Direct type backlight module and its lamp tube fixing device

A technology for fixing devices and backlight modules, which is applied to lighting devices, lighting auxiliary devices, components of lighting devices, etc., can solve the problems of inability to adjust spacing, inconsistent spacing between adjacent fixtures, and inconvenient assembly of traditional lamp tube fixing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

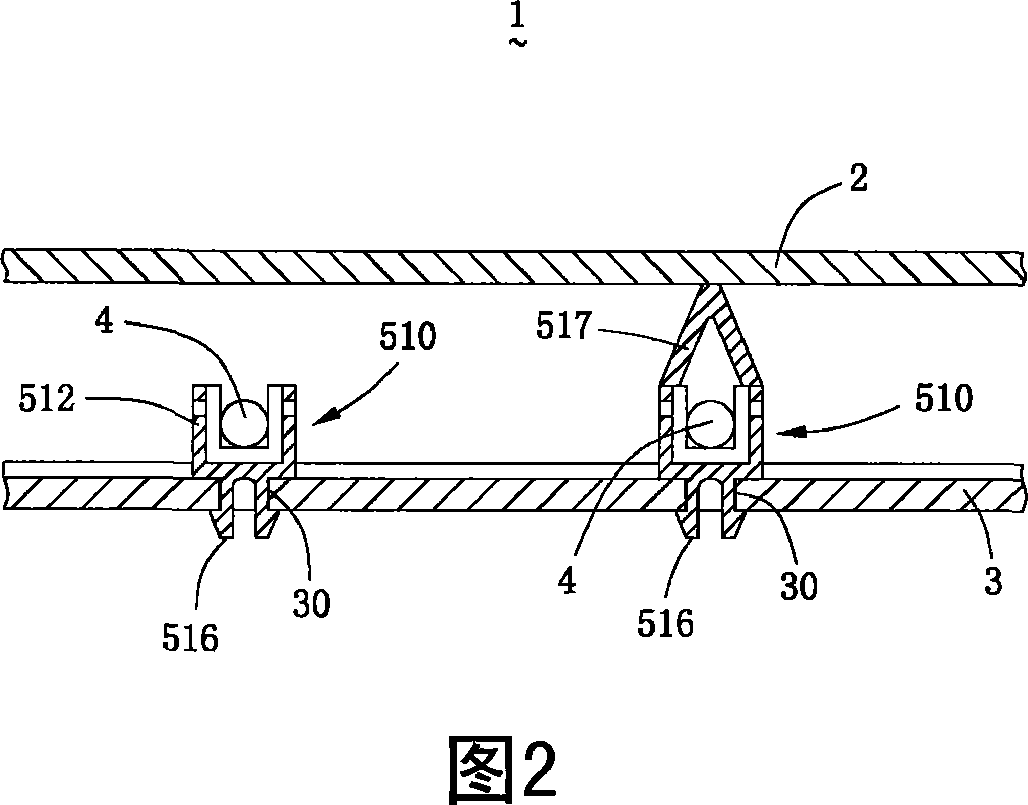

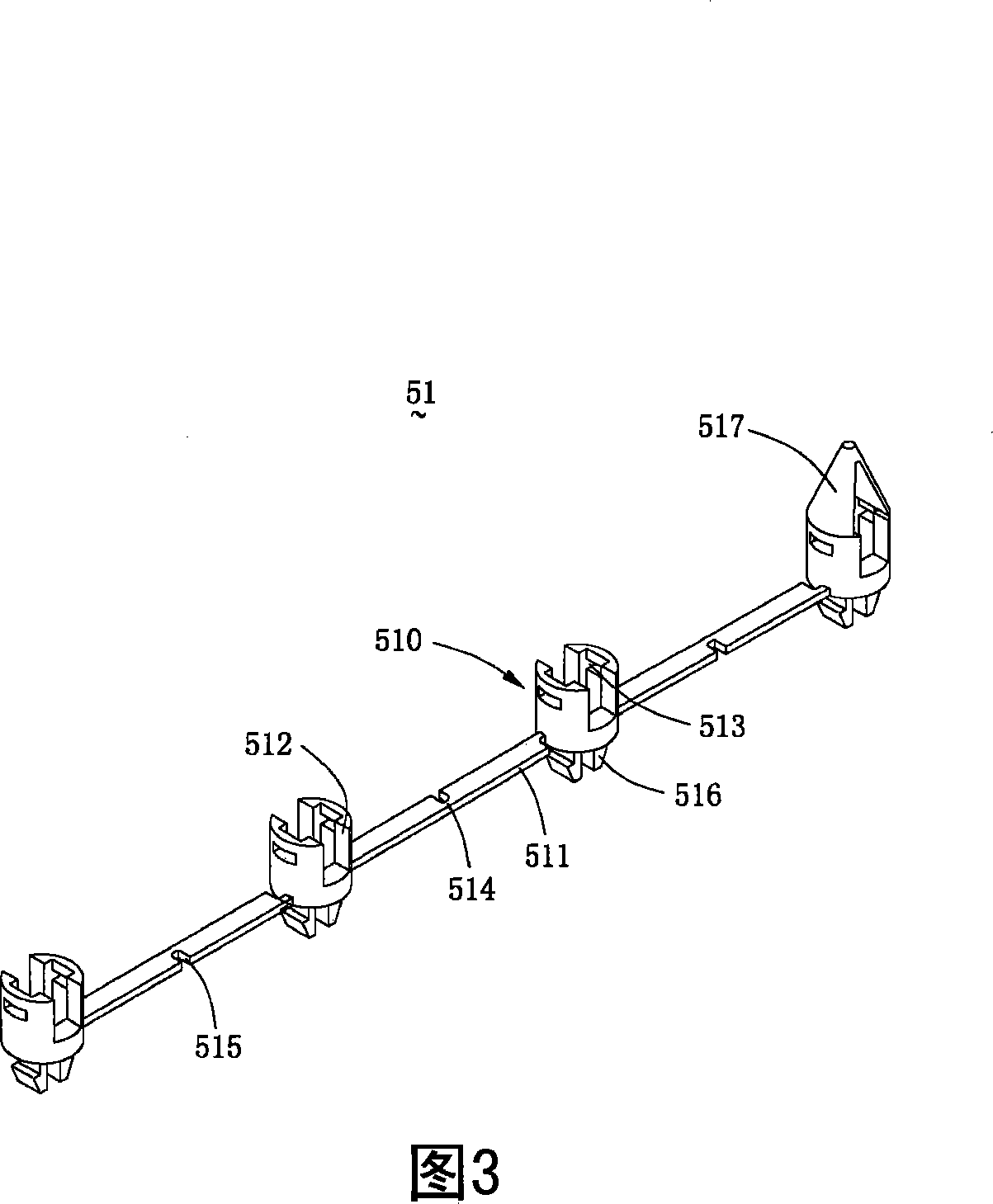

[0029] Please refer to FIG. 3 first. FIG. 3 is a structural diagram of a lamp fixing device 51 according to the first embodiment of the present invention. The seat 510 has a clamping portion 512 , and a slot 513 is formed above the clamping portion 512 . The slot 513 has a ㄩ-shaped cross section as shown in FIG. 2 for clamping a corresponding lamp tube 4 . A hook 516 is further provided at the bottom of each holder 510 . The opposite ends of each connecting rod structure 511 are respectively connected with the two adjacent clip seats 510 , and a bendable structure 514 is disposed between the opposite ends. In the present invention, the position of the bendable structure is not specifically limited, and can be arranged at any position of the connecting rod structure according to the needs of practical applications. The connecting rod structure 511 can be made of flexible material (such as plastic), so that the connecting rod structure 511 can be elastically bent, and in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com