Highpower light emitting diode light fixture with heat being eliminated by superconductive heat pipe

A technology of light-emitting diodes and superconducting heat pipes, applied in semiconductor devices, light sources, electric light sources, etc. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

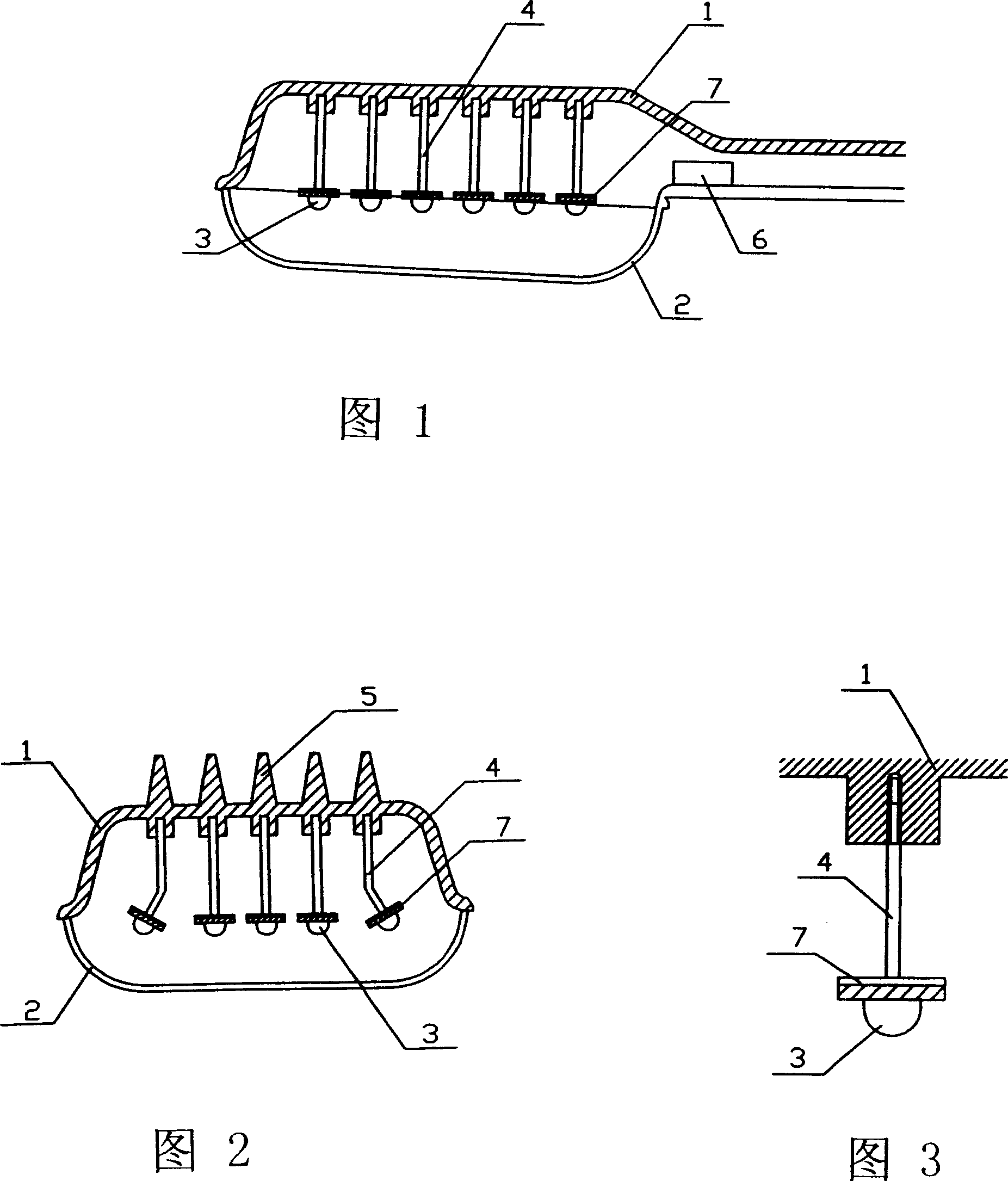

[0016] Embodiment 1: As shown in accompanying drawing 1, the high-power light-emitting diode light fixture of the present invention heat-dissipating by superconducting heat pipes consists of a lamp housing 1, a lampshade 2, several W-class high-power LED unit lamps 3, superconducting heat pipes 4 and Composed of constant current power supply 6, each W-level high-power LED unit lamp 3 is fixedly installed in the lamp housing 1 through a superconducting heat dissipation tube 4, the upper end of the superconducting heat dissipation tube 4 is screwed on the inner wall of the lamp housing 1, and the lower end It is fixed together with the heat dissipation bottom plate 7 of the W-class high-power LED unit lamp 3, and the constant-current power supply 6 is installed in the lamp housing 1, and each W-class high-power LED unit lamp 3 is electrically connected to the constant-current power supply 6, and the lampshade 2 and The lamp housing 1 is hermetically connected and integrated.

[...

Embodiment 2

[0018] Embodiment 2: As shown in accompanying drawing 2, the high-power LED light fixture of the present invention heat-dissipating by superconducting heat pipes consists of lamp housing 1, lampshade 2, several W-class high-power LED unit lamps 3, superconducting heat pipes 4, heat dissipation Composed of structure 5 and constant current power supply 6 (not shown in the figure), each W-level high-power LED unit lamp 3 is fixedly installed in the lamp housing 1 through a superconducting heat pipe 4, and the upper end of the superconducting heat pipe 4 is screwed on On the inner wall of the lamp housing 1, a heat dissipation structure 5 is added on the outer surface of the lamp housing 1. In this example, it is a heat sink. The current power source 6 is installed in the lamp housing 1, and each W-level high-power LED unit lamp 3 is electrically connected to the constant current power source 6, and the lampshade 2 and the lamp housing 1 are hermetically connected as one.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com