Fermented grain discharging device based on parallel mechanism

A wine grain, parallel technology, applied in loading/unloading, transportation and packaging, preparation of alcoholic beverages, etc., can solve the problems of less freedom at the end, difficult to take out the wine grain, achieve fast response speed, save manufacturing costs, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but this does not limit the protection scope of the present application.

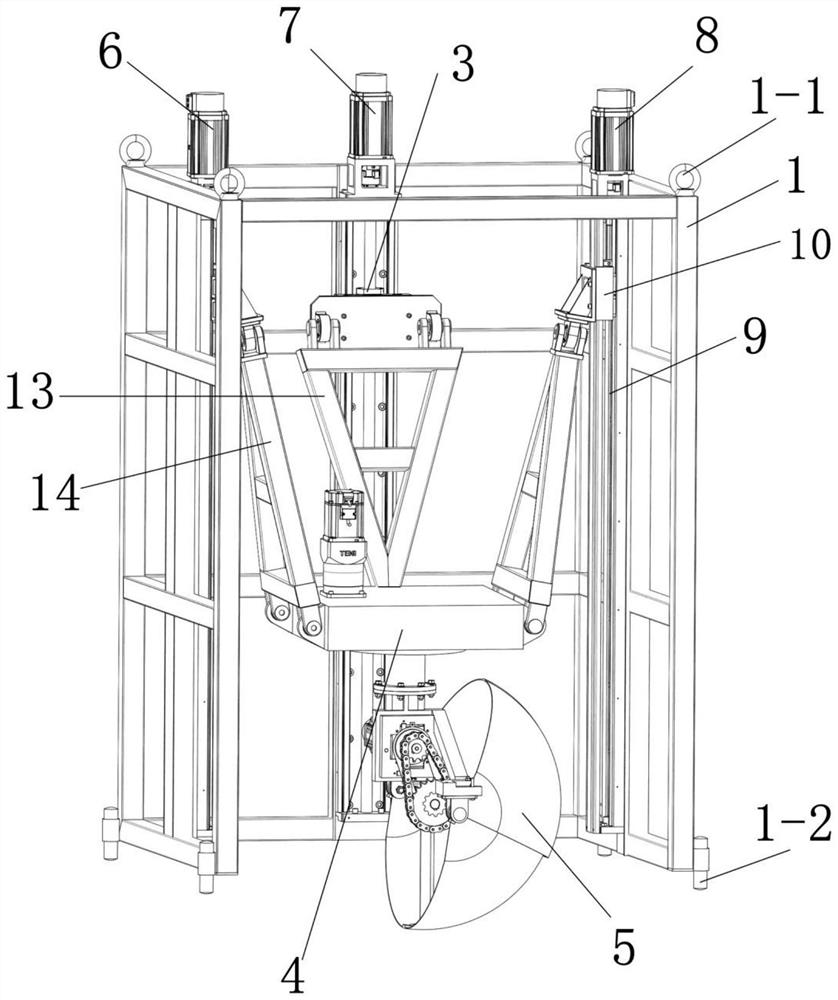

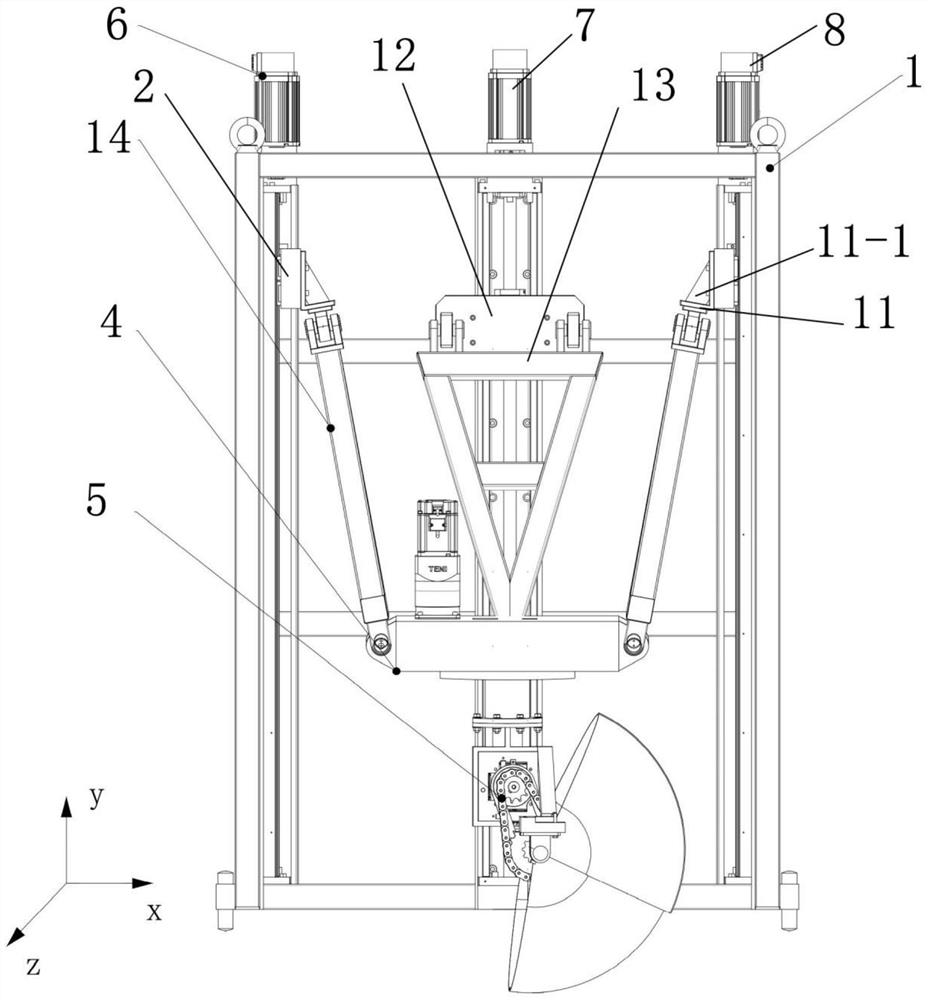

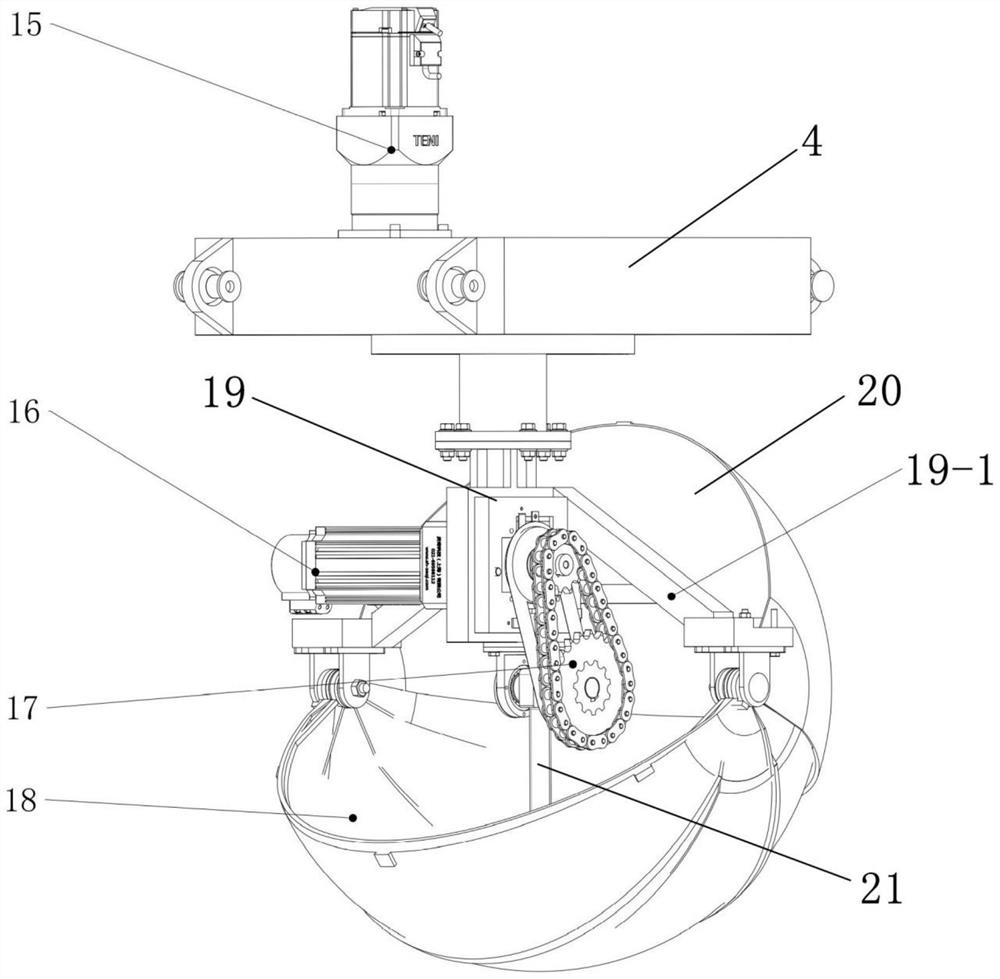

[0030] Such as Figure 1-7 As shown, the present invention is a wine grains unloading device (referred to as the device) based on a parallel mechanism. Platform 12, rear tripod 13, side tripod 14, first to third servo motors, and unloading grain delivery mechanism 5;

[0031] The frame 1 is a hollow three-dimensional frame structure, which is welded by several hollow square tubes; positioning pins 1-1 are welded around the bottom of the frame 1 to facilitate the positioning and installation of the device; Lifting rings 1-2 enable the device to be hoisted by lifting equipment to facilitate device movement; and the use of hollow square tubes not only reduces the cost, but also reduces the weight of the device, making the device move more convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com