Method for manufacturing electro-optical device and electro-optical device

A technology of electro-optical devices and manufacturing methods, applied in optics, identification devices, nonlinear optics, etc., capable of solving problems such as brightness shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

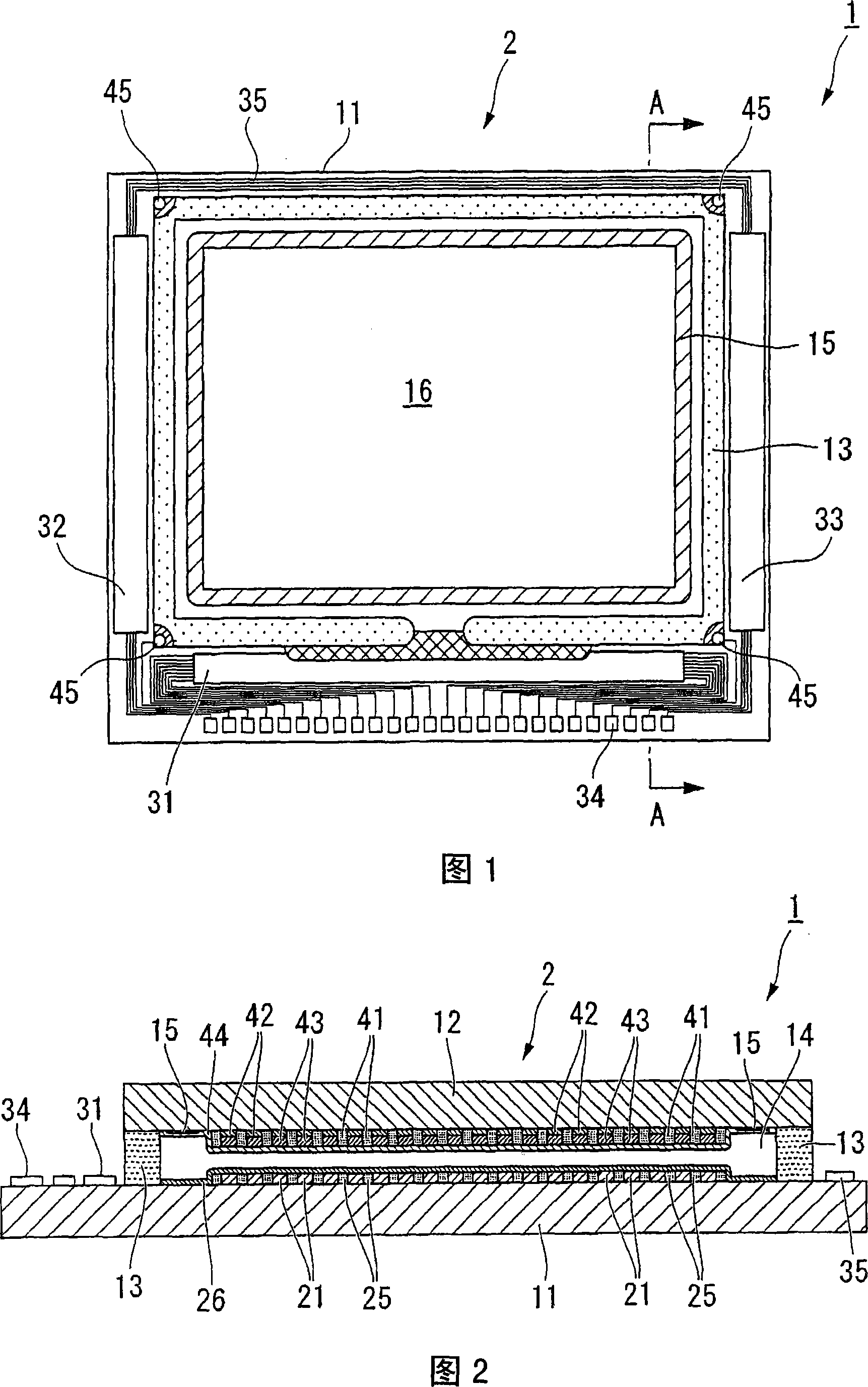

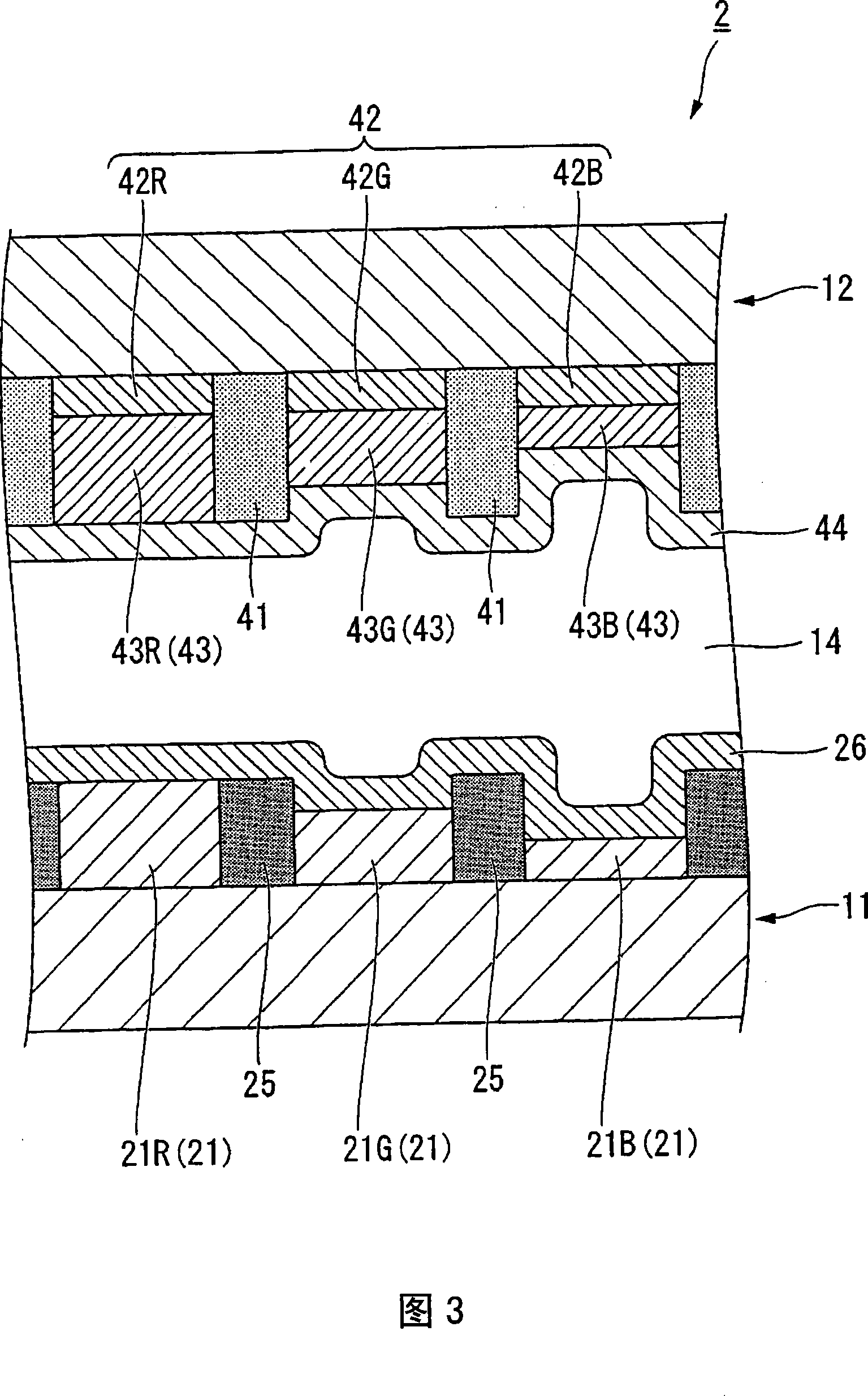

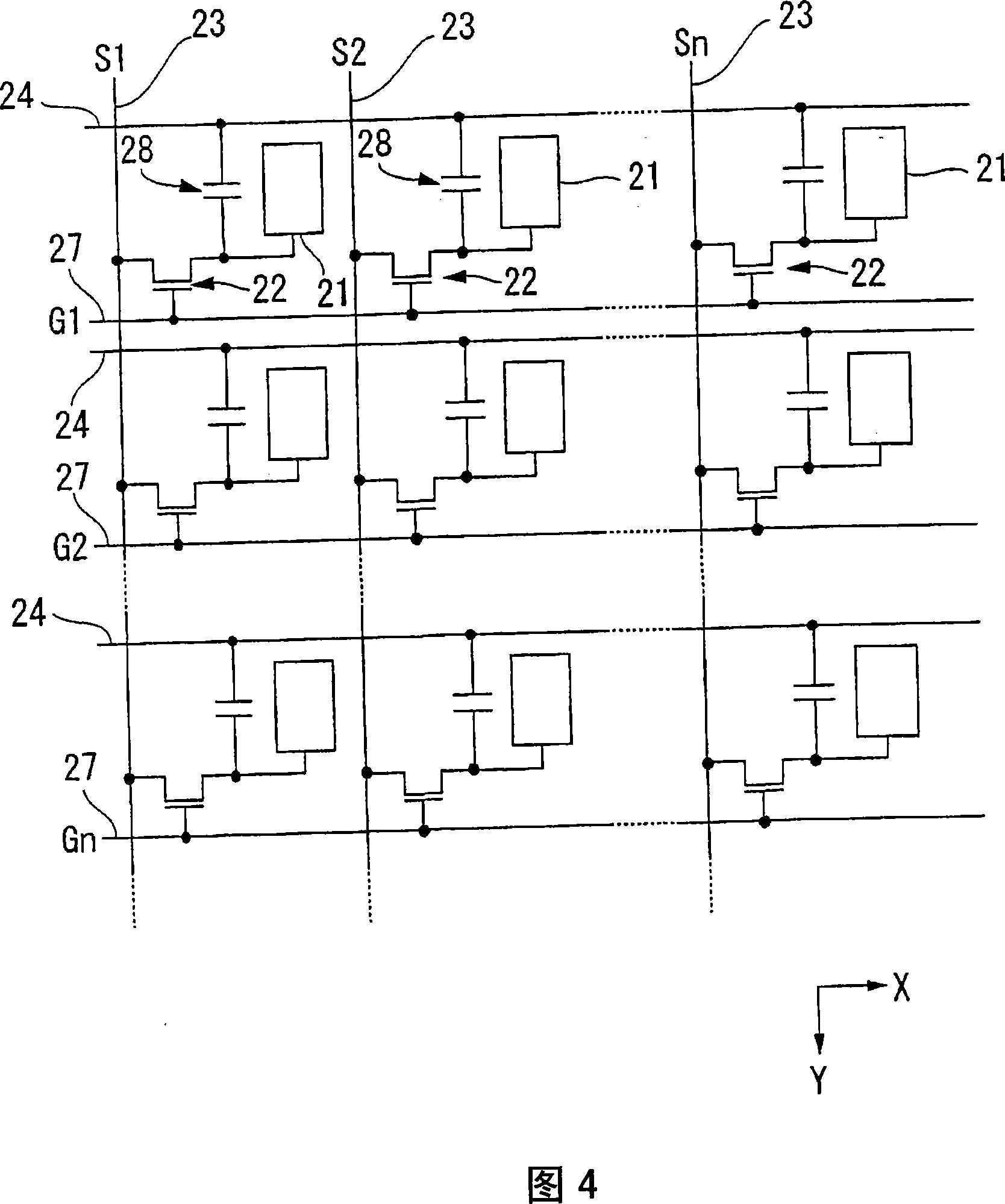

[0039] Hereinafter, an embodiment of a method of manufacturing an electro-optical device and an electro-optical device according to the present invention will be described with reference to the drawings. Here, FIG. 1 is a plan view of a liquid crystal device, FIG. 2 is a sectional view taken along the line A-A of FIG. 1, FIG. 3 is a partial enlarged view of FIG. 2, and FIG. 4 is an equivalent circuit diagram of the liquid crystal device. In addition, in each drawing used in the following description, in order to make each member recognizable, the dimension of each member is changed suitably.

[0040] The liquid crystal device (electro-optical device) 1 of this embodiment is a TFT active matrix type liquid crystal device using TFT (Thin Film Transistor: Thin Film Transistor) as a pixel switch. Furthermore, as shown in FIGS. 1 to 4 , the liquid crystal device 1 includes a liquid crystal panel 2 and polarizing plates (not shown) respectively arranged on the outer surfaces of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com