Stereo chamber type storage and mixed match method common used for semifinished thread and finished thread

A technology for semi-finished and finished silk, which is applied in the field of shared three-dimensional box storage and blending of semi-finished and finished silk, which can solve the problem of unsuitable types, specifications, production models, and finished silk storage links combined into warehouses, storage cabinets and the number of electronic scales To reduce the complexity of equipment layout and control, improve effective utilization and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

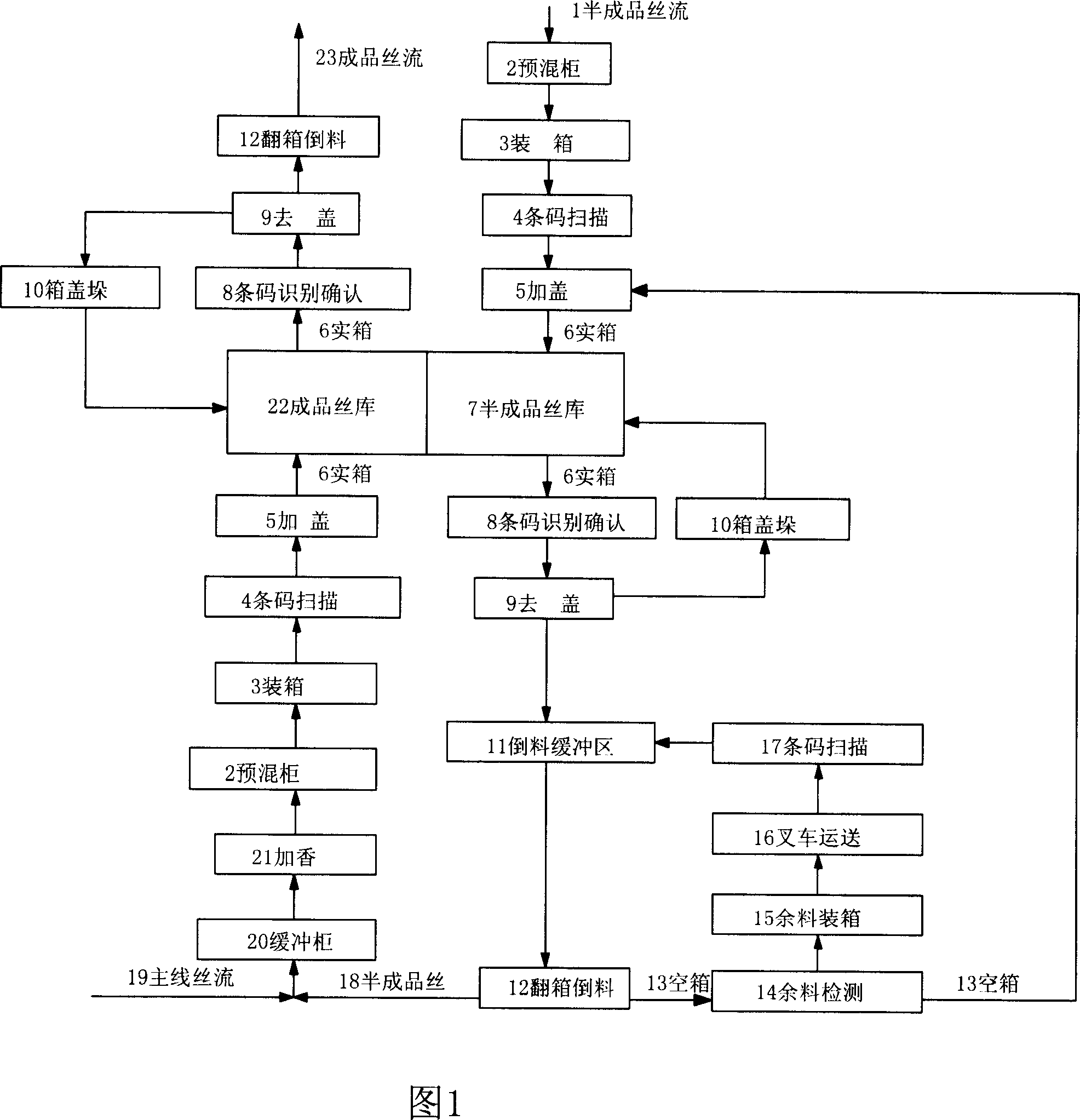

[0024] As shown in Figure 1, in the process flow diagram of the three-dimensional box-type storage and blending method shared by semi-finished silk and finished silk of the present invention, it shows the box-type storage process link and the combination of modern logistics and information technology in the tobacco factory silk production line. Blending link. The main technical feature of the present invention is that the box-type storage process and the blending process in the tobacco factory silk production line are organically combined with the box-type storage and blending process of semi-finished shredded tobacco and the box-type storage process of finished tobacco to form A complete semi-finished silk and finished silk together use a smaller ration as a unit, that is, use a storage box of 50-400 kg / box for storage and blending process system.

[0025] Shown in Fig. 1, main line silk stream 19, semi-finished silk stream 1, finished silk stream 23, semi-finished silk strea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com