Equipment of restraining spheroidized molybdenum powder of direct current plasma temperature field and method

A technology of plasma and spheroidizing molybdenum powder, which is applied in the field of powder metallurgy powder spheroidization, can solve the problems of uneven temperature field, large temperature field gradient, and low spheroidization rate, etc., and achieves prolonged residence time, simple operation, and improved The effect of nodulization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

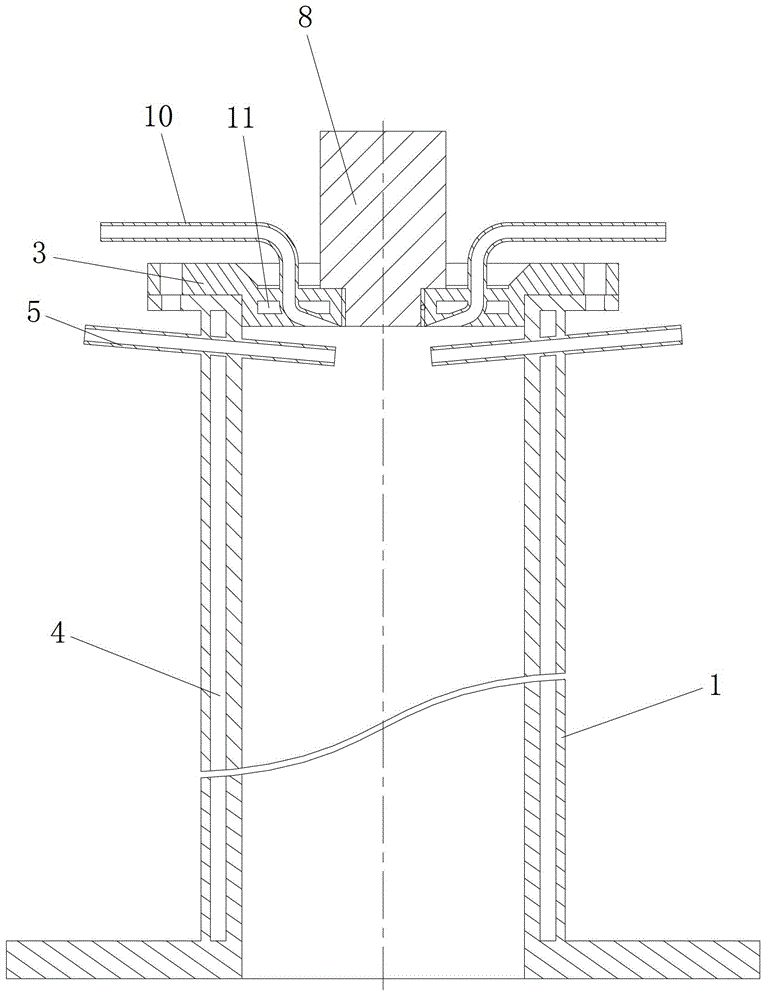

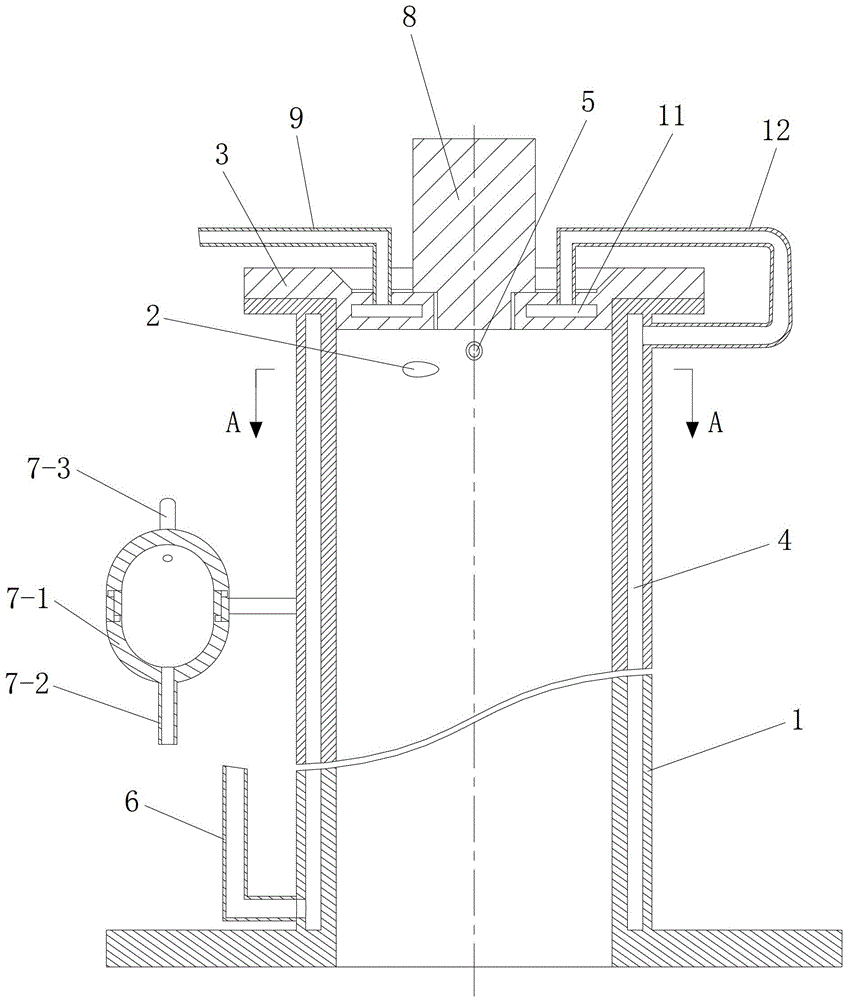

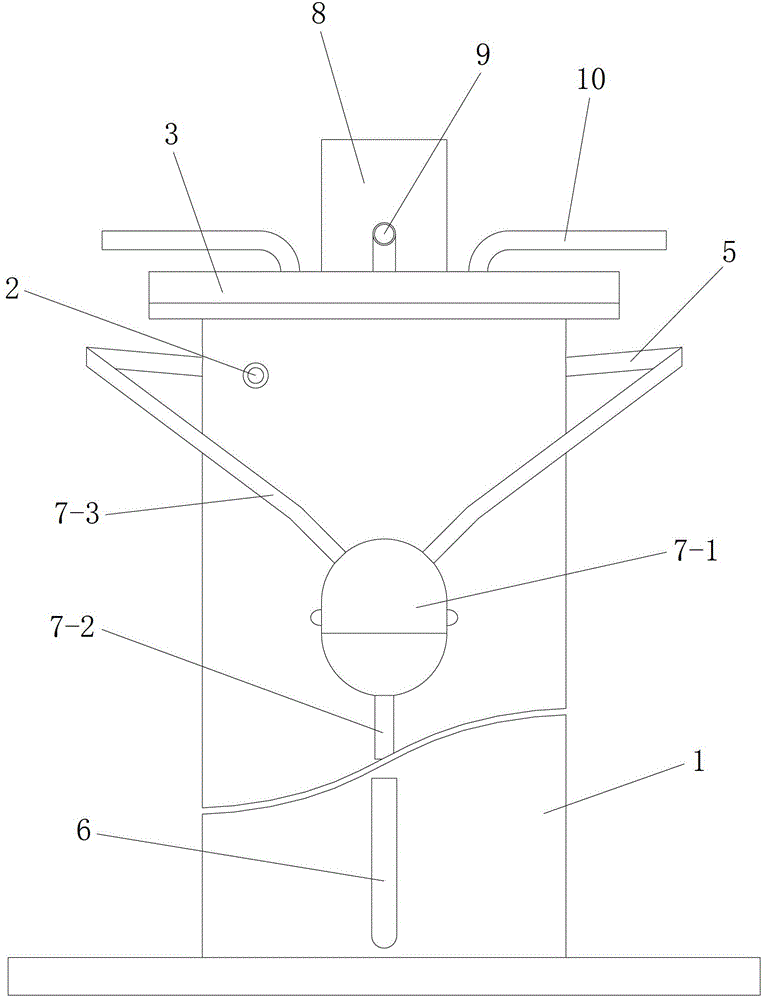

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4A device for spheroidizing molybdenum powder with direct current plasma temperature field confinement as shown, includes a temperature field confinement system and a plasma torch 8, and the temperature field confinement system includes a temperature field confinement tank 1 and is fixedly installed in the temperature field confinement tank 1. The end cover 3 at the top, the plasma torch head 8 is installed at the center of the end cover 3, and a working gas inlet 10 is installed on the end cover 3 and at the periphery of the plasma torch head 8, and the end cover The middle part of 3 is provided with an annular end cover cooling chamber 11, the main part of the temperature field constrained tank 1 is provided with an annular tank body cooling chamber 4 along the circumferential direction, and the lower part of the temperature field constrained tank 1 is provided with an annular tank body The cooling chamber 4 is co...

Embodiment 2

[0048] In this embodiment, the equipment for confining the spheroidized molybdenum powder by the DC plasma temperature field of the present invention is the same as that in Embodiment 1.

[0049] In the present embodiment, the method for spheroidizing molybdenum powder using the equipment of the present invention is as follows: firstly feed cooling water / gas into the cooling water / gas inlet 6, and secondly feed argon gas into the protective gas pipeline 2 as the protective gas , and then pass into the working gas in the working gas inlet 10, the working gas is hydrogen, or argon, or a mixed gas of hydrogen and argon; then energize the plasma torch head 8, and adjust the power of the plasma torch head 8 to be 45kW , the ionized working gas generates DC plasma; finally, the molybdenum powder to be spheroidized is uniformly collided with the powder feeding gas into the temperature field restraint tank 1, and the powder feeding rate of the molybdenum powder to be spheroidized is ad...

Embodiment 3

[0051] In this embodiment, the equipment for confining the spheroidized molybdenum powder by the DC plasma temperature field of the present invention is the same as that in Embodiment 1.

[0052] In the present embodiment, the method for spheroidizing molybdenum powder using the equipment of the present invention is as follows: firstly feed cooling water / gas into the cooling water / gas inlet 6, and secondly feed argon gas into the protective gas pipeline 2 as the protective gas , and then pass into the working gas in the working gas inlet 10, the working gas is hydrogen, or argon, or a mixed gas of hydrogen and argon; then energize the plasma torch head 8, and adjust the power of the plasma torch head 8 to be 60kW , the ionized working gas generates DC plasma; finally, the molybdenum powder to be spheroidized is sent into the temperature field restraint tank 1 through the uniform collision of the powder feeding gas, and the powder feeding rate of the molybdenum powder to be sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com