A wind channel heat radiator

A heat sink and air duct technology, which is applied in the field of air duct heat sinks, can solve problems such as limited heat dissipation area of aluminum substrates, rising LED chip temperature, and shortened service life, so as to reduce LED light decay, improve luminous efficiency, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

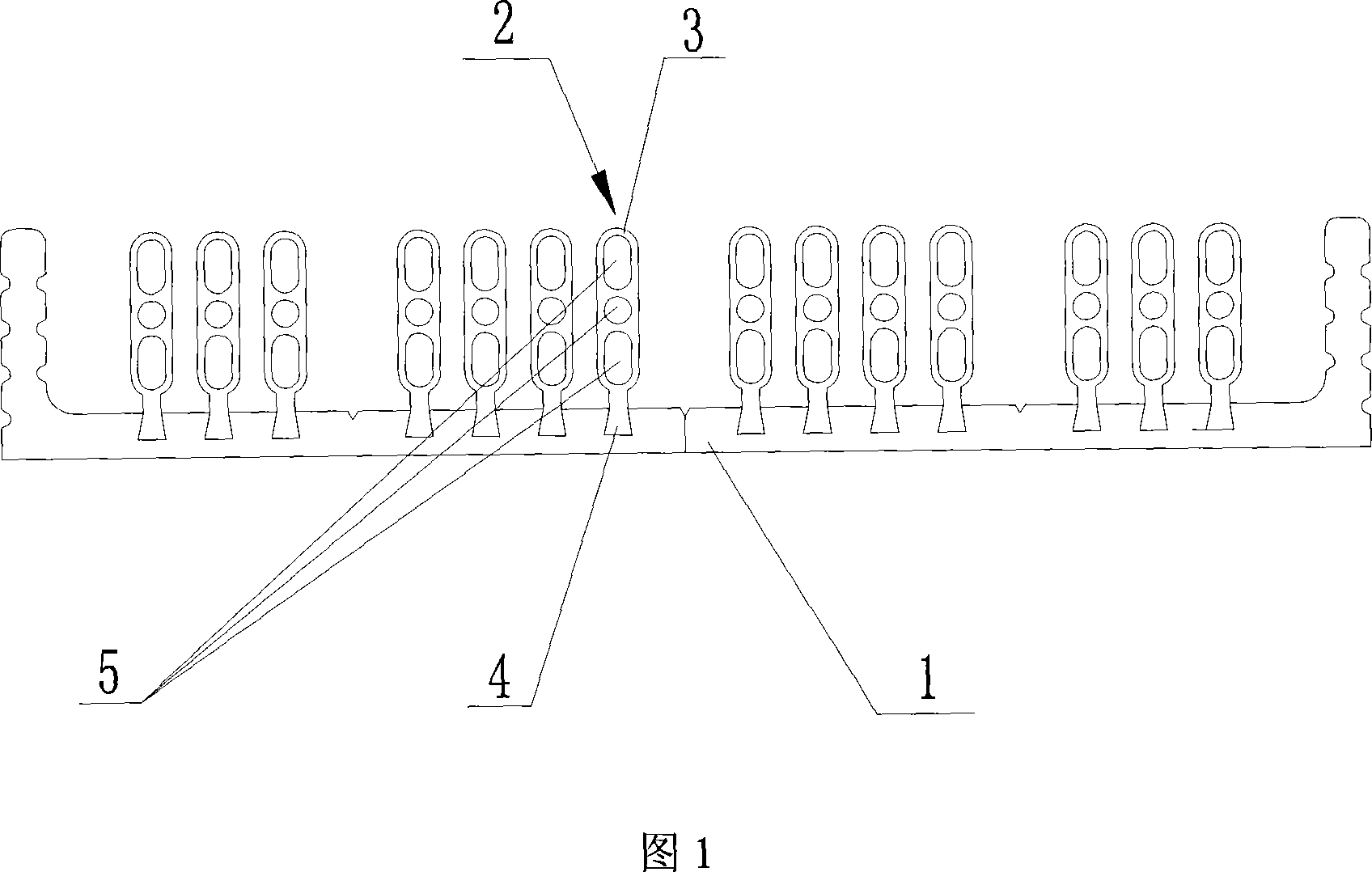

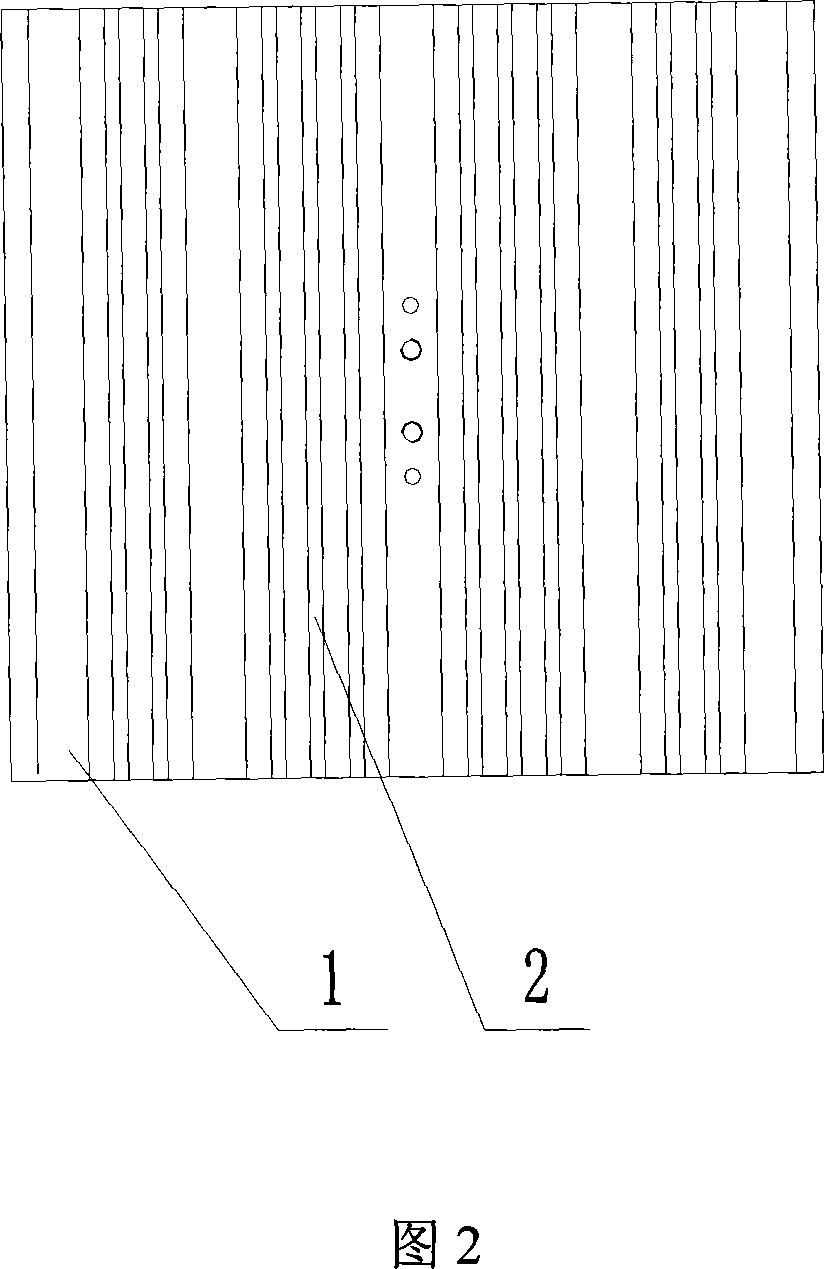

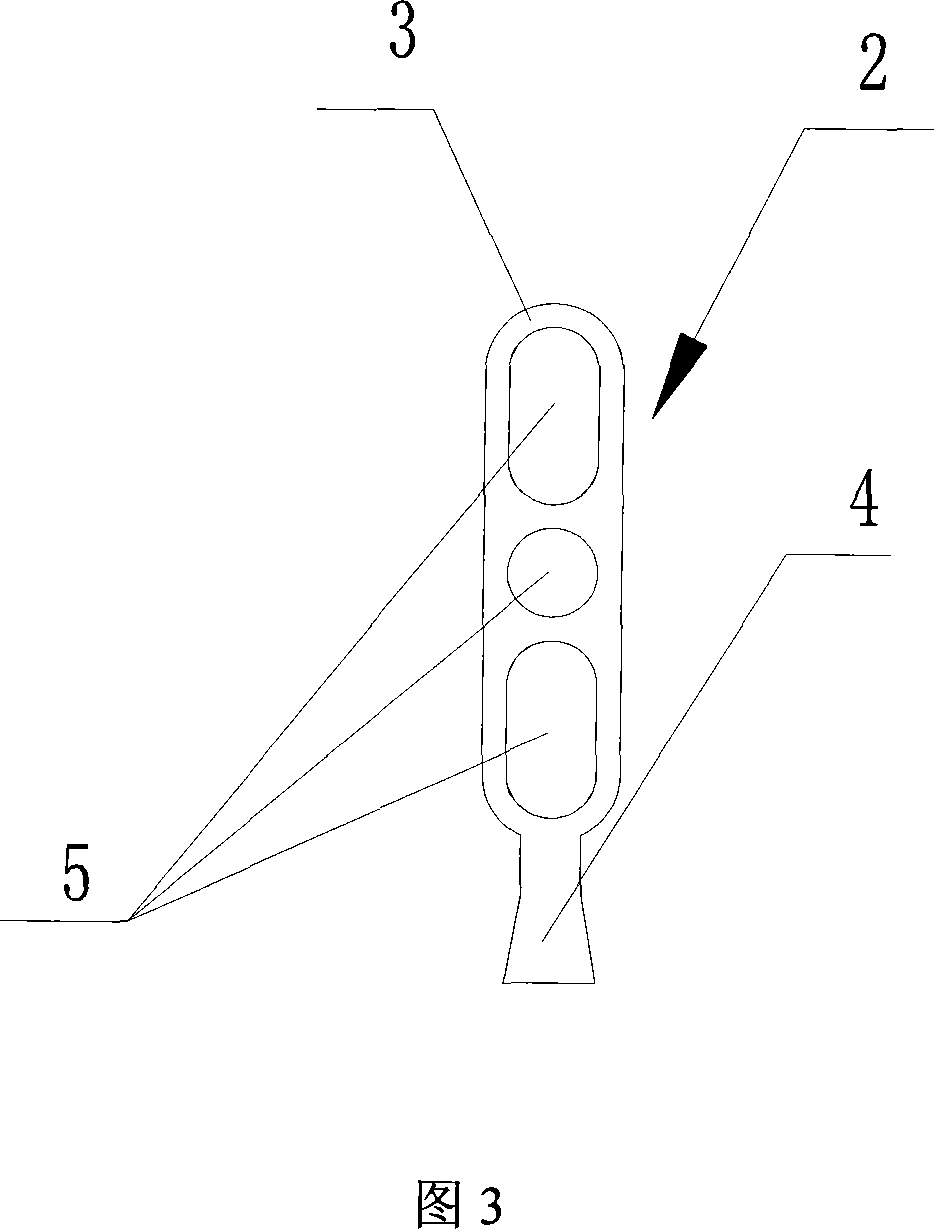

[0018] Several dovetail grooves of the same shape are evenly opened on the heat sink 1 at the same interval. The fin 3 of the air duct type heat sink is provided with three air ducts 5 from top to bottom. The rear ends are inlet and outlet. The air duct radiating fins 4 are integrally arranged at the lower end of the fin body 3. Its shape corresponds to the shape of the dovetail groove on the heat sink 1, and the air duct radiating fin 2 is embedded through it. The strip 4 is vertically embedded on the heat dissipation plate 1 with thermal conductive glue between the two, and also includes a bracket which is movably connected to the two ends of the heat dissipation plate 1 by screws.

Embodiment 2

[0020] Several rectangular grooves of the same shape are evenly opened on the heat sink 1 at the same interval. The fin 3 of the air duct type heat sink on the heat sink 1 is provided with two air ducts 5 from top to bottom. The front and rear ends of the fin body 3 are inlet and outlet, and the shape of the fillet 4 of the air duct type heat sink corresponds to the shape of the rectangular groove on the heat sink 1; the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com