Vacuum coating equipment with transfer rollers for transferring flat substrates

A technology of vacuum coating and conveying rollers, applied in the directions of vacuum evaporation coating, coating, sputtering coating, etc., to avoid leakage, realize re-installation and easy re-installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

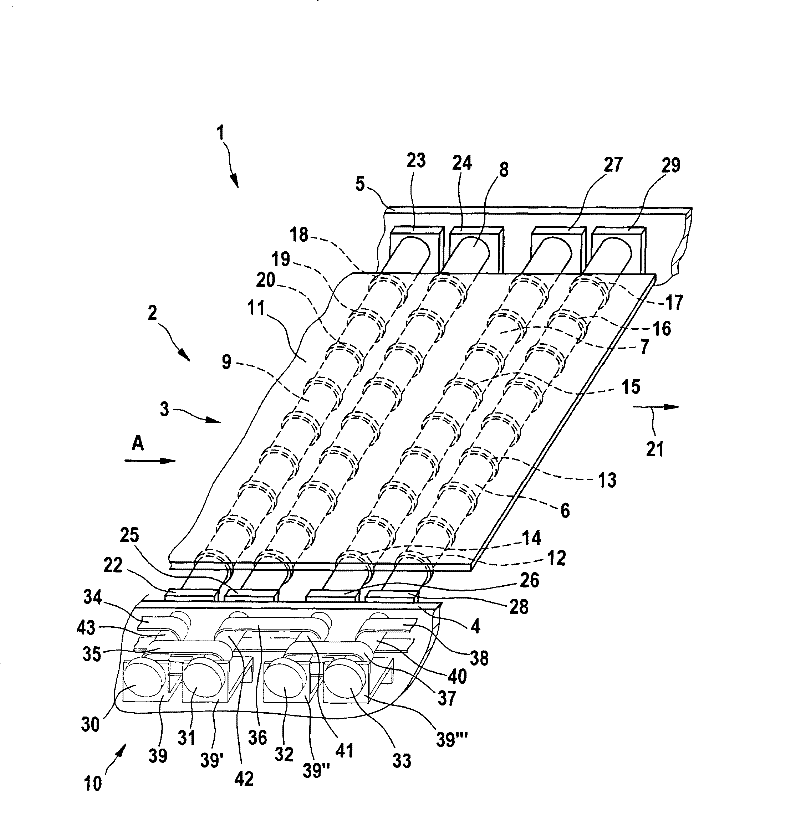

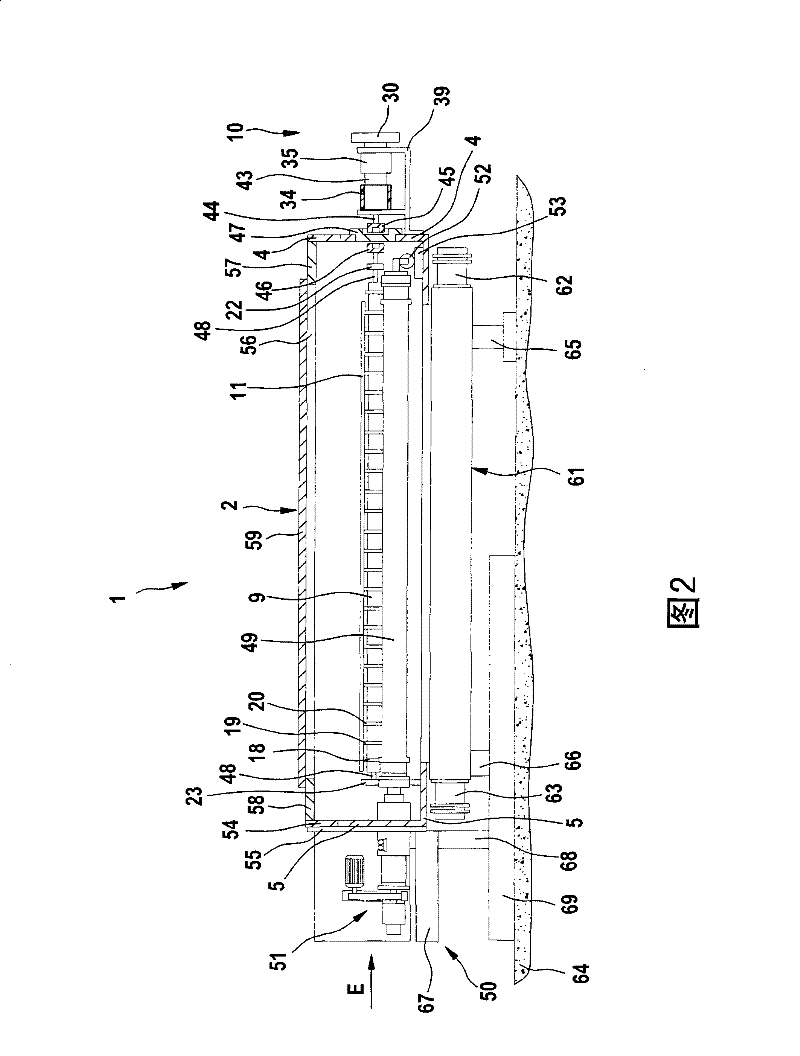

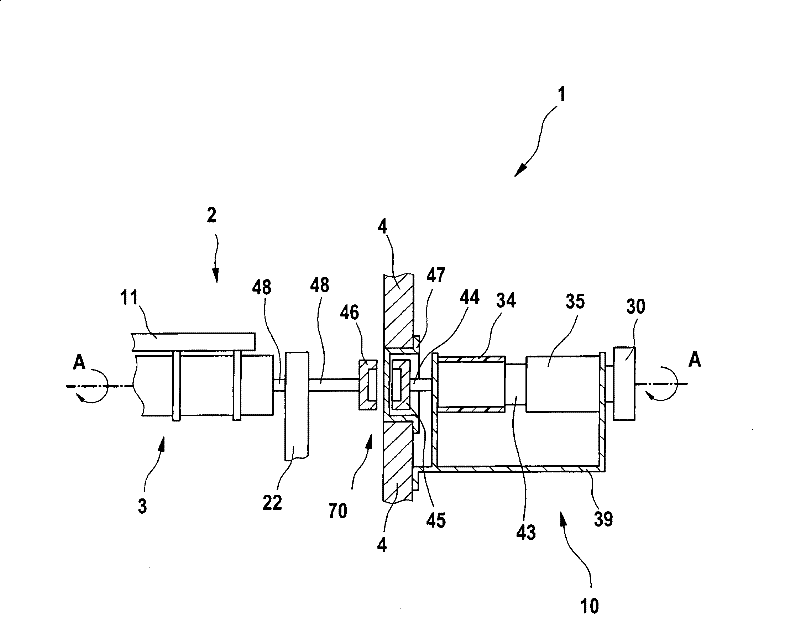

[0028] figure 1 A perspective view of a part of the vacuum coating chamber 2 in the vacuum coating device 1 is shown. Visible are parts of two opposing walls 4 , 5 delimiting the vacuum coating chamber 2 . The conveying device 3 is located in the vacuum coating chamber 2 and comprises several conveying rollers 6, 7, 8, 9 extending in parallel. These transport rollers 6 to 9 are driven via a drive system 10 located outside the vacuum coating chamber 2 . Under the action of the drive system 10, the transport rollers 6 to 9 undergo a rotational movement about their own longitudinal axes. The substrate 11 to be coated lies on transport rollers 6 to 9 . The substrate here is a flat substrate, such as architectural glass. In order that the substrate 11 does not rest directly on the transport rollers 6 to 9 , an elastic material, for example of the rubber type, can be applied to the outer sides of the transport rollers. This serves the purpose of preventing the substrate 11 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com