Ignition system and flame probe system

An automatic ignition and flame detection technology, applied in spark gaps, circuits dedicated to spark gaps, electrical components, etc., can solve the problems of inaccurate fire detection signal attenuation measurement, inability to achieve long-distance ignition control, etc. the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

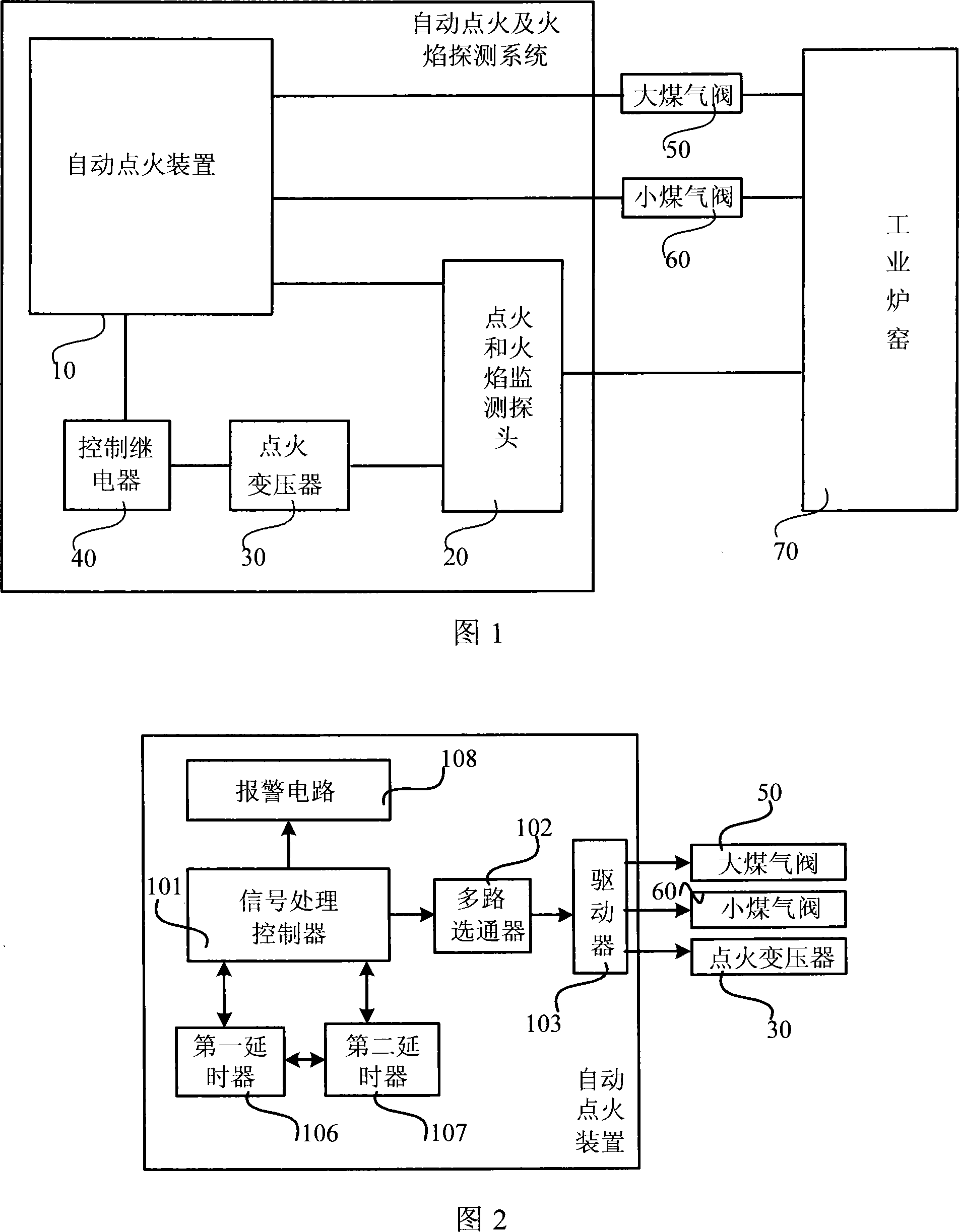

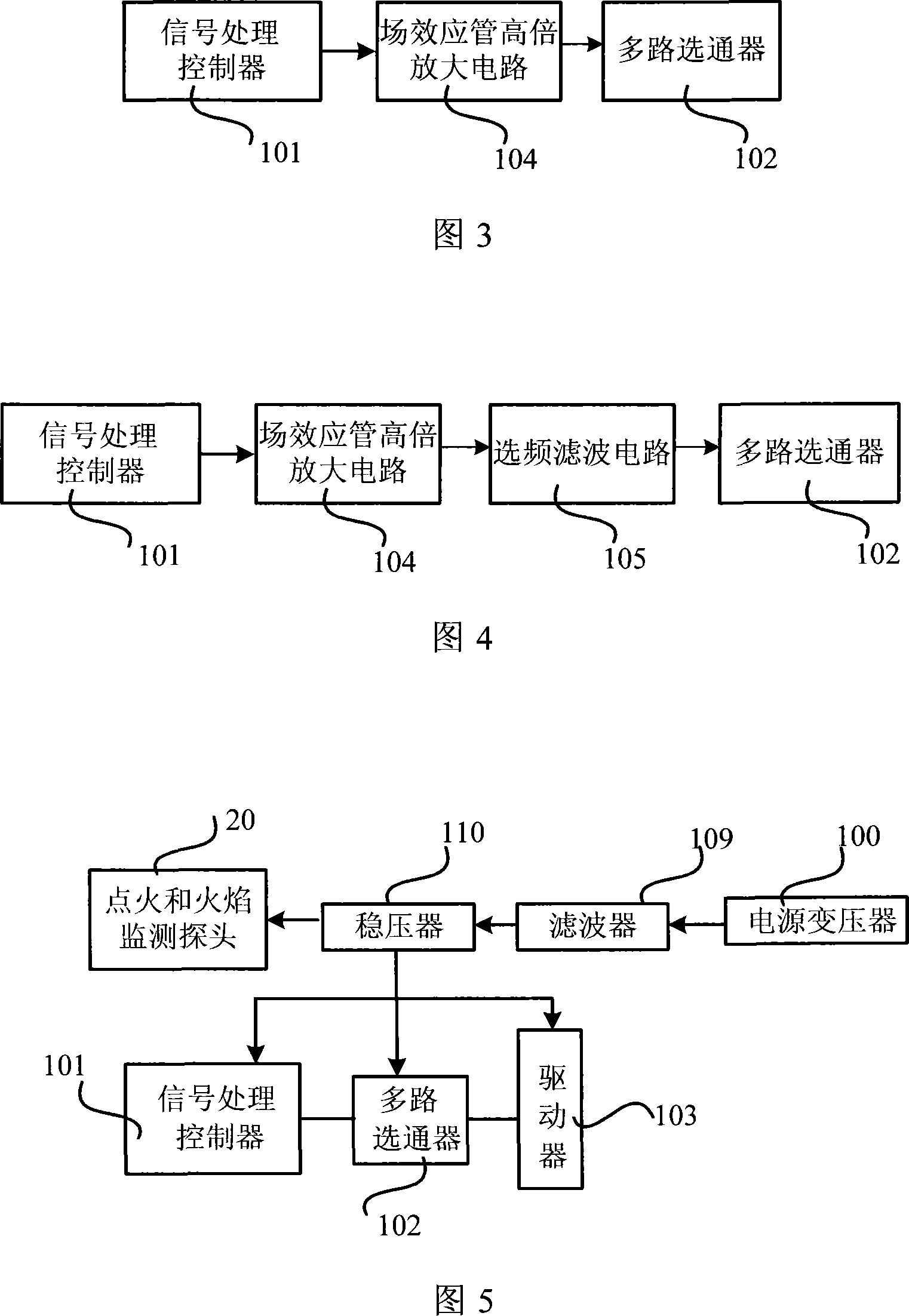

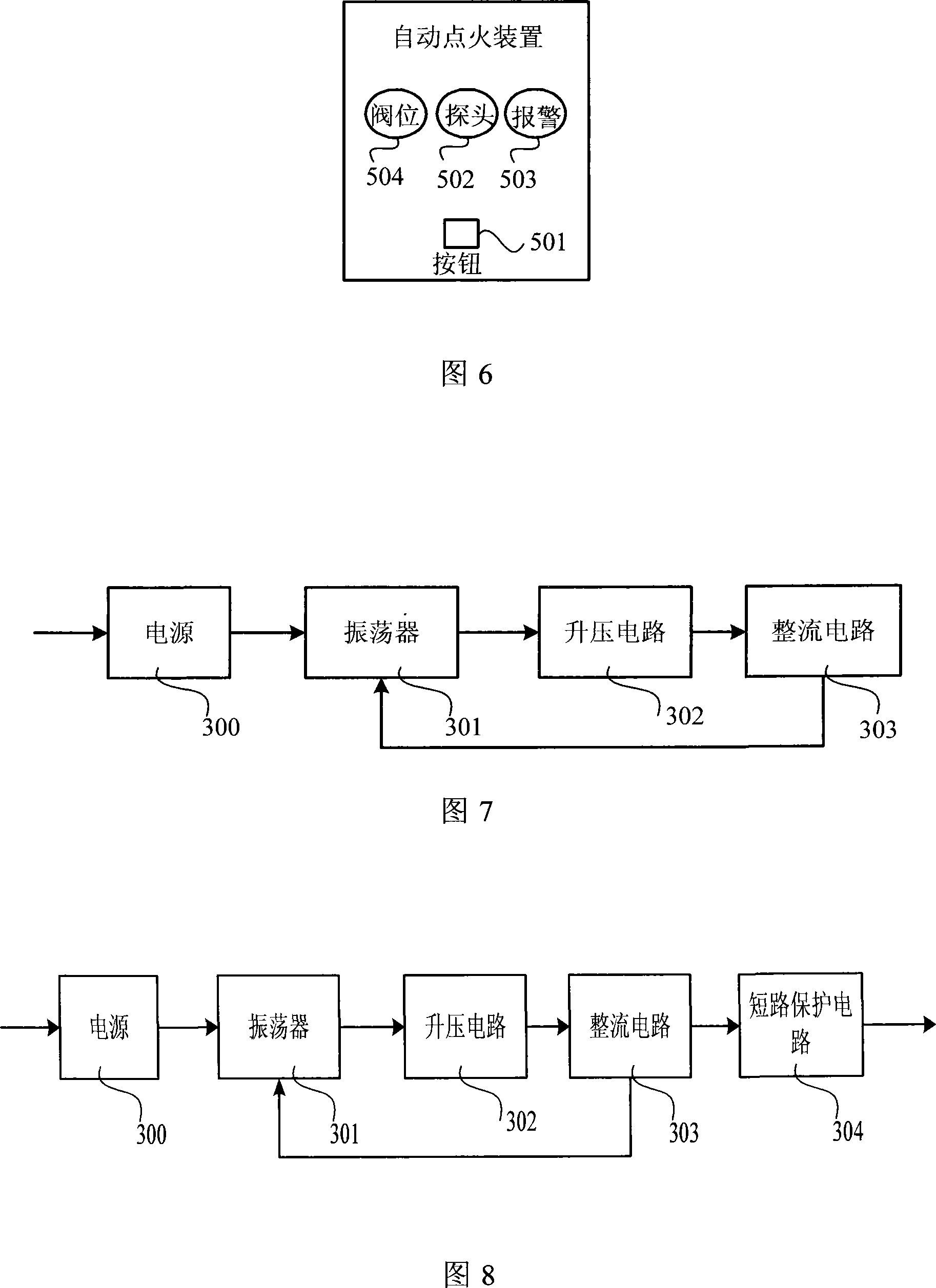

[0043] As shown in Figure 1, it is a schematic structural diagram of an automatic ignition and flame detection system of the present invention, including an automatic ignition device 10 for initiating an ignition control signal, opening a corresponding channel according to the ignition control signal; The signal is amplified and output; the ignition transformer 30 is connected to the automatic ignition device 10 through the control relay 40, and is used to drive the control relay to pull in when the automatic ignition device 10 passes the output amplified high-level voltage signal When the power is turned on, the input DC voltage is subjected to high-frequency oscillation, boosting, and rectification to generate a DC high voltage; the ignition and flame monitoring probe 20 is connected with the ignition transformer 30 and the automatic ignition device 10 for receiving the The DC high voltage generates ion flow, monitors the flame condition, and outputs a flame feedback signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com