Sealing device for end face of traversing part

A face sealing, component end technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of not being able to achieve long-term, perfect, stable and strict sealing, production line shutdown, bearing stuck, etc., and achieve a simple structure. , The effect of convenient installation and debugging, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

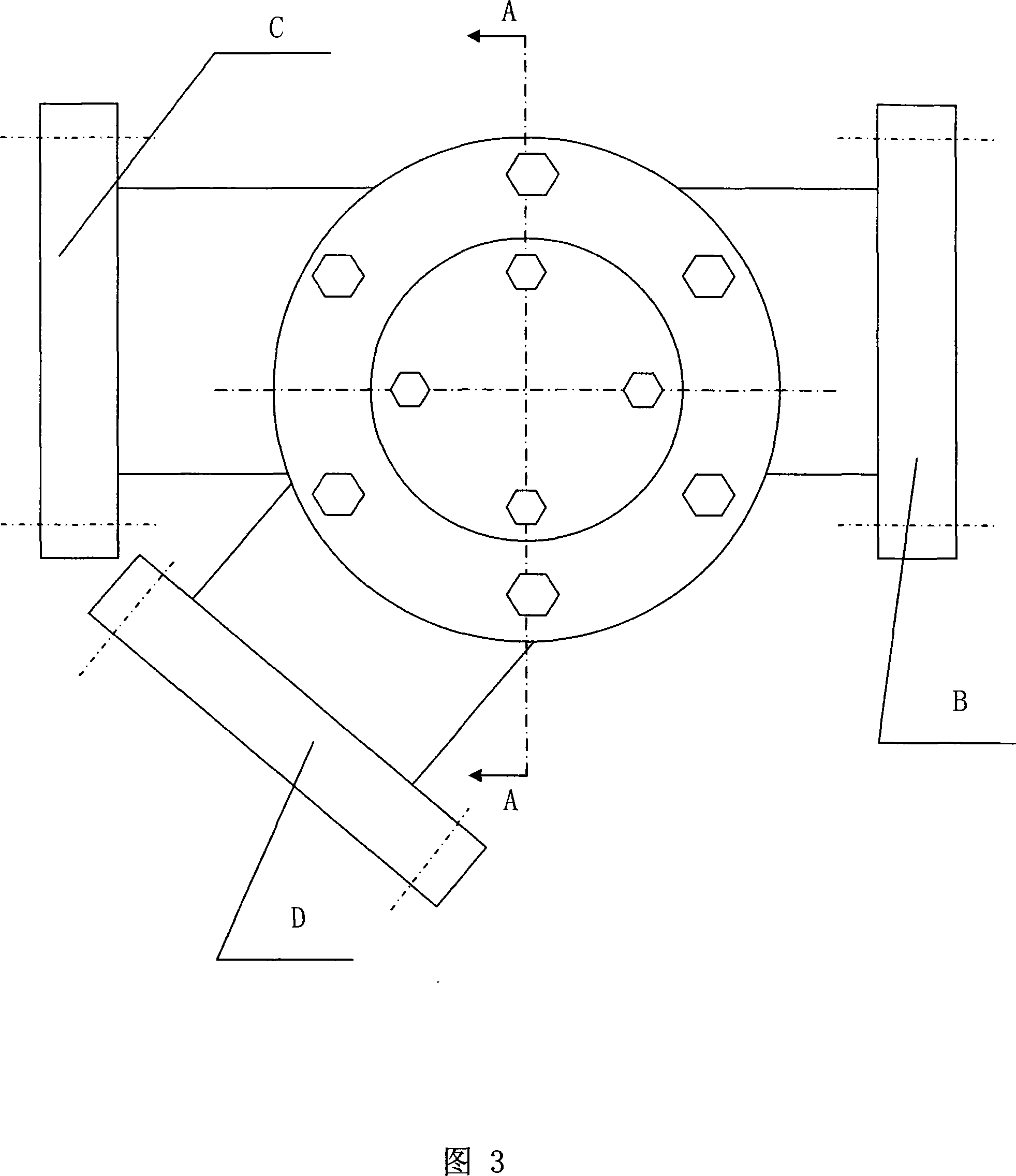

[0017] Referring to Figure 3 and Figure 4, it is a schematic diagram of the three-way reversing valve in the normal positive pressure material conveying system. The function of the three-way reversing valve in the positive pressure conveying system is to change the flow direction of the material according to the system requirements. When the system needs to change When the material flows, the torque is input from the gear side, and the rotating shaft 36 rotates to another position, thereby changing the direction of the material (for example, the material enters from the B port and flows out from the C port, and the rotating shaft 36 seals the D port. After the reversing, the material flows from the B port enters through port D, flows out from port D, and the rotating shaft 36 seals port C, thereby changing the direction of the material). From the figure, we can see that the dust in the pipeline easily passes through the gap between the shaft 36 and the housing 23. When the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com