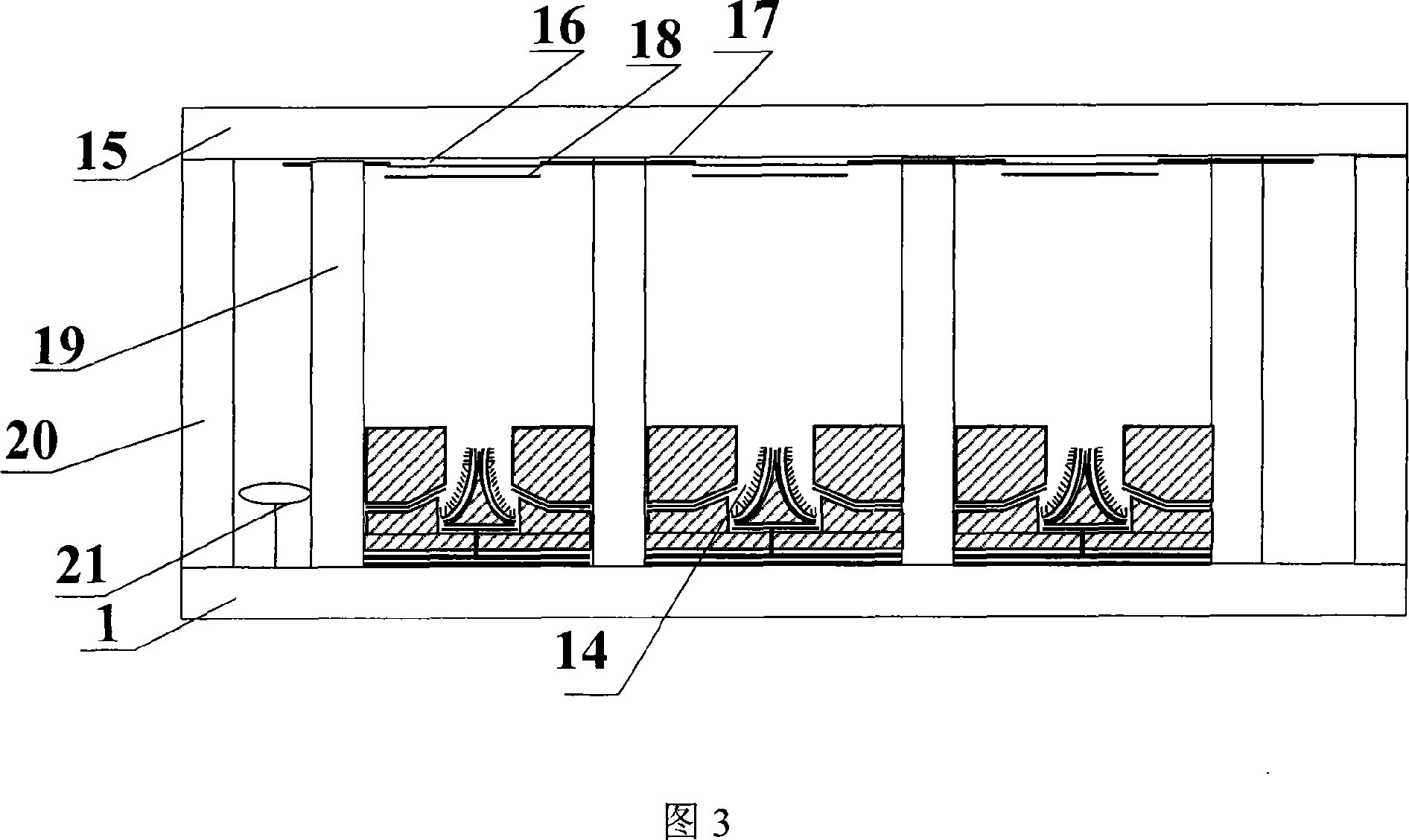

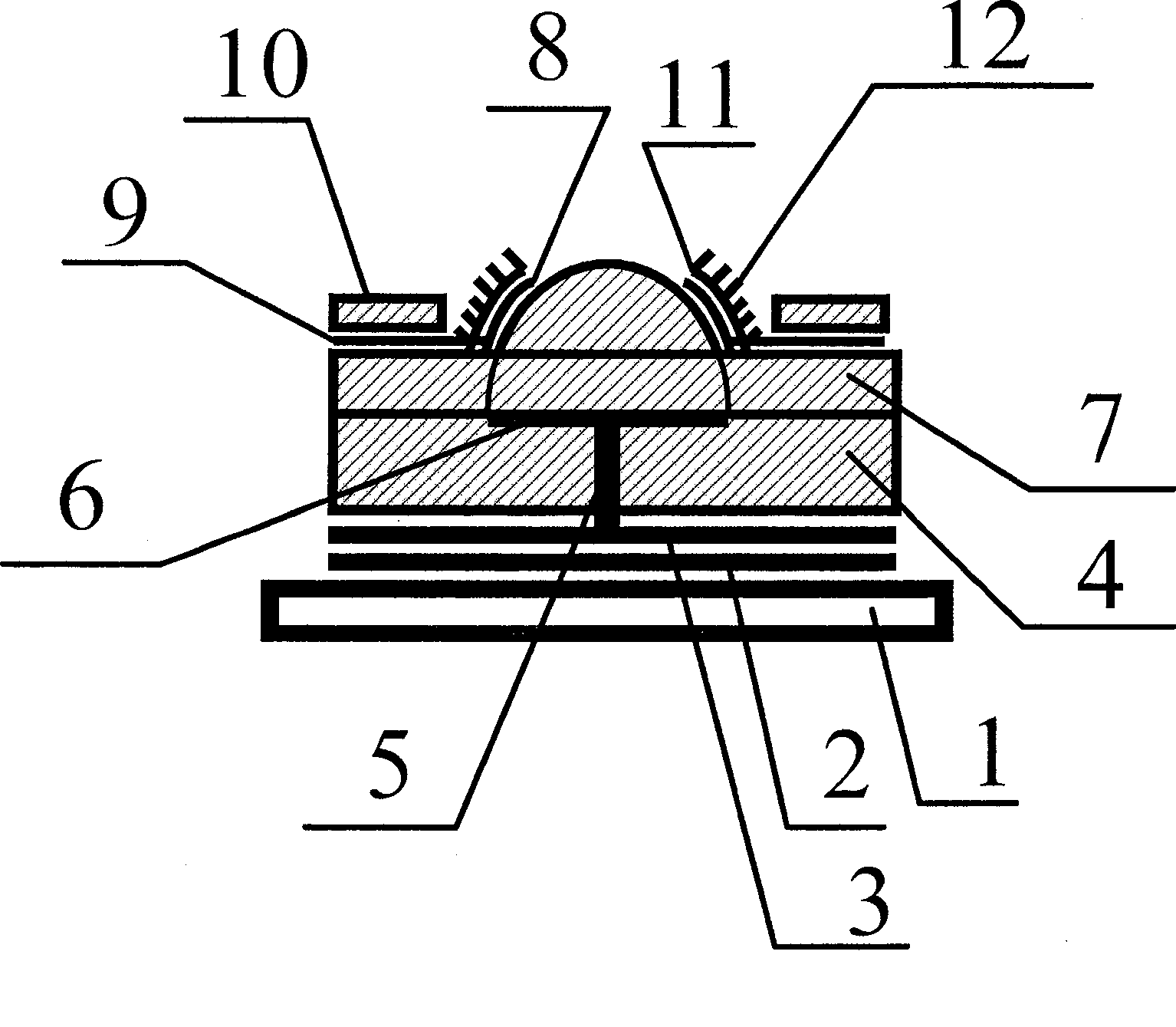

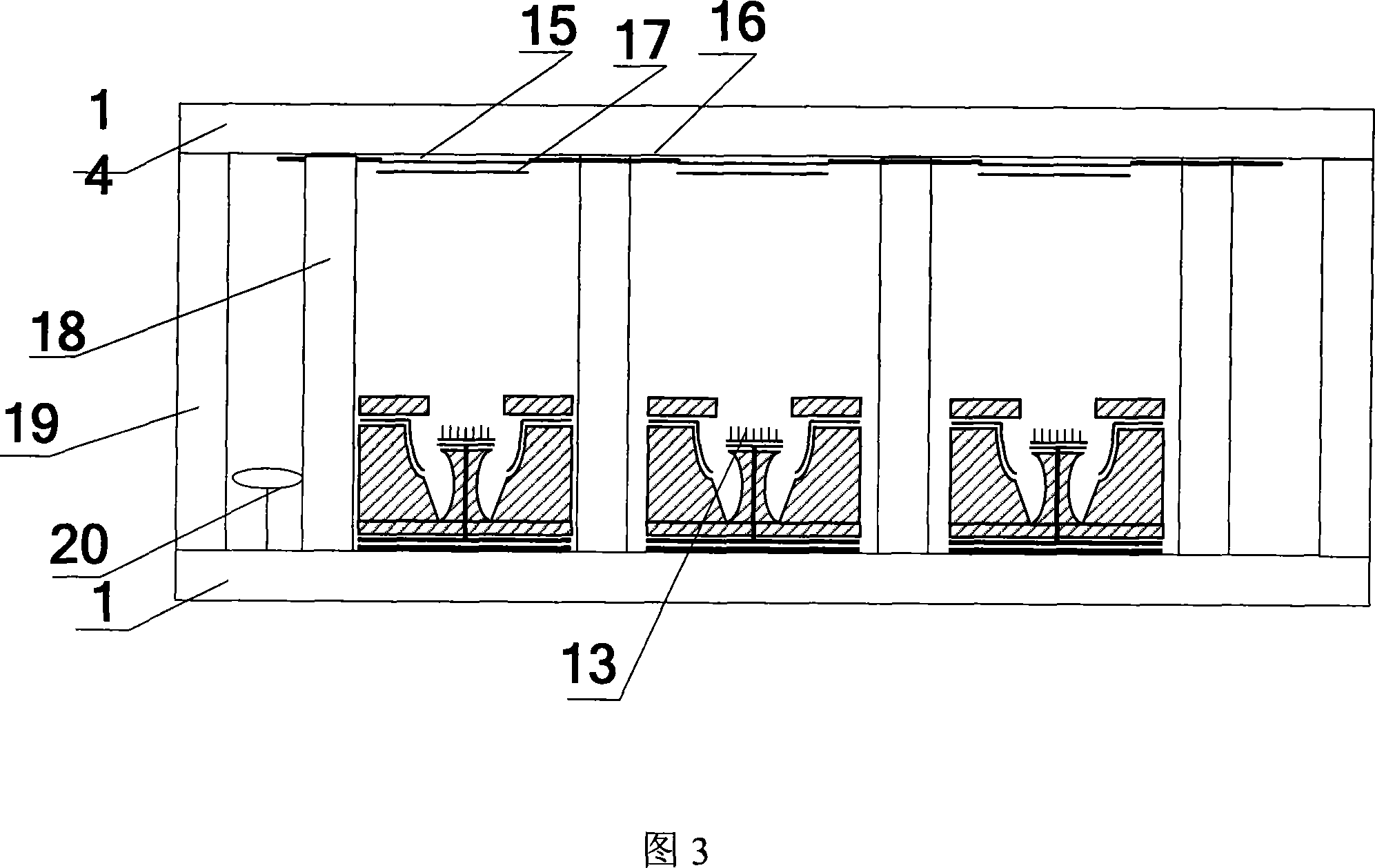

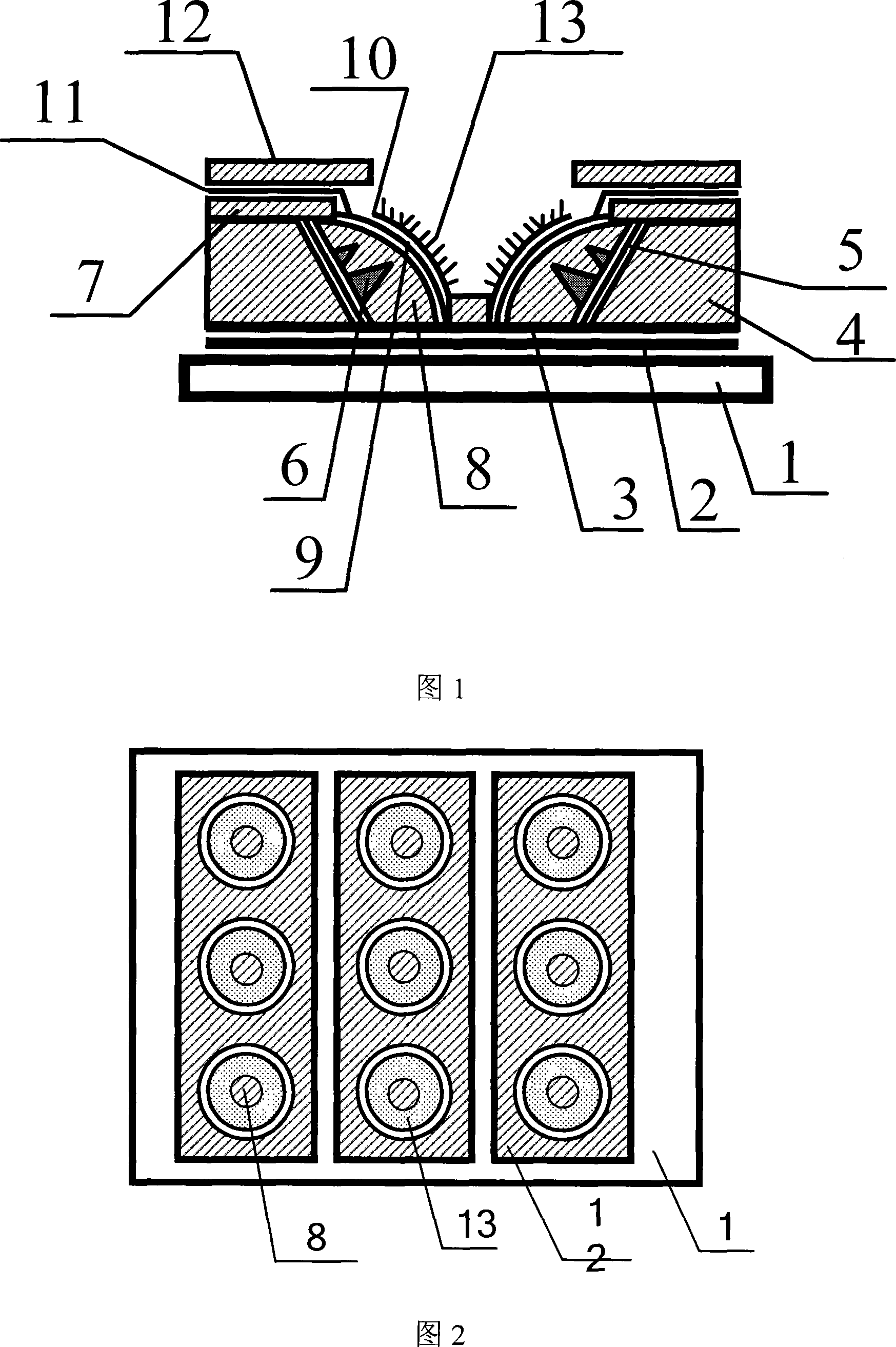

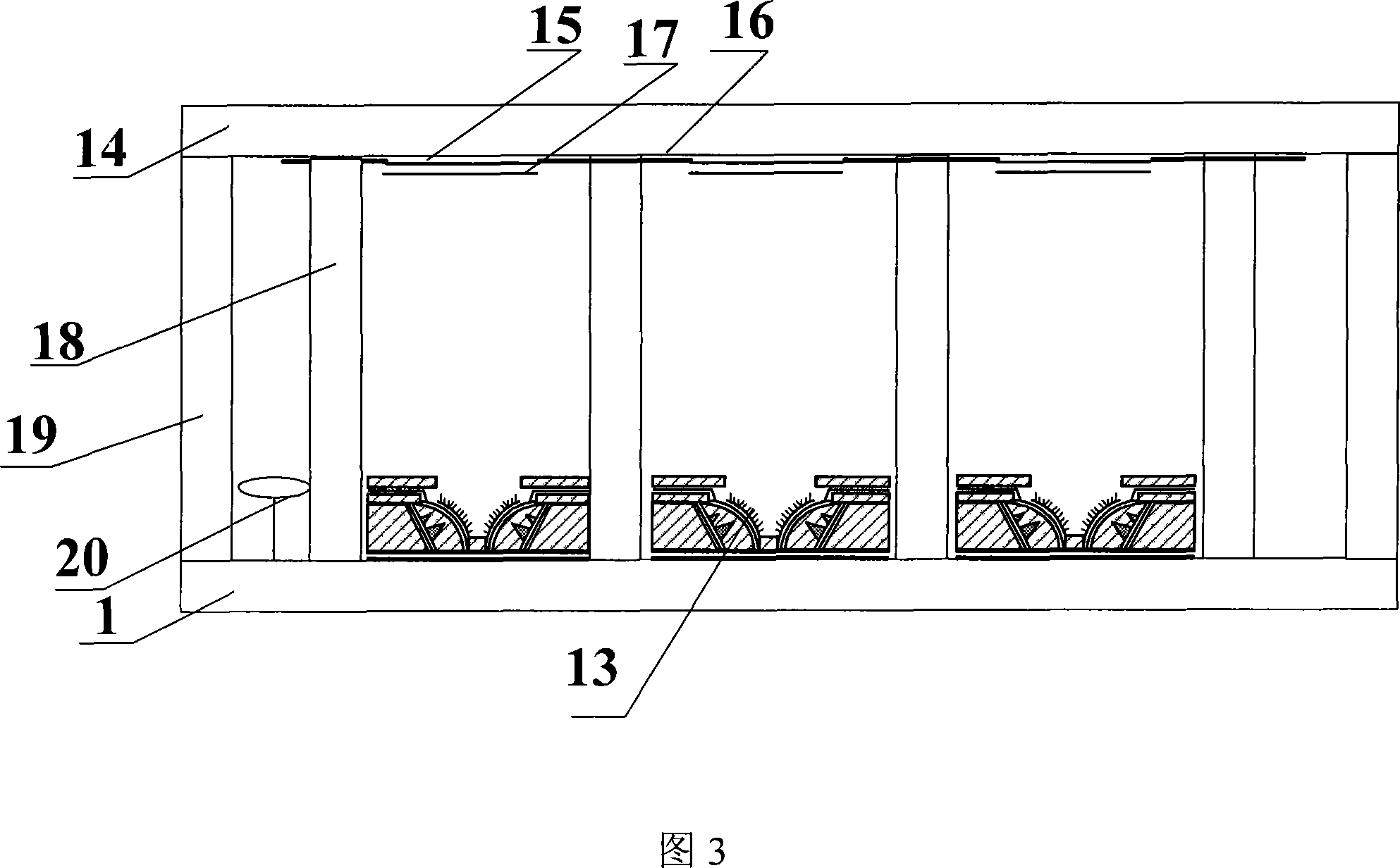

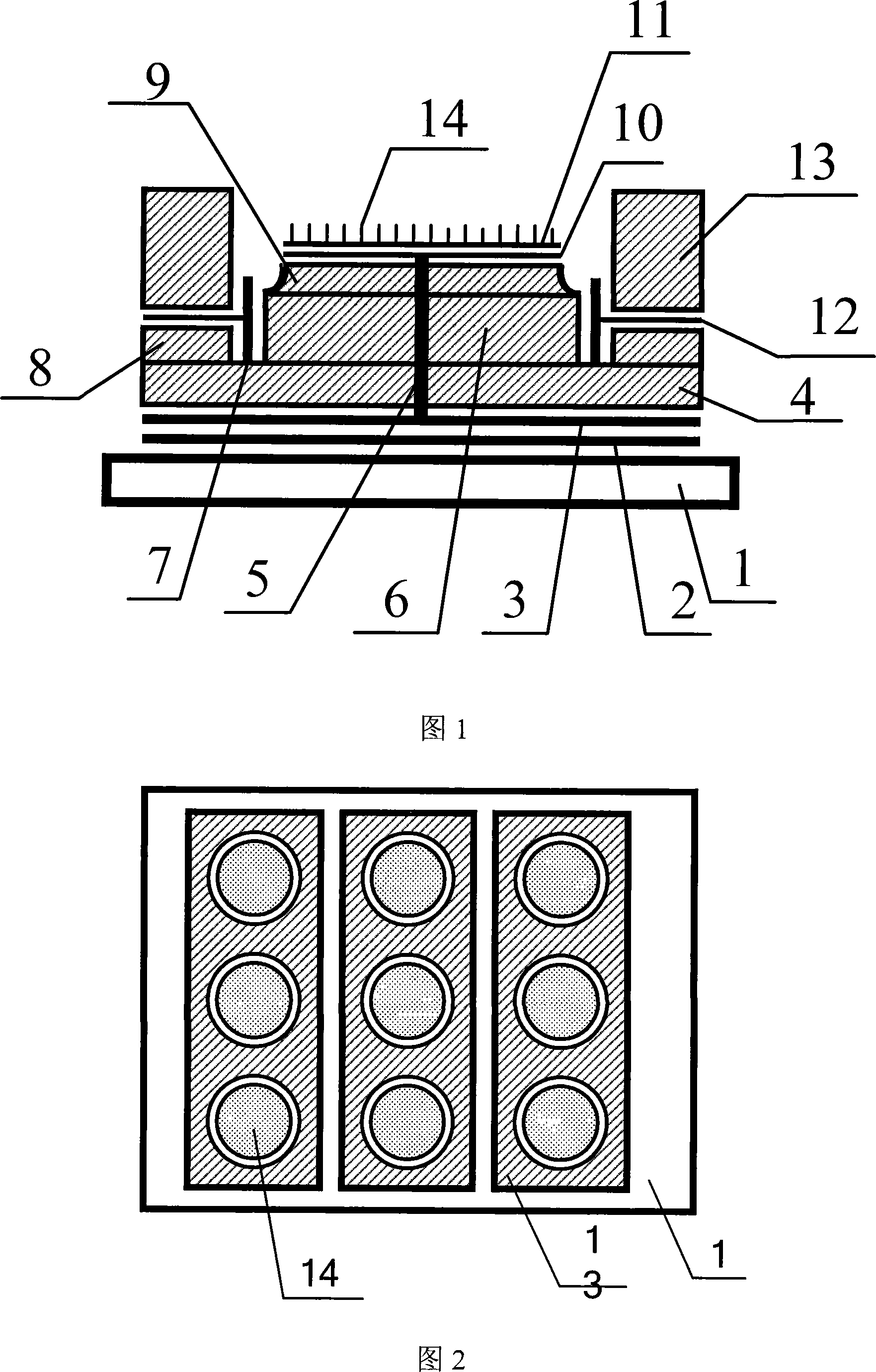

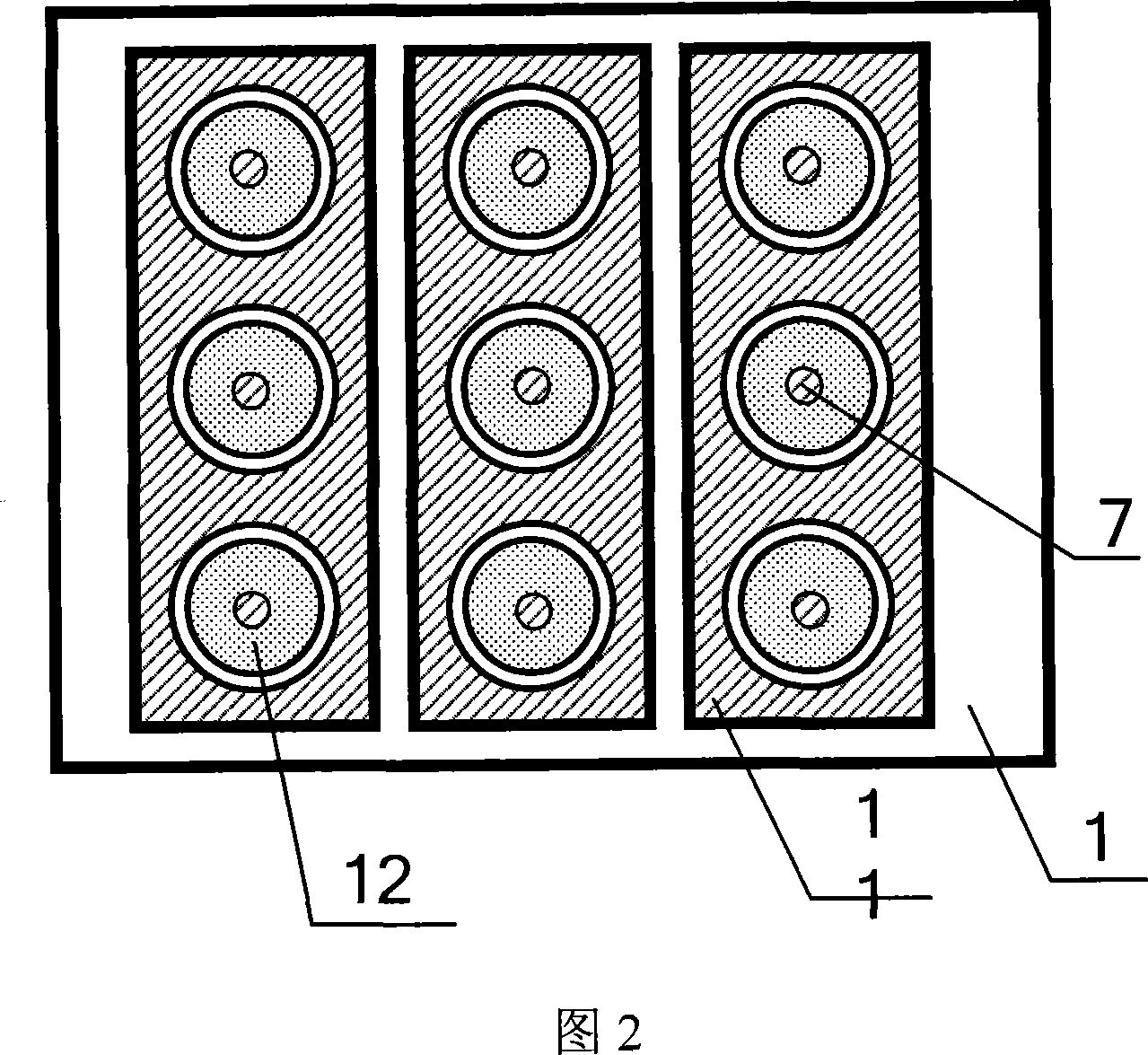

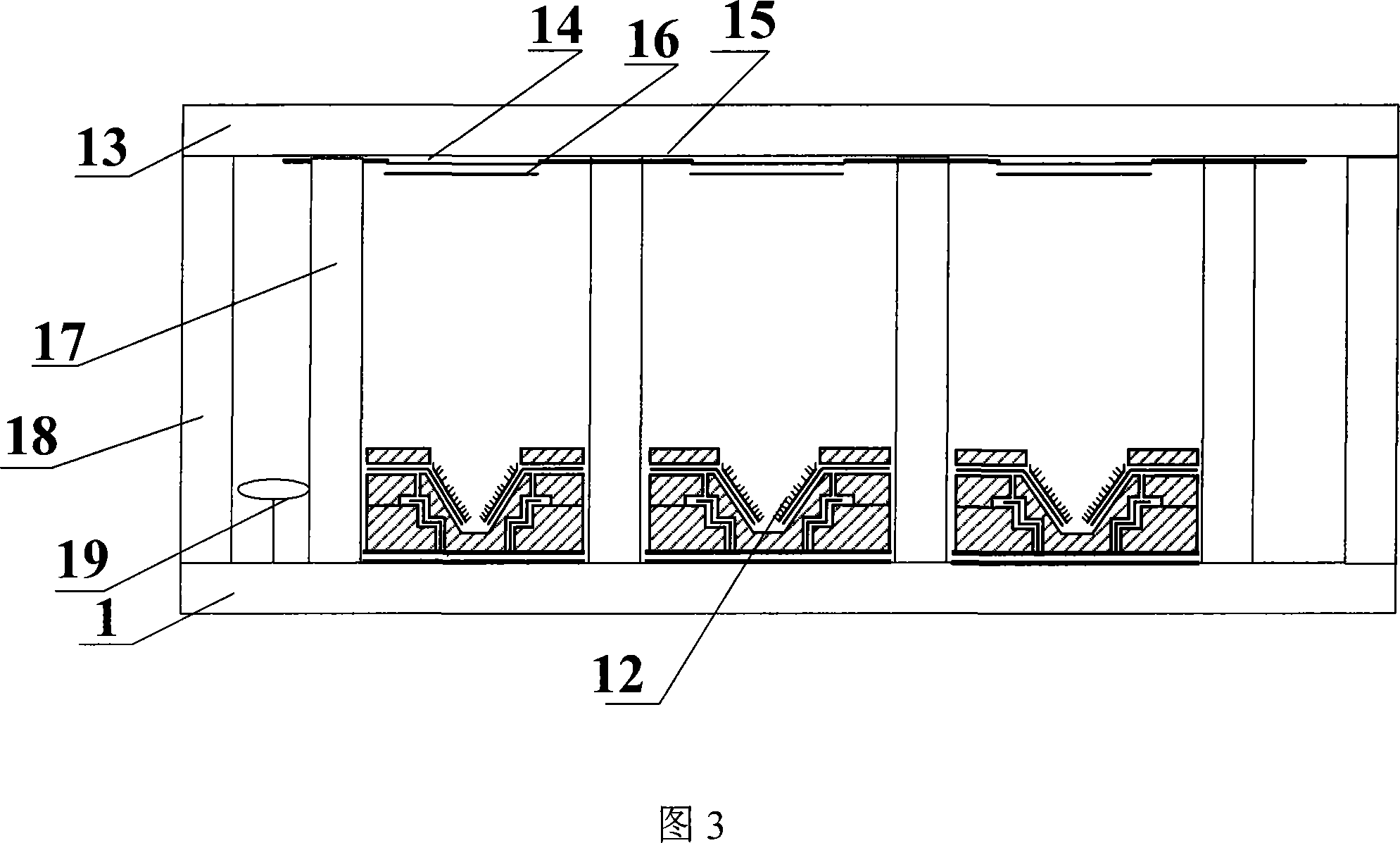

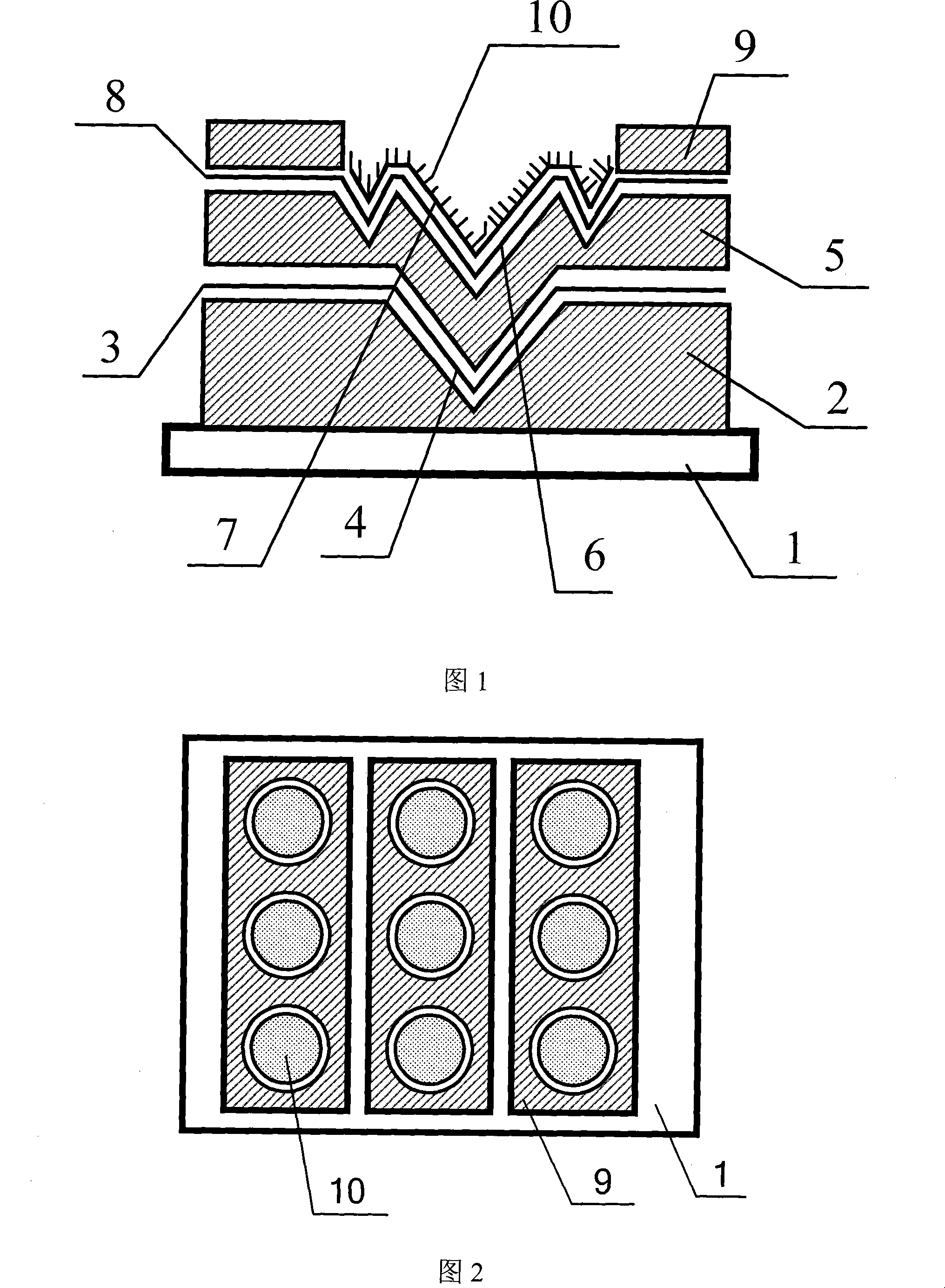

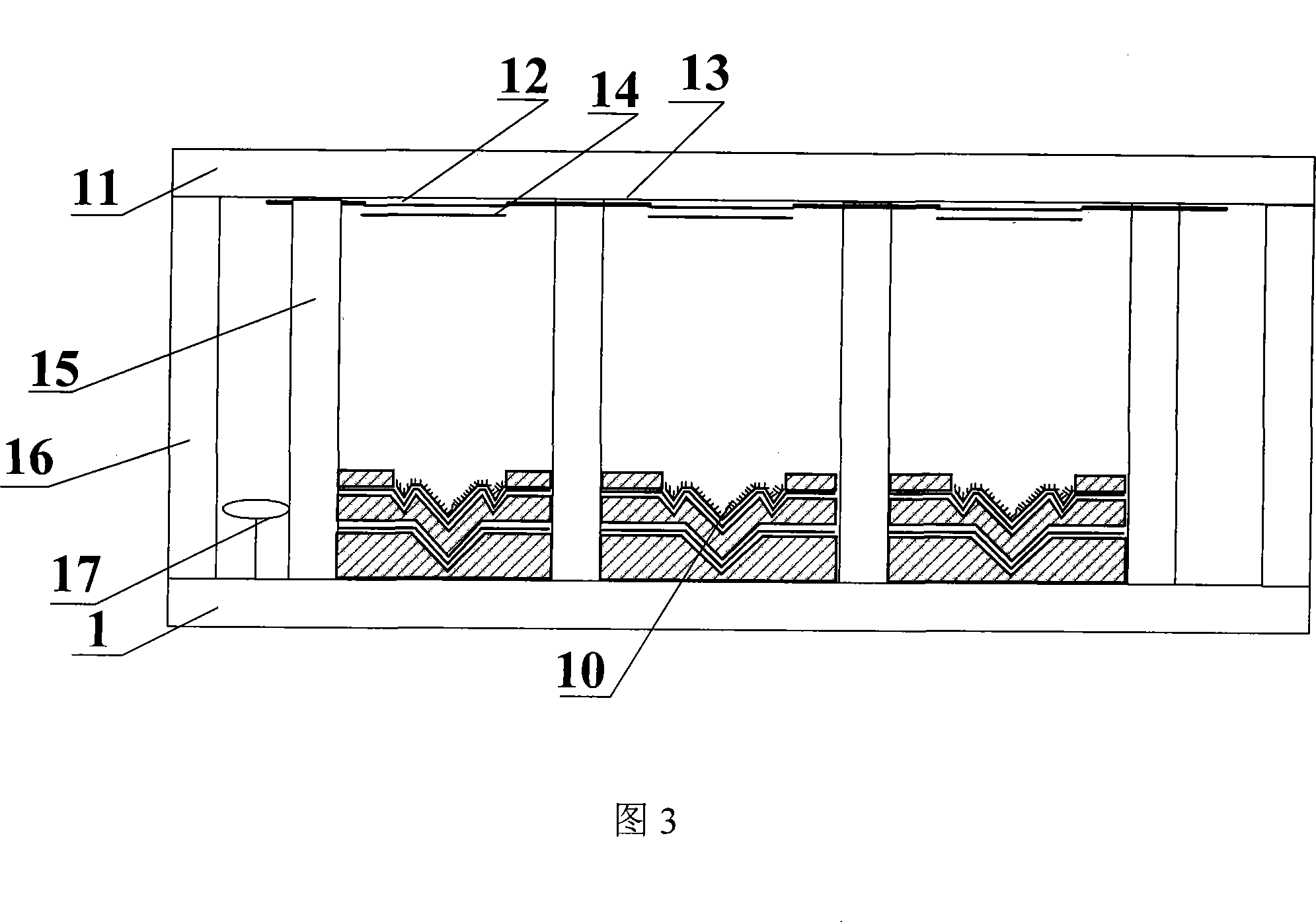

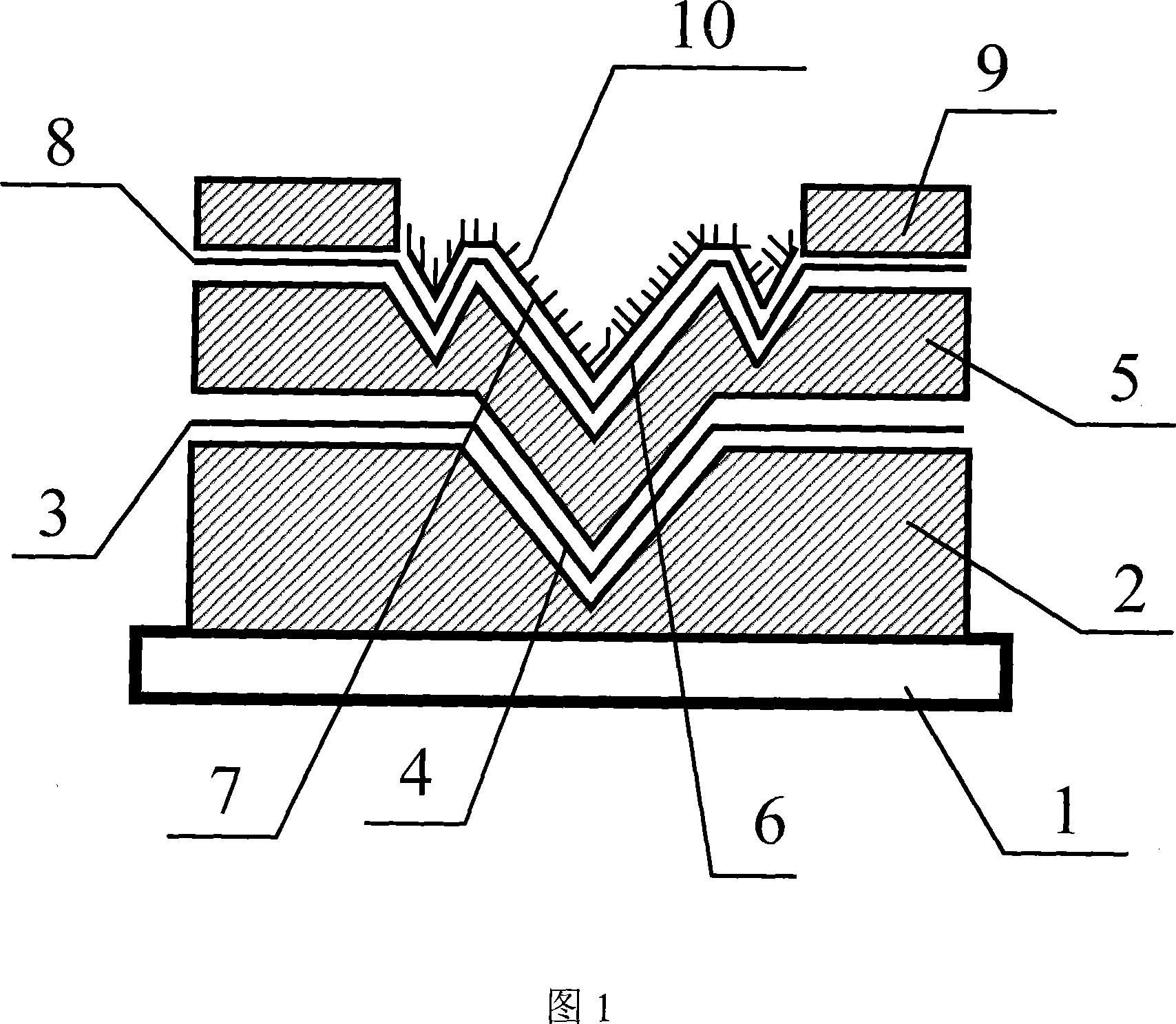

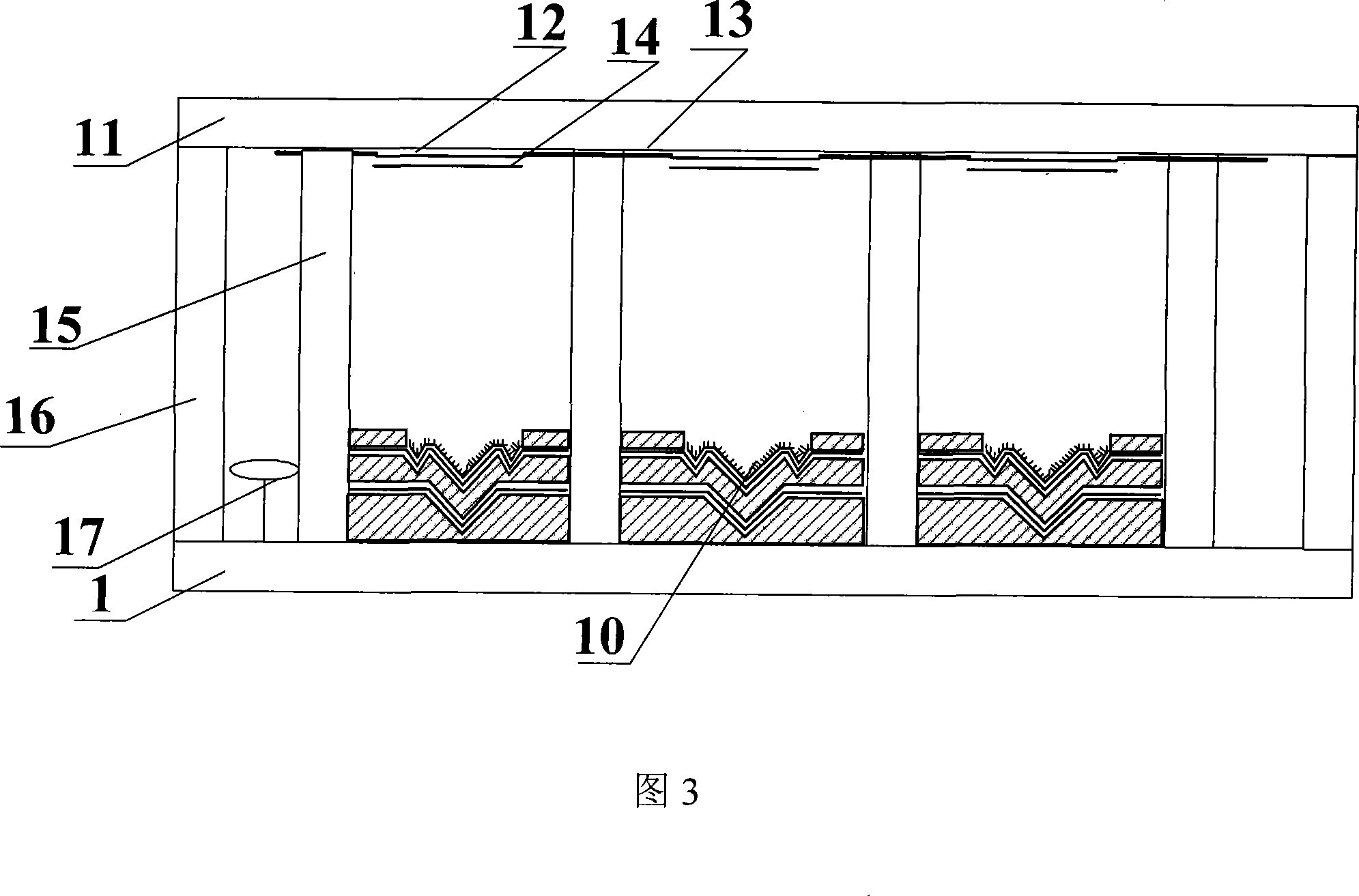

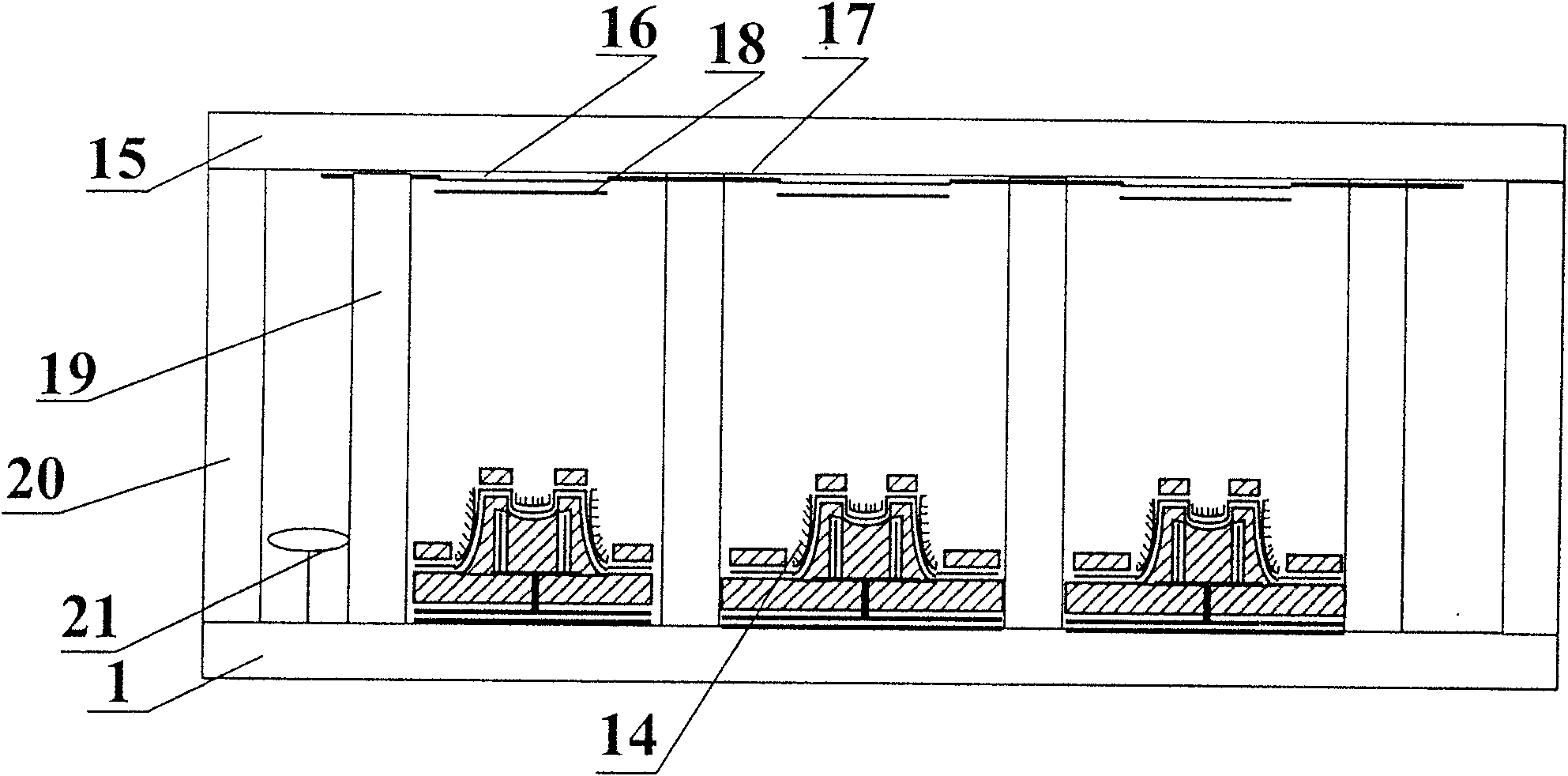

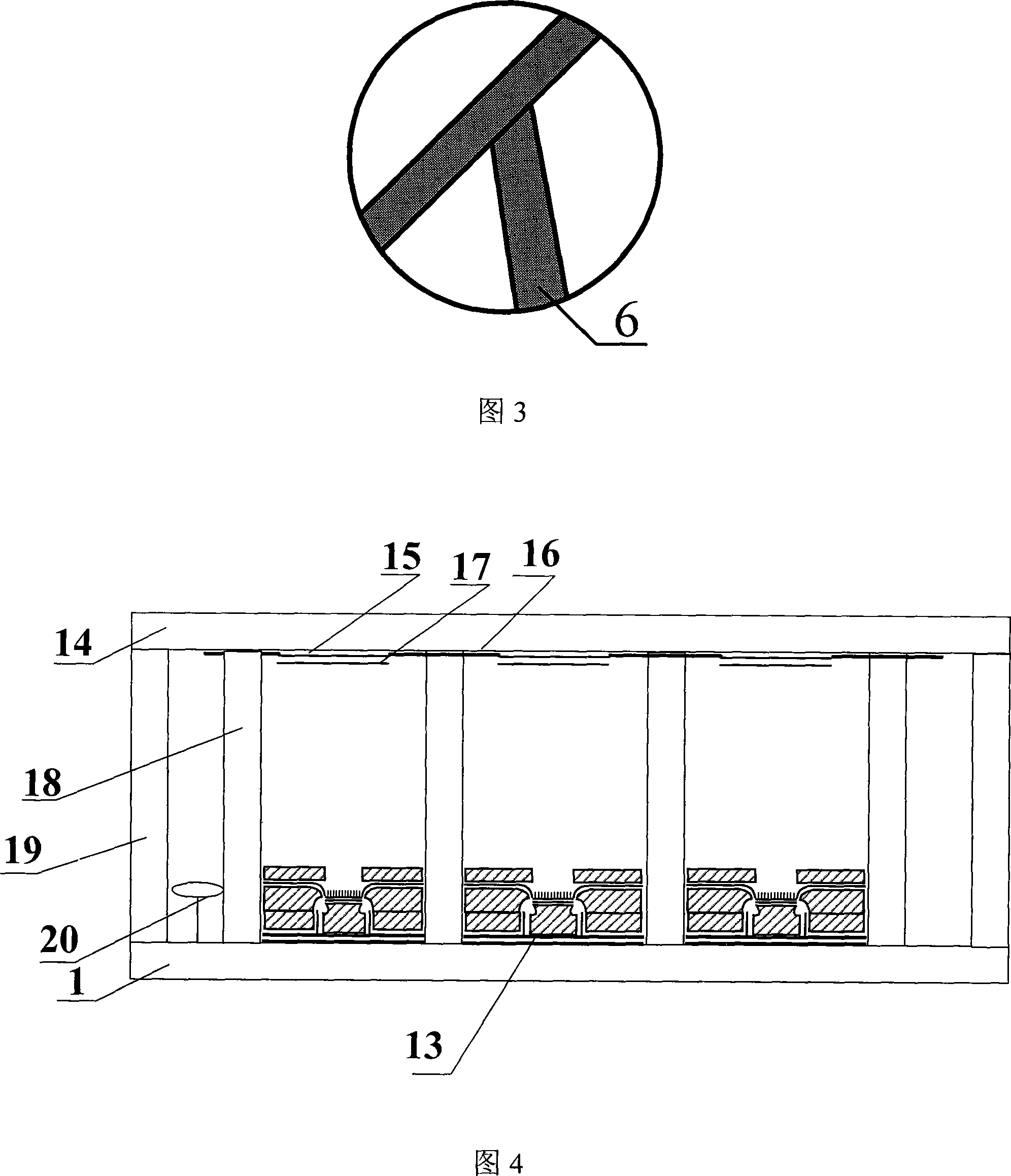

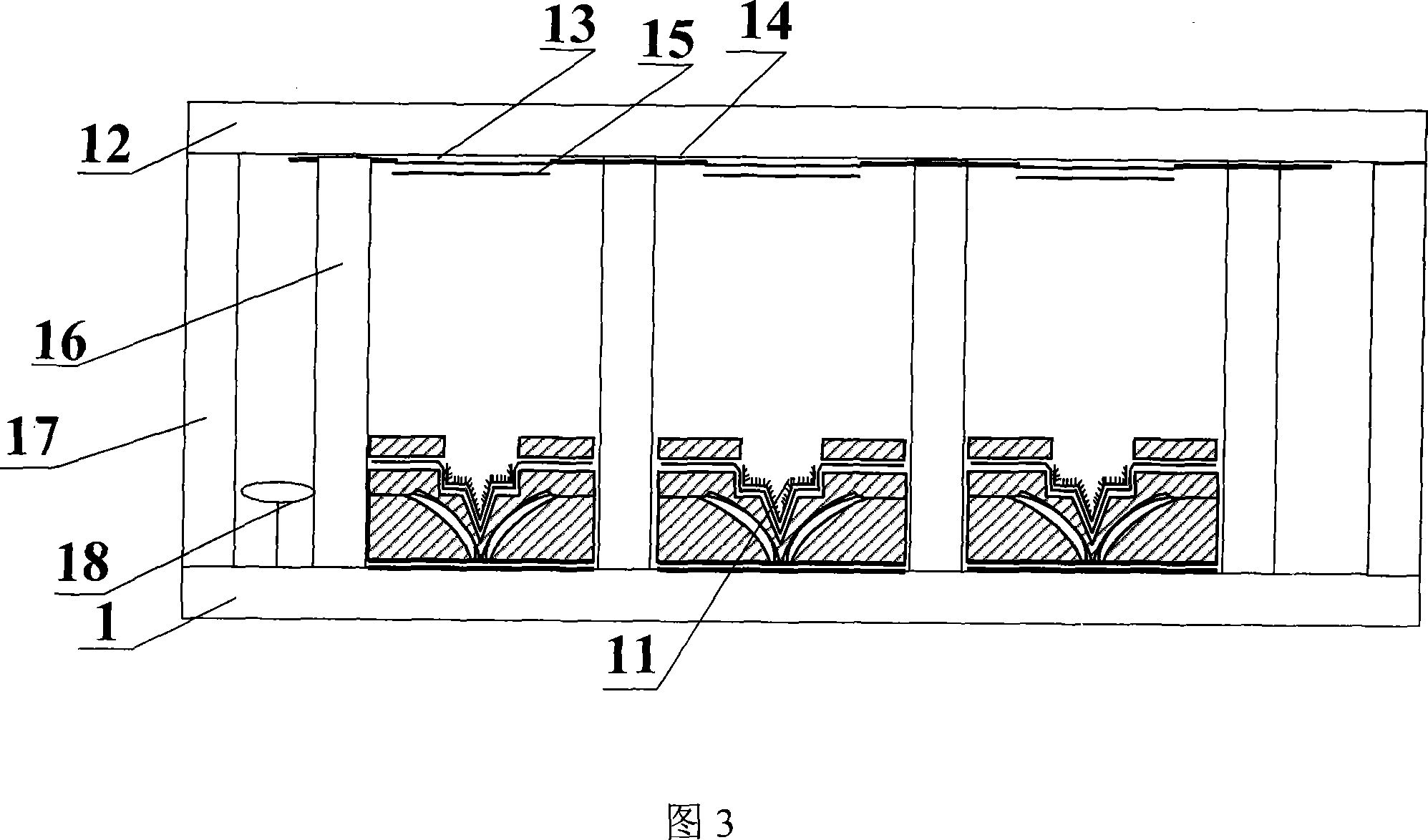

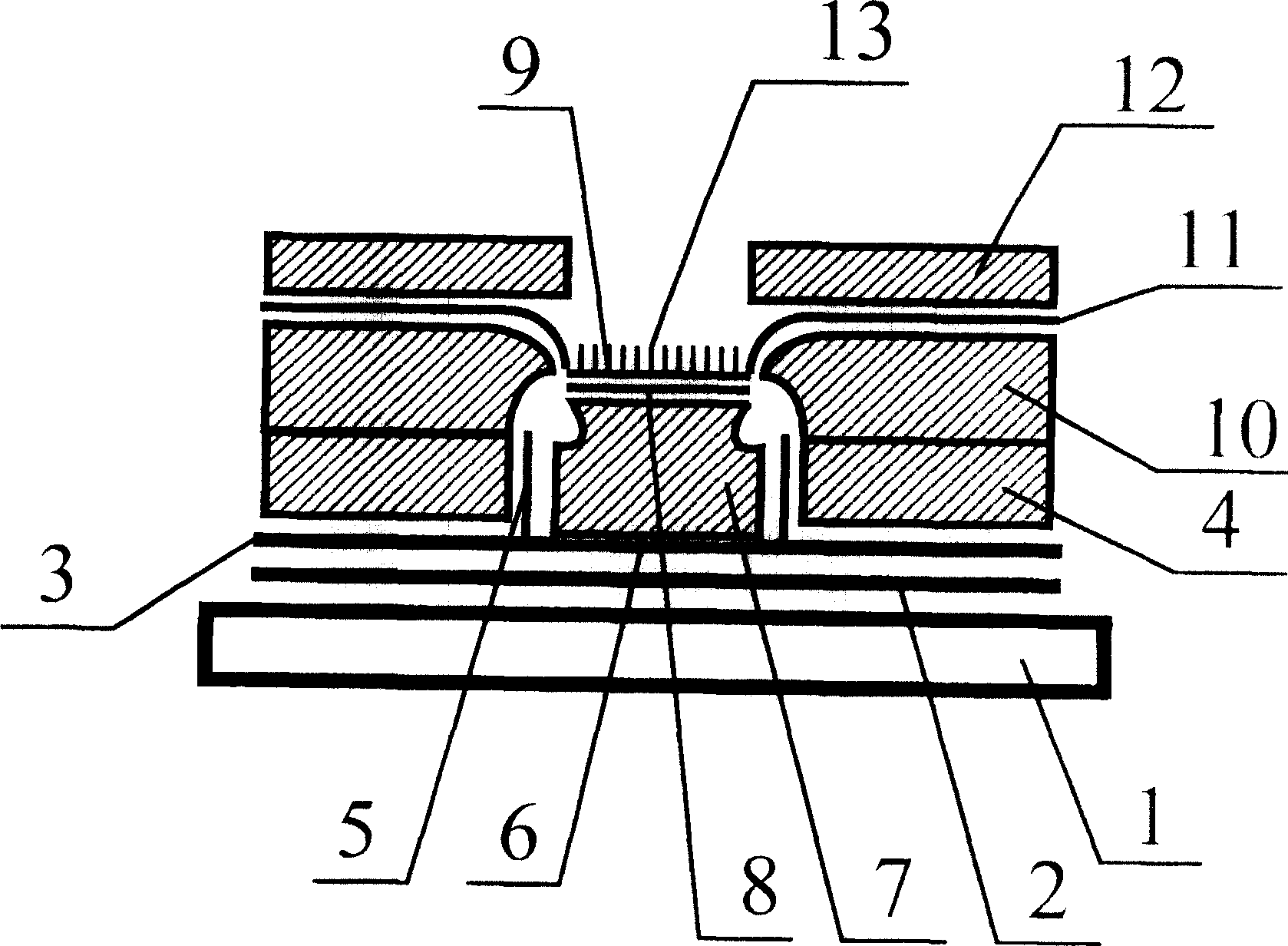

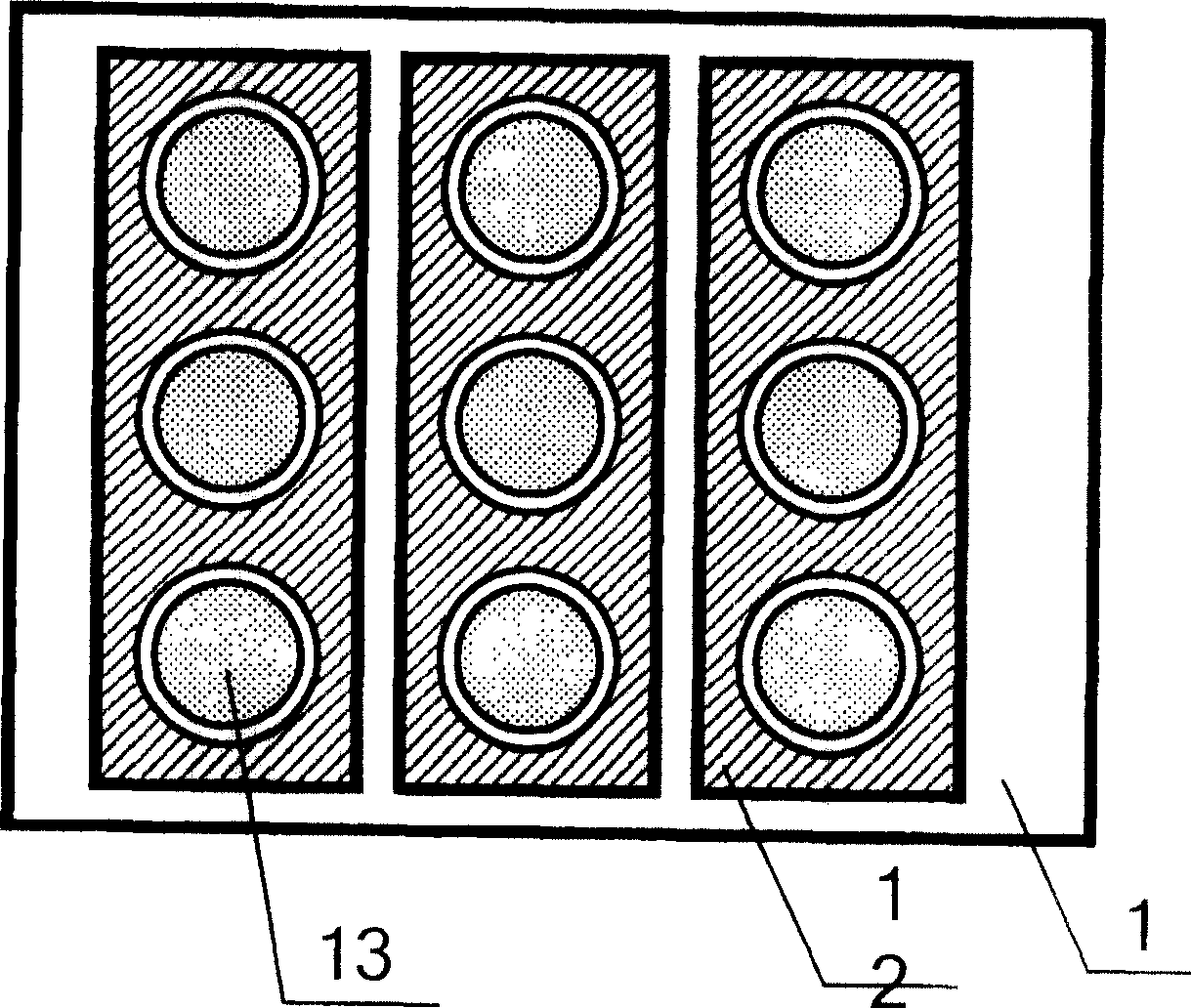

This invention relates to a flat display of slant grid-control structure and its manufacturing method including a closed vacuum cavity composed of an anode glass panel, a cathode glass panel and glass frame around it, in which, an anode conductive layer is set on the anode glass panel and a fluorescent powder layer is prepared on the anode conductive layer, a supporting wall structure and attached elements of a getter is set between the anode glass panel and the cathode glass panel, a grid lead layer, carbon nanometer tubes and a slant grid-control structure are set on the cathode glass panel to control efficiency of the grid structure and increase the electronic emission efficiency and quantity to increase image quality of the device.

Owner:ZHONGYUAN ENGINEERING COLLEGE

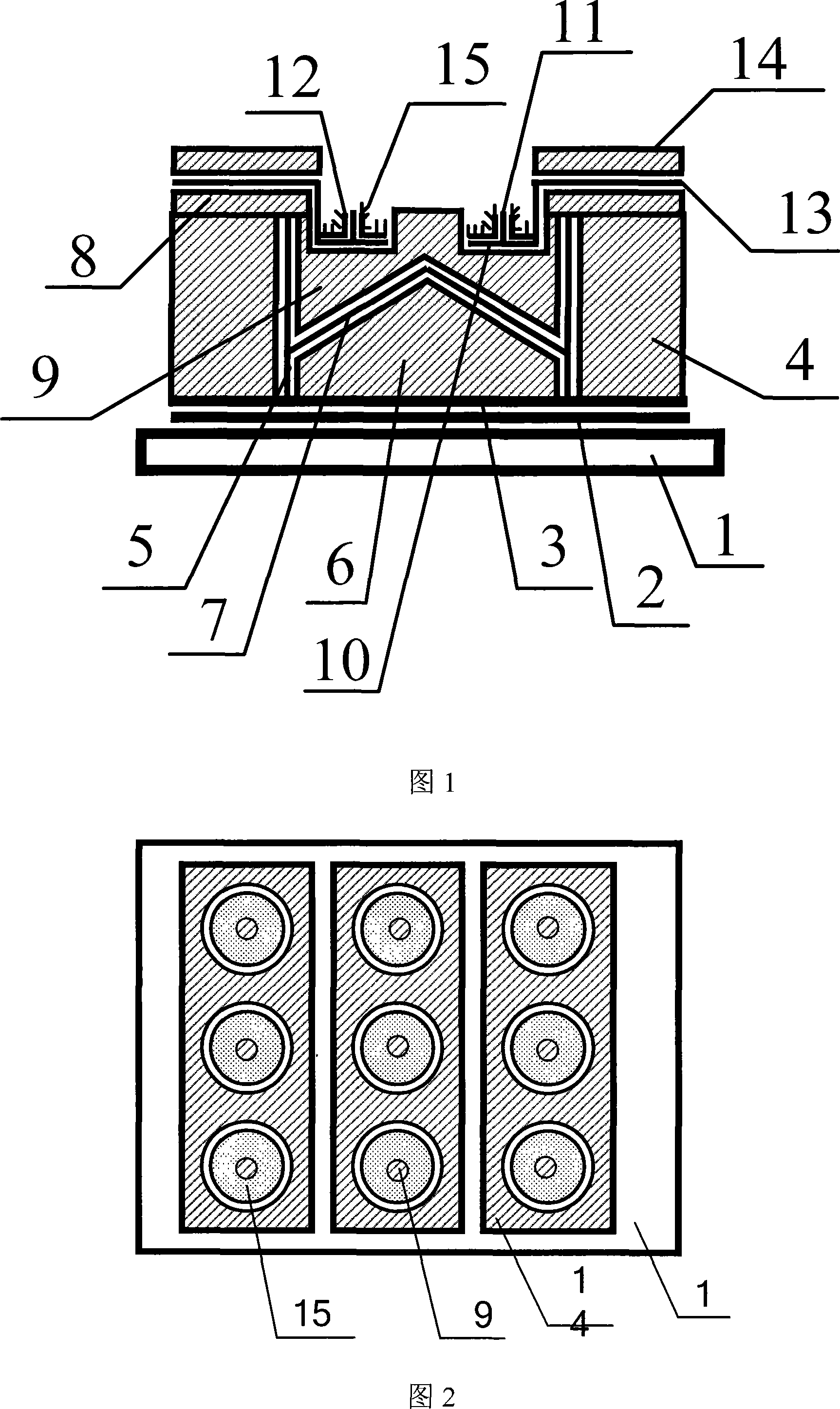

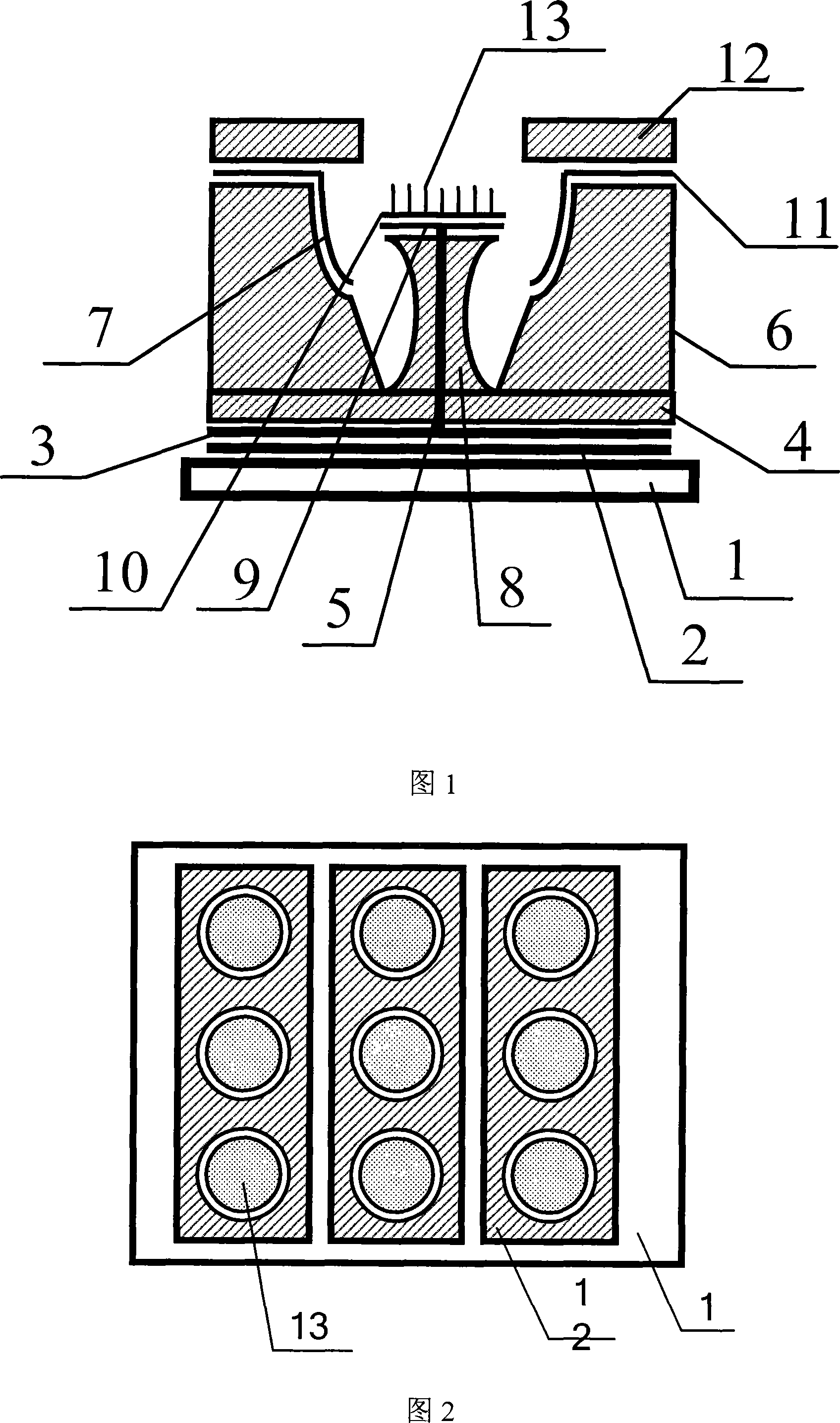

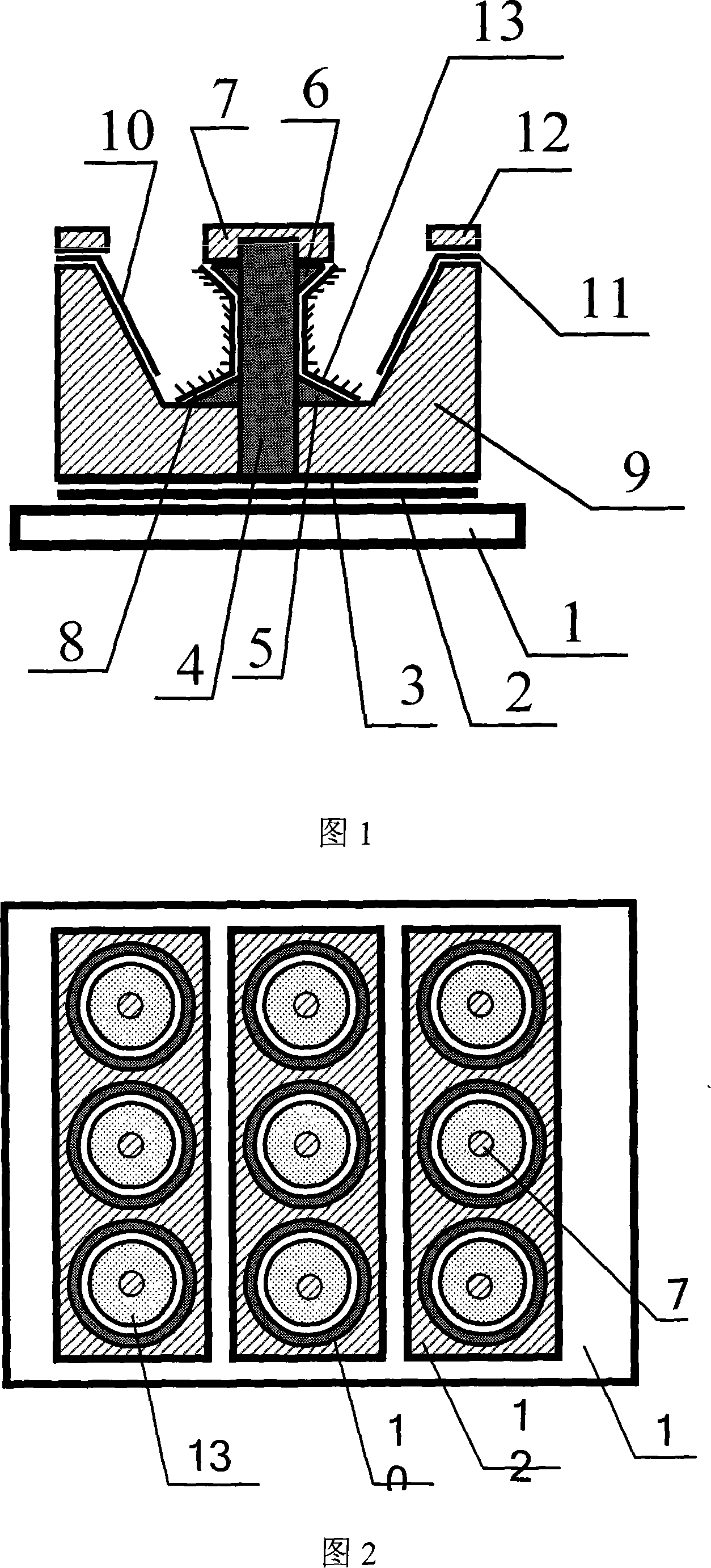

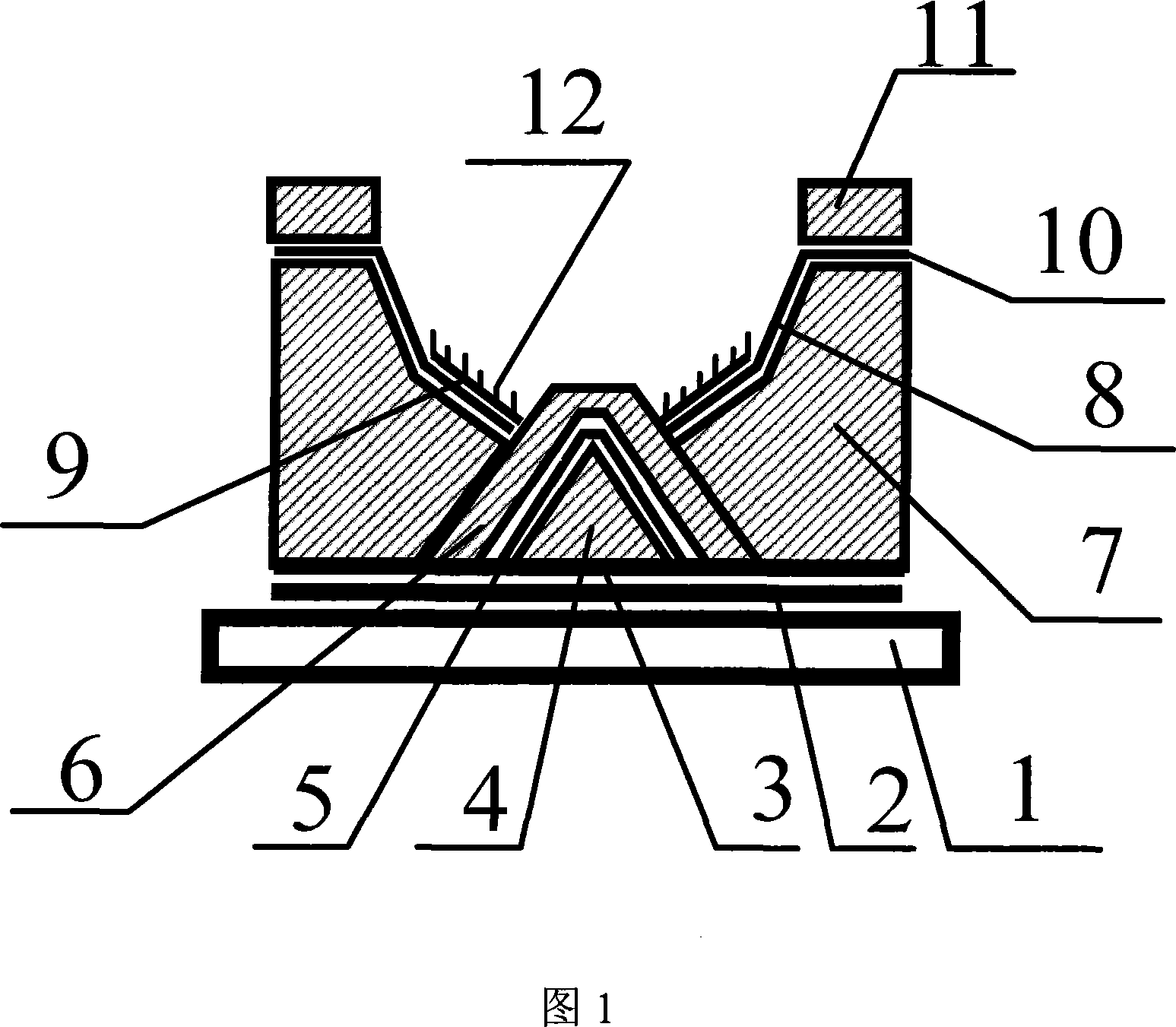

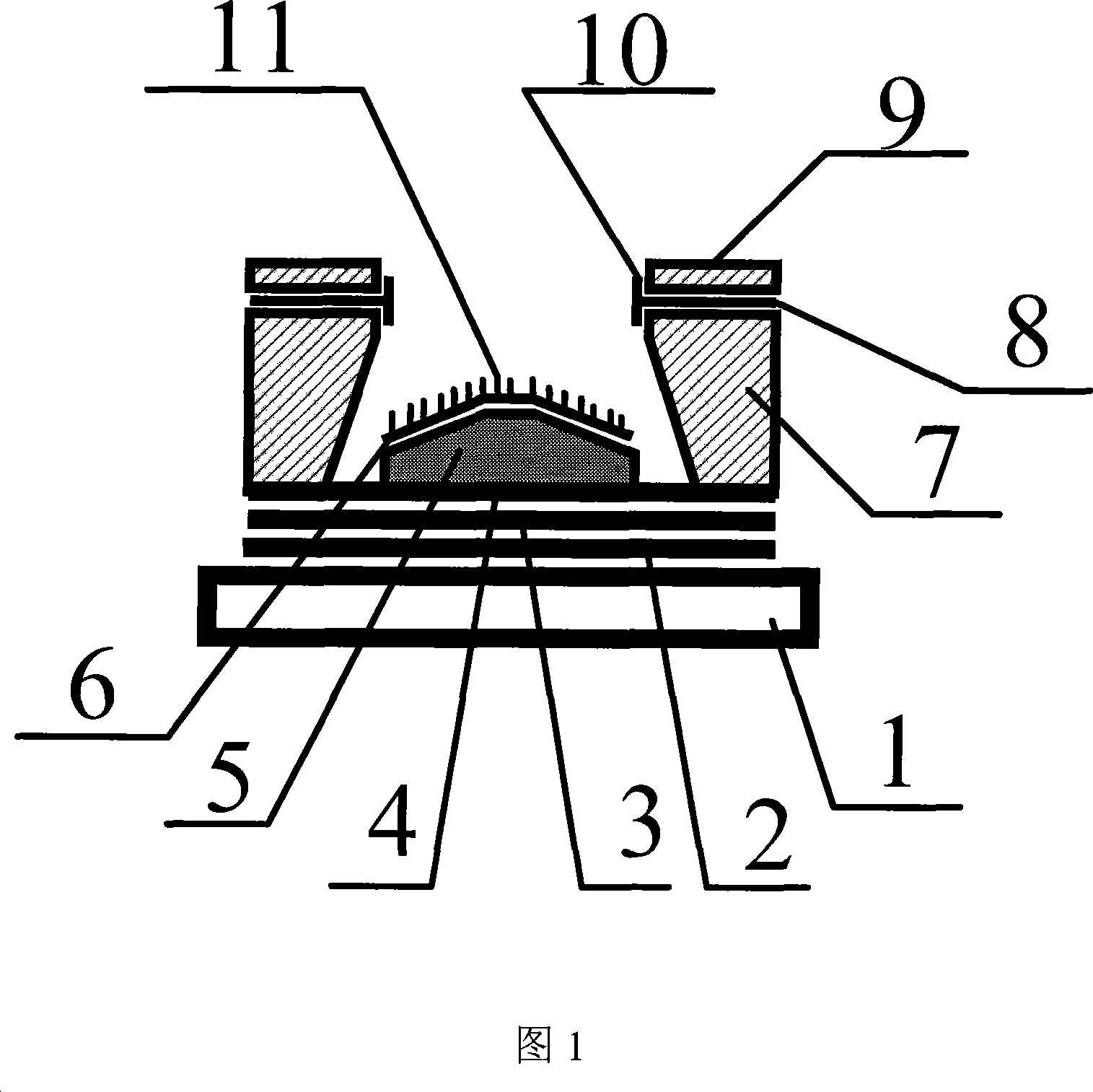

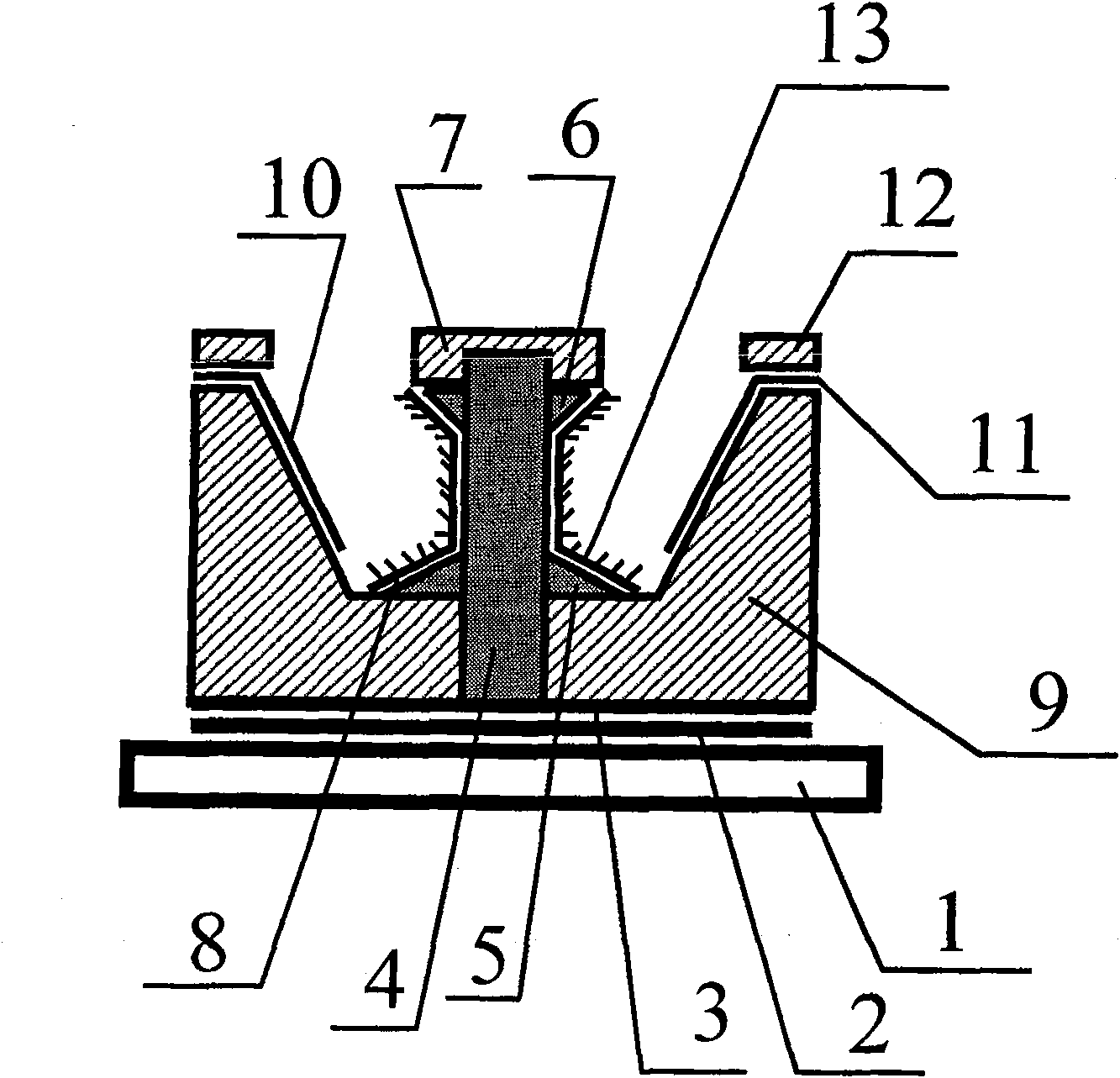

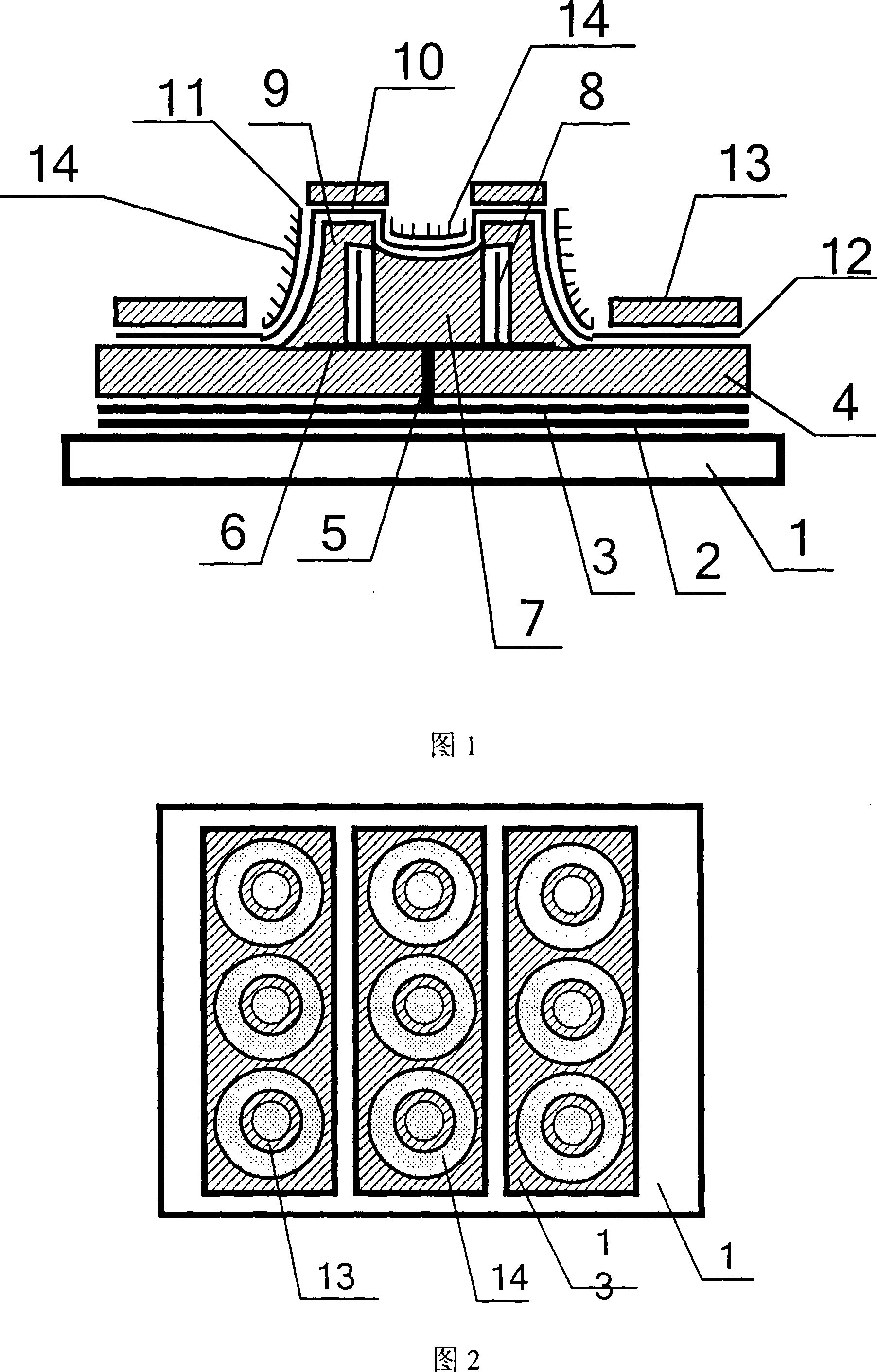

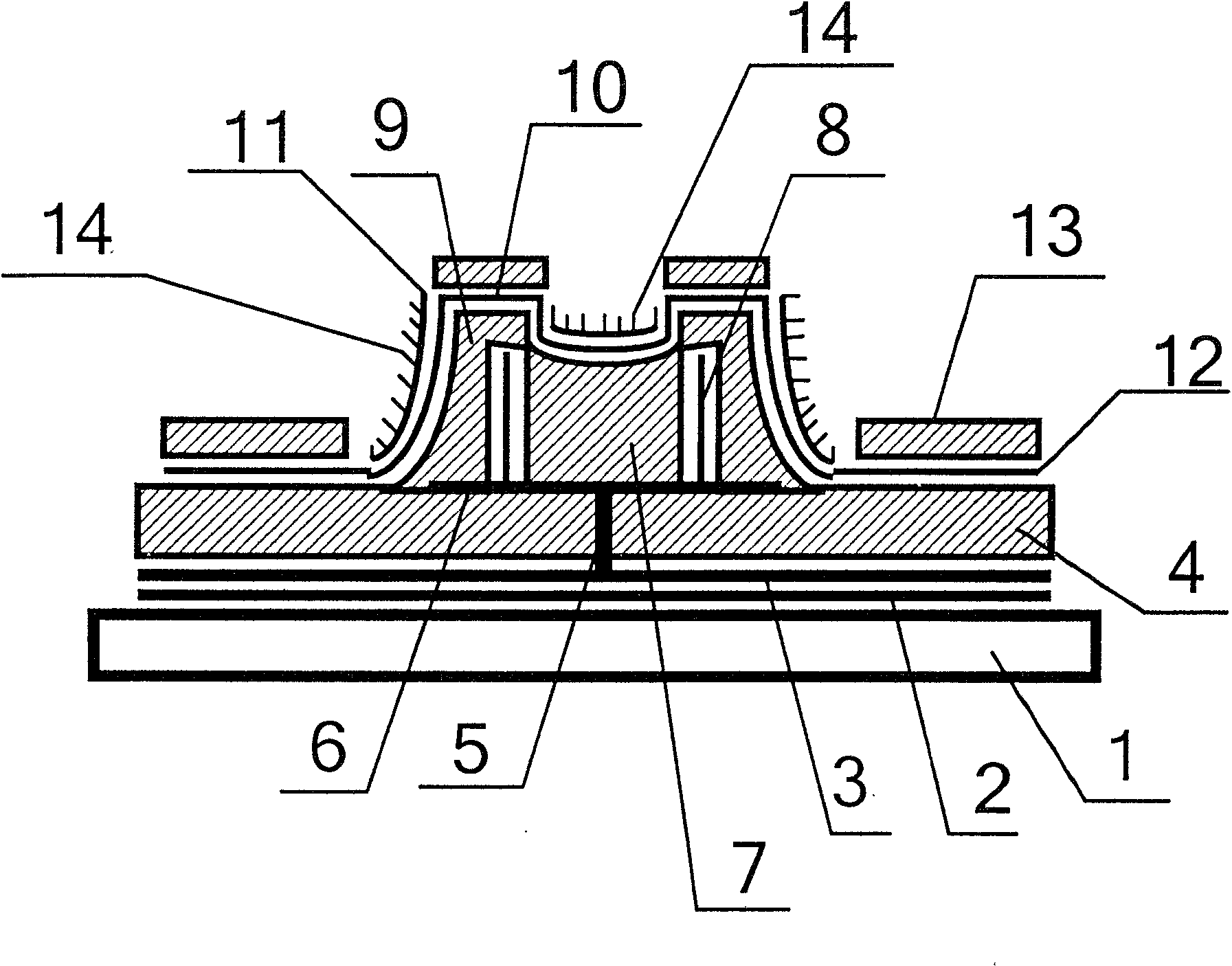

Flat panel display with bevelled grid controlled cathode structure in truncated cone form, and fabricating technique

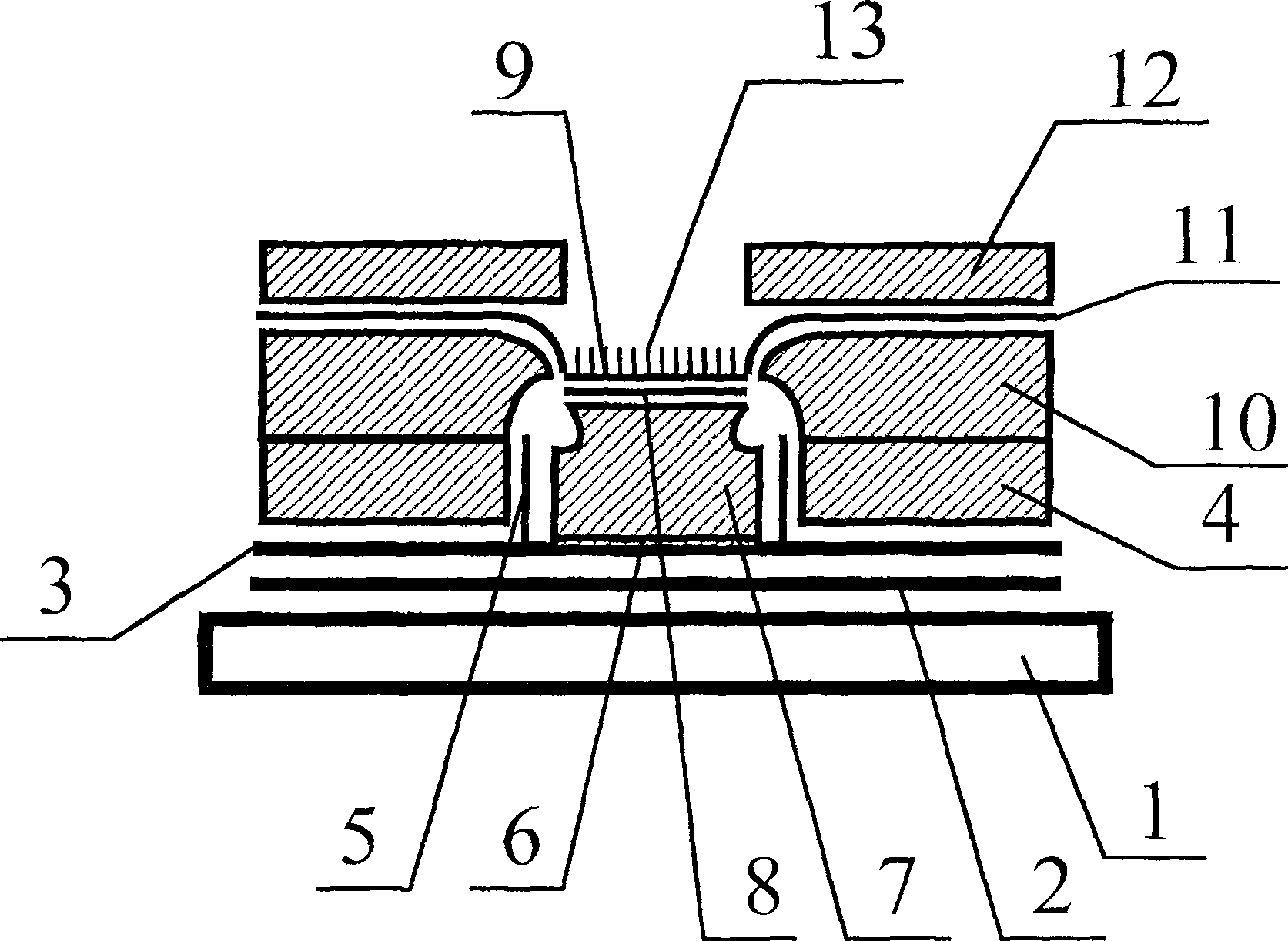

InactiveCN101093774ALow working voltageStrong electric field strengthControl electrodesImage/pattern display tubesPhosphorDisplay device

The flat panel display includes following parts: sealed vacuum cavity composed of glass faceplate of anode, glass faceplate of cathode, and glassed-in frame; anode conductive layer on the glass faceplate of anode, and phosphor layer on the anode conductive layer; the support wall structure between the glass faceplate of anode and the glass faceplate of cathode, and accessorial components for getter; cathode conductive layer, Nano carbon tube, and beveled circular truncated cone grid controlled cathode structure setup on the glass faceplate of cathode. The invention raises efficiency and quantity of electron emission of cathode in Nano carbon tube, reduces operating voltage of grid electrode so as to be in favor of preparing flat device in high quality. Advantages are: stable and reliable fabricating procedure, simple technique, low fabricating cost, and ordinary structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

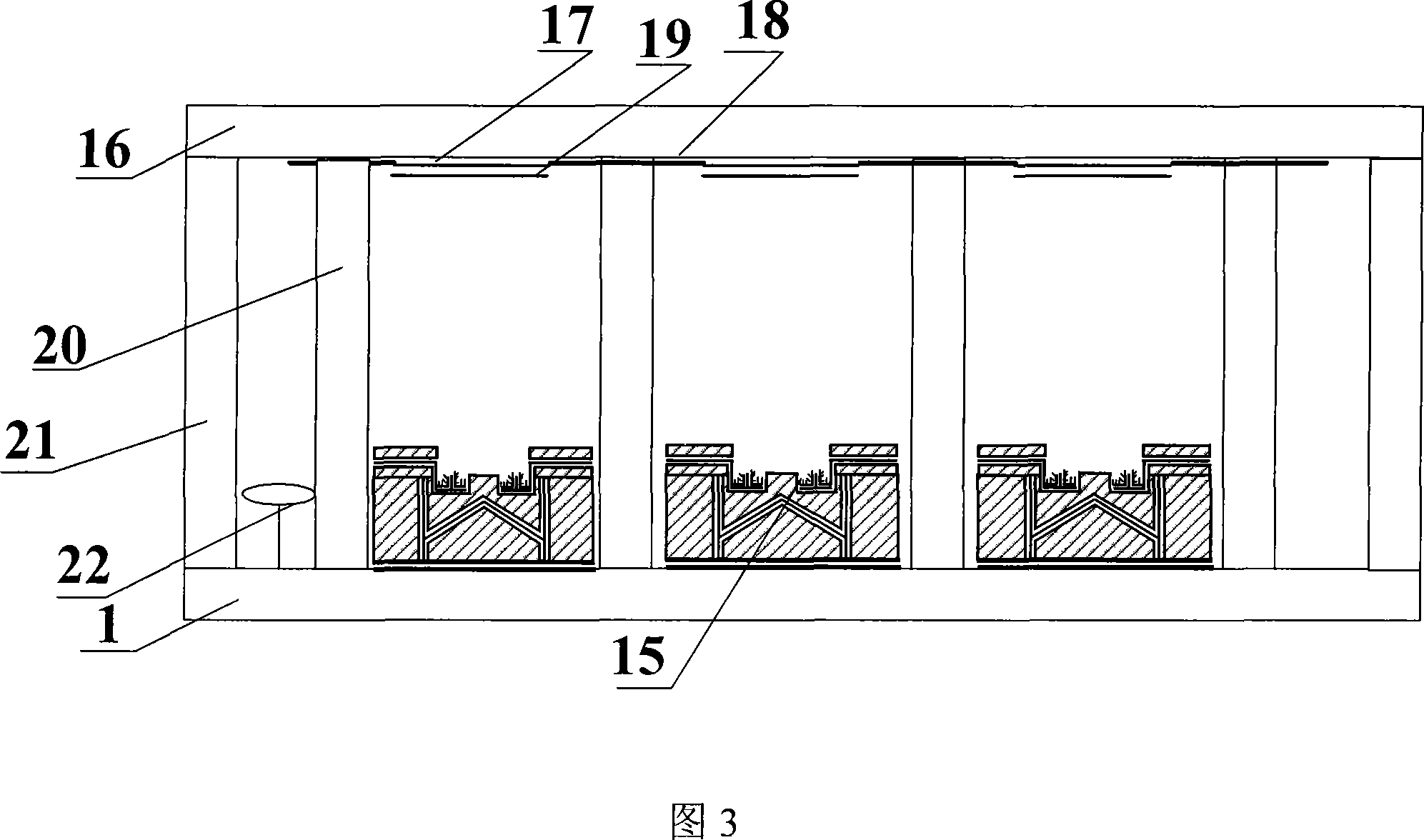

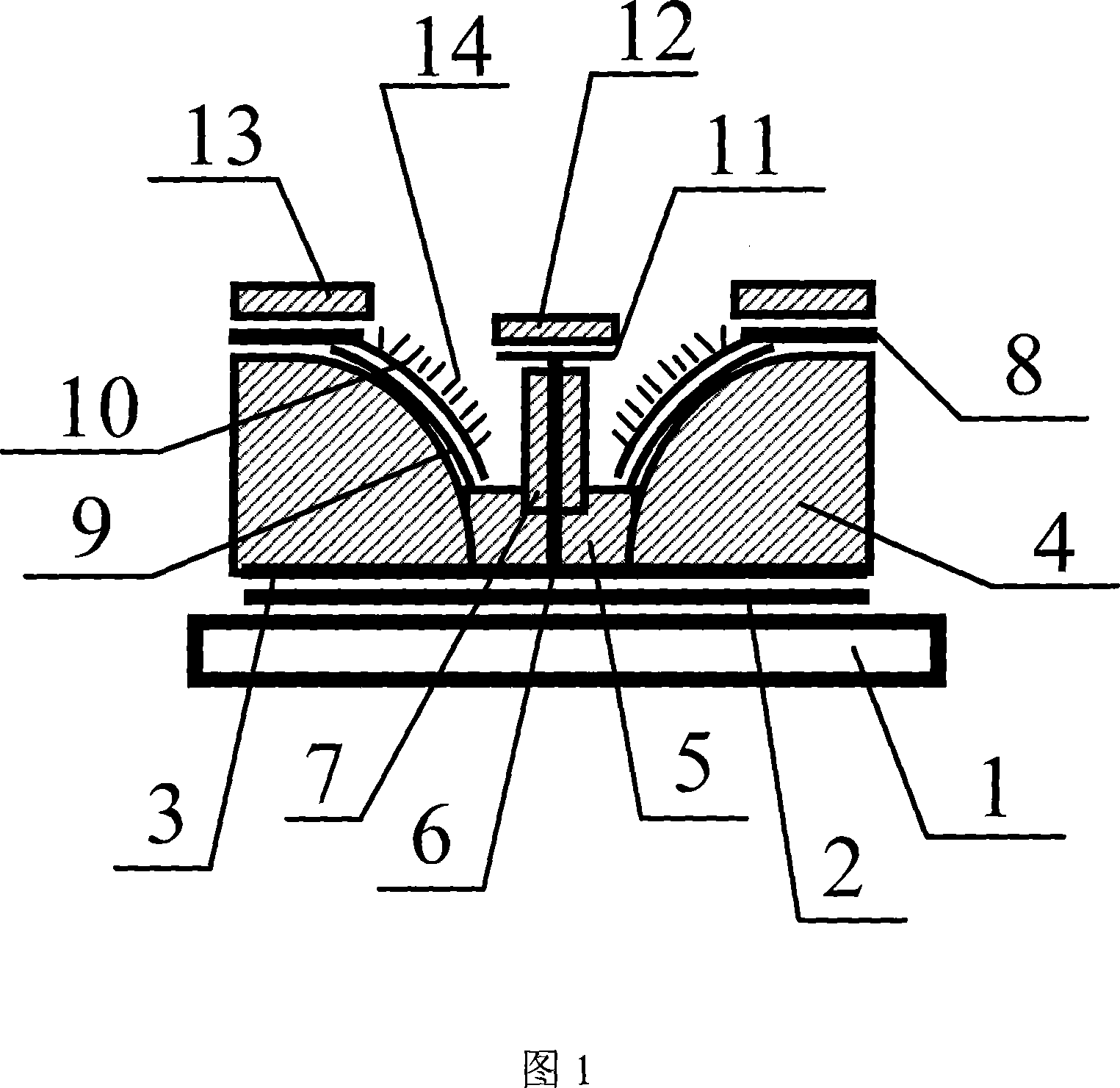

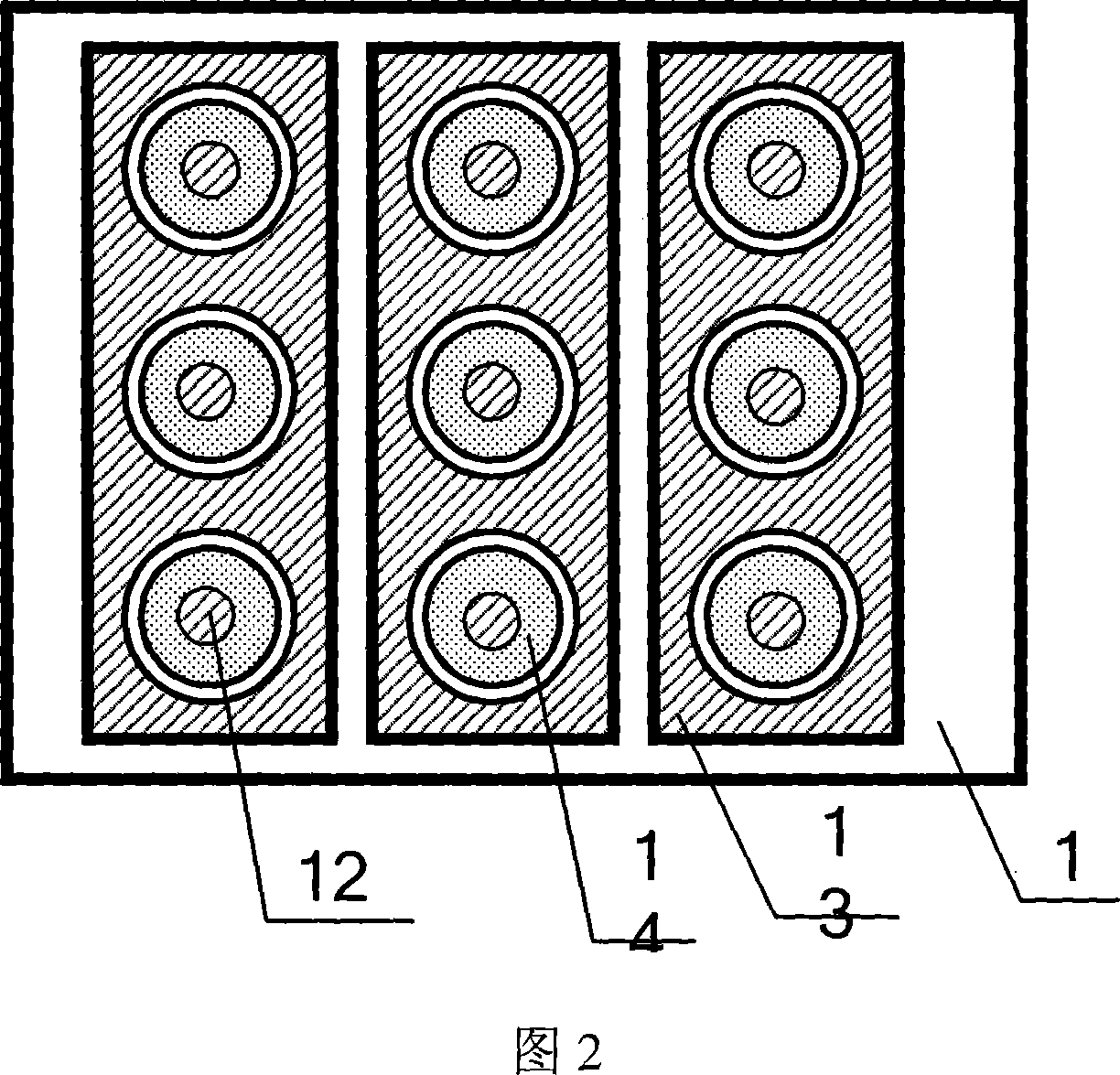

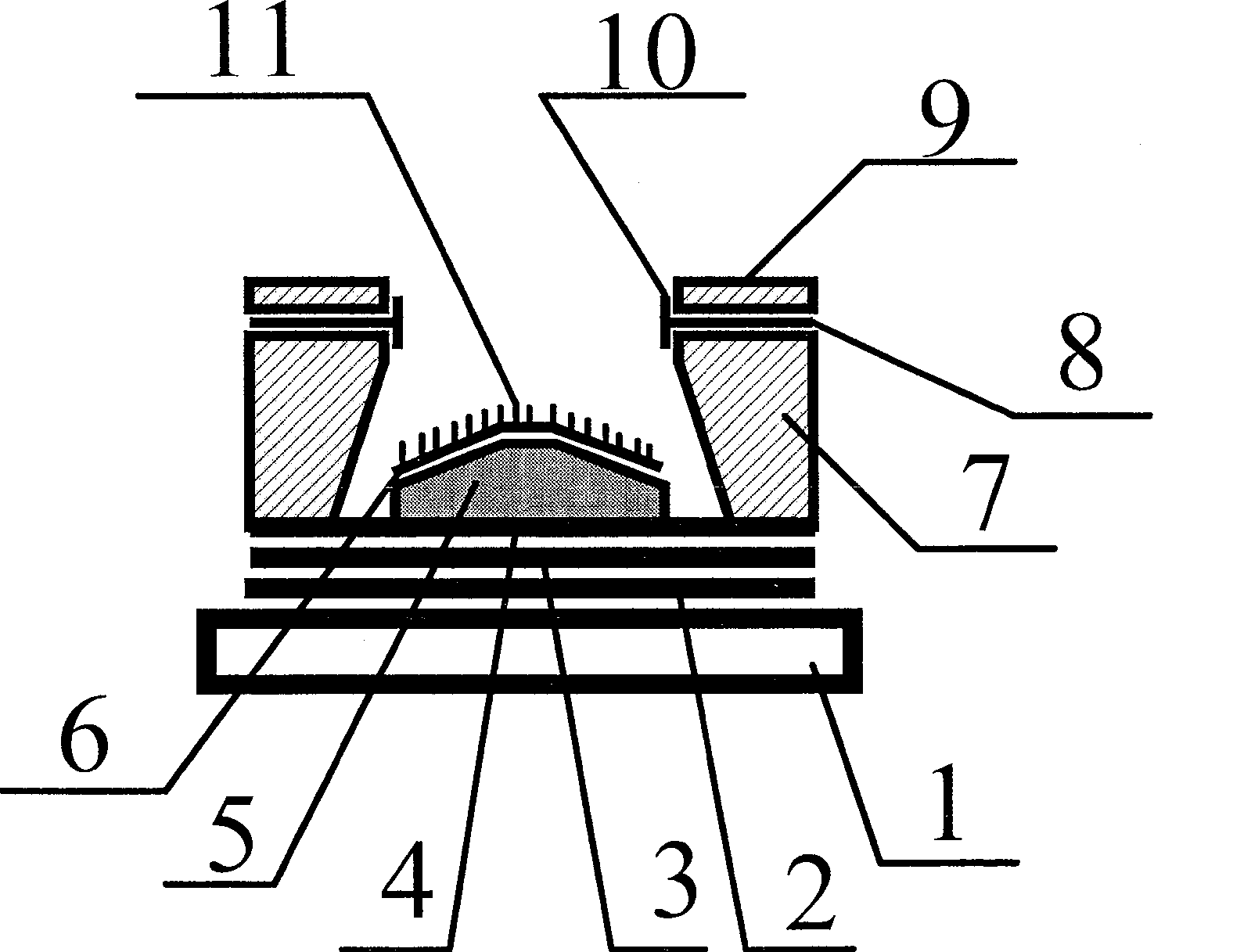

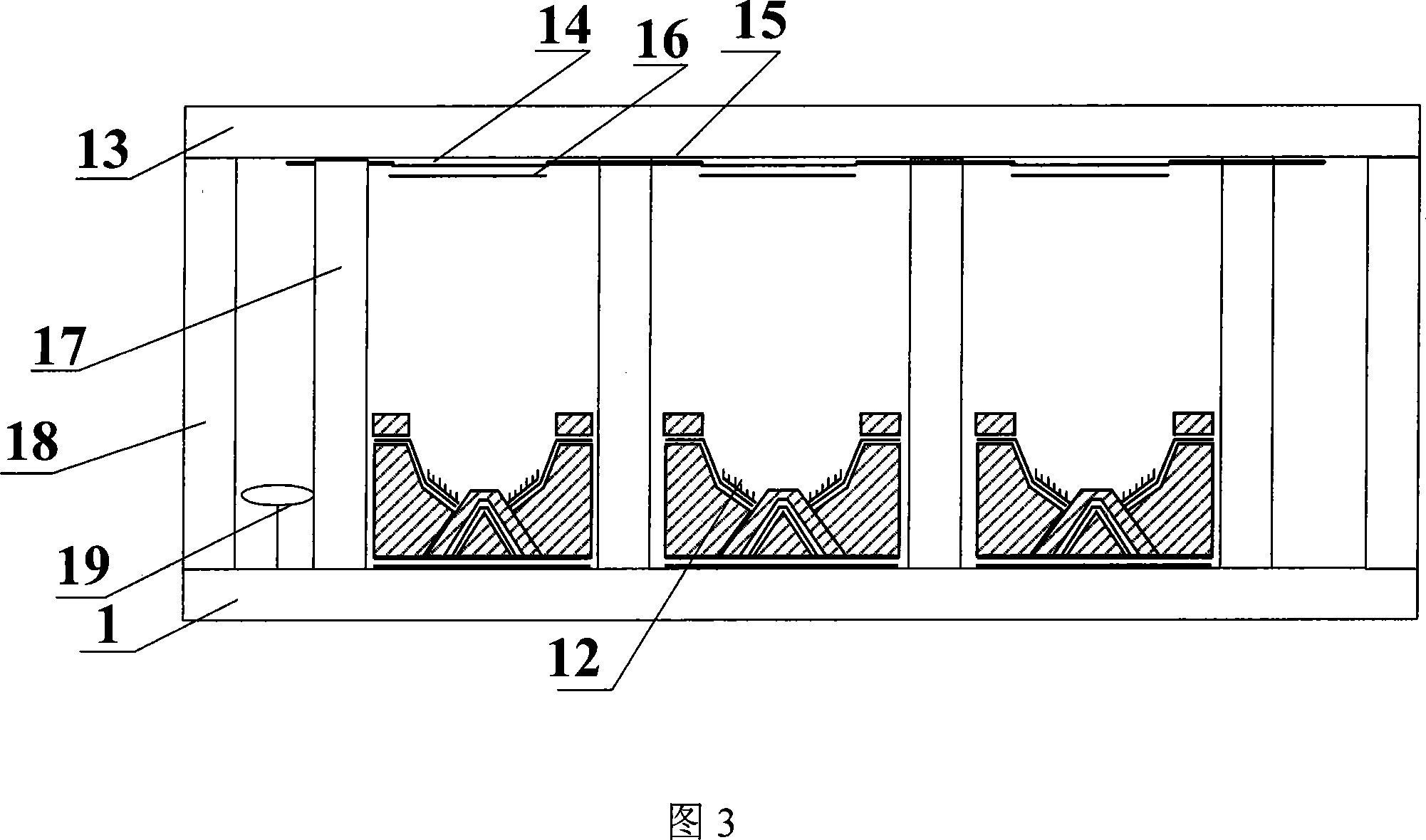

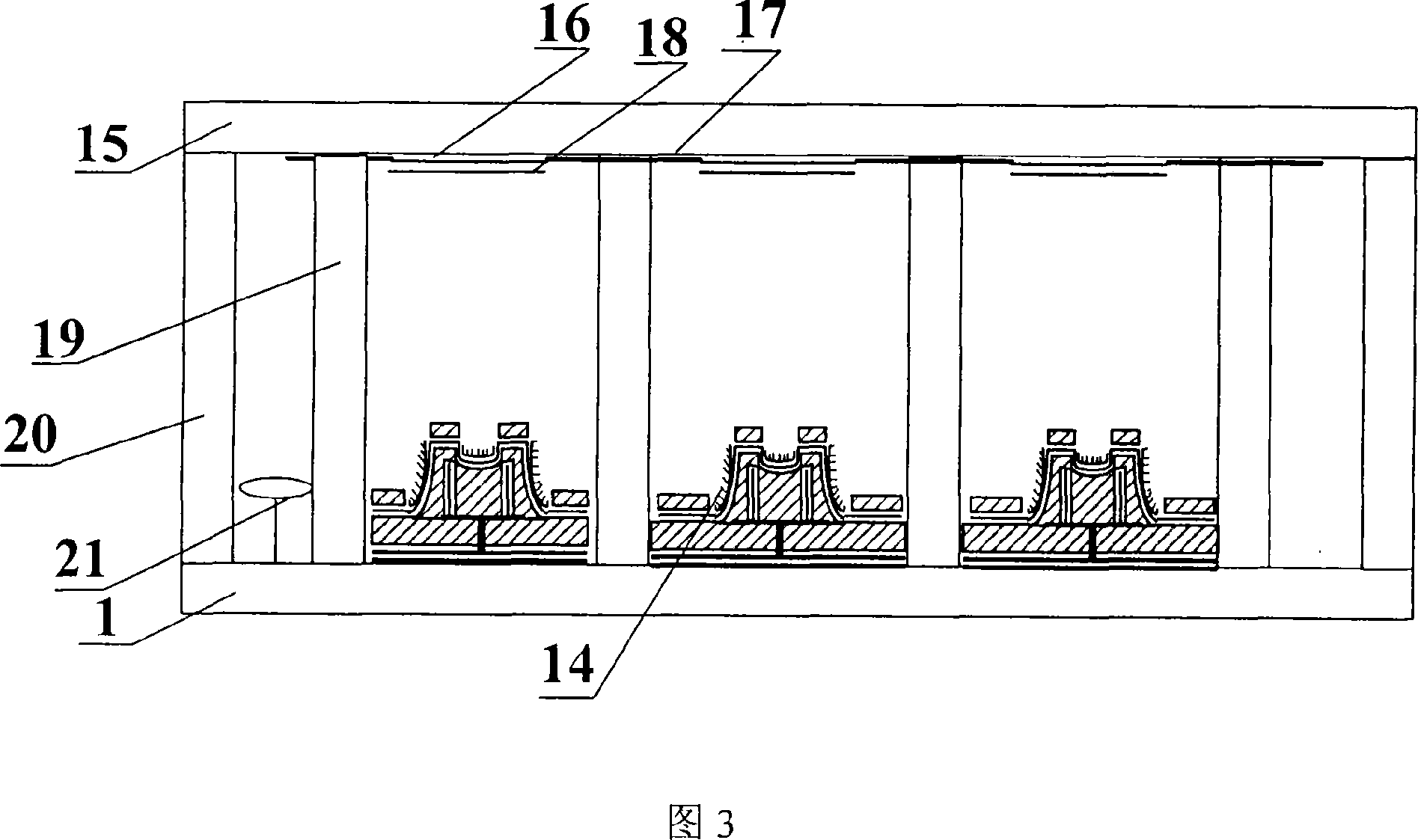

Flat-panel display device with tilt gate-modulated concave arc vertebra-type cathode structure and its preparing process

InactiveCN101071748AEmbodies powerful control functionsImprove control efficiencyControl electrodesImage/pattern display tubesCarbon nanotubeDisplay device

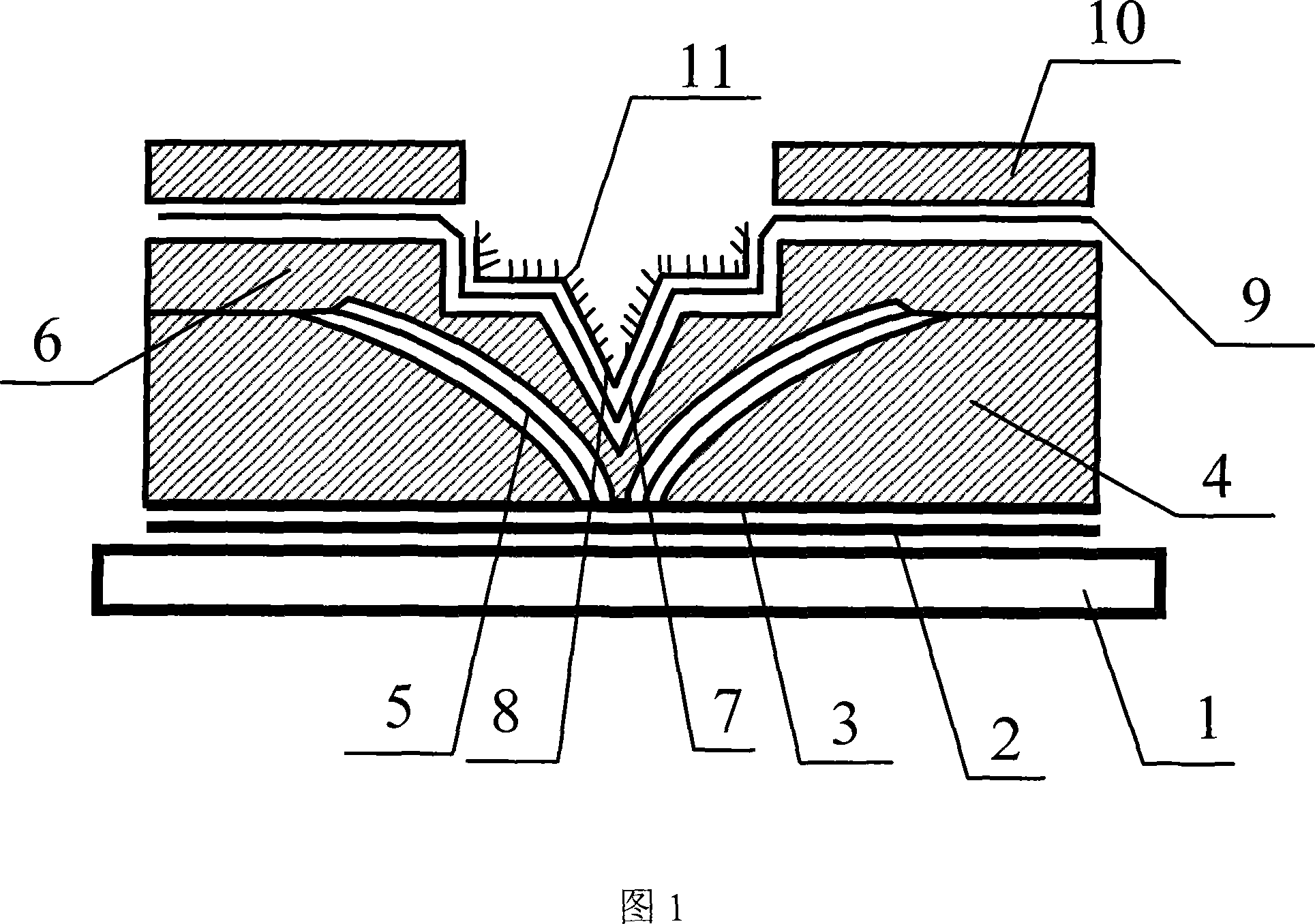

The invention relates to a flat-panel display of a tilted grid-controlled concave arc vertebra-type cathode structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and tilted grid-controlled concave arc vertebra-type cathode structure on the cathode glass panel; and it can raise electron emission efficiency of carbon nanotube and improve display brightness and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

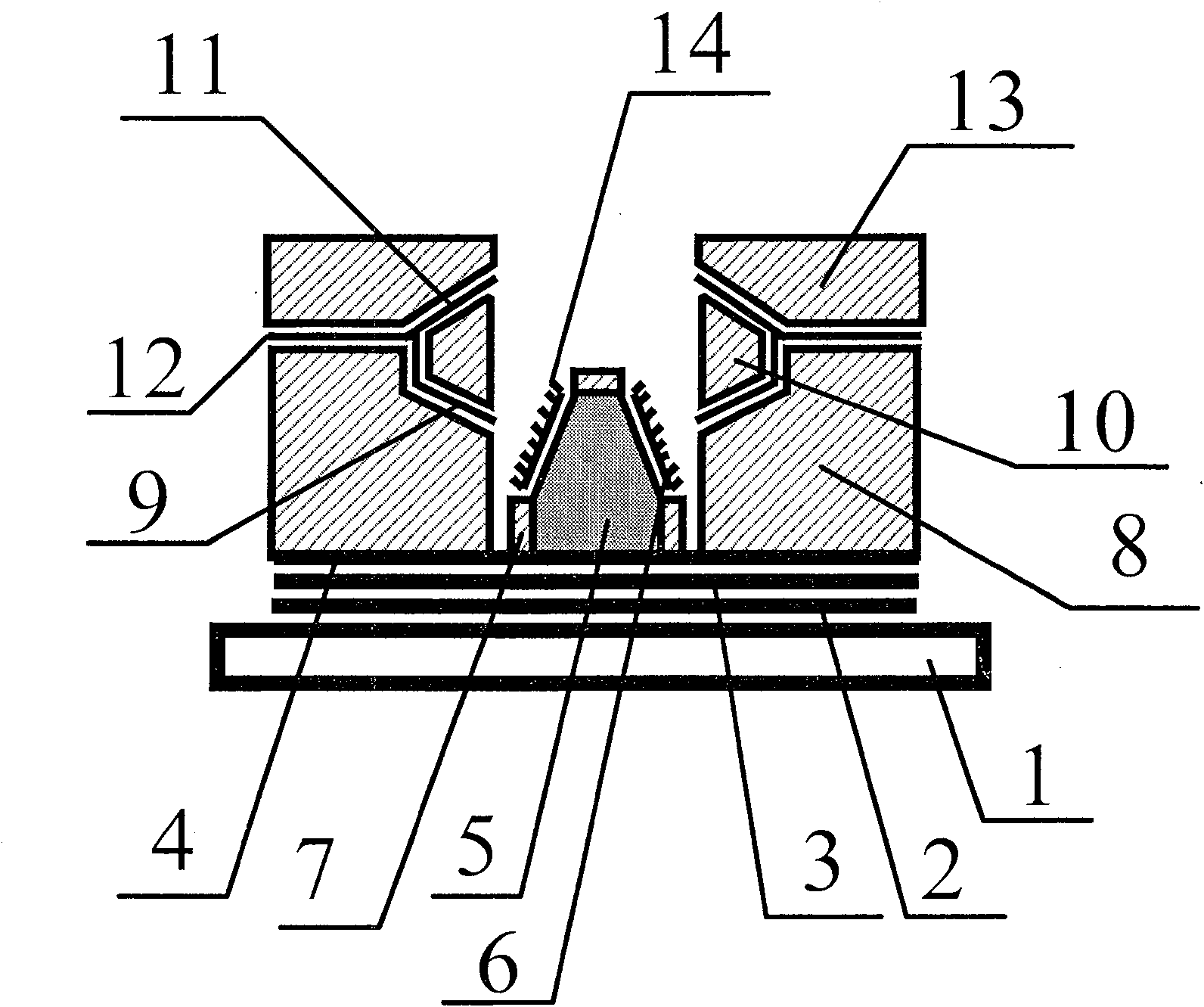

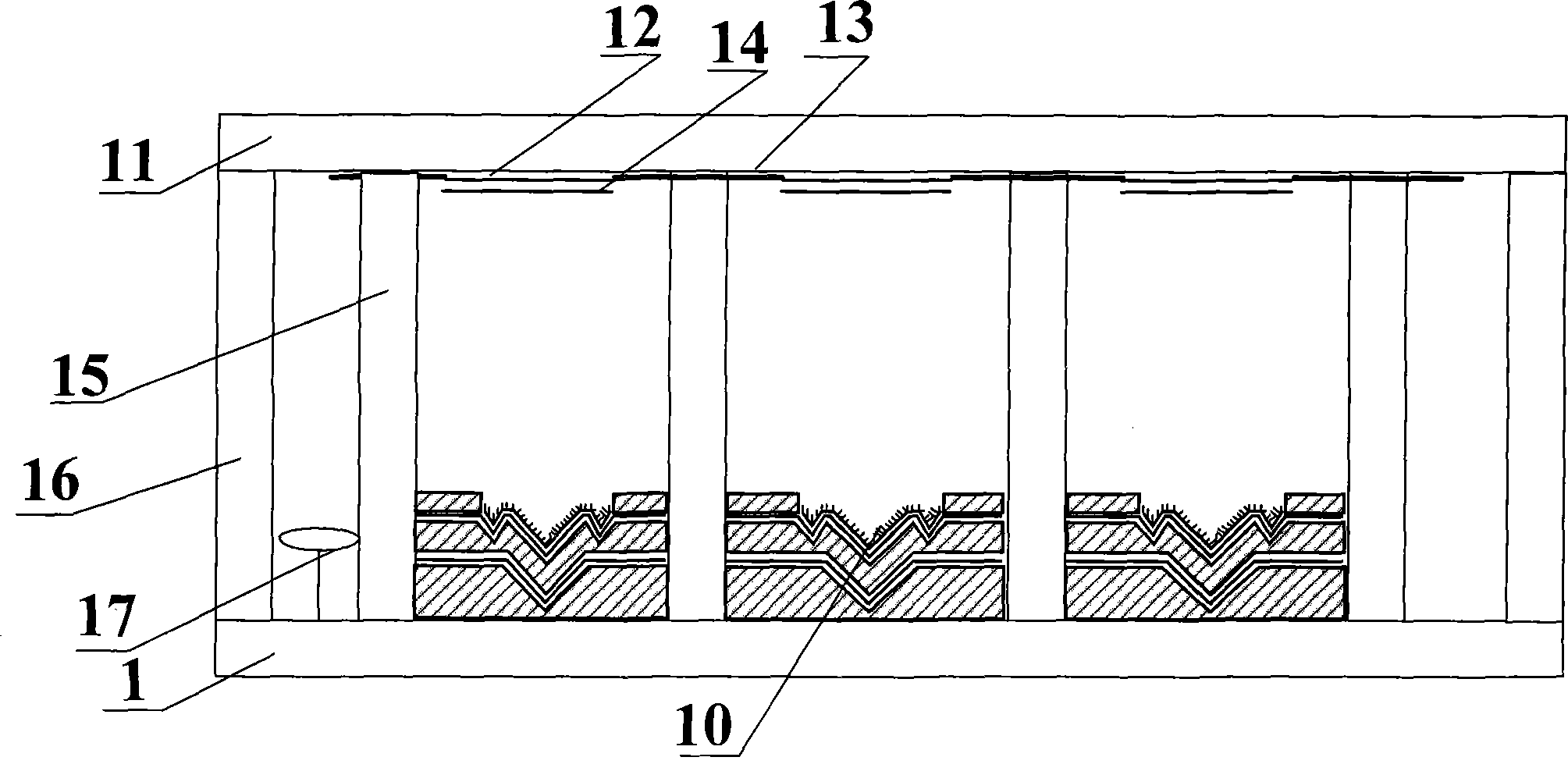

Planar display device with capped bottom-grid controlled cathode structure and its production

InactiveCN100527339CStrong control functionIncrease display brightnessControl electrodesImage/pattern display tubesCarbon nanotubeDisplay device

The invention relates to a flat panel display with hat-shaped bottom grid-controlled cathode structure and its manufacturing process, which includes a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; layer and the phosphor layer prepared on top of the anode conductive layer; the supporting wall structure and getter accessory components between the anode glass panel and the cathode glass panel, and the grid lead layer, carbon nanotubes and cap type on the cathode glass panel Bottom-gate-controlled cathode structure; it can reduce the working voltage of the grid, improve the display brightness of the overall device, and reduce the working current of the grid. It has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

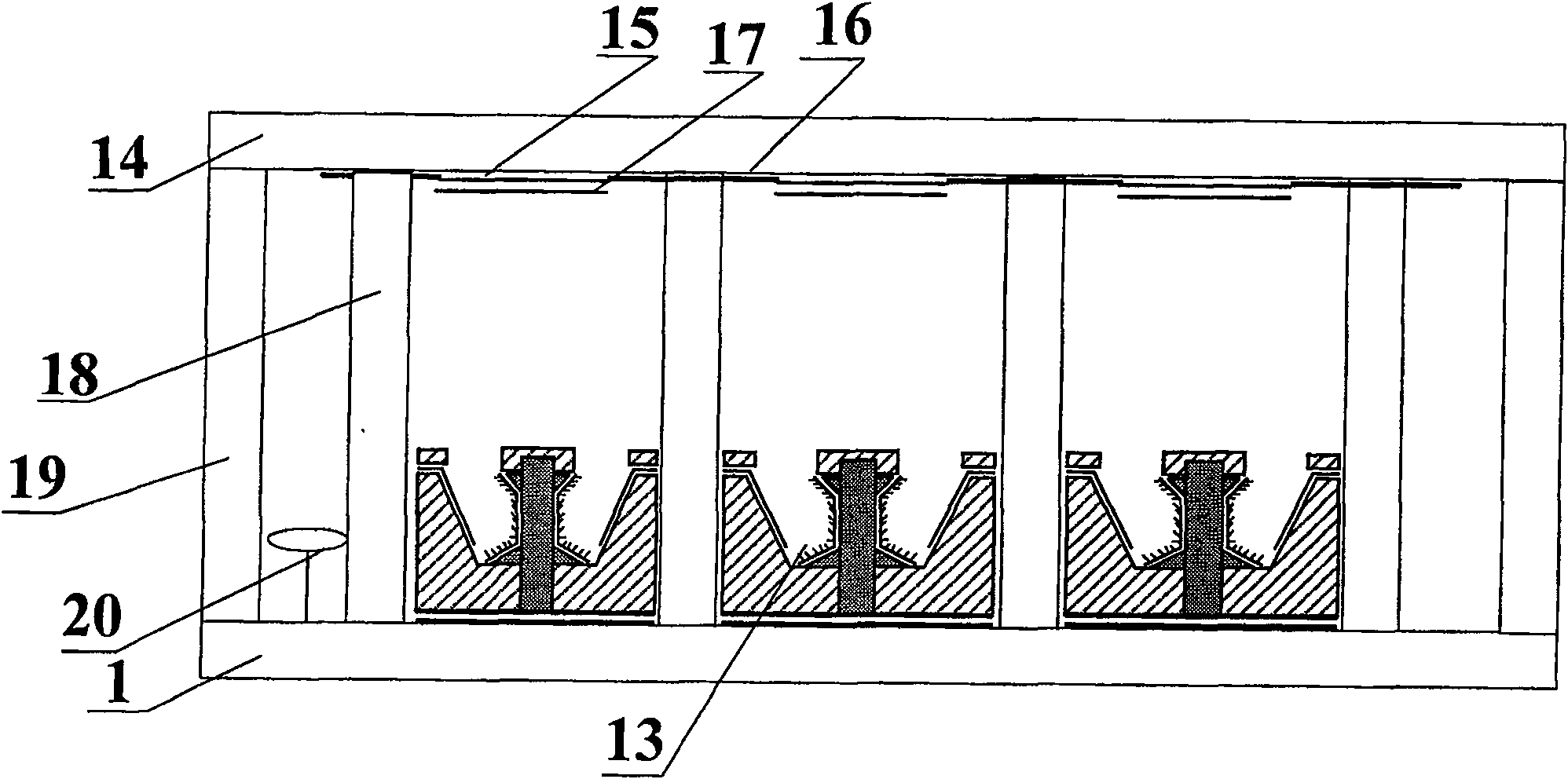

Flat-panel display device with branched side-bottom gate modulation structure and its preparing process

InactiveCN101071742AEasy to manufactureReduce manufacturing costControl electrodesImage/pattern display tubesCarbon nanotubeOptoelectronics

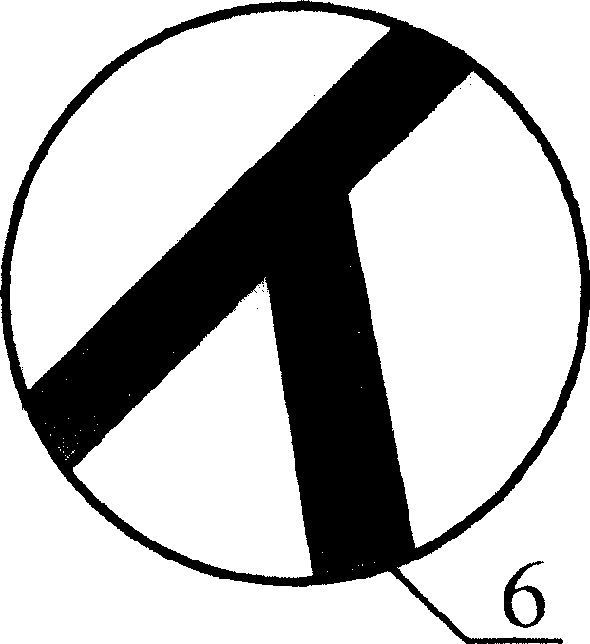

The invention relates to a flat-panel display of a forked side bottom grid-controlled structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and forked side bottom grid-controlled structure on the cathode glass panel; and it can further increase operating current of anode and reduce operating voltage of grid structure, and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

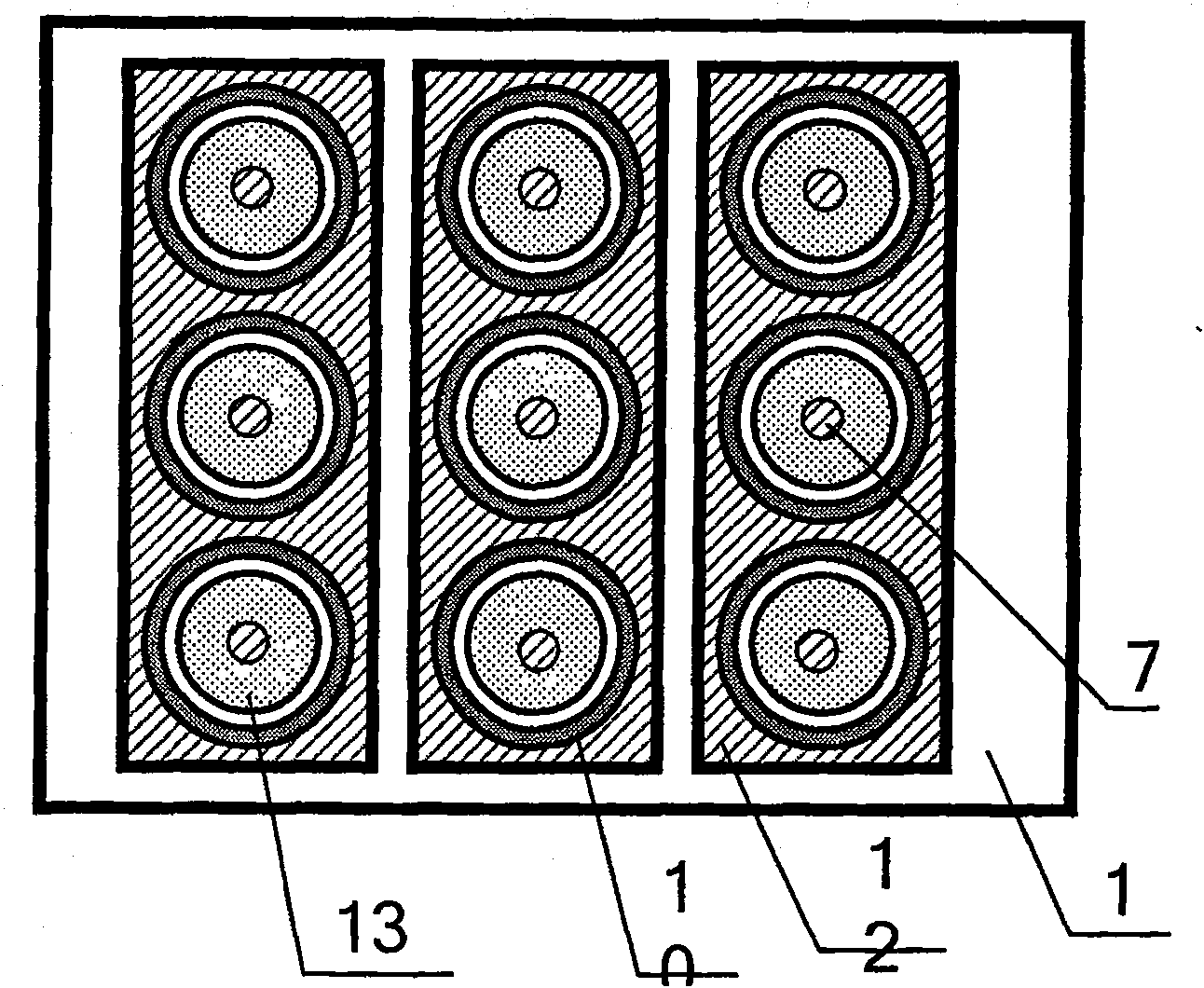

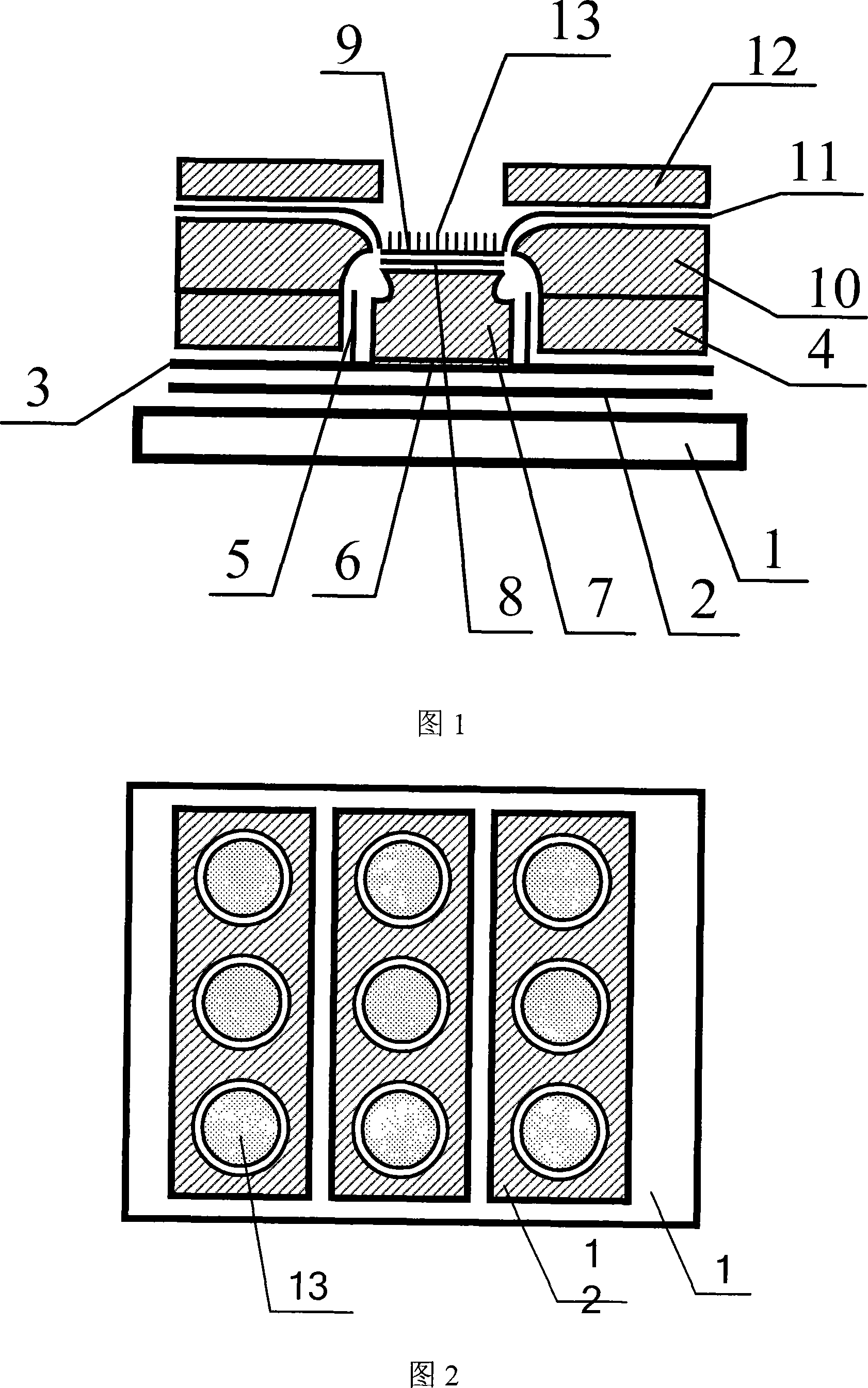

Planar display device with arrowhead-shaped grid controlled cathode structure and its production

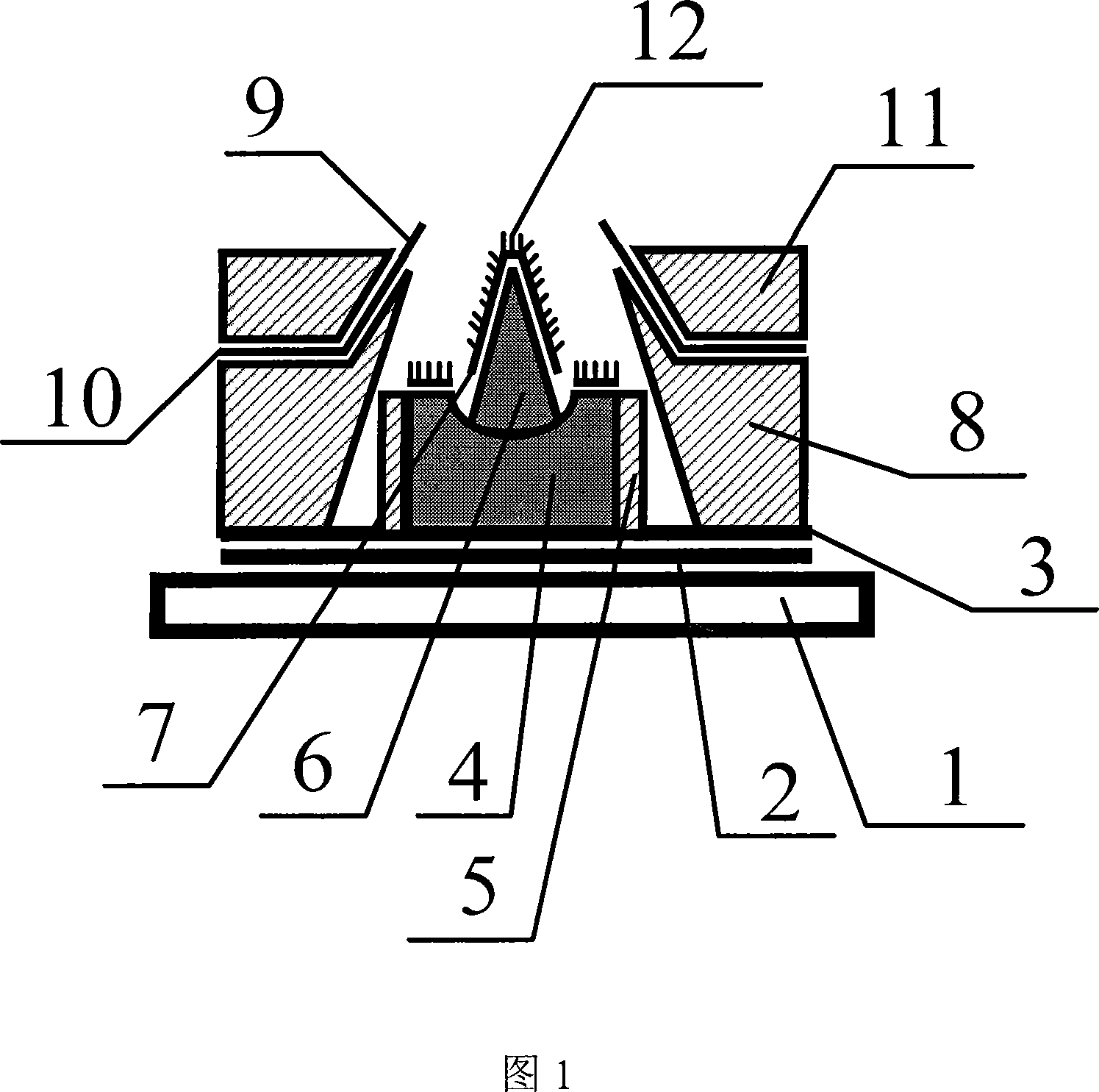

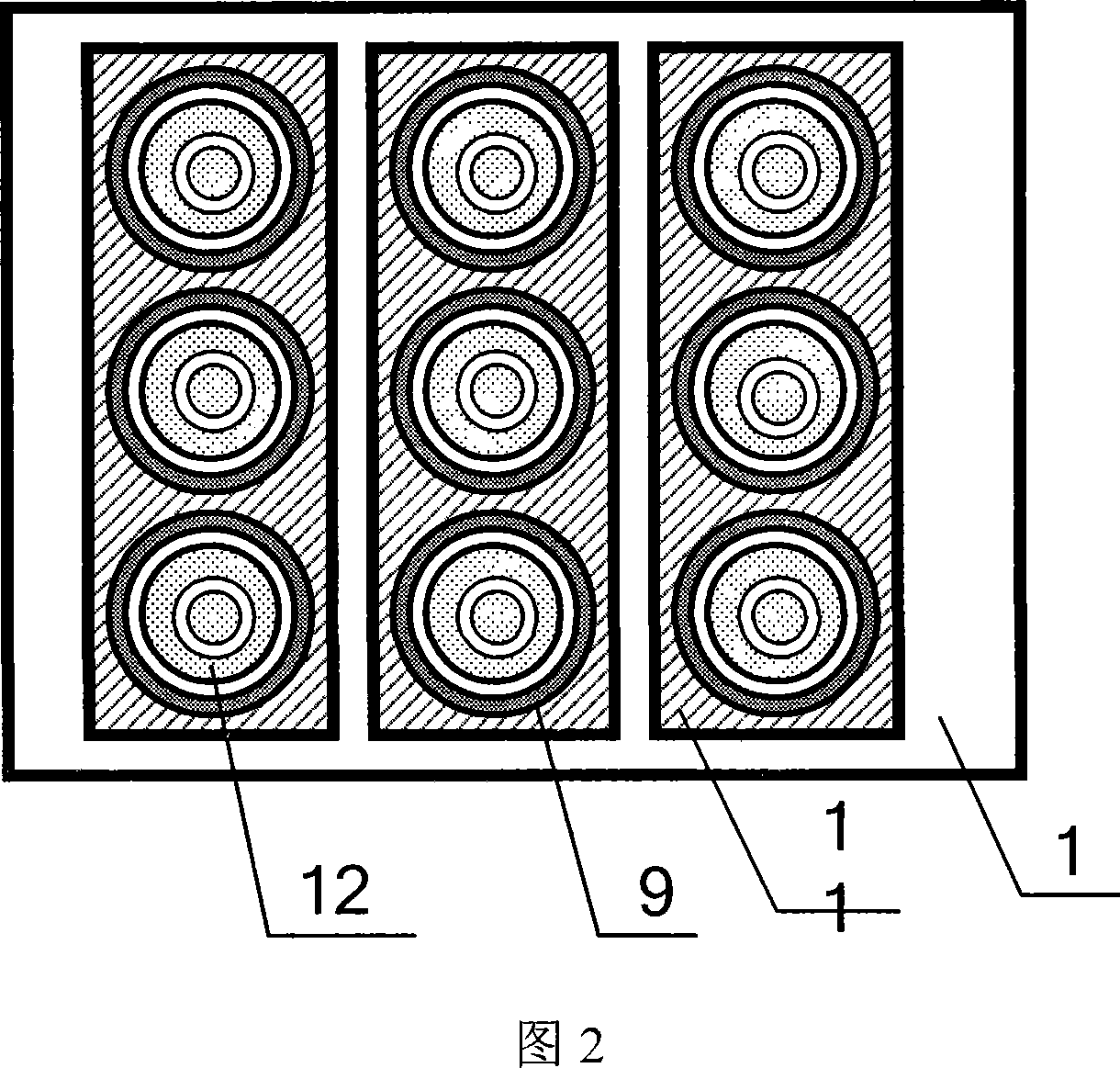

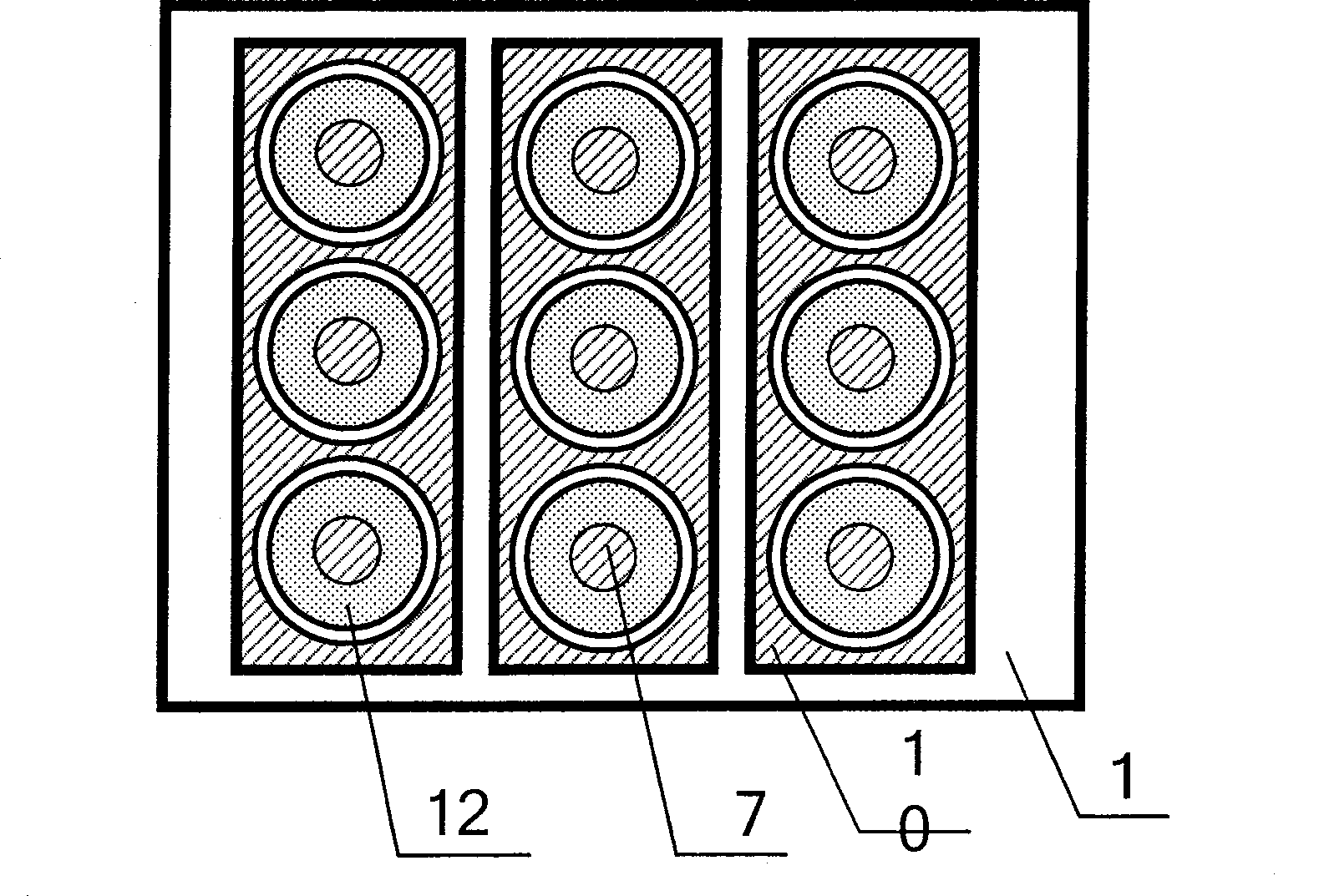

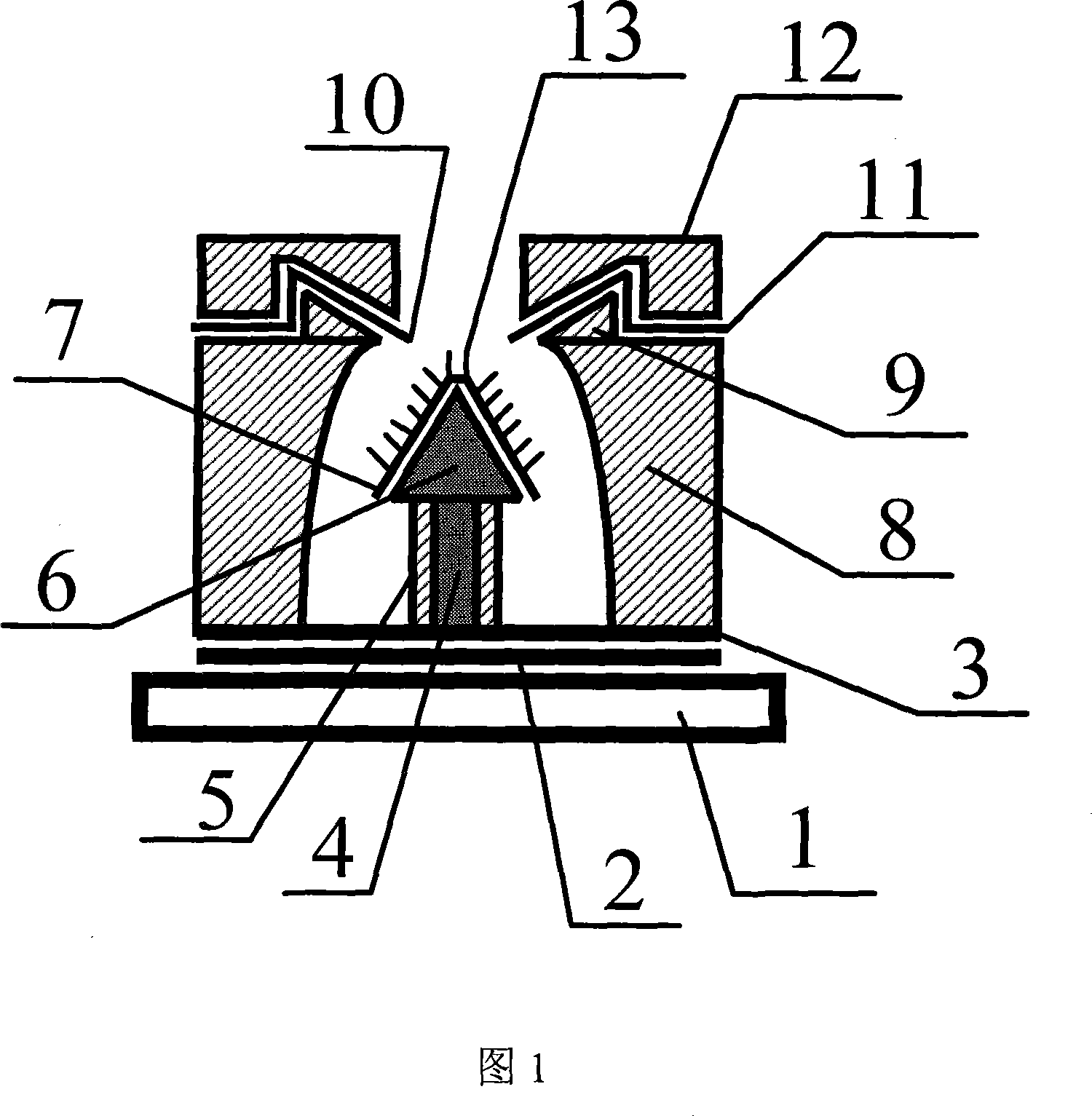

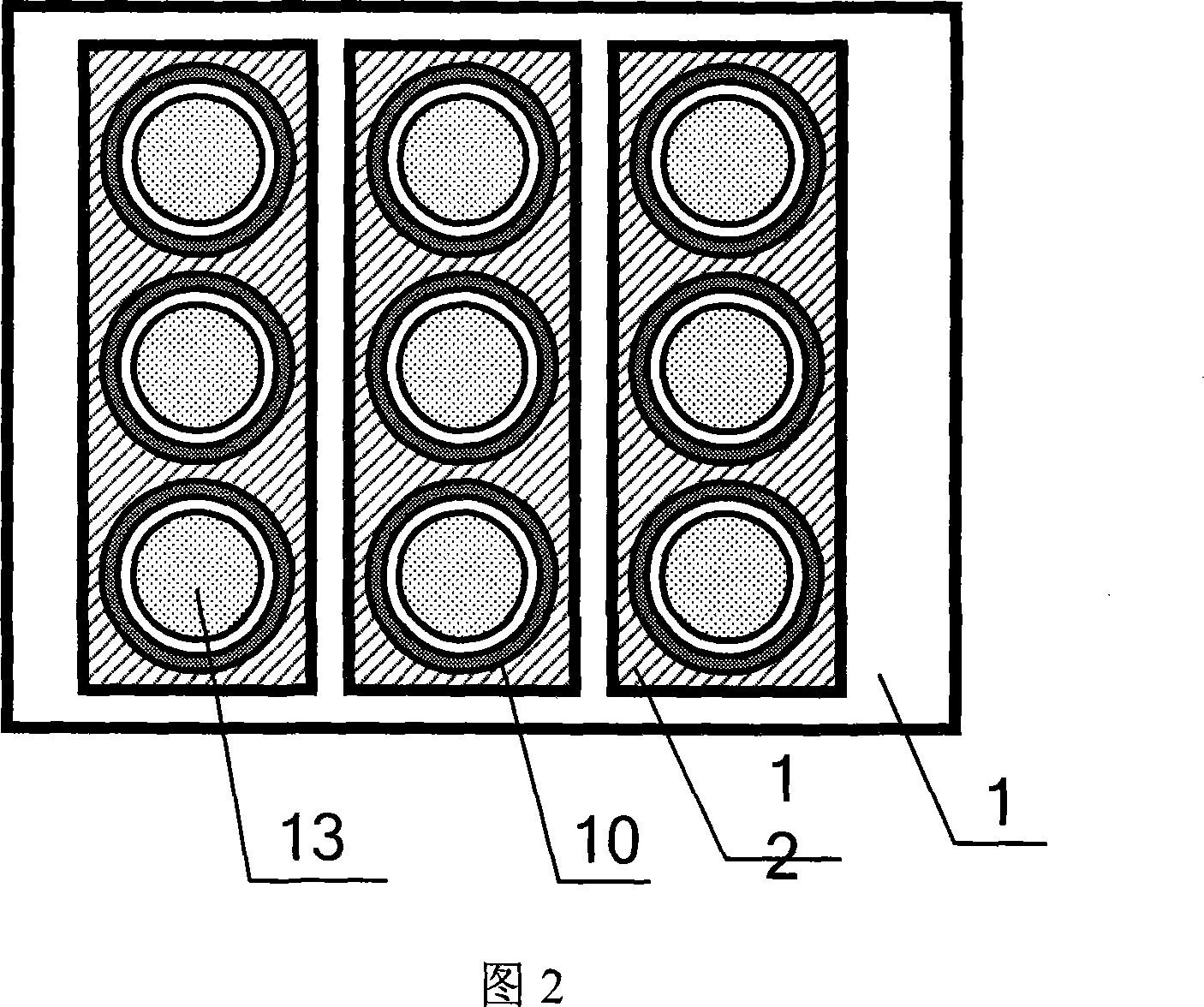

InactiveCN101075541AIncreased electron emission areaImprove electron emission efficiencyControl electrodesImage/pattern display tubesFluorescenceDisplay device

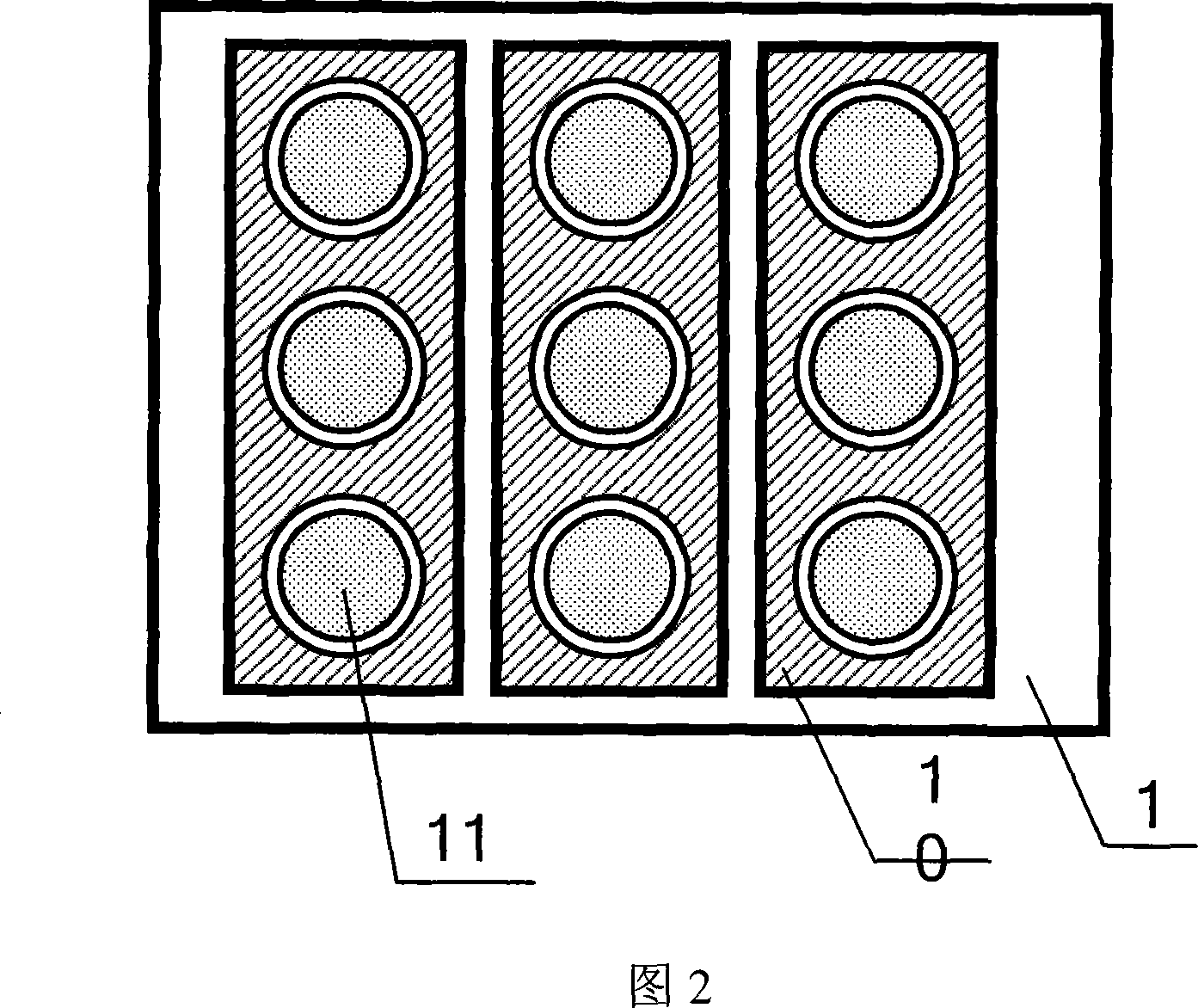

This is a flat displayer of arrow shape grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; on the cathode glass panel are a grid down-lead layer, carbon nanotube and arrow shape grid structure; a supporting wall between the anodic and cathode panel and a getter; which is capable of increasing electron ejecting amount and efficiency of the nanotube and decreasing the working voltage of the rid and increasing the display brightness.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with two-side recess internal-cathode gate modulation structure and its preparing process

InactiveCN101071747AIncreased electron emission areaIncrease display brightnessControl electrodesImage/pattern display tubesFlat panel displayCarbon nanotube

The invention relates to a flat-panel display of a double-sided sunken inner cathode grid-controlled structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and double-sided sunken inner cathode grid-controlled cathode structure on the cathode glass panel; and it can reduce operating voltage of grid and improve display brightness and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with two-sharp side gate-modulation structure and its preparing process

InactiveCN101071750AReflect control functionIncrease display brightnessControl electrodesImage/pattern display tubesDisplay deviceCarbon nanotube

The invention relates to a flat-panel display of a double-pointed side grid-controlled cathode structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and double-pointed side grid-controlled cathode structure on the cathode glass panel; and it can enlarge electron emission area of carbon nanotube cathode and improve control function of grid and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with inclined-down gate-modulated flat cadhode structure and its preparing process

InactiveCN101071737AEmbodies powerful control functionsLow working voltageControl electrodesImage/pattern display tubesFluorescenceImage resolution

The invention relates to a flat-panel display of a tilted lower grid-controlled flat cathode structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; and grid lead layer, carbon nanotube and tilted lower grid-controlled flat cathode structure on the cathode glass panel; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and it can improve whole display brightness and resolution and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with stair-shaped sided-grid controlled transmitting structure and its production

InactiveCN101075530AEmbodies powerful control functionsLow working voltageControl electrodesImage/pattern display tubesDisplay deviceCarbon nanotube

This is a flat displayer of step shape side grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and step shape side grid structure, which is capable of decreasing working voltage of the grid and increasing the control function and efficiency.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with H-shaped sided-grid controlled structure and its production

InactiveCN101075540ALow working voltageIncrease display brightnessControl electrodesImage/pattern display tubesDisplay deviceEngineering

This is a flat displayer of I shape side grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and I shape side grid structure, which is capable of increasing the electron ejecting area and efficiency of the nanotube and increasing the control function of the grid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat panel display with bevelled grid controlled cathode structure in truncated cone form, and fabricating technique thereof

InactiveCN100580861CLow working voltageStrong electric field strengthControl electrodesImage/pattern display tubesPhosphorCarbon nanotube

The flat panel display includes following parts: sealed vacuum cavity composed of glass faceplate of anode, glass faceplate of cathode, and glassed-in frame; anode conductive layer on the glass faceplate of anode, and phosphor layer on the anode conductive layer; the support wall structure between the glass faceplate of anode and the glass faceplate of cathode, and accessorial components for getter; cathode conductive layer, Nano carbon tube, and beveled circular truncated cone grid controlled cathode structure setup on the glass faceplate of cathode. The invention raises efficiency and quantity of electron emission of cathode in Nano carbon tube, reduces operating voltage of grid electrode so as to be in favor of preparing flat device in high quality. Advantages are: stable and reliable fabricating procedure, simple technique, low fabricating cost, and ordinary structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

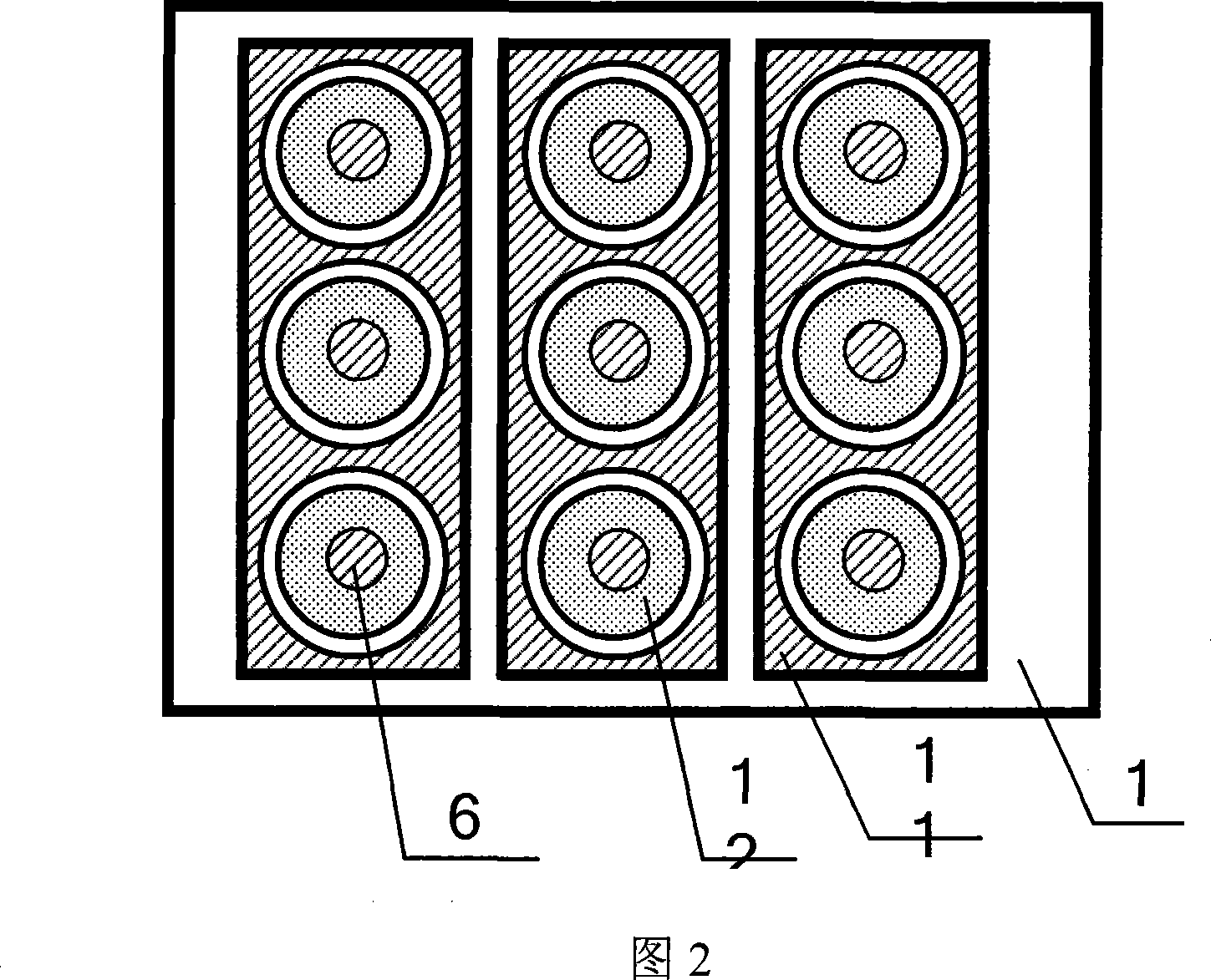

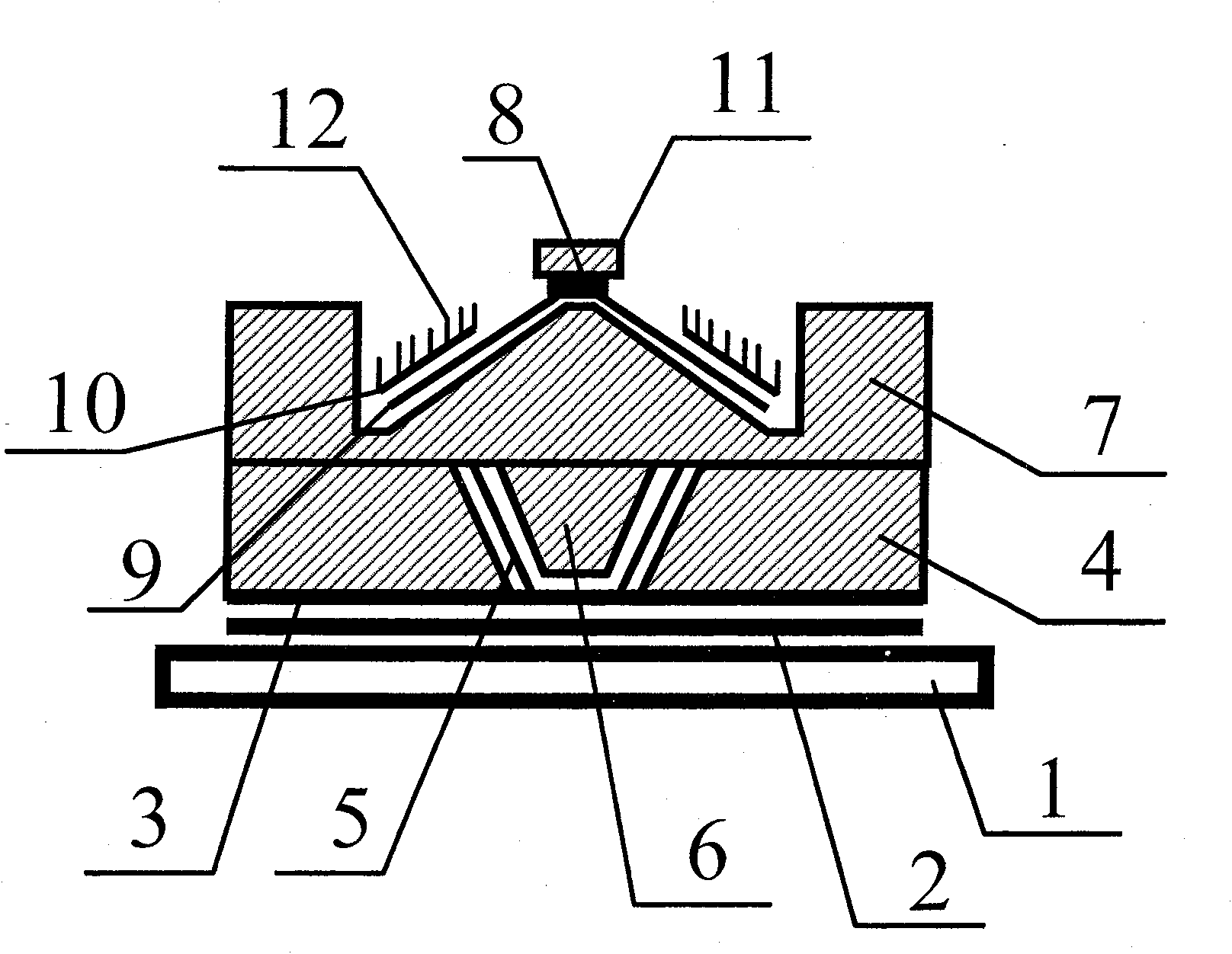

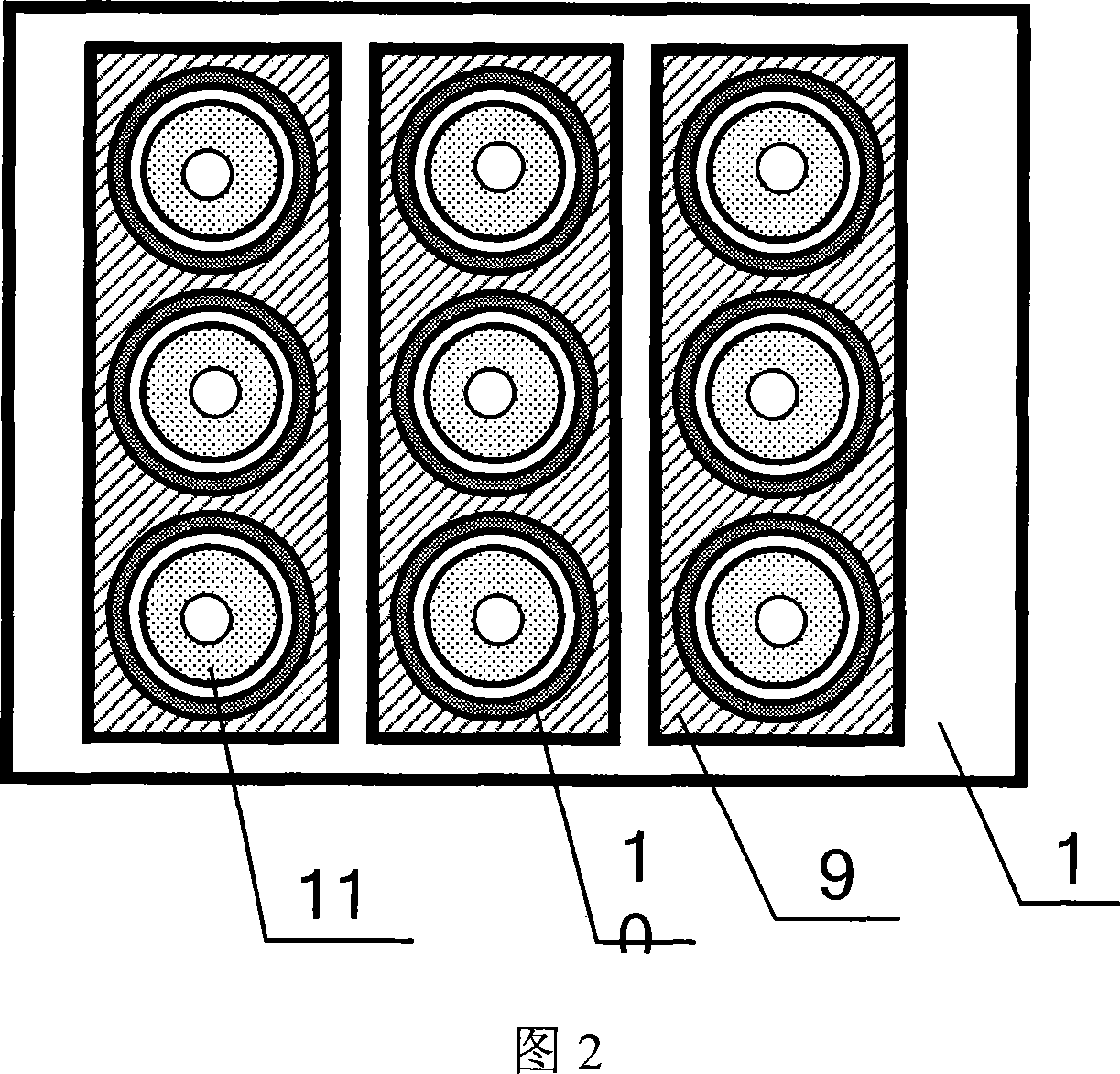

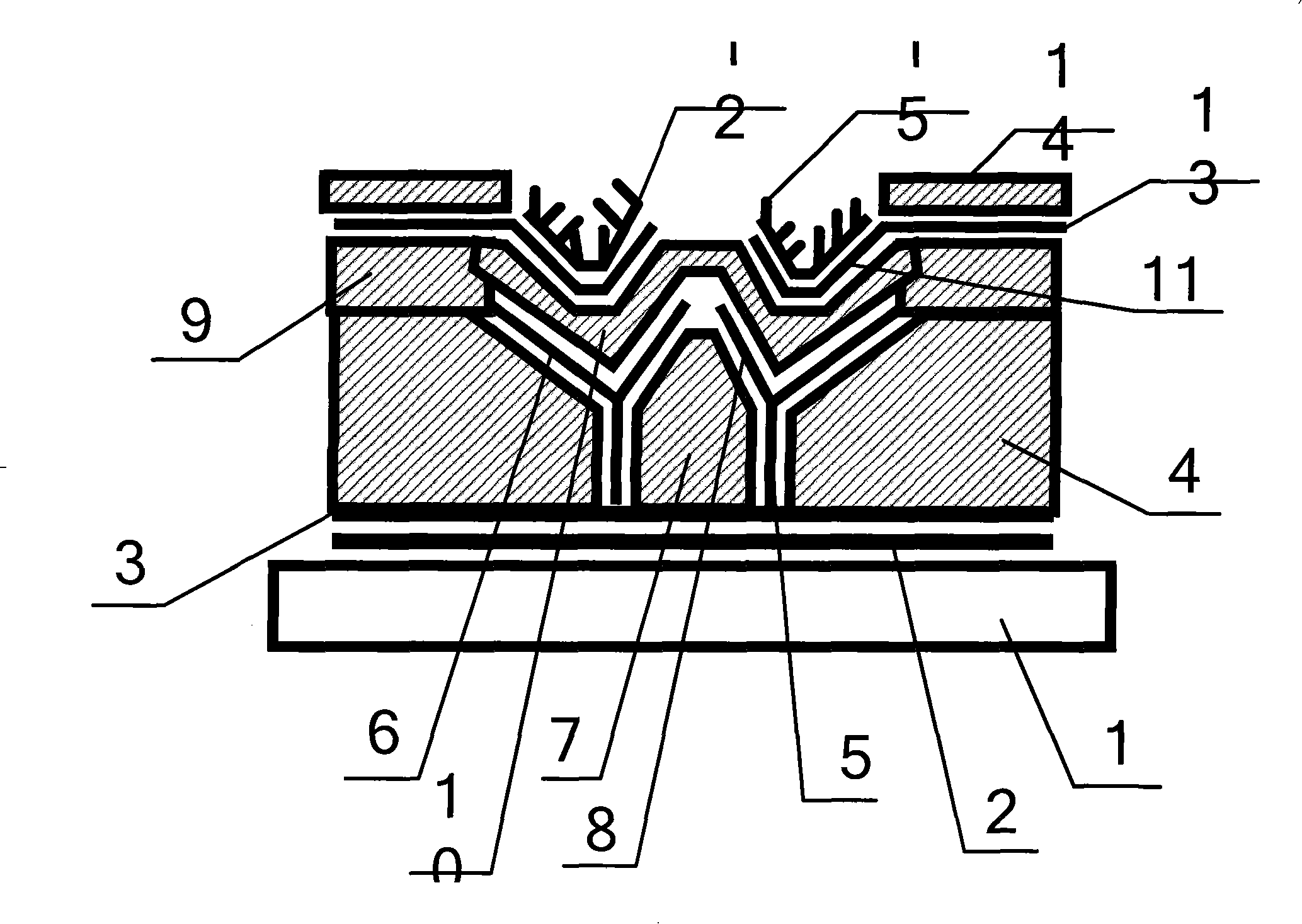

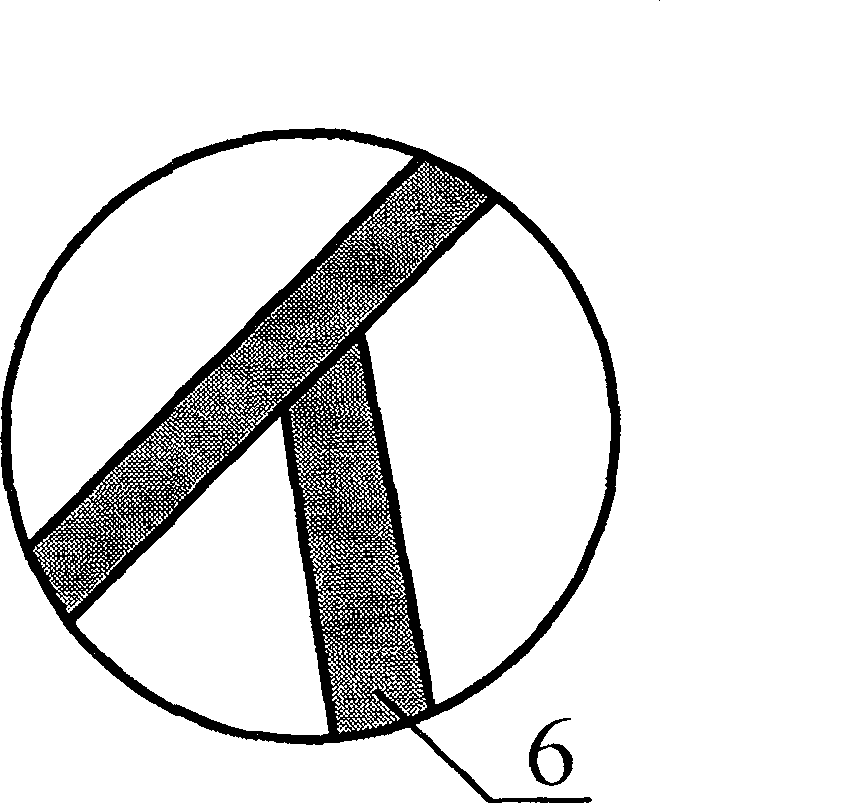

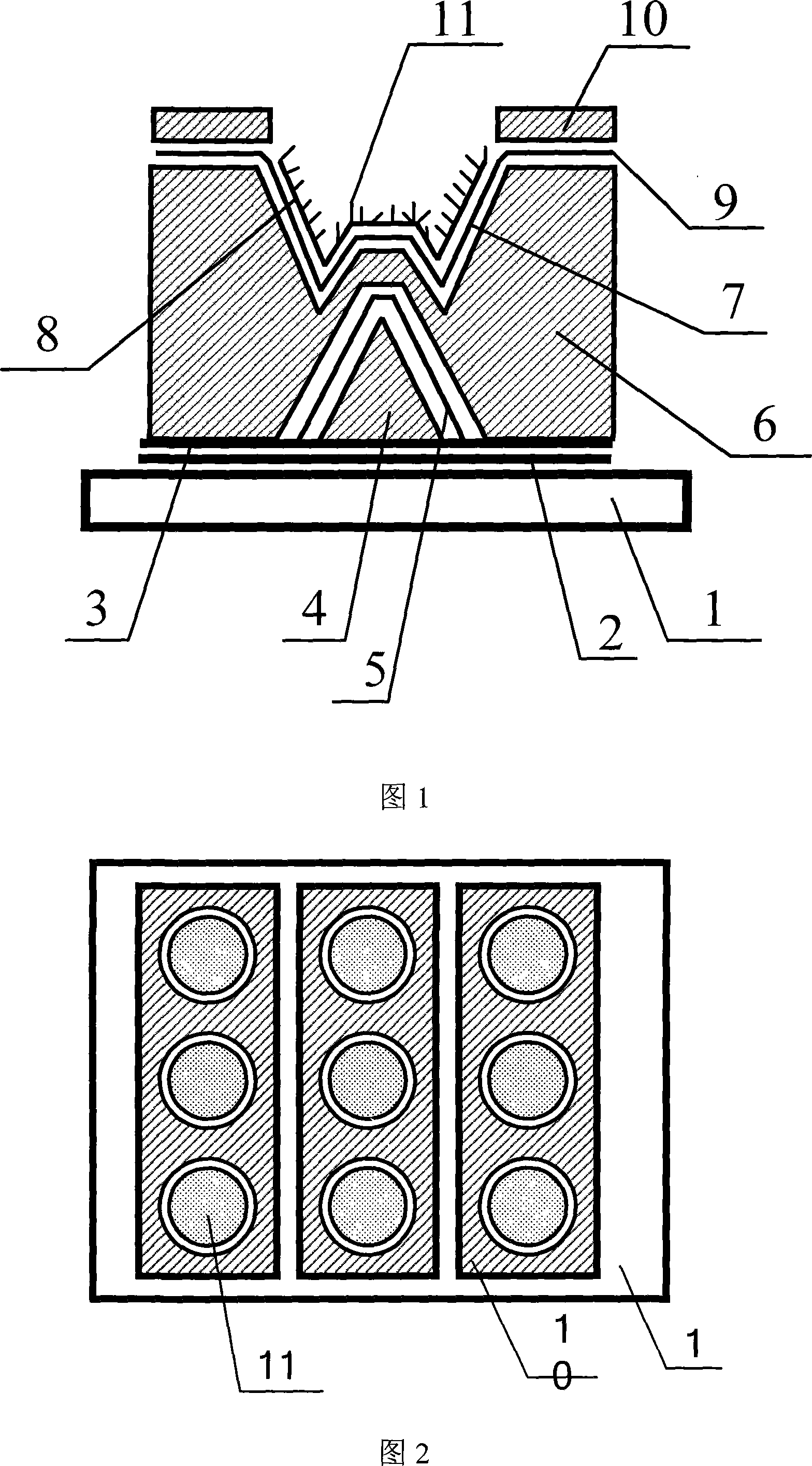

Planar display device with reversed-angle laminated multi-bending cathode structure and its production

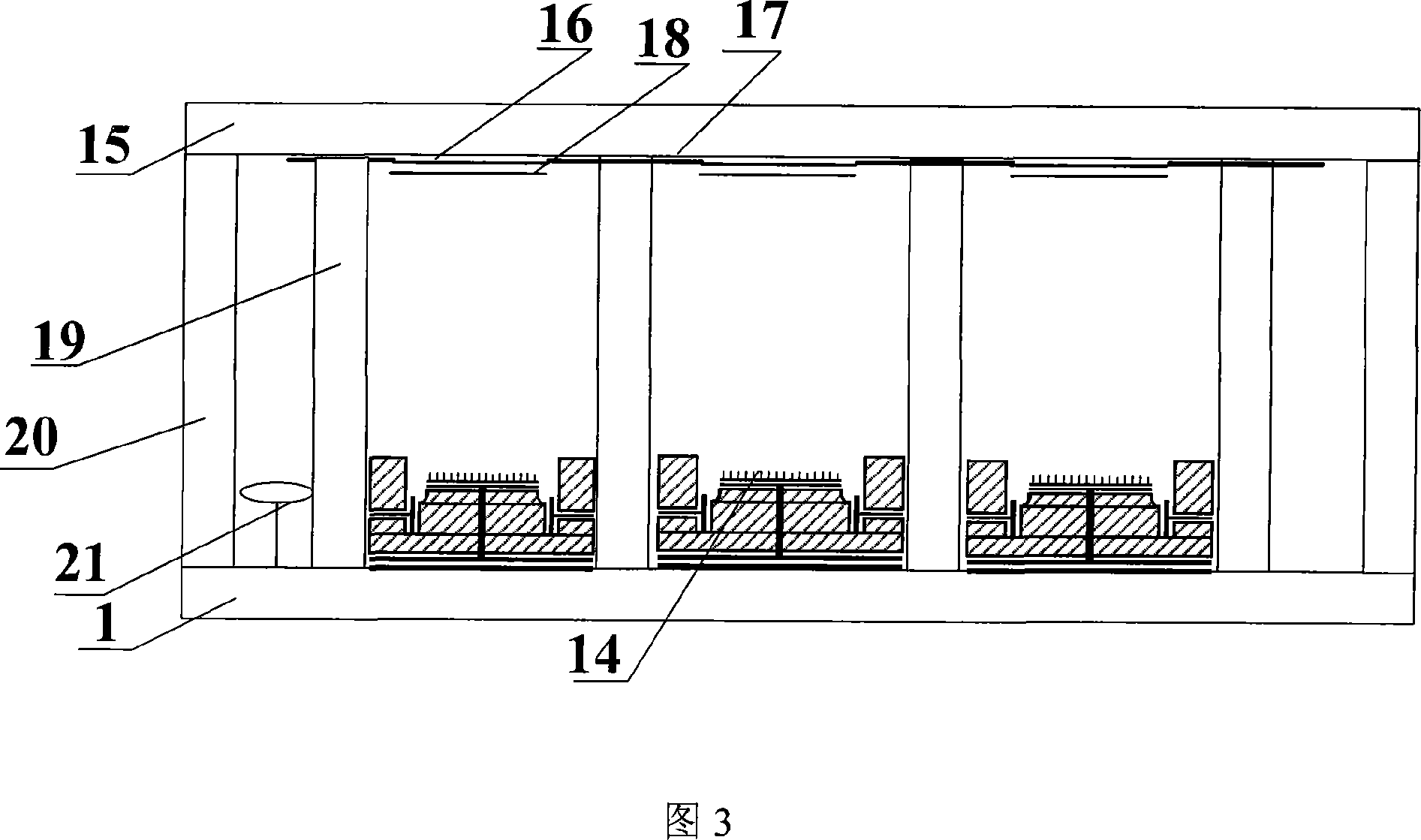

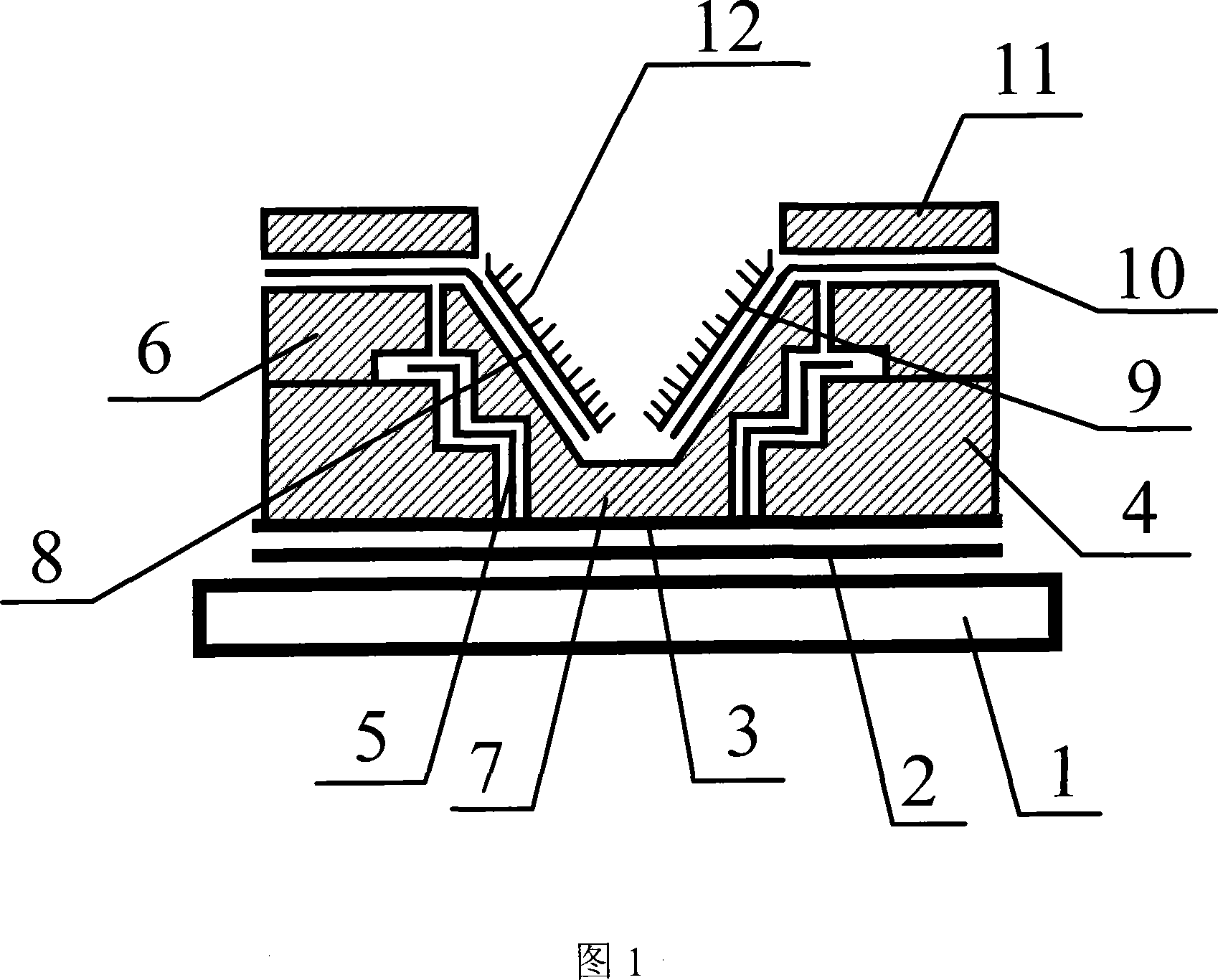

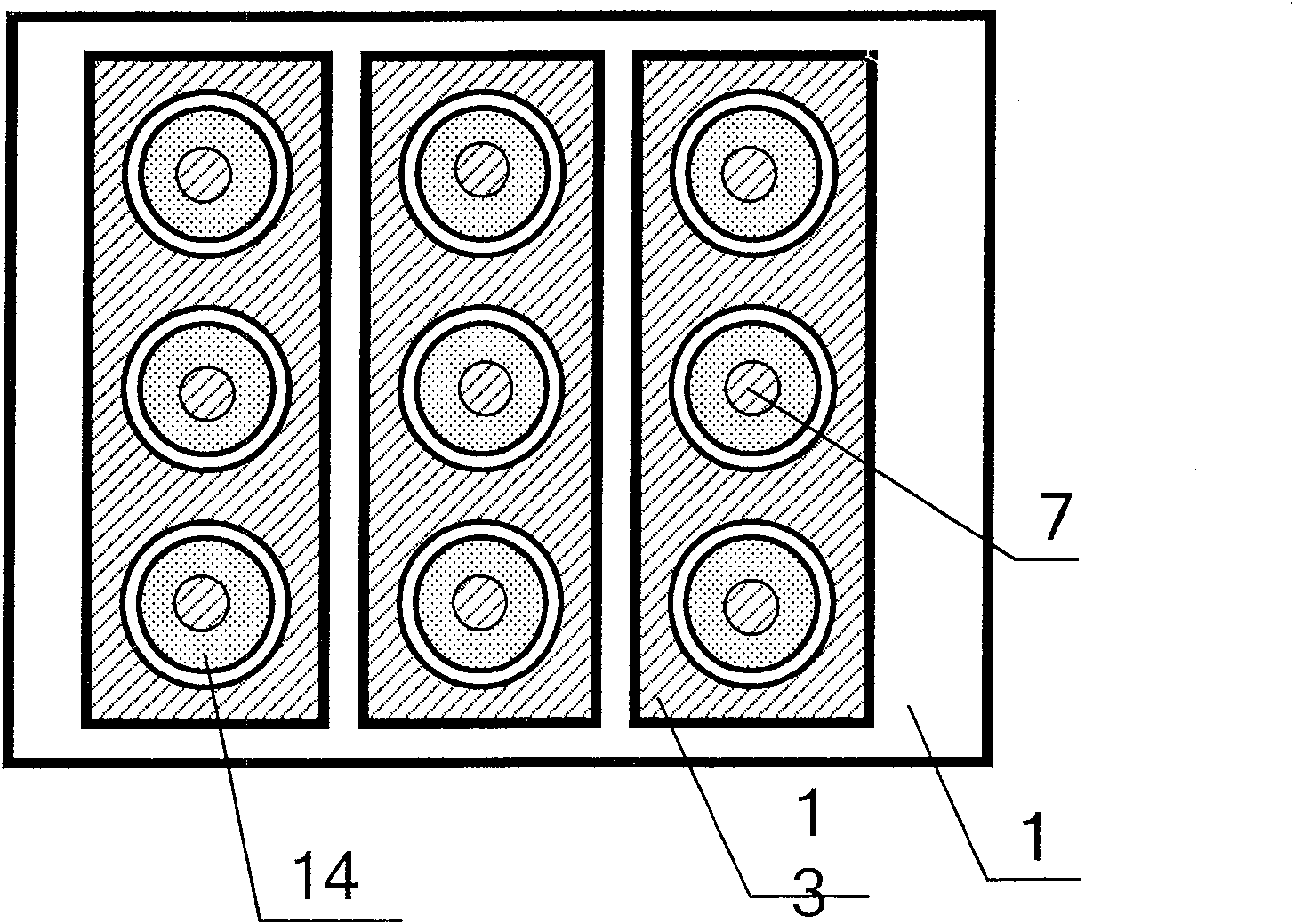

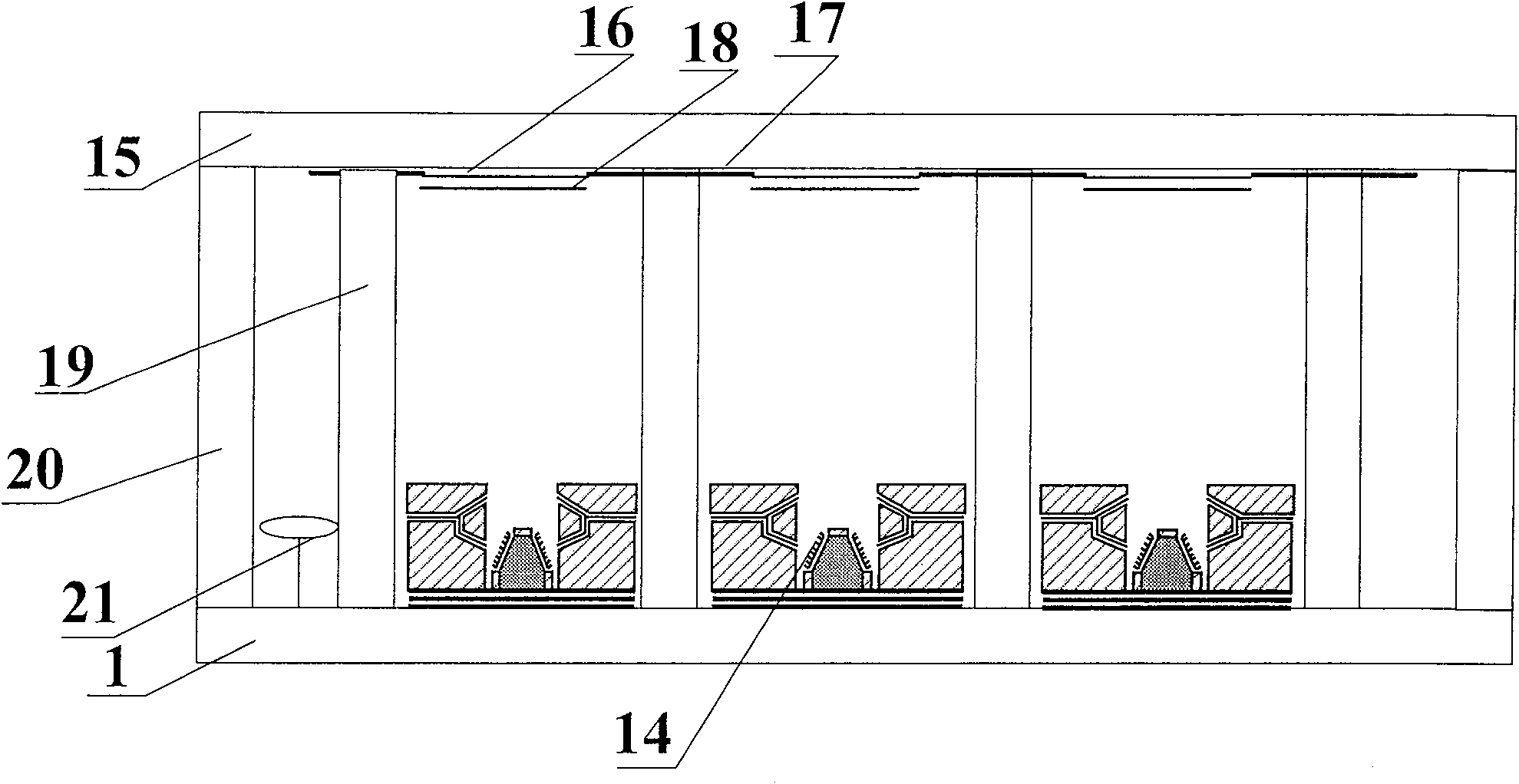

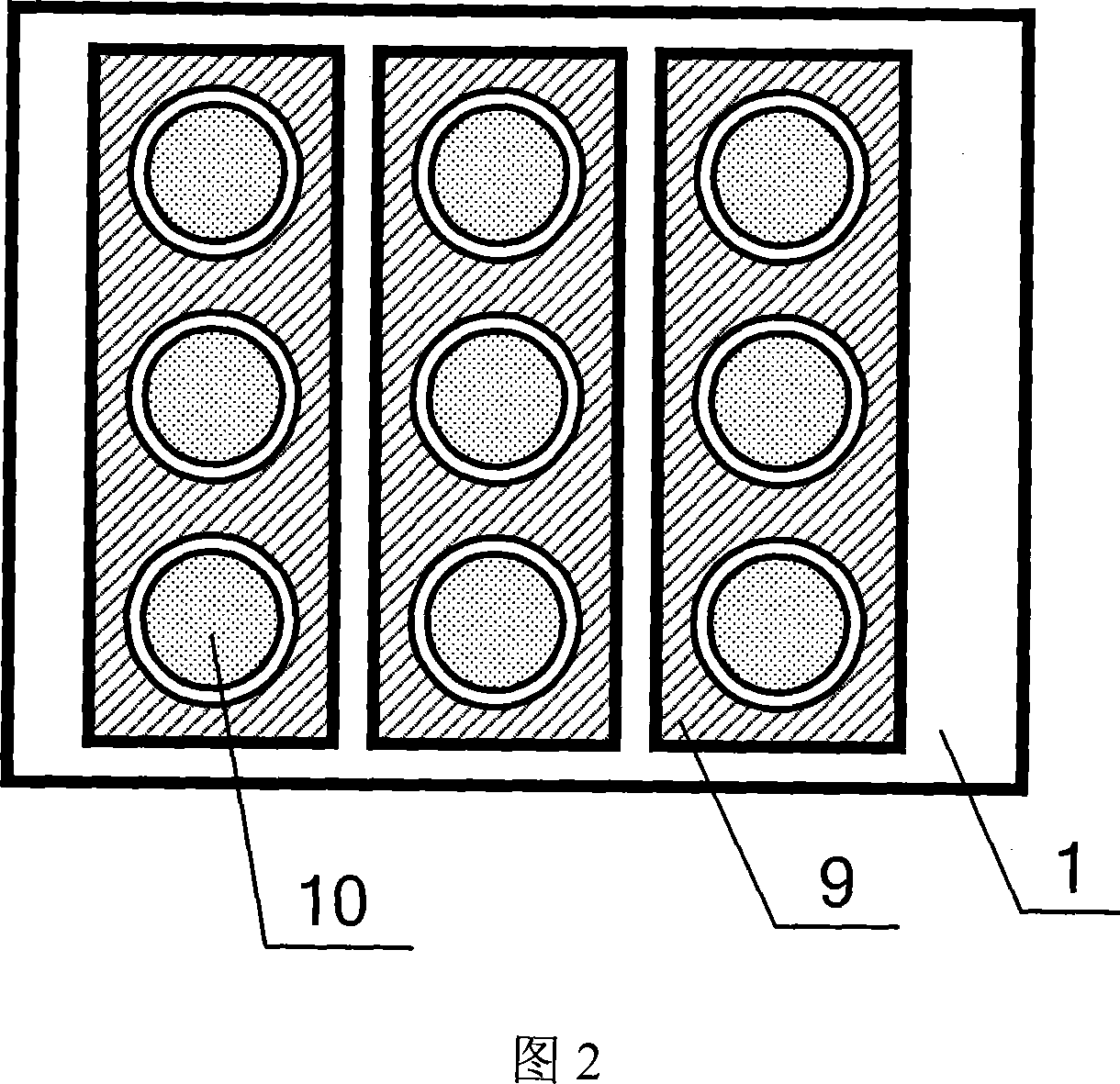

InactiveCN101075528BImprove electron emission efficiencyIncreased electron emission areaControl electrodesImage/pattern display tubesDisplay deviceVacuum chamber

This is a flat displayer of V shape overlaping cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and V shape overlapping cathode structure, which is capable of increasing the efficiency and area of electron ejection by the nanotube and the display quality.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with oblique flat-gate structure and its preparing process

InactiveCN101071728AIncrease display brightnessReduce gate currentControl electrodesImage/pattern display tubesCarbon nanotubeDisplay device

The invention relates to a flat-panel display of a inclined-plane flat grid structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; cathode conducting layer, carbon nanotube and inclined-plane flat grid structure on the cathode glass panel; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel, and it can further improve control function of grid, reduce operating voltage of grid, and besides, raise electron emission efficiency and number of emitted electrons of carbon nanotube cathode, and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

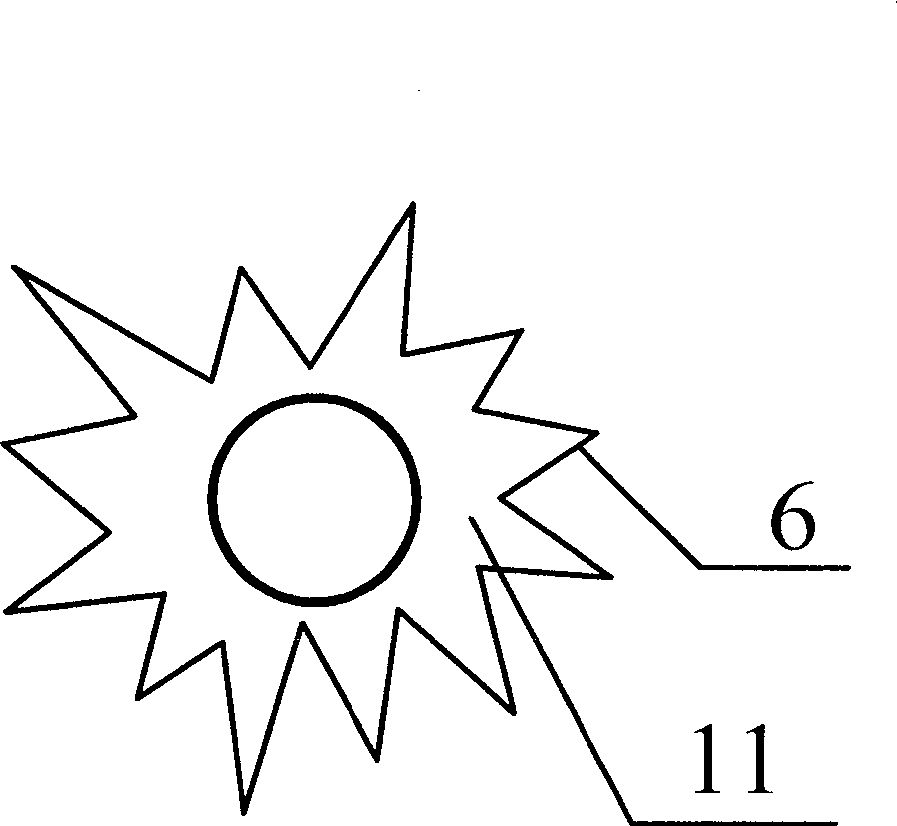

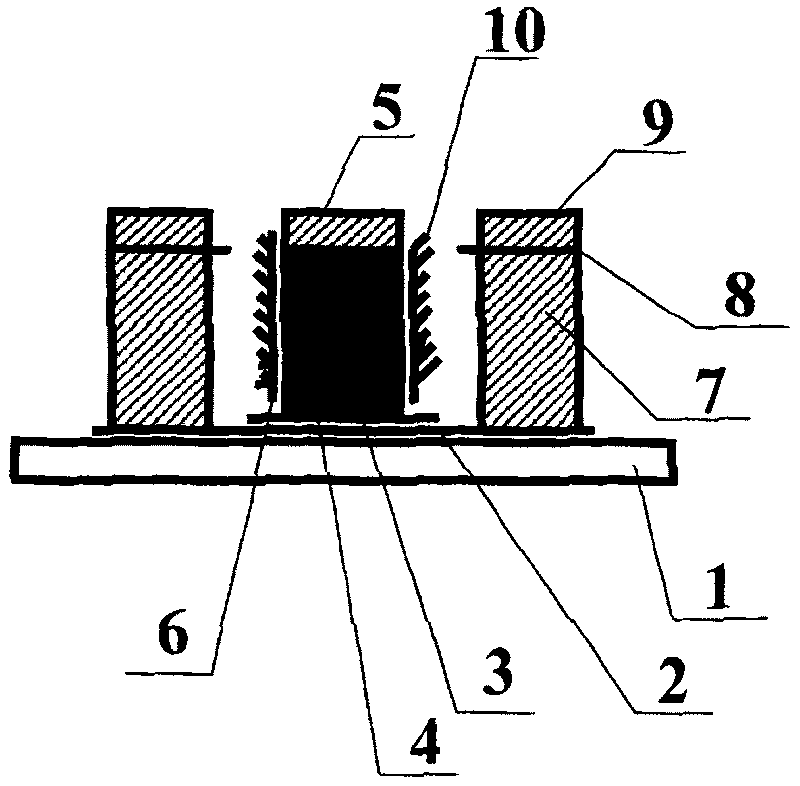

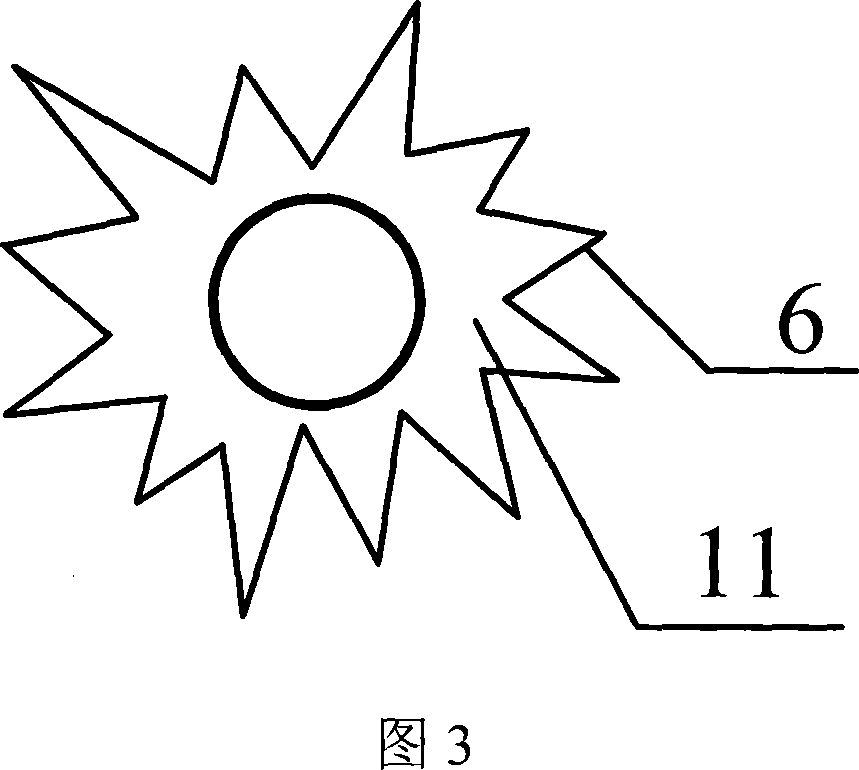

Planar display device with explosive star-typed cathode structure and its production

InactiveCN100527340CIncreased electron emission areaIncrease display brightnessImage/pattern display tubesDischarge tube/lamp detailsFluorescenceImaging quality

The invention relates to a flat panel display with an explosive star cathode structure and its manufacturing process, comprising a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; an anode conductive layer is arranged on the anode glass panel and Phosphor layer prepared on top of the anode conductive layer; grid lead layer, carbon nanotubes and burst star cathode structure on the cathode glass panel; support wall structure and getter attachment between the anode glass panel and cathode glass panel The component can further improve the electron emission efficiency of the carbon nanotube cathode, reduce the gate operating voltage, and help improve the display image quality of the device. It has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with triangular bottom-grid controlled cathode structure and its production

InactiveCN101075537ADemonstrate strong controlLow working voltageControl electrodesImage/pattern display tubesDisplay deviceFlat panel display

This is a flat displayer of triangle shape low grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and triangle shape low grid structure, which is capable of increasing the control function and efficiency of the grid, and increasing the electron ejecting area of the nanotube and display brightness.

Owner:ZHONGYUAN ENGINEERING COLLEGE

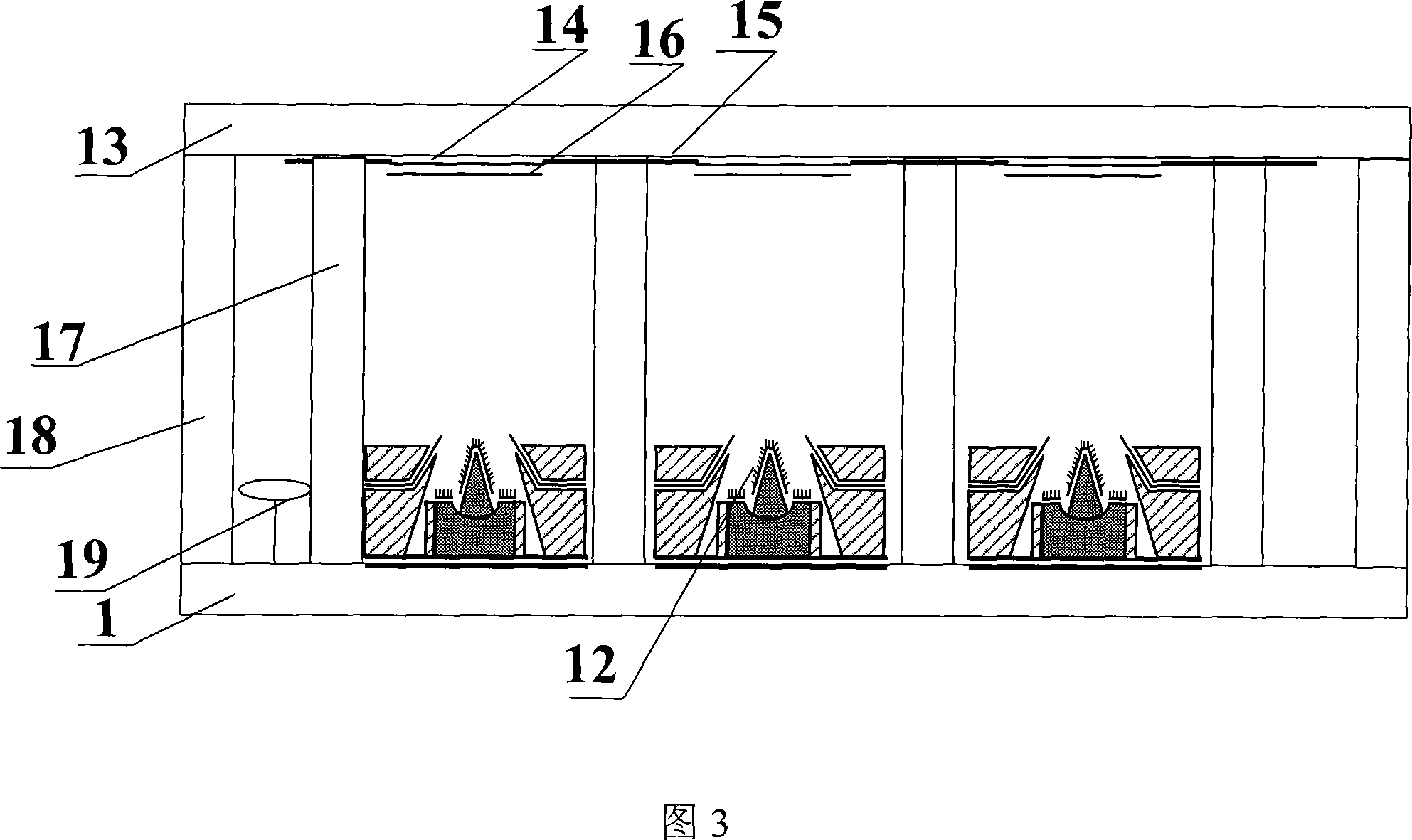

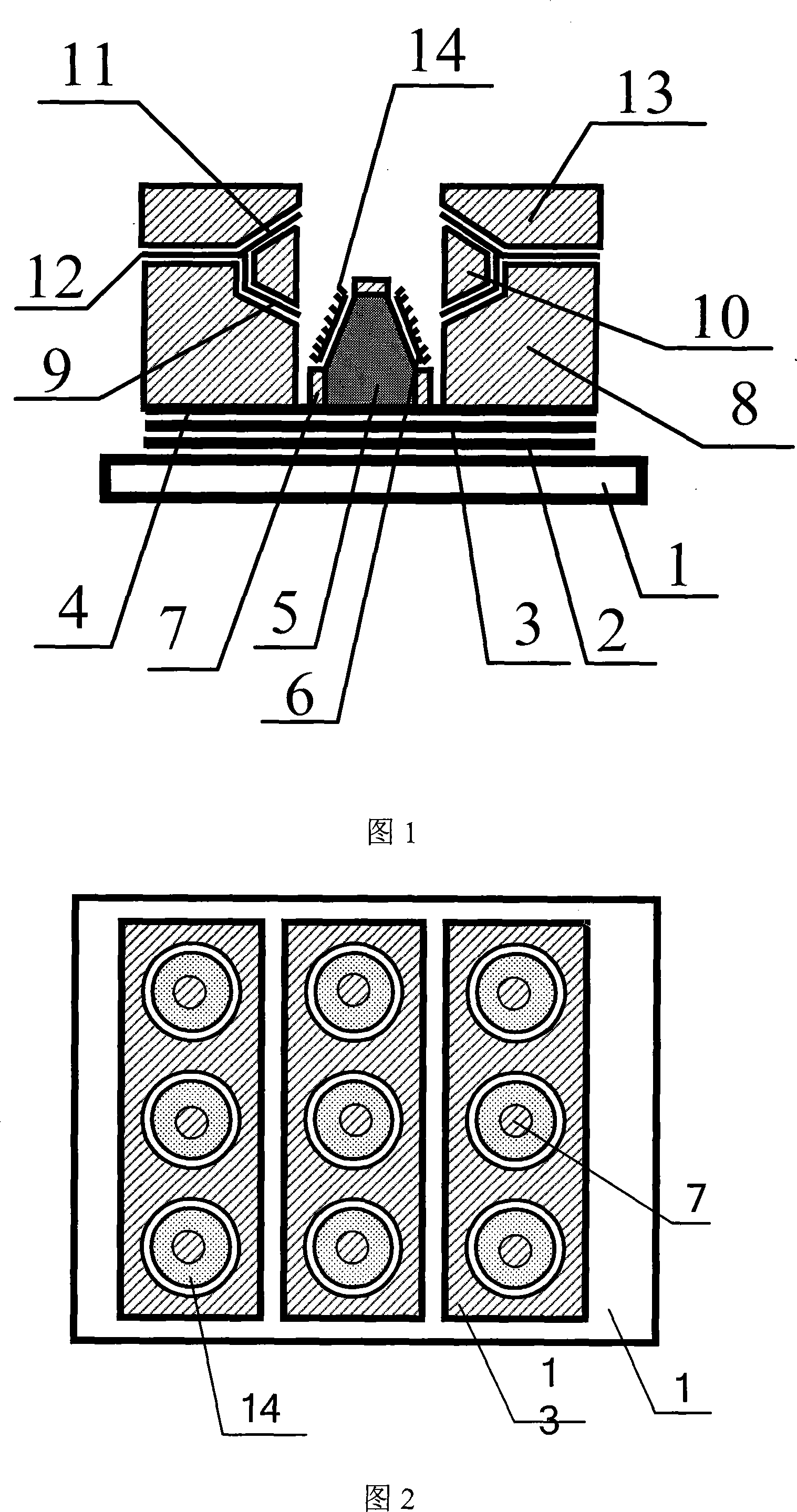

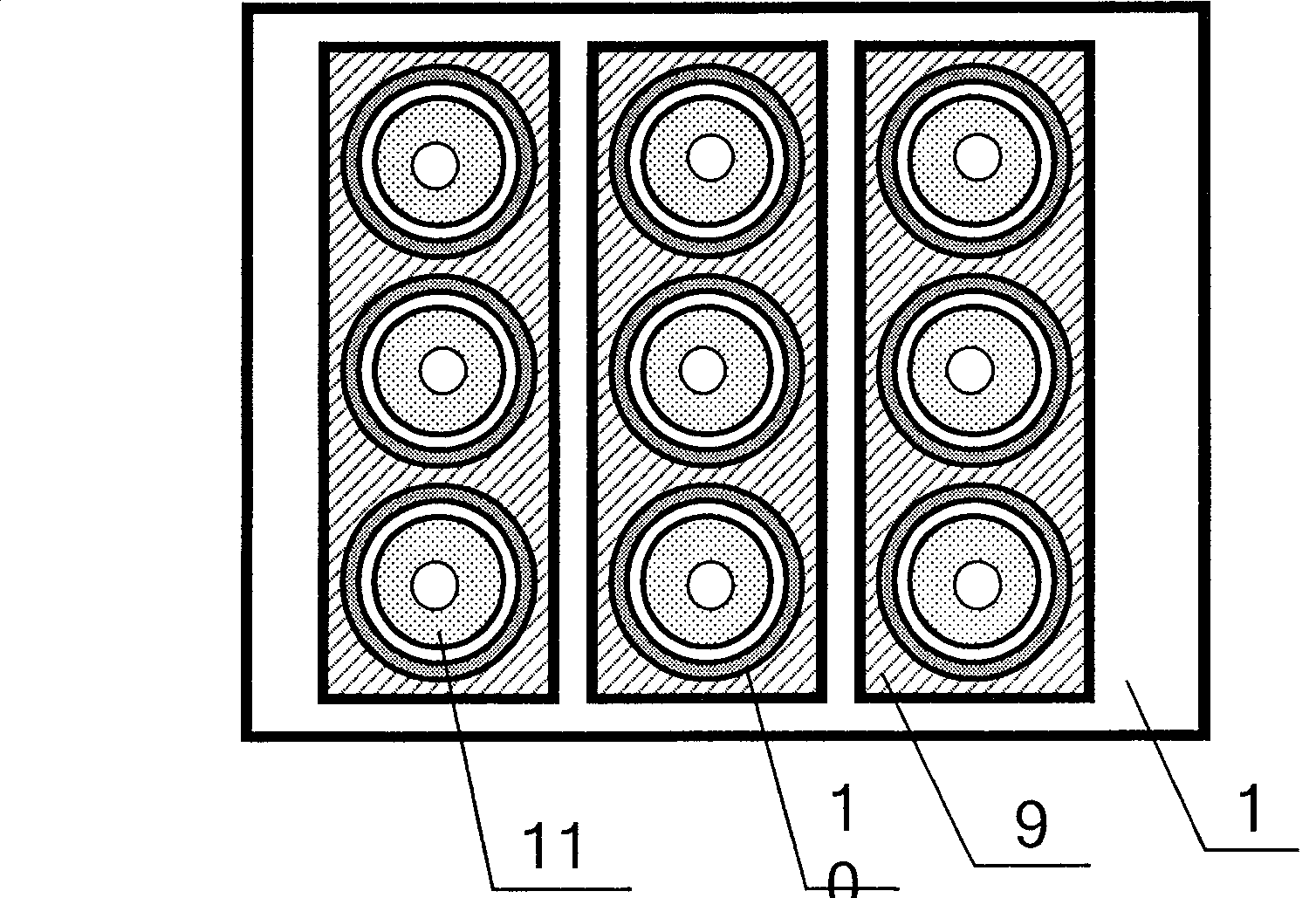

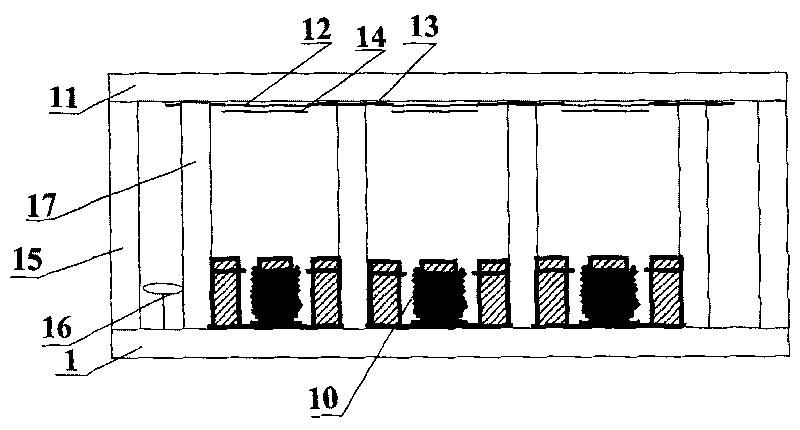

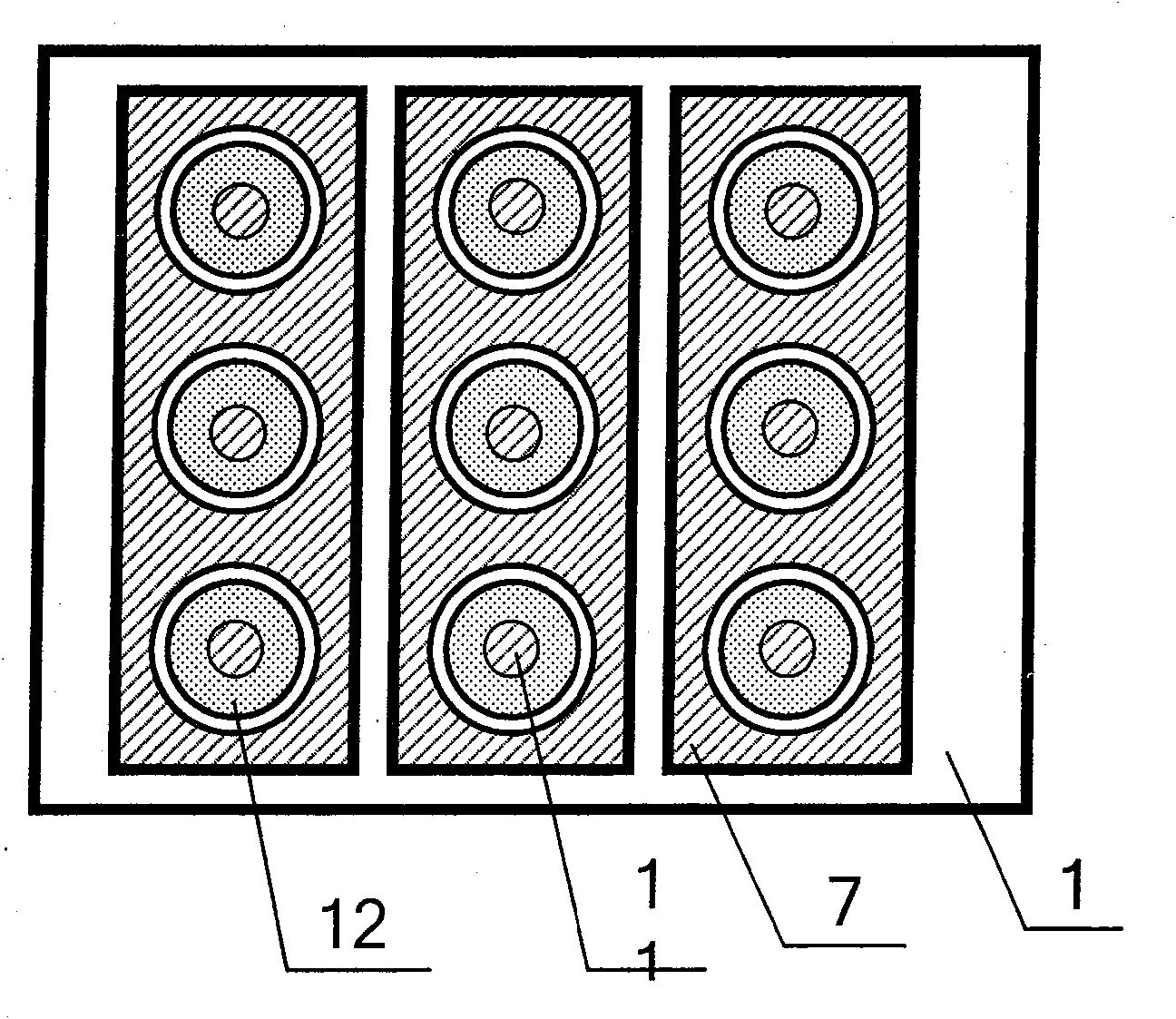

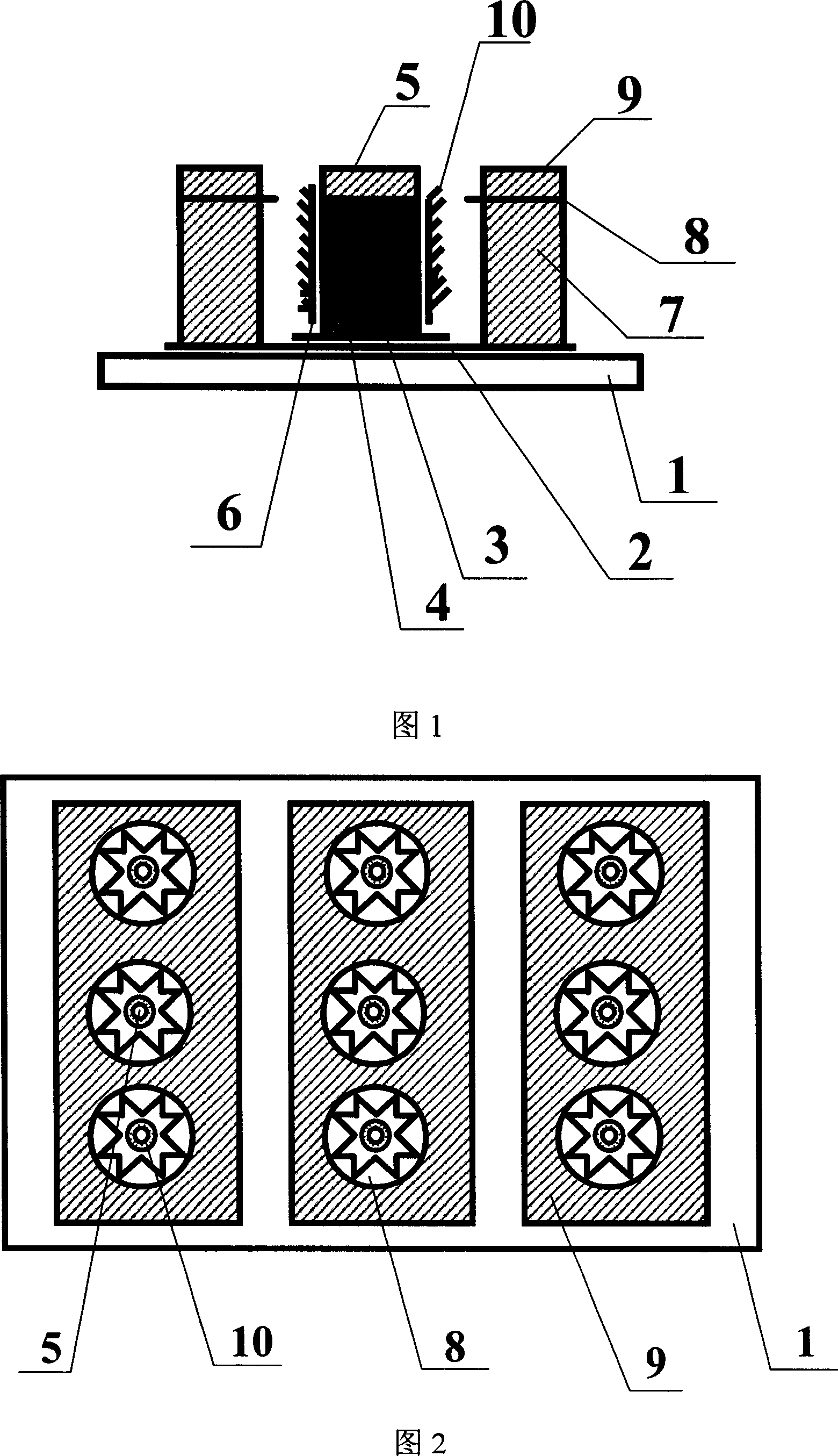

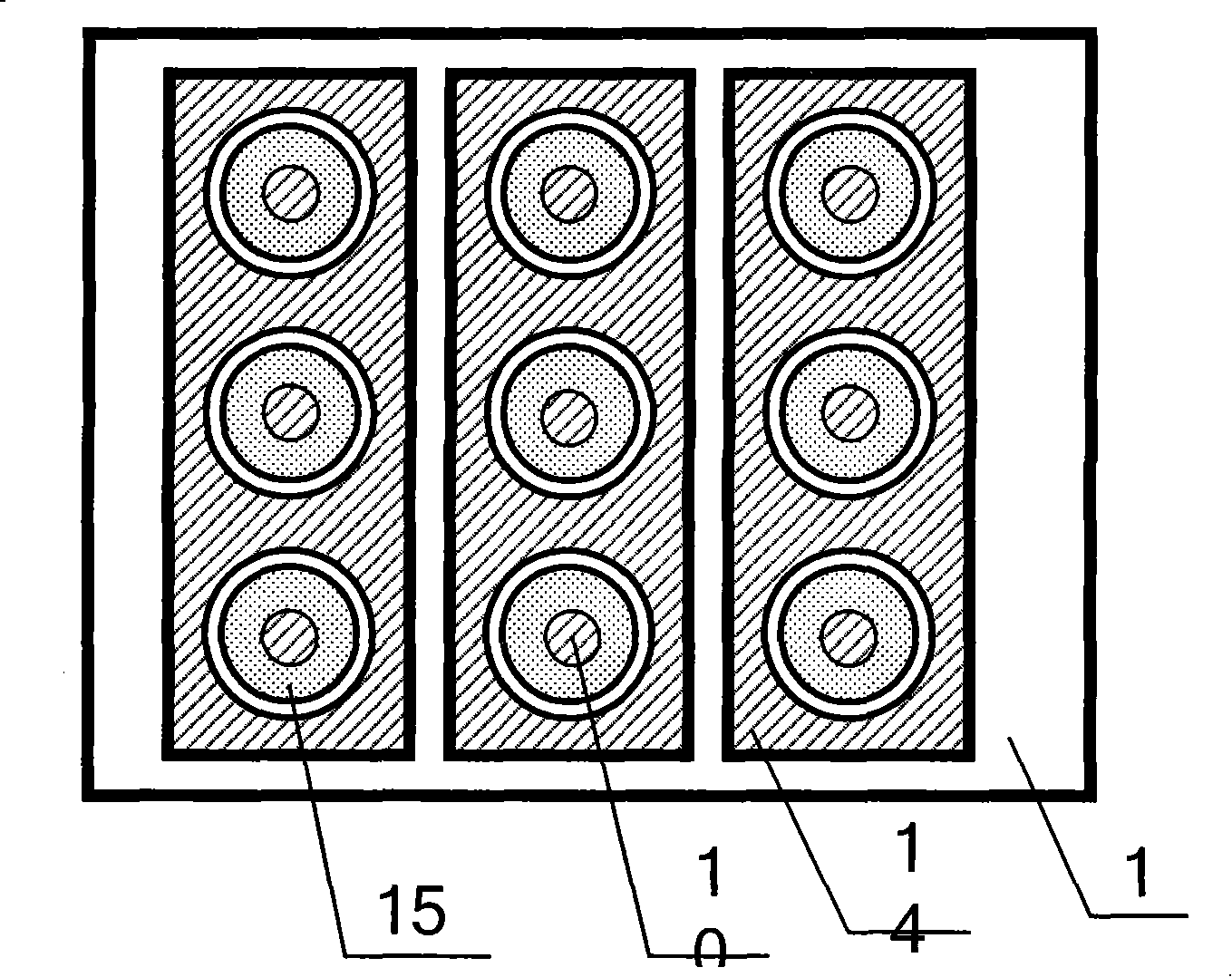

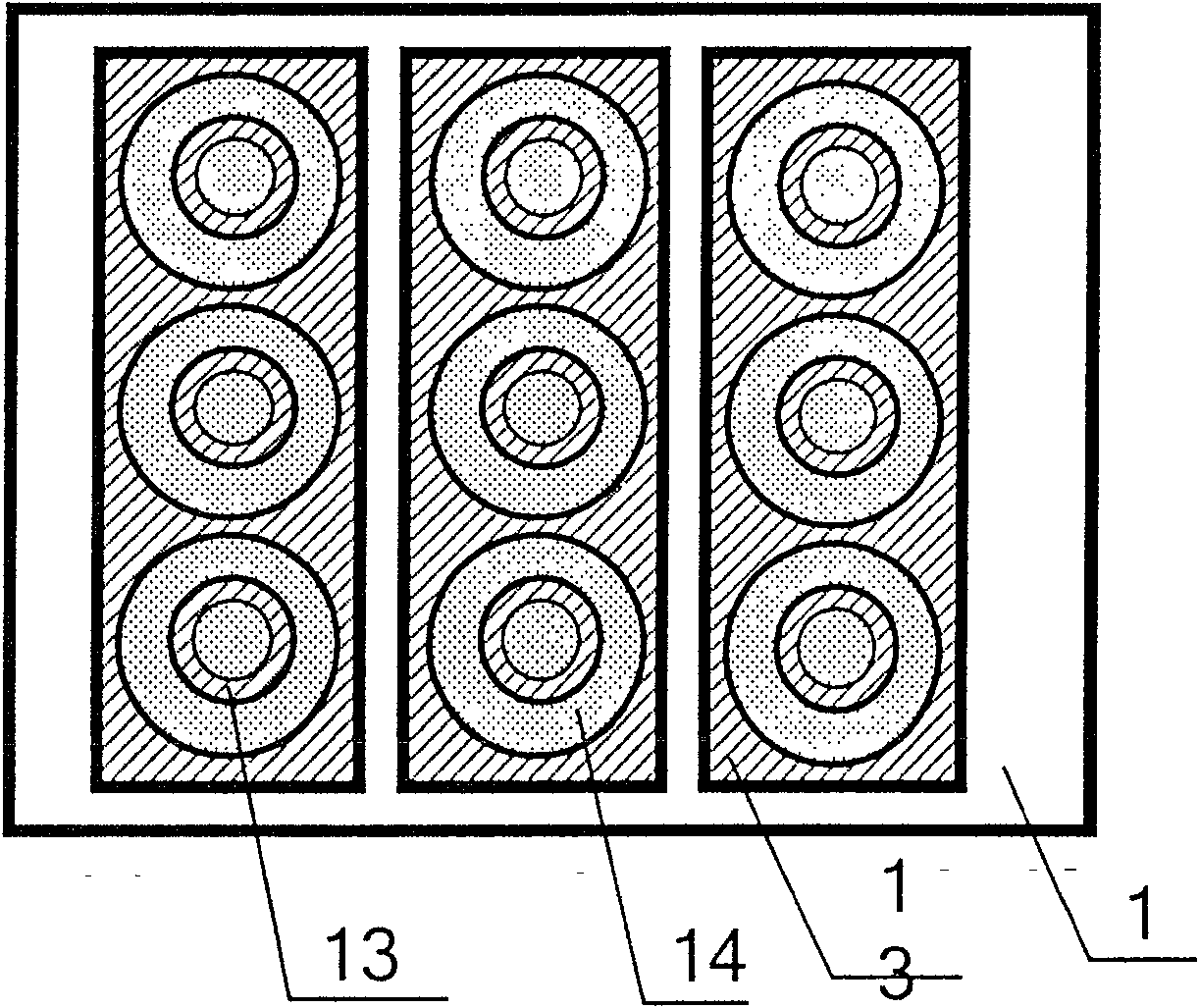

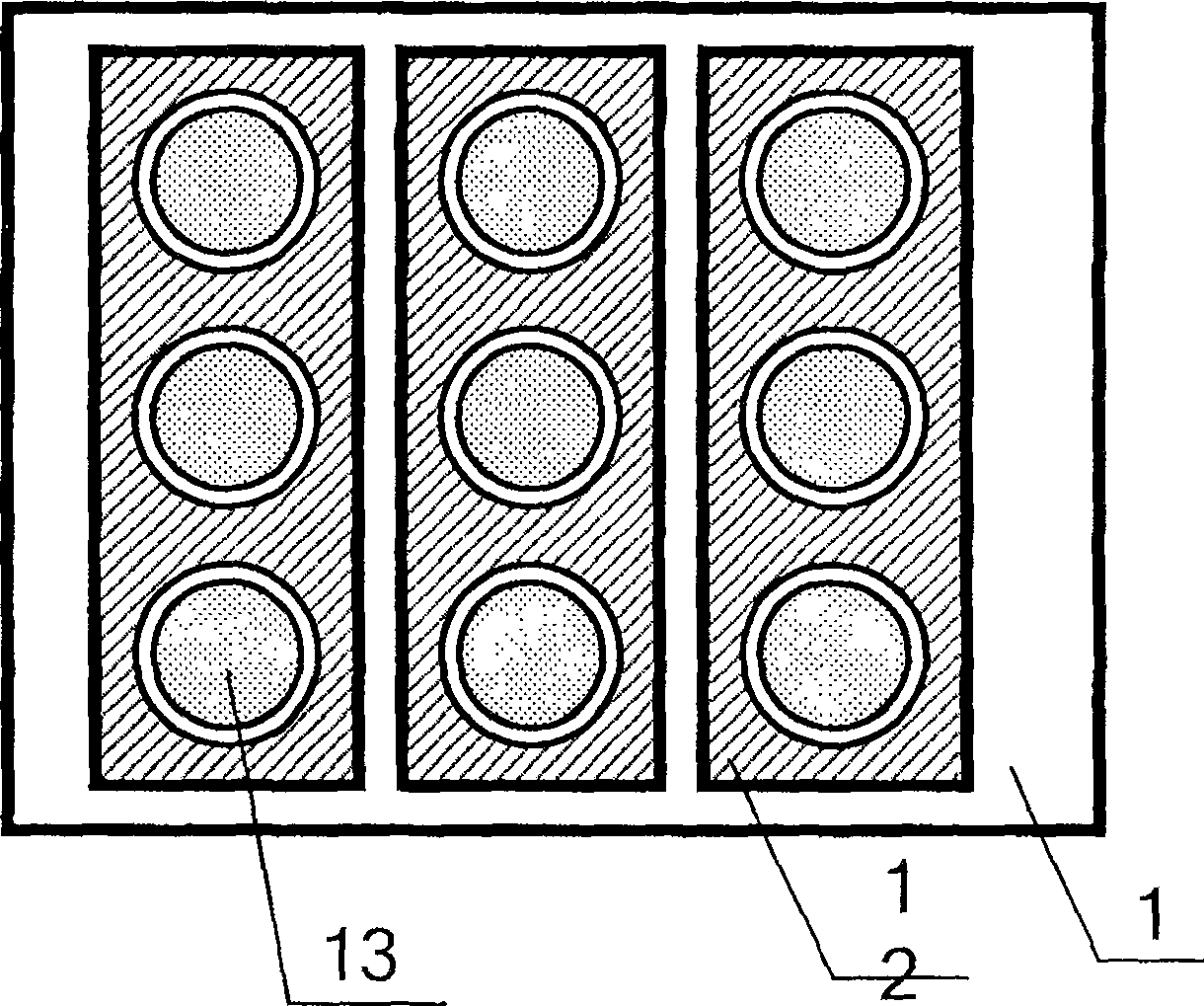

Hackle sidegrid-controlled structure panel display and its manufacturing method

InactiveCN1971831BIncreased electron emission areaIncrease display brightnessControl electrodesElectrode and associated part arrangementsGratingFluorescence

This invention relates to one gear grating control plane display process, which comprises the following parts: cathode glass panel, cathode glass panel and circle glass frame to form sealed vacuum chamber; fluorescence layer on anode electrode layer with anode conductive layer on anode glass panel; supportive wall structure and air detrained assistant elements between anode glass panel and cathodeglass panel; control grating electrode, carbon nanometer tube cathode and emission structure on cathode glass panel.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with reversed-angle laminated multi-bending cathode structure and its production

InactiveCN101075528AImprove electron emission efficiencyIncreased electron emission areaControl electrodesImage/pattern display tubesDisplay deviceFlat panel display

This is a flat displayer of V shape overlaping cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and V shape overlapping cathode structure, which is capable of increasing the efficiency and area of electron ejection by the nanotube and the display quality.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with bent lower-grid controlled structure and its production

InactiveCN100595871CSmall working currentIncrease display brightnessControl electrodesImage/pattern display tubesFluorescenceDisplay device

This is a flat displayer of bent shape low grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; on the cathode glass panel are a grid down-lead layer, carbon nanotube and bent shape low grid structure; a supporting wall between the anodic and cathode panel and a getter; which is capable of increasing the electron ejecting area of the nanotube and decreasing the working voltage of the rid.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with explosive star-typed cathode structure and its production

InactiveCN101075542AIncreased electron emission areaIncrease display brightnessImage/pattern display tubesDischarge tube/lamp detailsFluorescenceDisplay device

This is a flat displayer of star shape grid cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; on the cathode glass panel are a grid down-lead layer, carbon nanotube and star shape grid structure; a supporting wall between the anodic and cathode panel and a getter; which is capable of increasing electron ejecting efficiency of the nanotube and decreasing the working voltage of the rid and increasing the display quality.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Hackle sidegrid-controlled structure panel display and its manufacturing method

InactiveCN1971831AIncreased electron emission areaIncrease display brightnessControl electrodesElectrode and associated part arrangementsGratingFluorescence

This invention relates to one gear grating control plane display process, which comprises the following parts: cathode glass panel, cathode glass panel and circle glass frame to form sealed vacuum chamber; fluorescence layer on anode electrode layer with anode conductive layer on anode glass panel; supportive wall structure and air detrained assistant elements between anode glass panel and cathode glass panel; control grating electrode, carbon nanometer tube cathode and emission structure on cathode glass panel.

Owner:ZHONGYUAN ENGINEERING COLLEGE

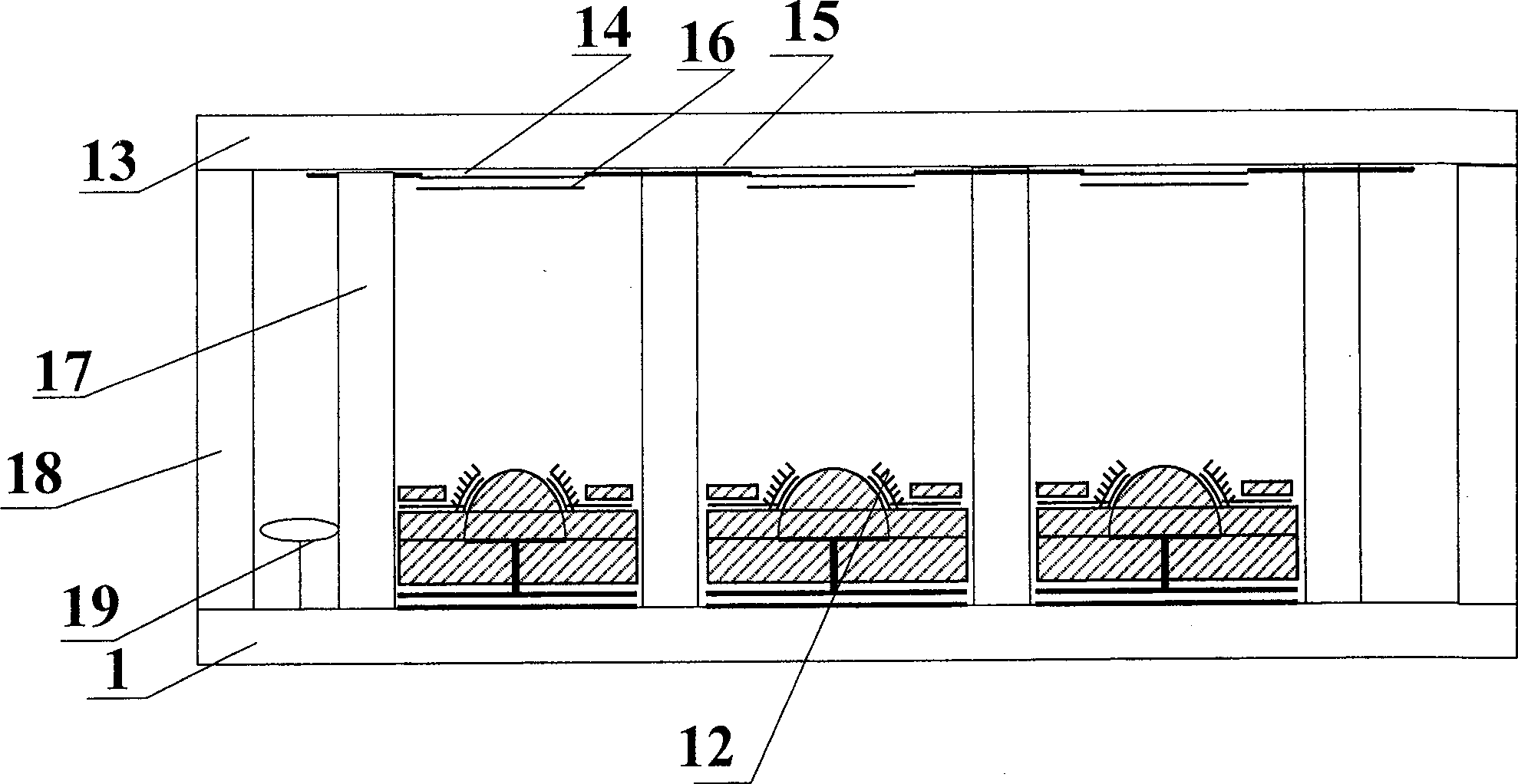

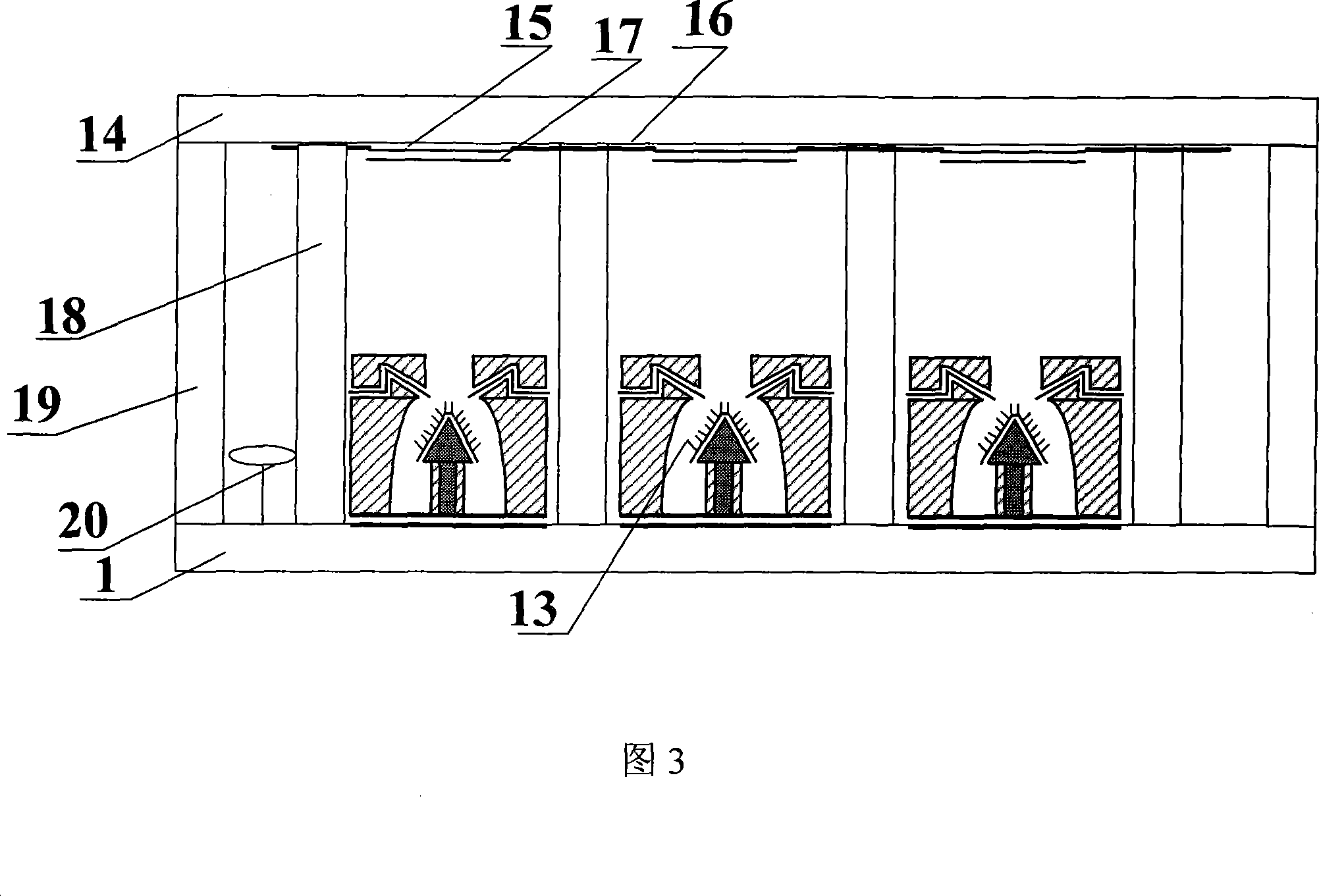

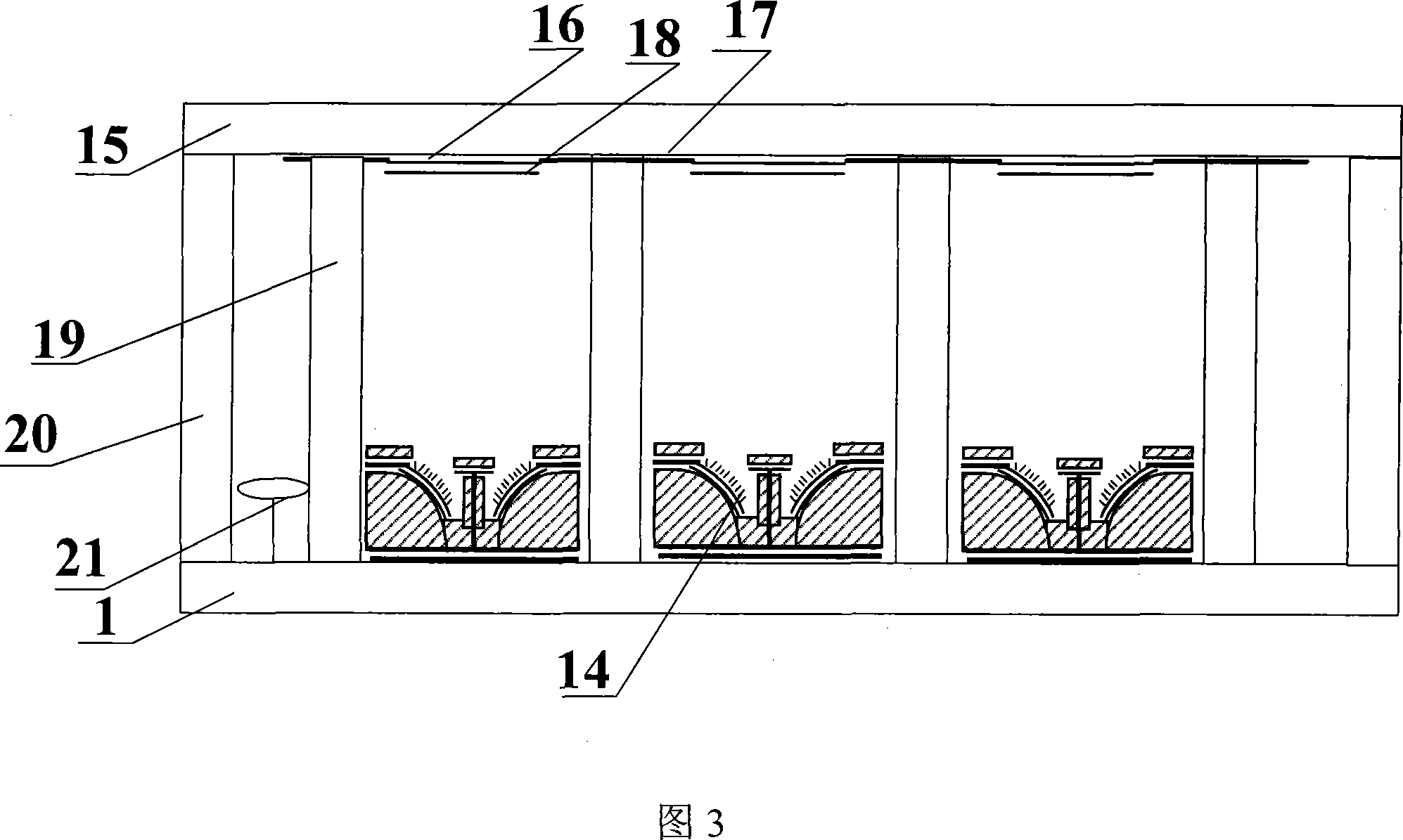

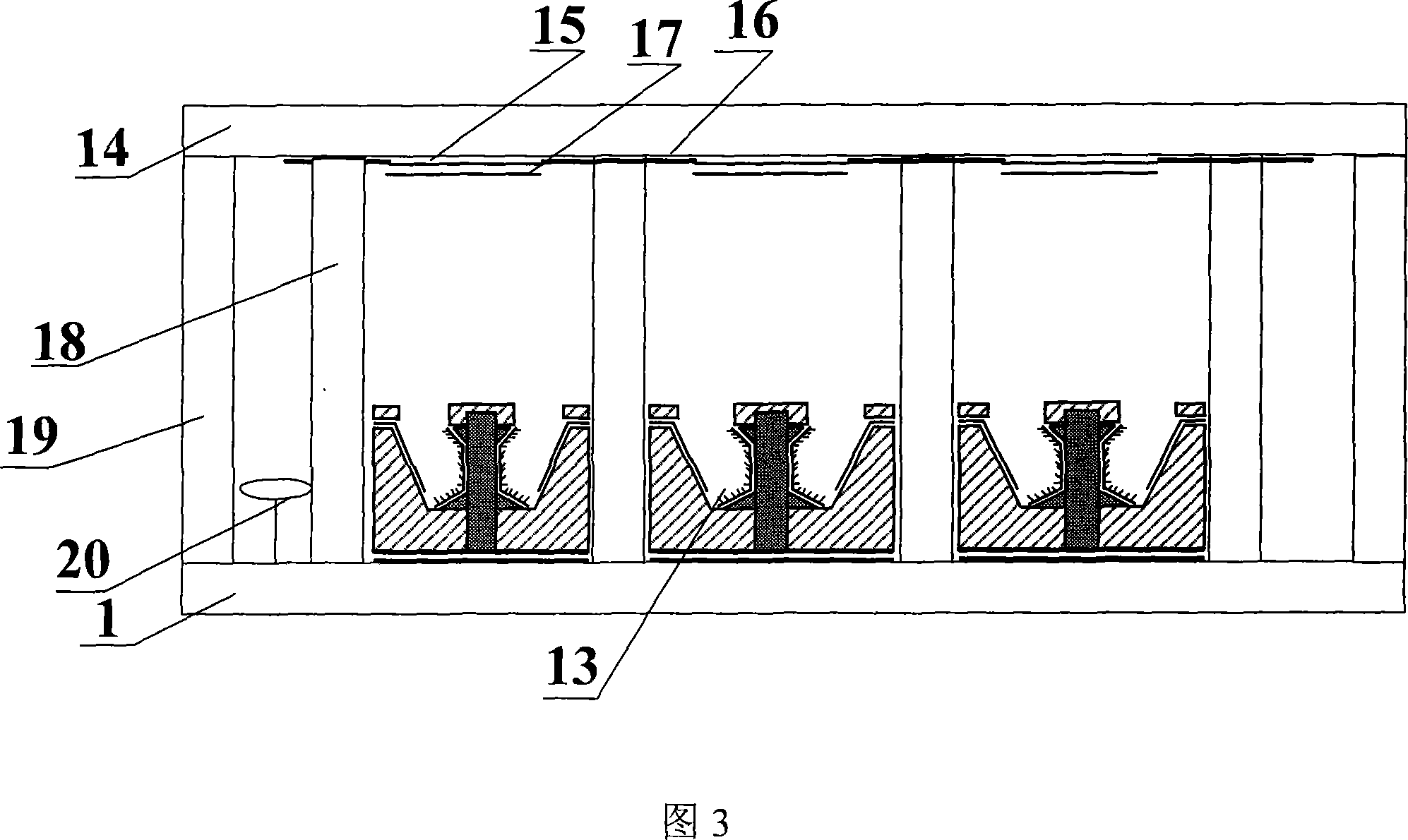

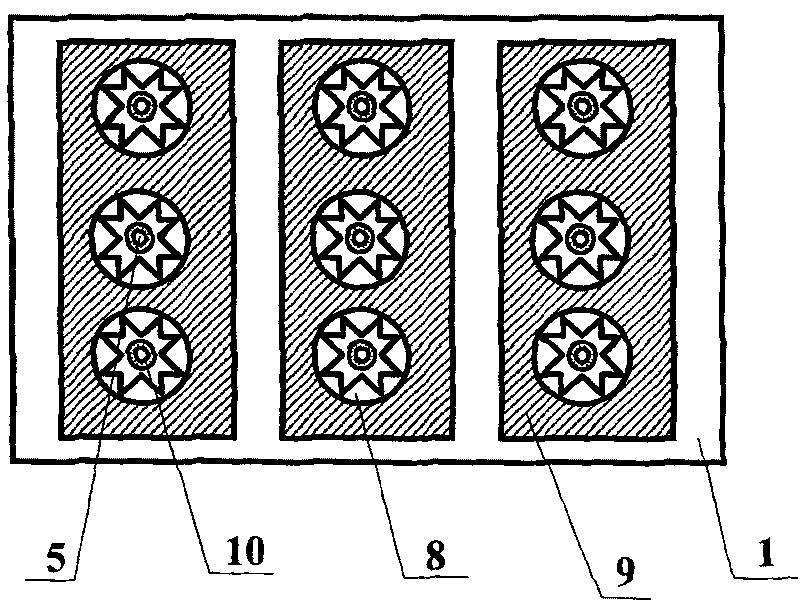

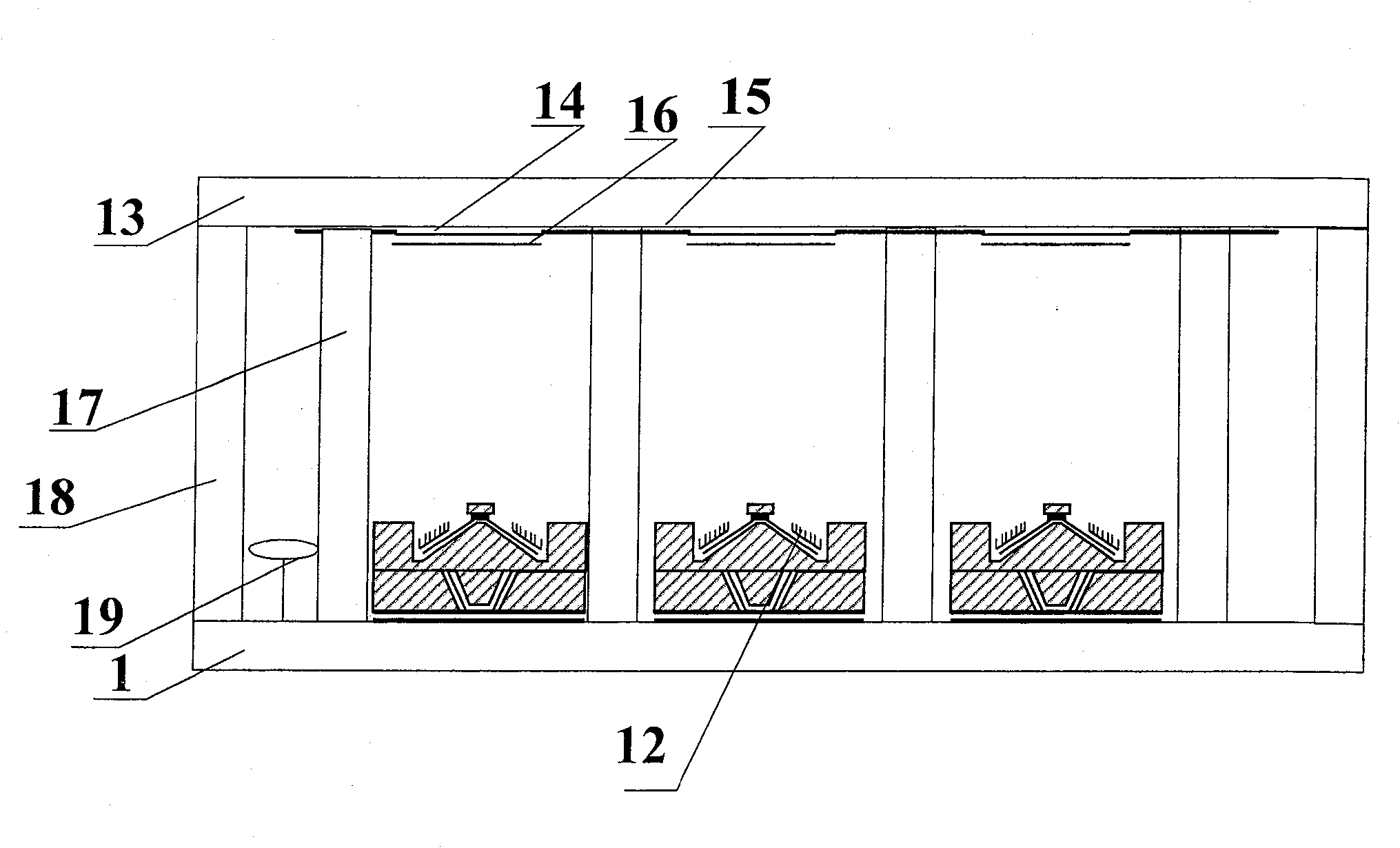

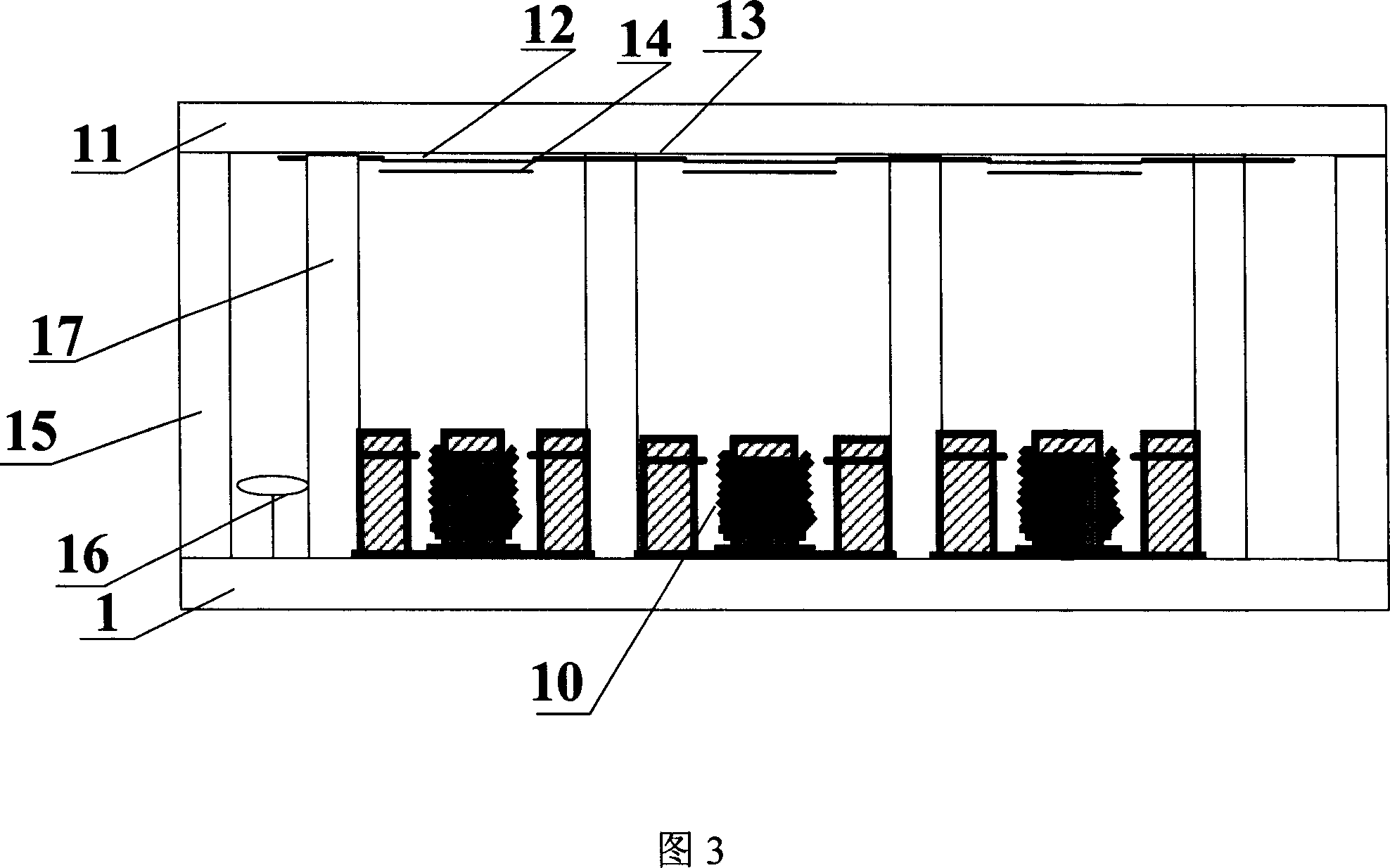

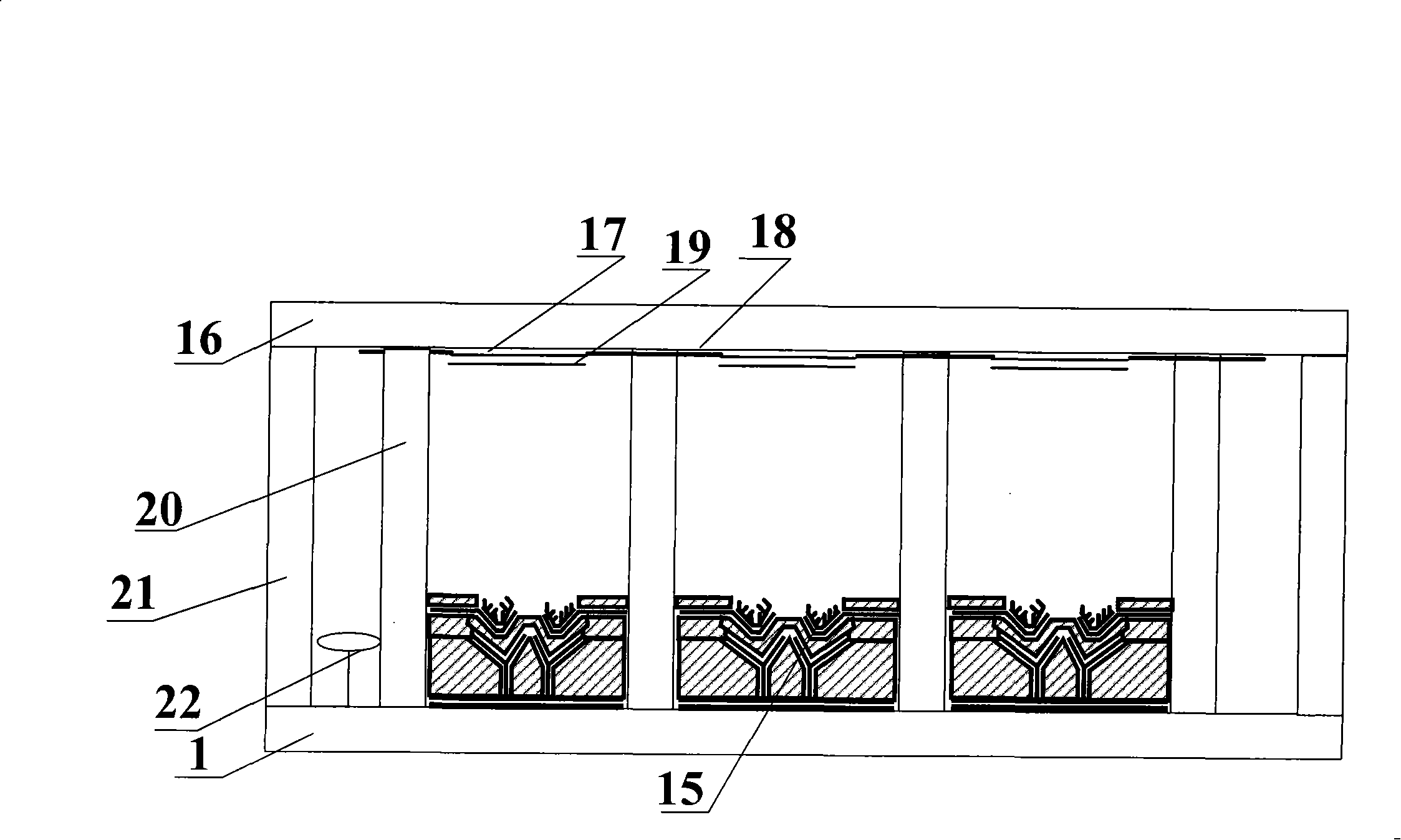

Flat panel display with branching control inflected arch cathode type structure and production process thereof

InactiveCN101226867ASmall working currentStrong control functionControl electrodesImage/pattern display tubesDisplay deviceCarbon nanotube

The invention relates to a flat panel display of cathode structure of branch controlled inverted arch and a fabrication process thereof, and the flat panel display comprises a sealed vacuum chamber formed by an anodic glass panel, a cathodic glass panel and peripheral glass enclosure frames, a supporting wall structure and an getter auxiliary element, wherein the anodic glass panel is provided with an anodic conductive layer and a fluorescent powder layer prepared on the anodic conductive layer and the supporting wall structure and the getter auxiliary element are arranged between the anodic glass panel and the cathodic glass panel, and the cathodic glass panel is provided with a grid lead wire layer, a carbon nanometer tube and the cathode structure of branch controlled inverted arch. The invention is capable of increasing the electronic emission area and the electronic emission efficiency of a cathode of the carbon nanometer tube and reducing grid voltage, and has the advantages of stable and reliable manufacturing process, simple fabrication process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with oblique flat-gate structure and its preparing process

InactiveCN100555546CIncrease display brightnessReduce gate currentControl electrodesImage/pattern display tubesCarbon nanotubeDisplay device

The invention relates to a flat-panel display with inclined flat grid structure and its manufacturing process, comprising a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; an anode conductive layer is arranged on the anode glass panel; Phosphor layer on top of the anode conductive layer; cathode conductive layer, carbon nanotubes and beveled flat grid type structure on the cathode glass panel; support wall structure and getter accessory elements between the anode glass panel and the cathode glass panel, The control function of the grid can be further enhanced, the working voltage can be reduced, and the electron emission efficiency and electron emission quantity of the carbon nanotube cathode can be improved at the same time, and the invention has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat panel display with dual forked type side controlled cathode emission structure, and fabricating technique

InactiveCN101093775ADemonstrate strong controlSmall working currentControl electrodesImage/pattern display tubesPhosphorCarbon nanotube

The flat panel display includes following parts: sealed vacuum cavity composed of glass faceplate of anode, glass faceplate of cathode, and glassed-in frame; anode conductive layer on the glass faceplate of anode, and phosphor layer on the anode conductive layer; the support wall structure between the glass faceplate of anode and the glass faceplate of cathode, and accessorial components for getter; lead wire layer of grid electrode, Nano carbon tube, and dual fork type cathode emission structure in side control setup on the glass faceplate of cathode. The invention enhances control function and control efficiency of grid structure, and raises efficiency and area of electron emission of cathode in Nano carbon tube. Advantages are: stable and reliable fabricating procedure, simple technique, low fabricating cost, and ordinary structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat panel display with dual forked type side controlled cathode emission structure, and fabricating technique

InactiveCN100561654CDemonstrate strong controlSmall working currentControl electrodesImage/pattern display tubesPhosphorCarbon nanotube

The invention relates to a double-fork type side-controlled cathode emission flat-panel display and its manufacturing process, including a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; an anode set on the anode glass panel A conductive layer and a phosphor layer prepared on the anode conductive layer; a support wall structure and an accessory component of a getter between the anode glass panel and the cathode glass panel; a grid lead layer, carbon nanotubes and Bifurcated side-controlled cathode emission structure; it can further enhance the control function and control efficiency of the gate structure, improve the electron emission area and emission efficiency of the carbon nanotube cathode, and has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost, and structural The advantage of simplicity.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with circular cross-angle lower gate-modulated cathode structure and its preparing process

InactiveCN101071745AIncreased electron emission areaIncrease the anode working currentControl electrodesImage/pattern display tubesCarbon nanotubeDisplay device

The invention relates to a flat-panel display of an annular twist angled lower grid-controlled cathode structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and annular twist angled lower grid-controlled cathode structure on the cathode glass panel; and it can reduce operating voltage of grid and raise electron emission efficiency of carbon nanotube cathode, and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Planar display device with reversed arced lower-grid controlled multi-sided cathode structure and its production

InactiveCN101075527AGuarantee stabilityStrong electric field strengthControl electrodesImage/pattern display tubesFlat panel displayGetter

This is a flat displayer of arc low grid multi-faces cathode structure and its production process. It includes a sealed vacuum chamber formed by a anodic glass panel, a cathode glass panel and surrounded glass frame; on the anodic glass panel is a conducting layer coated with fluorescent; a supporting wall between the anodic and cathode panel and a getter; on the cathode glass panel are a grid down-lead layer, carbon nanotube and arc low grid multi-faces structure, which is capable of increasing the efficiency of electron ejection by the nanotube and decreasing the working voltage of the grids.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with circular cross-angle lower gate-modulated cathode structure and its preparing process

InactiveCN100527344CIncreased electron emission areaIncrease the anode working currentControl electrodesImage/pattern display tubesDisplay deviceCarbon nanotube

The invention relates to a flat panel display with a ring prong angle lower grid-controlled cathode structure and its manufacturing process, including a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; it is arranged on the anode glass panel The anode conductive layer and the phosphor layer prepared on the anode conductive layer; the support wall structure between the anode glass panel and the cathode glass panel and the accessory components of the getter; there are grid lead layers, carbon nanotubes on the cathode glass panel And the lower grid-controlled cathode structure of ring prong angle; can reduce the working voltage of the grid, improve the electron emission efficiency of the carbon nanotube cathode, and has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with apex-angle down gate-modulated cathode structure and its preparing process

InactiveCN101071738AEnsuring strong controlsReduce capacitive effectControl electrodesImage/pattern display tubesCarbon nanotubeEmission efficiency

The invention relates to a flat-panel display of a sharp-angled lower grid-controlled cathode structure and the making process thereof, comprising: sealed vacuum cavity composed of anode glass panel, cathode glass panel, and peripheral glass frame; anode conducting layer on the anode glass panel and fluorescent powder layer prepared on the anode conducting layer; supporting wall structure and degassing agent auxiliary component between the anode glass panel and cathode glass panel; and grid lead layer, carbon nanotube and sharp-angled lower grid-controlled cathode structure on the cathode glass panel; and it can effectively reduce operating voltage of grid structure and raise electron emission efficiency of carbon nanotube and has advantages of stable and reliable making course, simple making process, low making cost, and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Flat-panel display device with two-side recess internal-cathode gate modulation structure and its preparing process

InactiveCN100527345CIncreased electron emission areaIncrease the anode working currentControl electrodesImage/pattern display tubesPhosphorDisplay device

The invention relates to a flat panel display with a ring prong angle lower grid-controlled cathode structure and its manufacturing process, including a sealed vacuum chamber composed of an anode glass panel, a cathode glass panel and surrounding glass frames; it is arranged on the anode glass panel The anode conductive layer and the phosphor layer prepared on the anode conductive layer; the support wall structure between the anode glass panel and the cathode glass panel and the accessory components of the getter; there are grid lead layers, carbon nanotubes on the cathode glass panel And the lower grid-controlled cathode structure of ring prong angle; can reduce the working voltage of the grid, improve the electron emission efficiency of the carbon nanotube cathode, and has the advantages of stable and reliable manufacturing process, simple manufacturing process, low manufacturing cost and simple structure.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com