Polyvinyl acetal resin film for laminated glass

A polyvinyl acetal resin, laminated glass technology, applied in synthetic resin layered products, glass/slag layered products, coatings, etc., can solve the problem of poor stretchability of PET film, reduced glass heating efficiency, and head impact index. To solve problems such as change, to achieve the effect of suppressing deformation and damage, and suppressing the deviation of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0214] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to the said Example at all.

reference example 1

[0216] Polyvinyl butyral resin 1 (hereinafter referred to as "resin 1") and polyvinyl butyral resin 2 (hereinafter referred to as "resin 2") were mixed at a mass ratio of 75:25 and melt-blended. Refined, extruded in strips, and pelletized. The obtained pellets were melt-extruded with a single-screw extruder and a T-die, and a polyvinyl acetal resin film c having a smooth surface and a thickness of 50 μm was obtained using a metal elastic roll.

[0217]

[0218] Film-forming properties when the pellets were melt-extruded with a single-screw extruder were evaluated according to the following criteria. The results are shown in Table 2.

[0219] AThe film forming property is very favorable.

[0220] B film formation is good.

[0221] C causes coloring and generation of decomposition gas, but film formation is possible.

[0222] D cannot be filmed.

[0223]

[0224] The resins constituting the obtained polyvinyl acetal resin film were analyzed by GPC. In the GPC analysis,...

reference example 5

[0240] UV-curable nano-silver ink was printed on the polyvinyl acetal resin film c by letterpress printing to a thickness of 10 μm to form a linear conductive material pattern with a line width of 300 μm, a pitch of 100 μm, a length of 5 cm, and a number of 20 lines . The aforementioned pattern is irradiated with UV light to cure the ink.

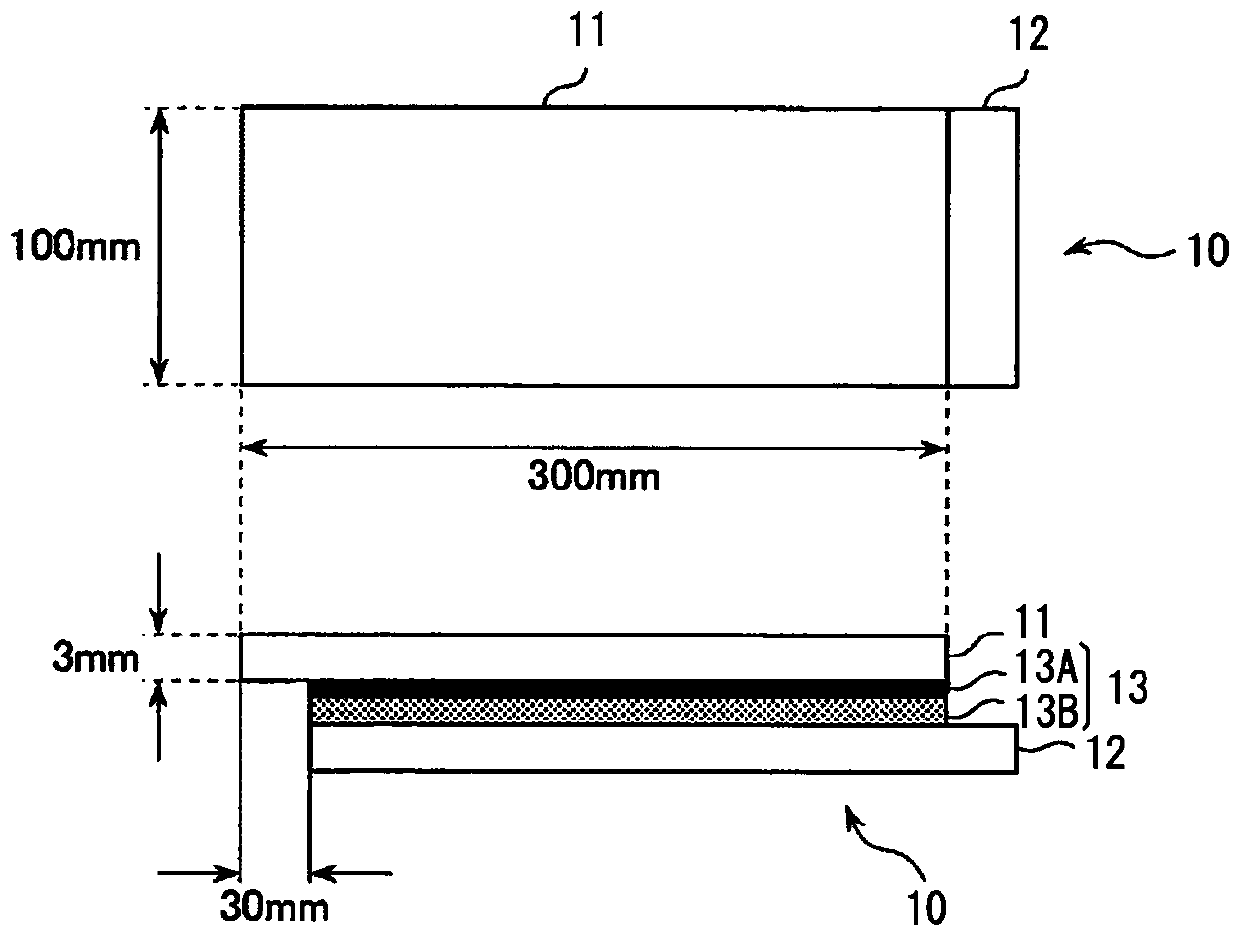

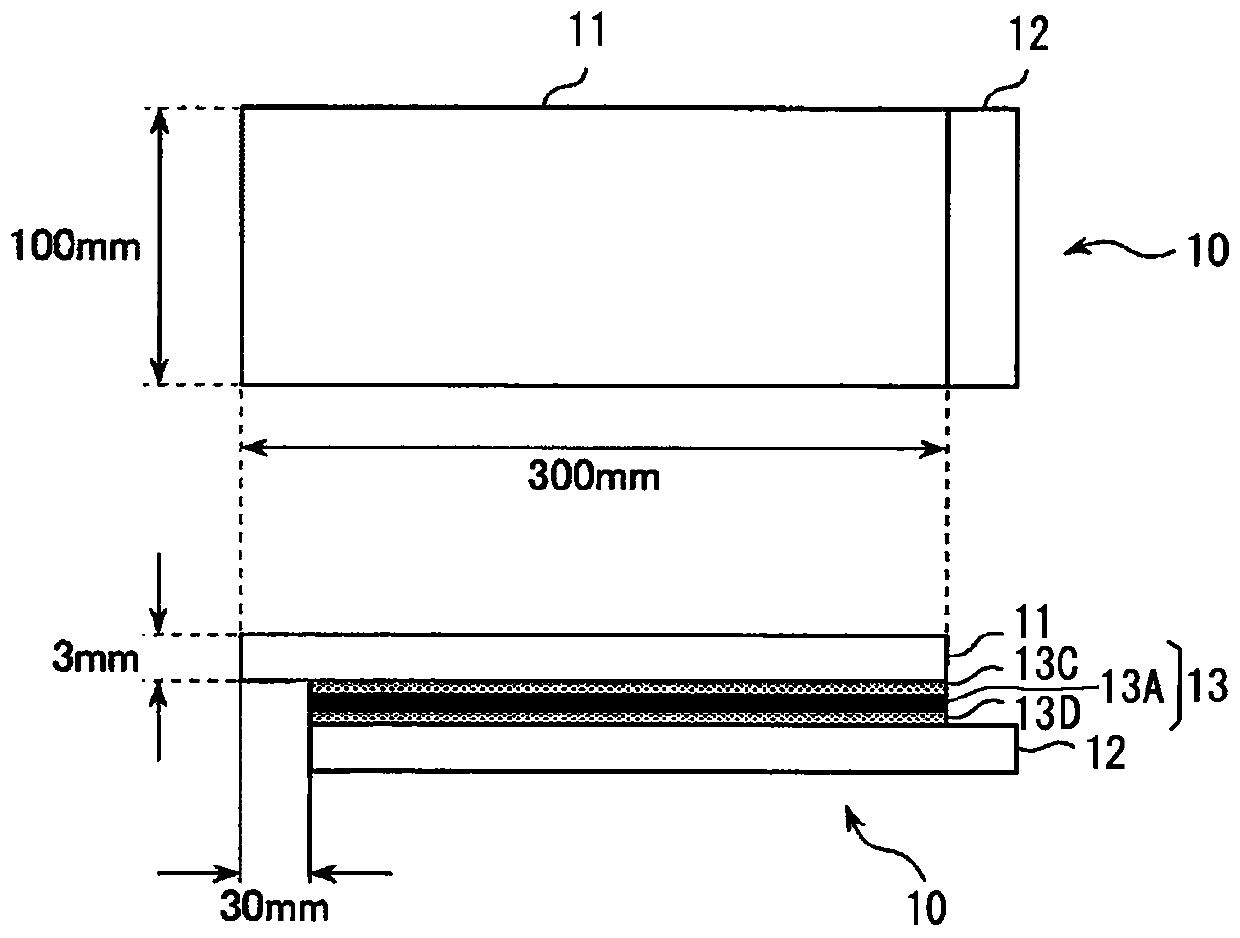

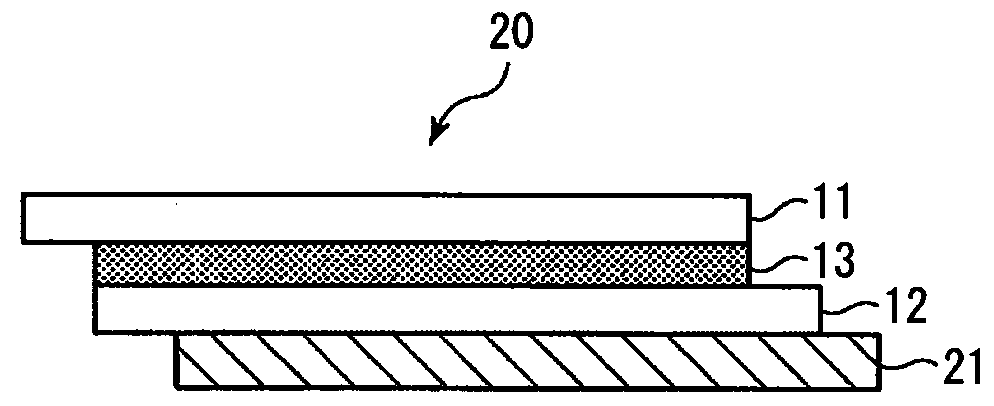

[0241] Next, on glass with a length of 10 cm, a width of 10 cm, and a thickness of 3 mm, the polyvinyl acetal resin film provided with the aforementioned pattern is arranged with the printing surface facing up, so as to be at right angles to the direction of the linear conductive material of the aforementioned pattern. A copper foil tape (width 5 mm, length 15 cm) having a conductive adhesive layer as a bus bar was overlapped with both ends of each linear conductive material. In addition, each bus bar is provided as an electrode so that it may protrude from a polyvinyl acetal resin film. Next, a plasticized polyvinyl acetal resin layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com