Mining hard alloy coal cutting teeth

A technology of hard alloy and coal cutting teeth, which is applied in cutting machinery and other directions, can solve problems such as rock dust discharge, achieve the effects of prolonging service life, protecting health, and improving continuous work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

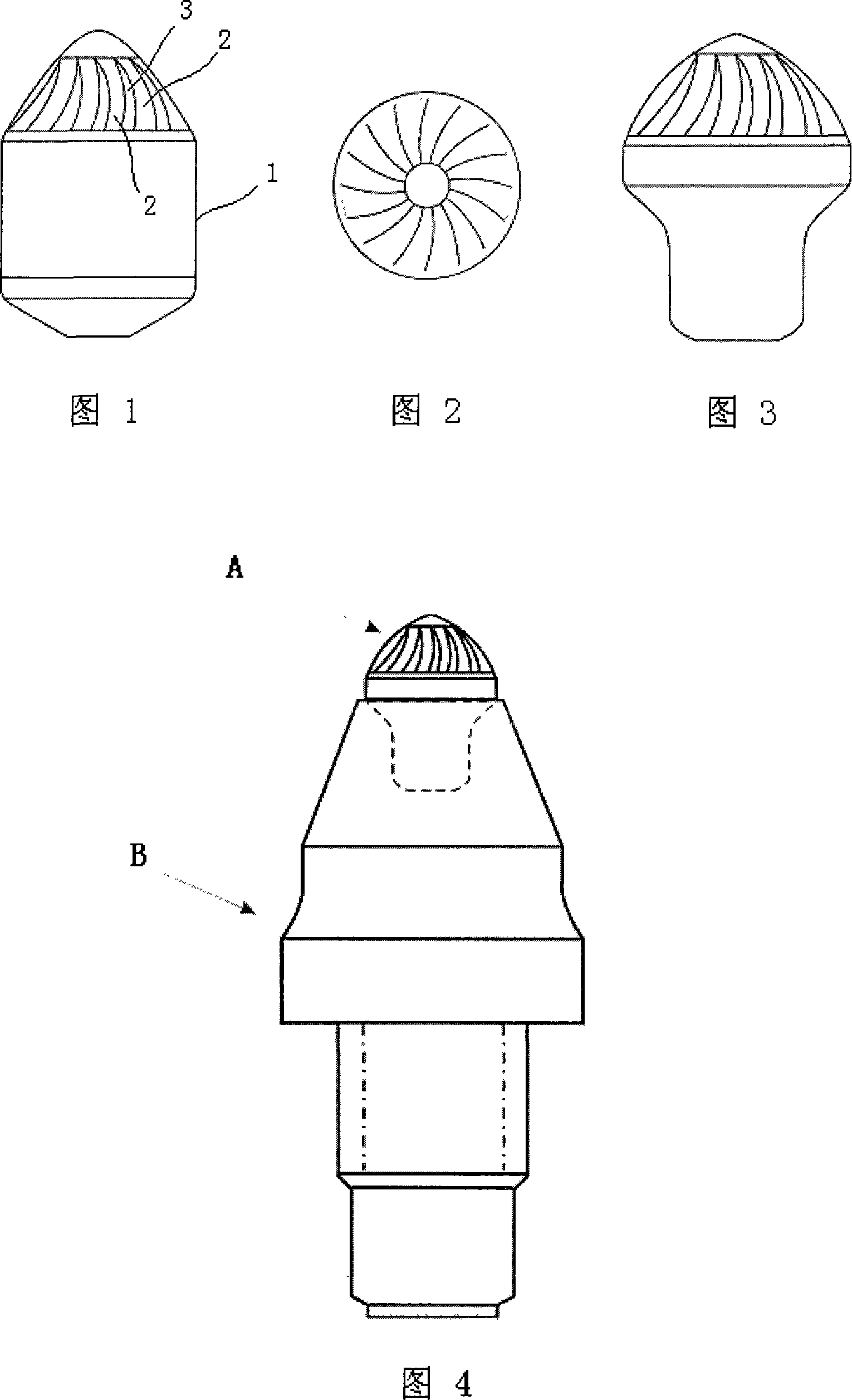

[0012] Embodiment 1: As shown in Figures 1 and 2, the cemented carbide coal cutting tooth for mining is composed of a tooth body 1 and a conical head, and several convex threads 2 with the same direction of rotation are arranged on the conical head. 2 to form a concave thread 3 with the same direction of rotation.

Embodiment 2

[0013] Embodiment 2: The present invention also includes the structure shown in FIG. 3 , its head is a hemispherical crown, and the concave and convex threads on it are the same as those in Embodiment 1.

[0014] The usage of the present invention is shown in Fig. 4, and the tooth body of hard alloy coal cutting tooth A for mining is brazed in the hole at the front end of steel tooth body B, and is assembled into engineering roadheader coal cutting tooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com