Spatial crank rocker weft insertion device for rapier loom

A technology of crank rocker and weft insertion mechanism, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high manufacturing cost, many transmission links, excessive size, etc., and achieves simple and compact structure, stable and reliable movement, The effect of convenient machining of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

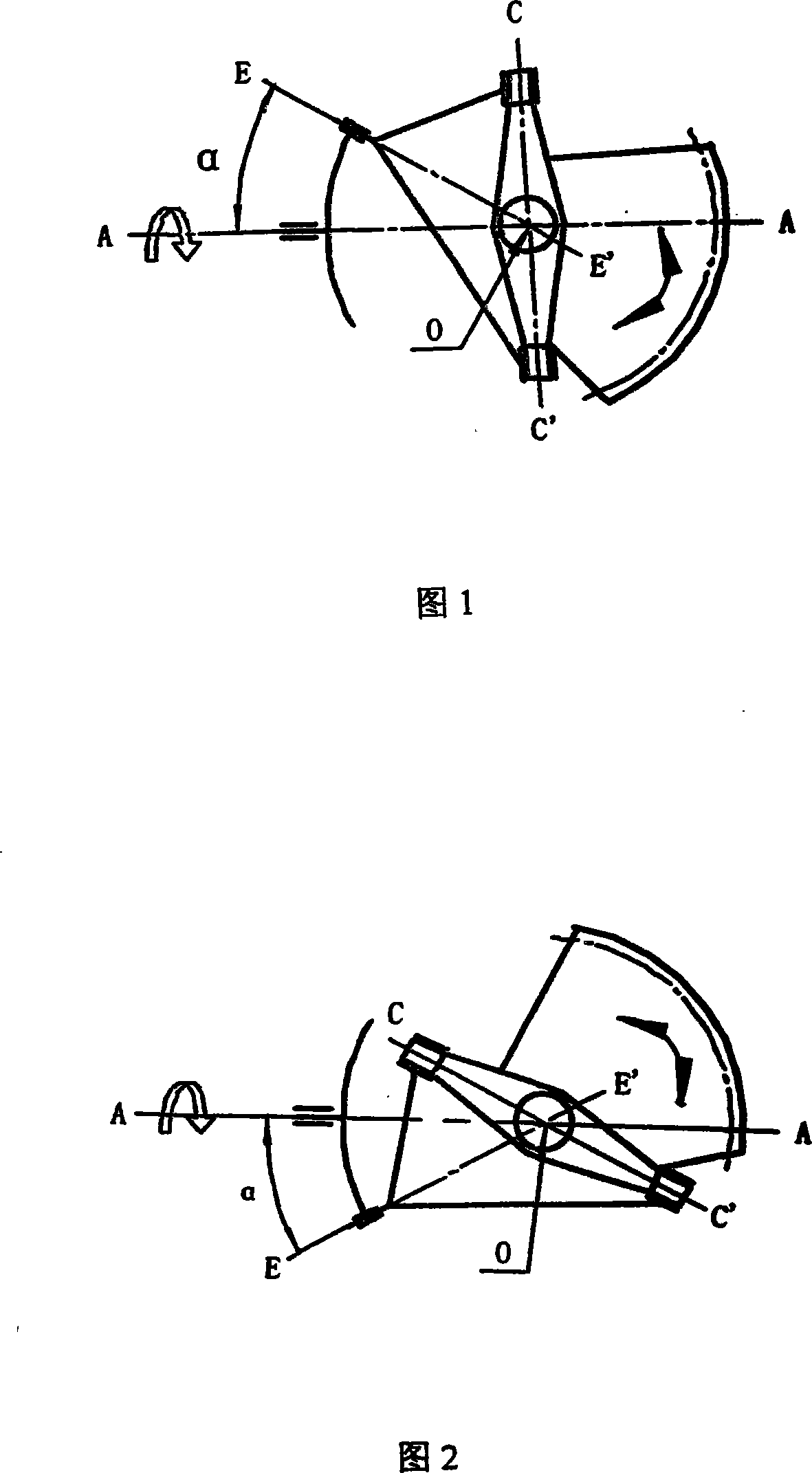

Method used

Image

Examples

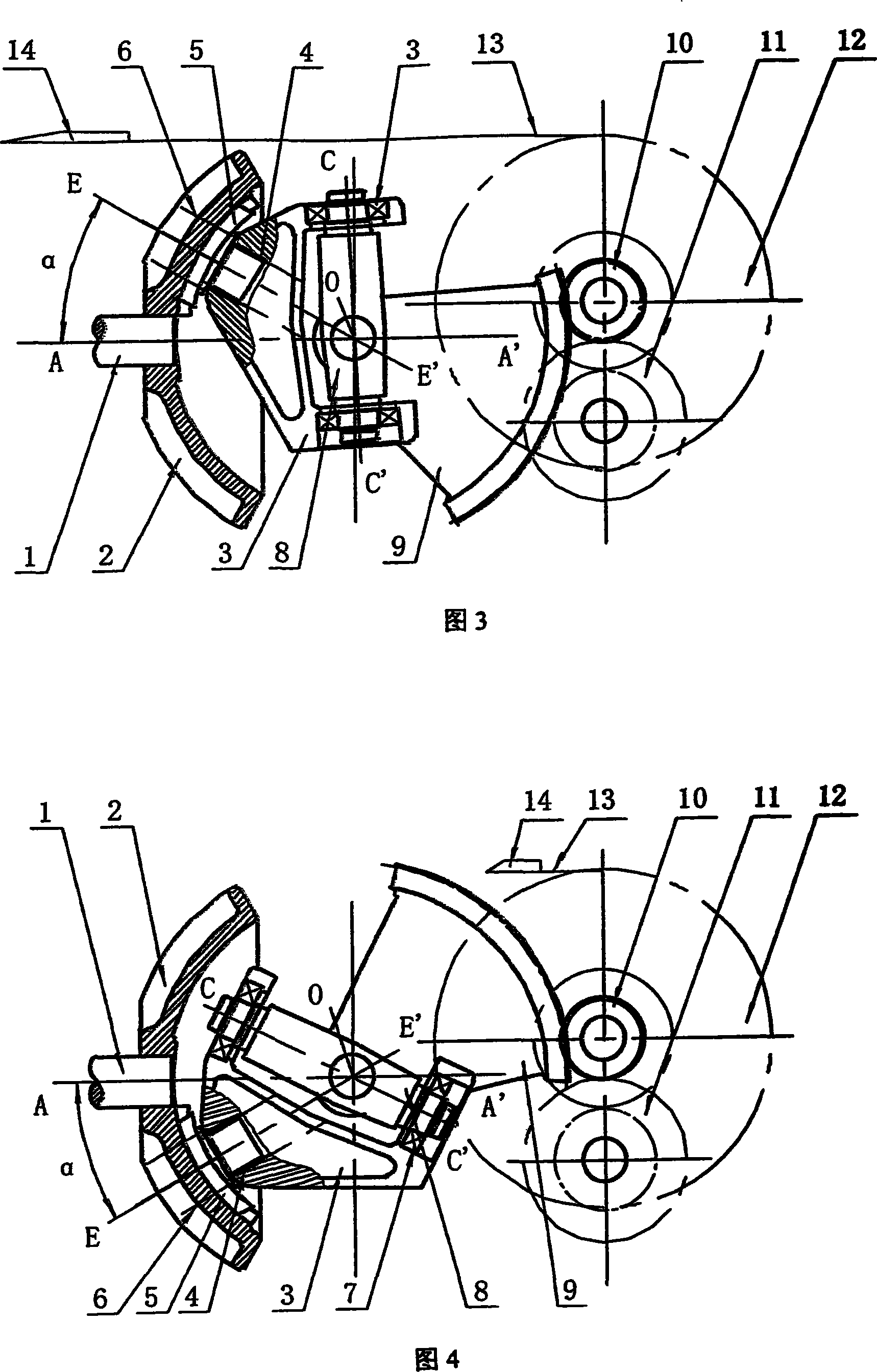

Embodiment 1

[0020] 3 and 4, the present invention is a space crank rocker weft insertion mechanism for a rapier loom, which is mainly composed of a main shaft 1, a crank rocker mechanism, a gear pair 11, a shaft gear 10 and a sword transmission wheel 12. . The crank-rocker mechanism is mainly composed of a crank 2 , a cradle 3 , a swinging body 8 and a sector gear 9 . The end face of the crank 2 is spherical, the middle of the crank 2 is connected to one end of the main shaft 1, the shaft end of the cradle 3 is connected to the crank 2 through the rolling bearing 4, the slider 5 and the screw 6, and the two shaft ends of the swing body 8 are connected to the cradle through the rolling bearing 7. 3 is connected, the swing body 8 is fixed with a sector gear 9, the sector gear 9 meshes with the shaft gear 10, or meshes with the shaft gear 10 through the gear pair 11, the shaft gear 10 is coaxial with the sword transmission wheel 12, and the sword transmission wheel 12 is The drive parts of ...

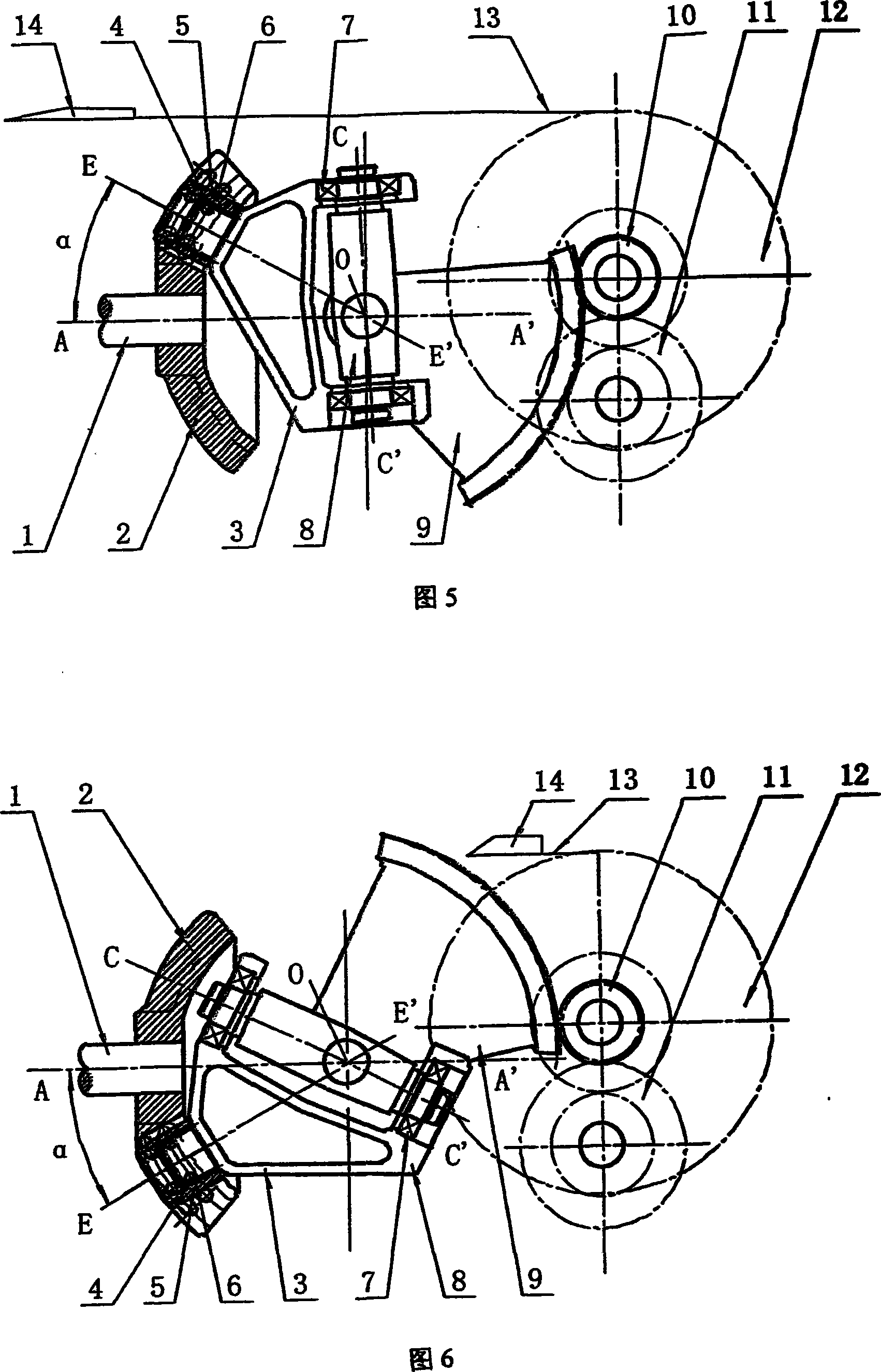

Embodiment 2

[0025] 5 and 6, the difference between this embodiment and Embodiment 1 is that a groove is provided in the crank 2, the slider is fixedly connected in the groove with a screw 6, and the rolling bearing 4 is embedded in the slider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com