Multiple layer facing machine

A veneer machine and frame technology, applied in the direction of mechanical processing/deformation, can solve problems affecting normal operation, lower production efficiency, difficult debugging and maintenance, etc., to achieve easy debugging and maintenance, high production efficiency, and lamination accuracy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

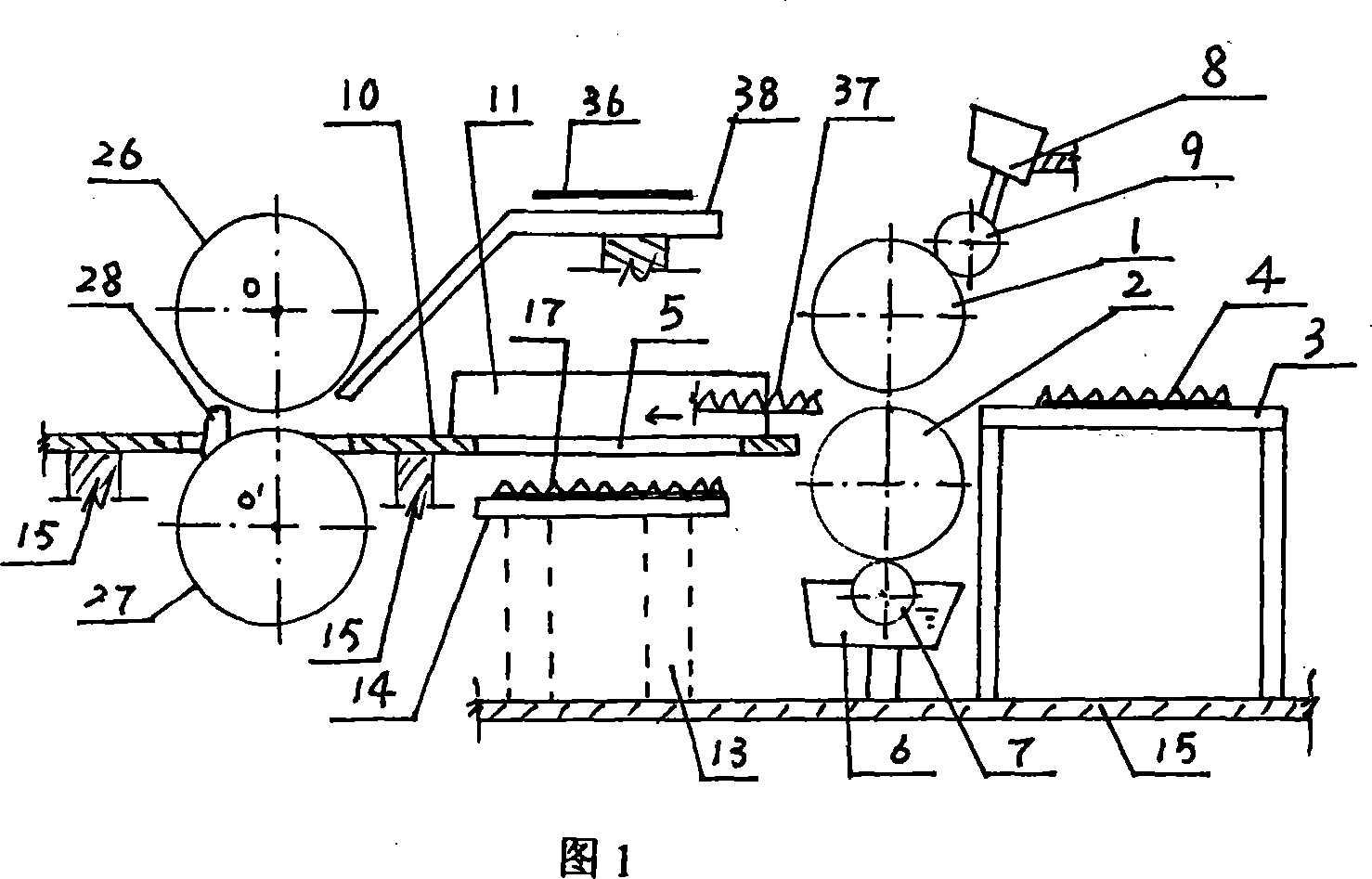

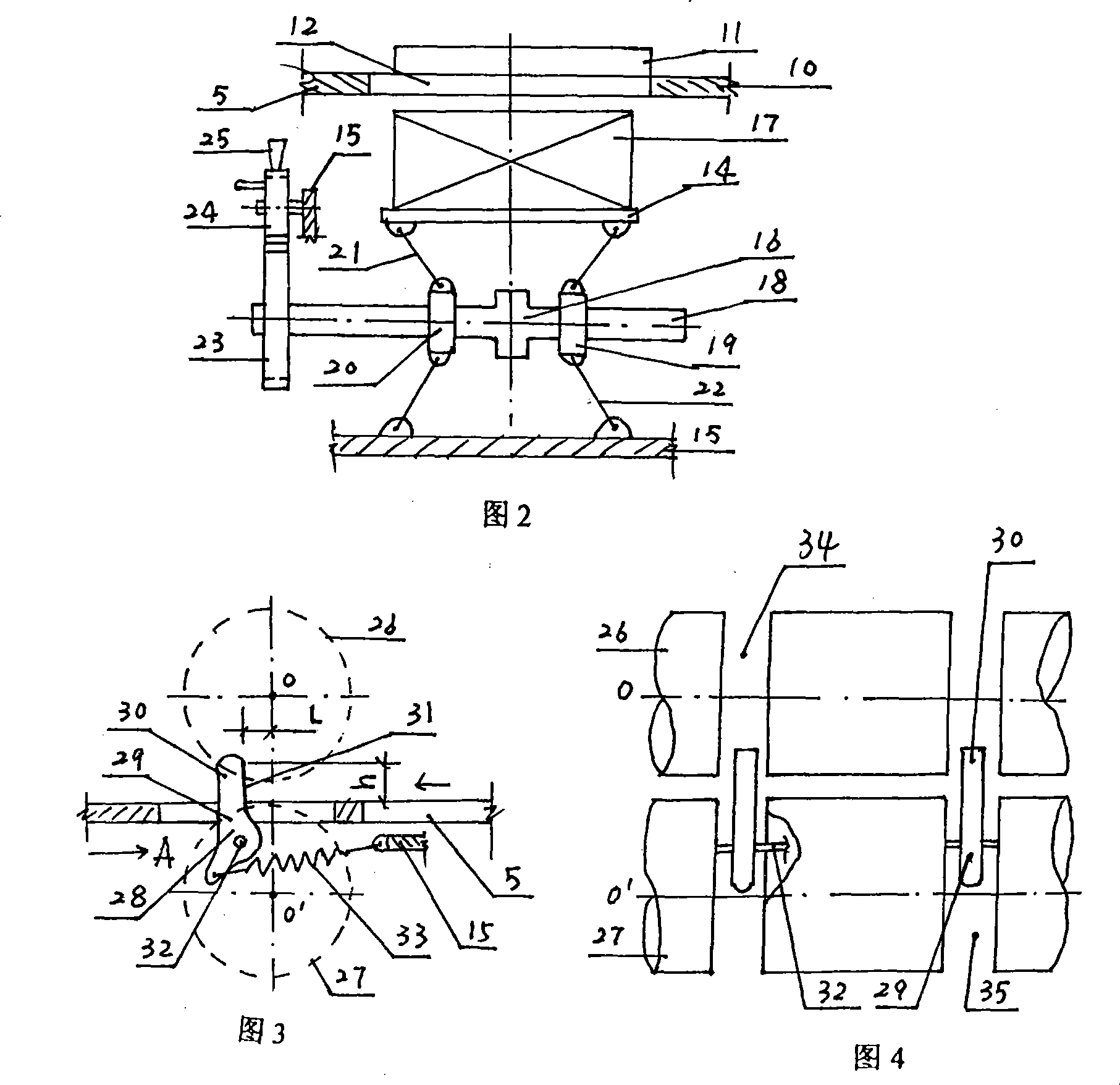

[0013] Further explain in detail in conjunction with accompanying drawings;

[0014] The arrow above the gummed paper bridge 5 in Figures 1 and 3 shows the direction in which the backing paper advances;

[0015] As shown in Figure 1, the upper glue roller 1 and the lower glue roller 2 are opposite to each other and rotate synchronously and reversely, so that the upper bottom paper 4 conveyed from the bottom paper table 3 can be glued on both sides and then transported to the glued paper On the bridge 5; the glue leveling device is as follows, with a glue box 6, a matching lower rubber roller 7 in the box, the rubber roller is associated with the lower rubber roller 2, and the glue is glued by the lower rubber roller 7. The glue in the liquid tank 6 is automatically evenly distributed to the lower rubber roller 2; it also has an upper rubber roller 9 that automatically distributes the glue sent by the glue supply device 8 to the upper rubber roller 1; the glue tank 6 , the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com