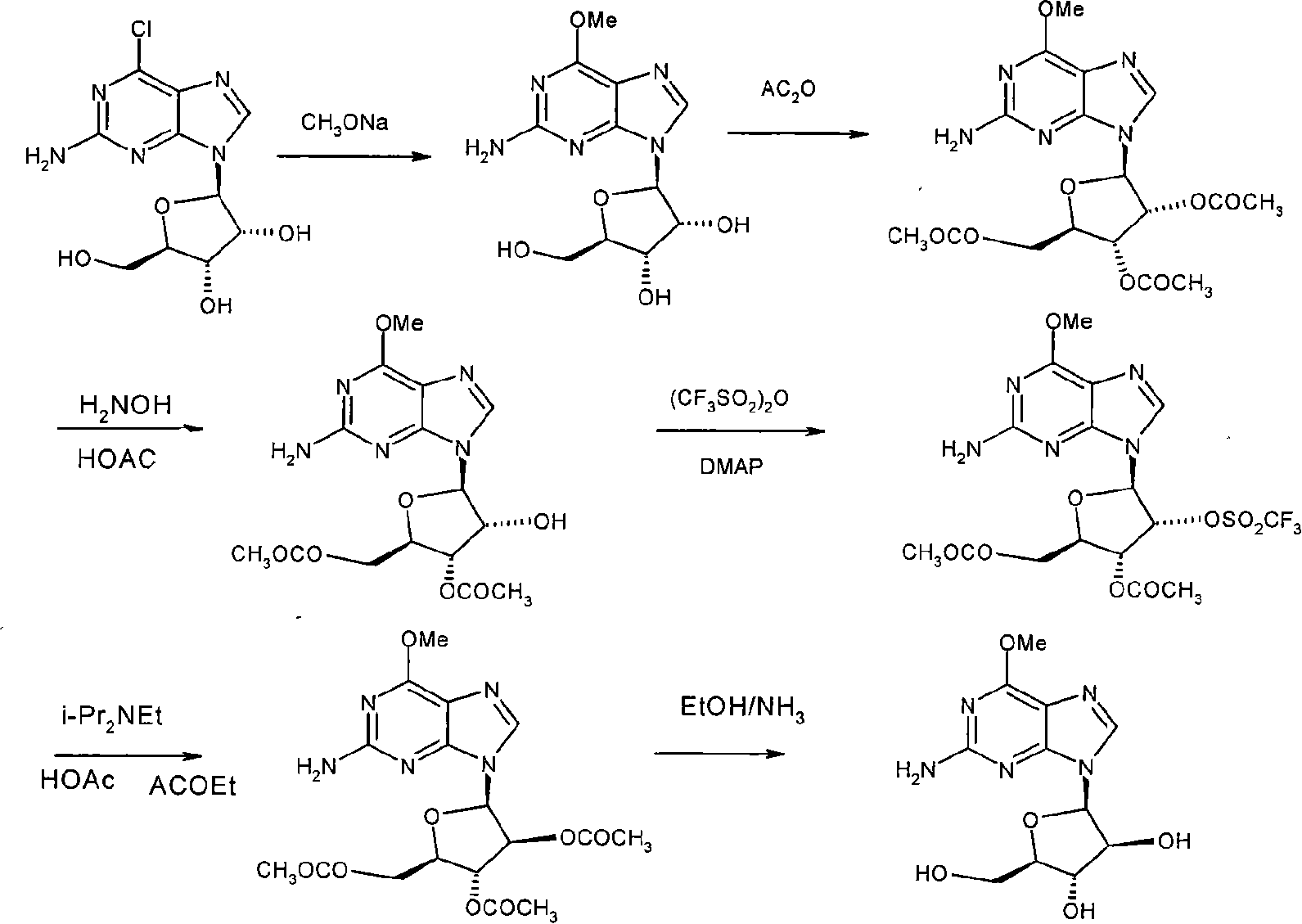

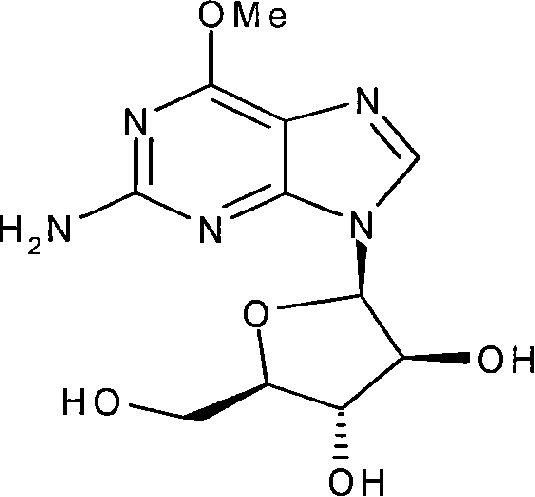

Method for synthesizing nelarabine

A synthesis method and a technology for chemical synthesis, applied in the field of medicine, can solve the problems of strict equipment requirements, high price, low nerabine yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The preparation method of 6-methoxyguanosine is as follows: take 248.0 grams of sodium methoxide and add it to methanol, stir to obtain a white turbid liquid, add 310 grams of 6-chloroguanosine material to dissolve rapidly to obtain a light yellow solution, and then add Precipitate a white solid, heat to reflux, continue the reaction, cool to room temperature, carefully add hydrochloric acid solution dropwise with stirring to neutralize to pH=8-9, remove the solvent and add distilled water to the remaining pale yellow viscous material, dissolve under stirring at 70°C, Then add activated carbon, hot filter, filtrate, naturally cool and crystallize, filter to obtain colorless crystalline solid, vacuum dry to obtain 196.7 g of white solid, namely 6-methoxyguanosine. mp: 133-135°C; TLC (ethyl acetate:methanol=6:1), product Rf=0.4, starting Rf=0.45.

[0074] The preparation method of 2', 3', 5'-tri-O-acetyl-6-methoxyguanosine is as follows: dissolve 195.0 grams of 6-methoxyg...

Embodiment 2

[0082] Wherein the preparation method of 6-methoxyguanosine is: get 128 grams of sodium methylate and join in the methanol, stir, obtain white turbid liquid, add 160 grams of 6-chloroguanosine materials and dissolve rapidly, obtain light yellow solution, then again Precipitate a white solid, heat to reflux, continue the reaction, cool to room temperature, carefully dropwise add hydrochloric acid solution to neutralize to PH = 8-9 while stirring, add distilled water to the remaining light yellow viscous substance after removing the solvent, dissolve under stirring at 70°C, Activated carbon was then added, hot filtered, and the filtrate was naturally cooled and crystallized, filtered to obtain a colorless crystalline solid, and vacuum-dried to obtain 102.6 g of a white solid, namely 6-methoxyguanosine. mp: 133-135°C; TLC (ethyl acetate:methanol=6:1), product Rf=0.4, starting material Rf=0.45.

[0083] Wherein 2′, 3′, 5′-tri-O-acetyl-6-methoxyguanosine is prepared by dissolving 1...

Embodiment 3

[0091] Wherein the preparation method of 6-methoxyguanosine is: get 800 grams of sodium methylate and join in methanol, stir, obtain white turbid liquid, add 1000 grams of 6-chloroguanosine materials and dissolve rapidly, obtain light yellow solution, then again Precipitate a white solid, heat to reflux, continue the reaction, cool to room temperature, carefully dropwise add hydrochloric acid solution to neutralize to PH = 8-9 while stirring, add distilled water to the remaining light yellow viscous substance after removing the solvent, dissolve under stirring at 70°C, Activated carbon was then added, hot filtered, and the filtrate was naturally cooled and crystallized, filtered to obtain a colorless crystalline solid, and vacuum-dried to obtain 598.8 g of a white solid, namely 6-methoxyguanosine. mp: 133-135°C; TLC (ethyl acetate:methanol=6:1), product Rf=0.4, starting material Rf=0.45.

[0092]Wherein, the preparation method of 2', 3', 5'-tri-O-acetyl-6-methoxyguanosine is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com