Belt type super position material-distributing device and material-distributing method

A cloth device and belt-type technology, which is applied to supply devices, manufacturing tools, etc., can solve the problems of low production efficiency, inability to achieve the effect of laminating decorative cloth with pulp, complicated maintenance and debugging, etc., and achieve the effect of improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

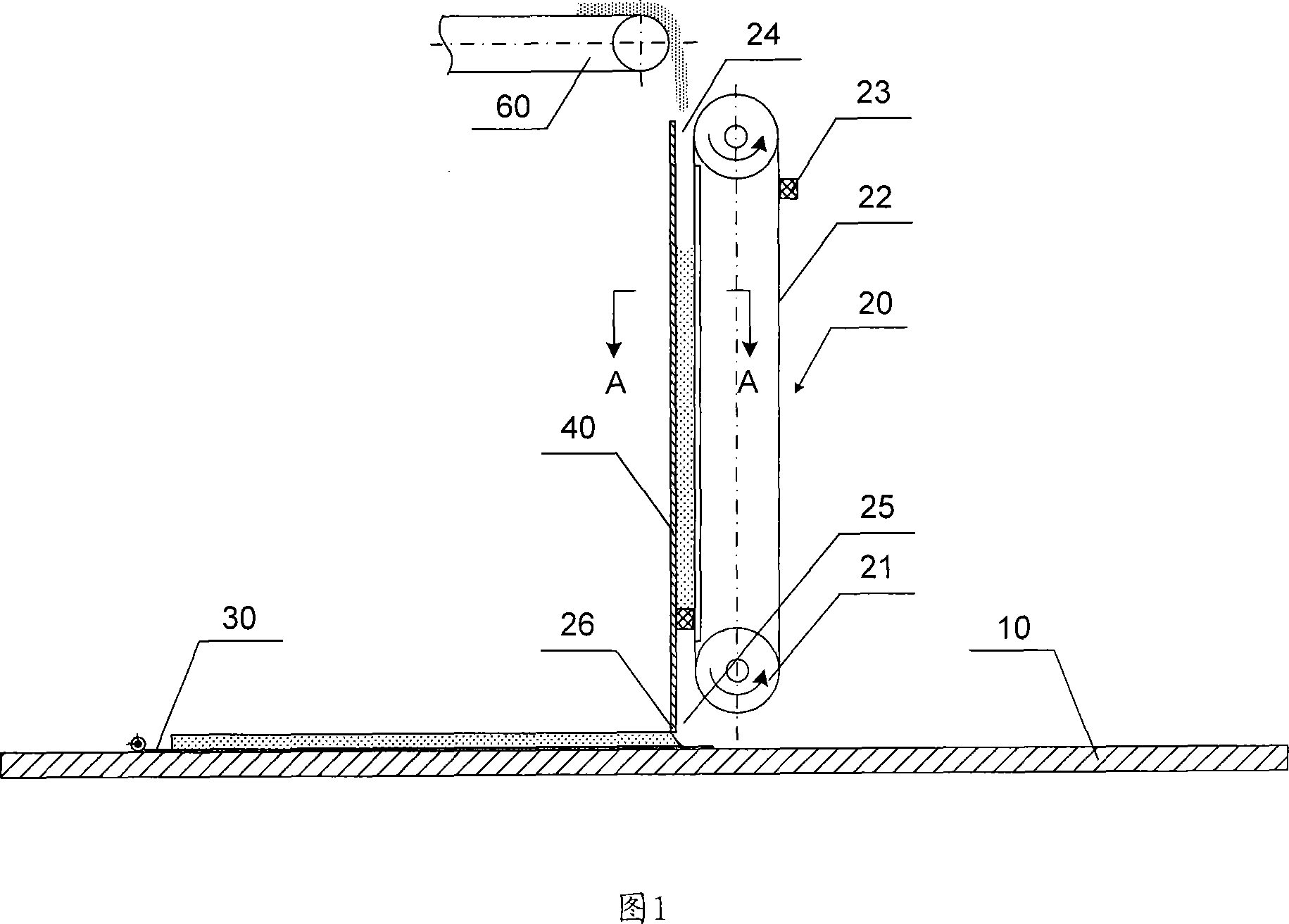

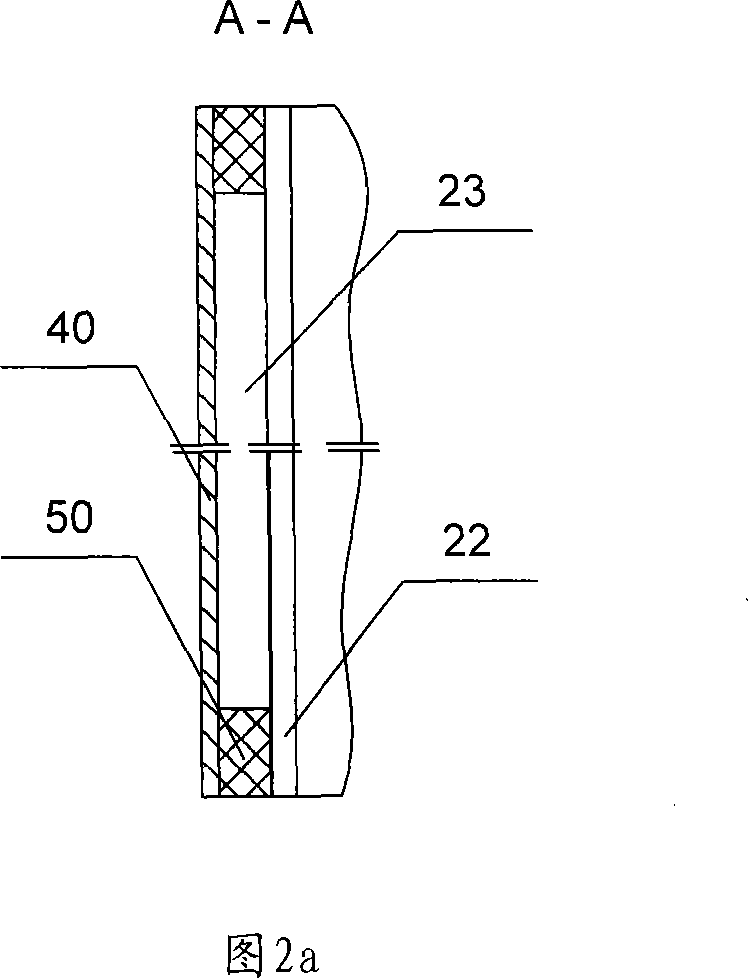

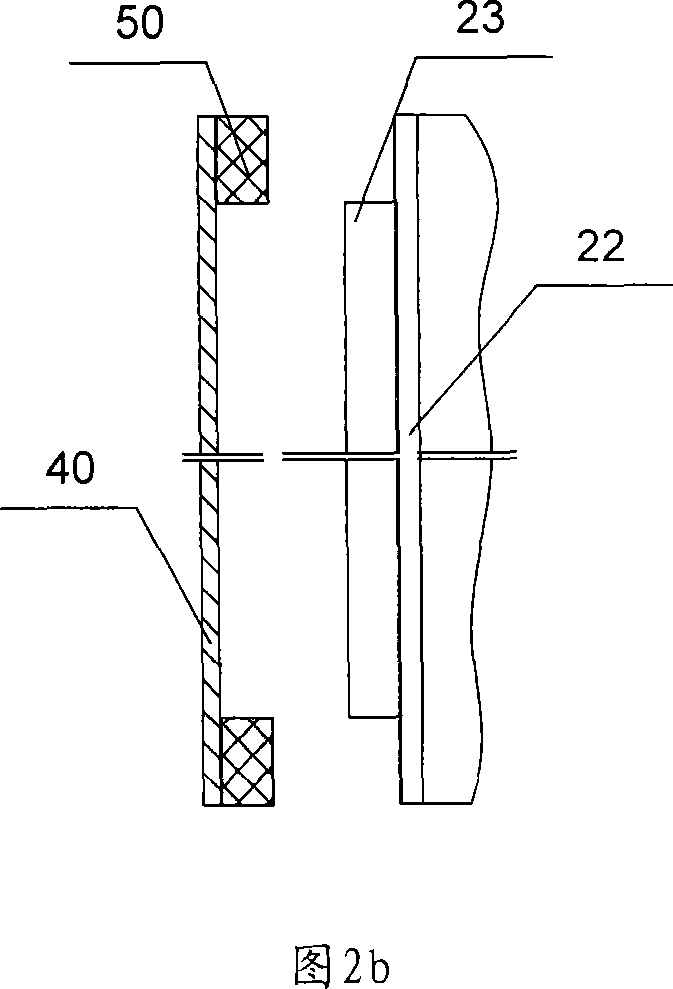

[0054] Fig. 1 is a structural schematic diagram of a belt-type superimposed distribution device of the present invention. As shown in FIG. 1 , the main structure of the belt-type superimposed material distribution device includes a belt conveyor 20 located above the conveying platform 10 , a side plate 40 , a filling device 60 and a powder carrier 30 located on the conveying platform 10 responsible for conveying powder. Belt conveyor 20 is provided with the belt 22 that can circulate transmission; Side plate 40 is positioned at the side of belt conveyor 20, and the both sides on one side towards belt conveyor 20 are respectively provided with retaining bar 50, makes side plate 40, belt 22 and two The side bar 50 forms a closed enclosure around; the belt 22 is fixedly connected with at least one spacer 23, and the belt 22 drives the spacer 23 to enter the enclosure from the upper part of the enclosure, so that the upper part of the enclosure forms a spacer with an upper filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com