Planetary clutch type self-control winding machine

A clutch-type hoist technology, applied in the field of hoist, can solve problems such as unsafe, labor-intensive, etc., and achieve the effect of strong adaptability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

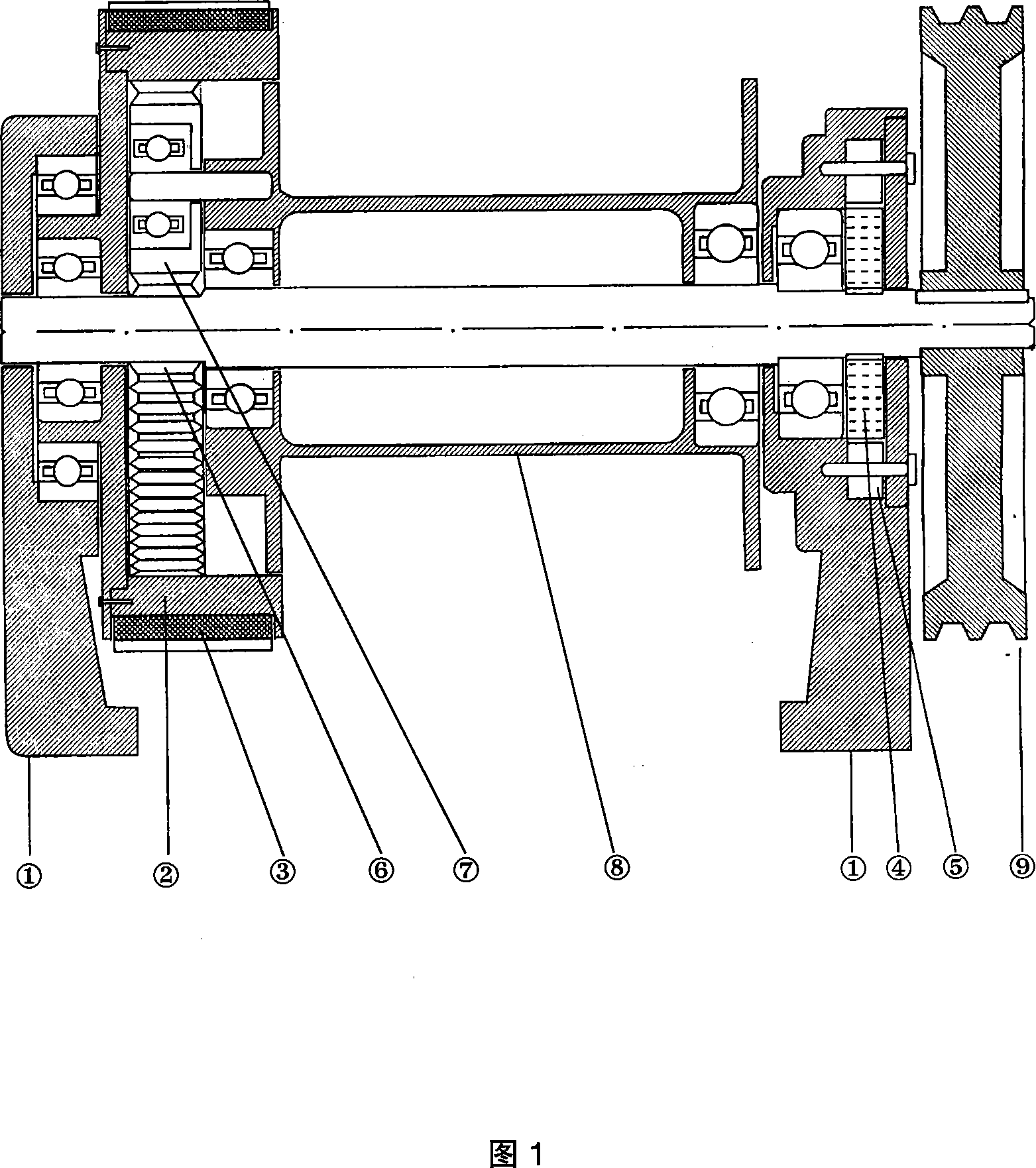

[0011] Figure 1 is a two-stage variable speed planetary clutch eye-controlled winch, the spool shaft is supported by the bearing seat ①, the ring gear ② is indirectly combined with the frame by the friction belt ③; the ratchet energy ④ is fixed on the spool shaft by a key On the upper side, the pawl ⑤ is fixed on the bearing seat ① by the rotating shaft and is correspondingly combined with the ratchet ④. The sun gear ⑥ is the gear with the smallest number of teeth on the reel shaft. On the reel, the pulley ⑨ is keyed to the other end of the reel shaft.

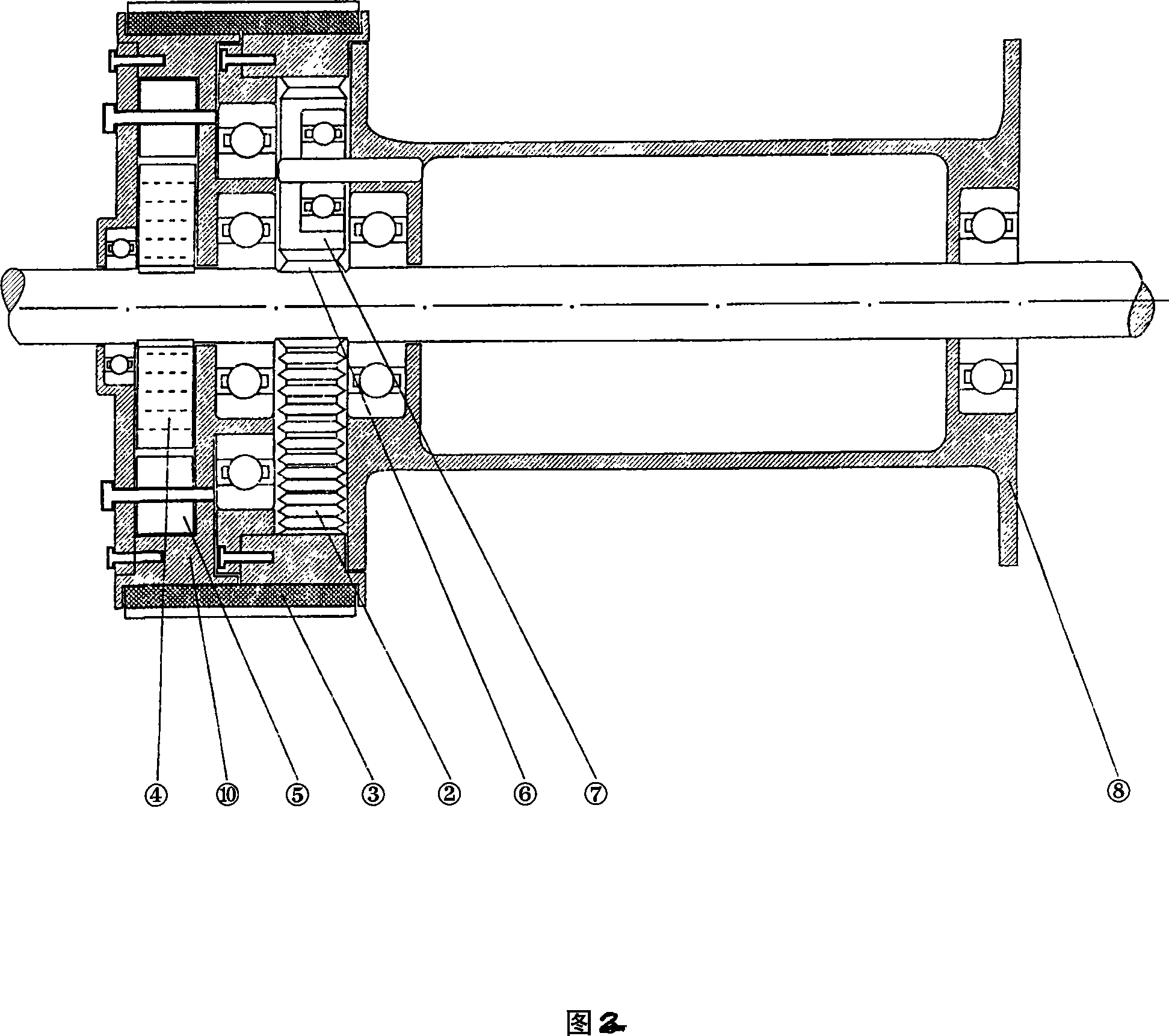

[0012] In Figure 2, the friction wheel ⑩ is sleeved on the spool shaft by the bearing, and the pawl ⑤ can be combined with the ratchet wheel fixed on the spool shaft correspondingly, and is the tooth of the planetary clutch mounted on the spool ⑧. The rings ② are juxtaposed on the same end and can rotate relative to each other, and the force of receiving the friction belt ③ is controlled by the same handle.

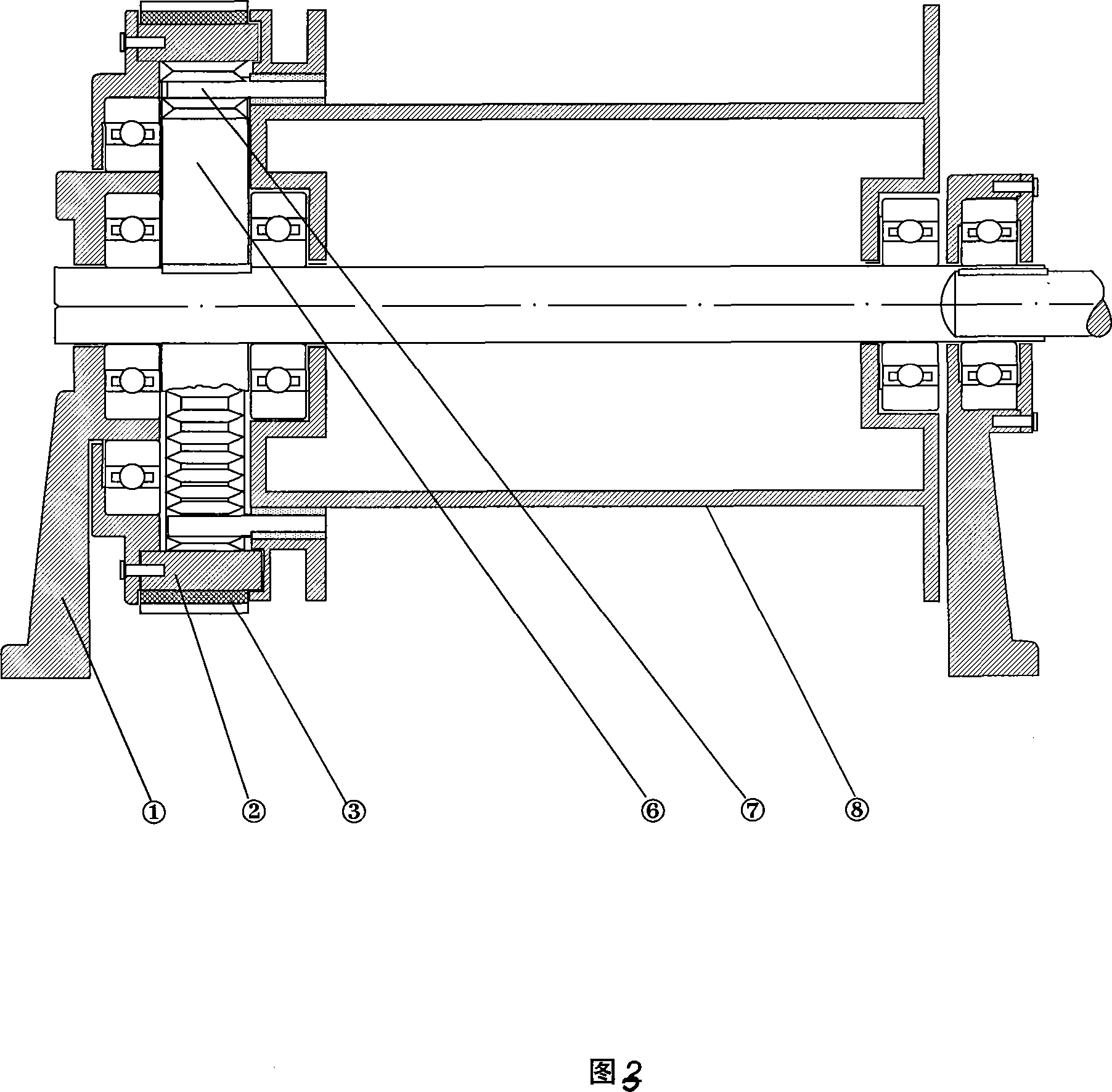

[0013] In Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com