Low temperature electric dust removal system based on thermoelectric power generation

A technology of thermoelectric power generation and thermoelectric power generation sheets, which is applied in the direction of generators/motors, electrical components, electrostatic separation, etc., can solve the problems of lack of heat recovery devices, etc., and achieve the effect of improving dust removal efficiency and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

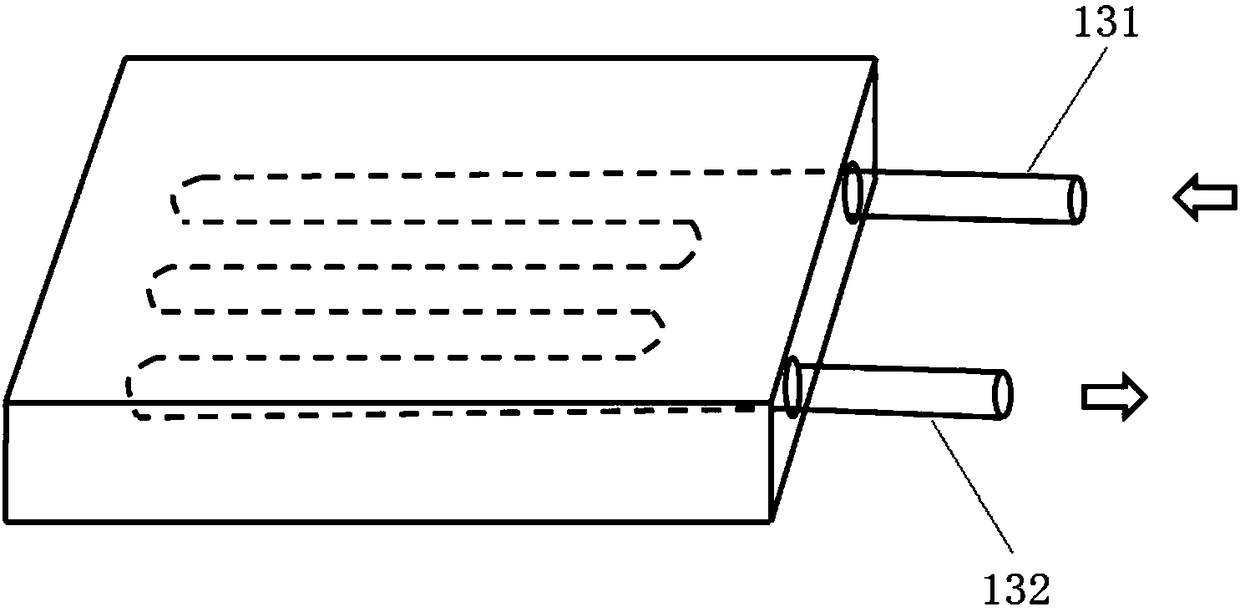

[0025] Thermoelectric power generation is a new type of power generation. It uses the Seebeck effect to directly convert heat energy into electrical energy. During the conversion process, no mechanical moving parts are required, and no additional drive and transmission systems are required. Therefore, the structure is compact and there is no vibration and noise. High-temperature flue gas combined with artificially set low-temperature circulating cooling water can provide the temperature difference required for thermoelectric power generation, and combined with thermoelectric power generation sheets can generate electricity.

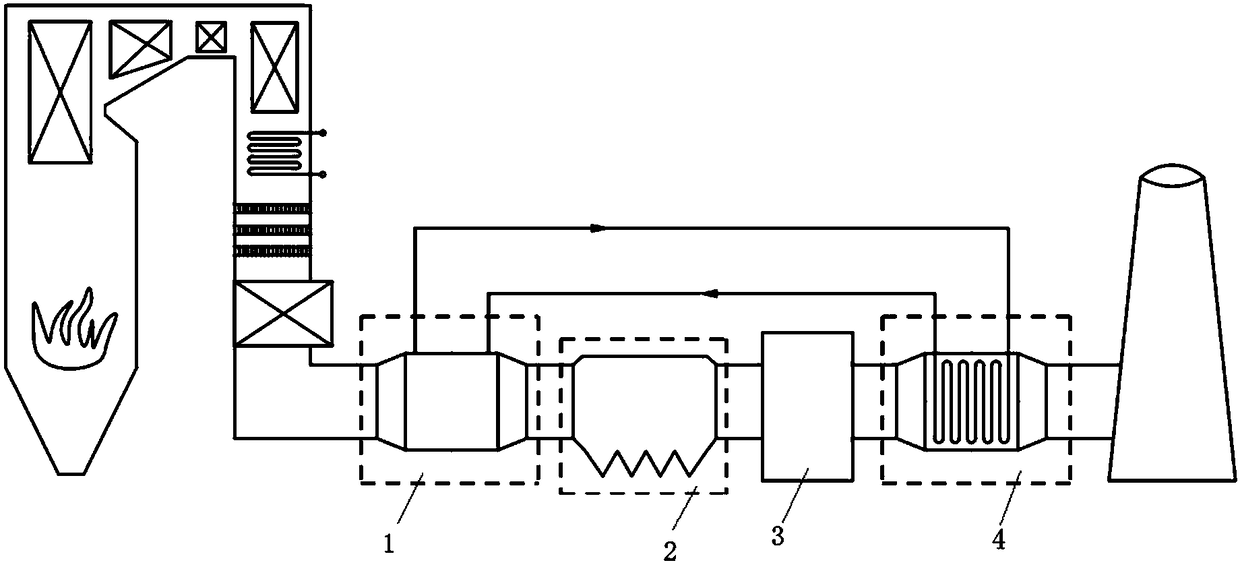

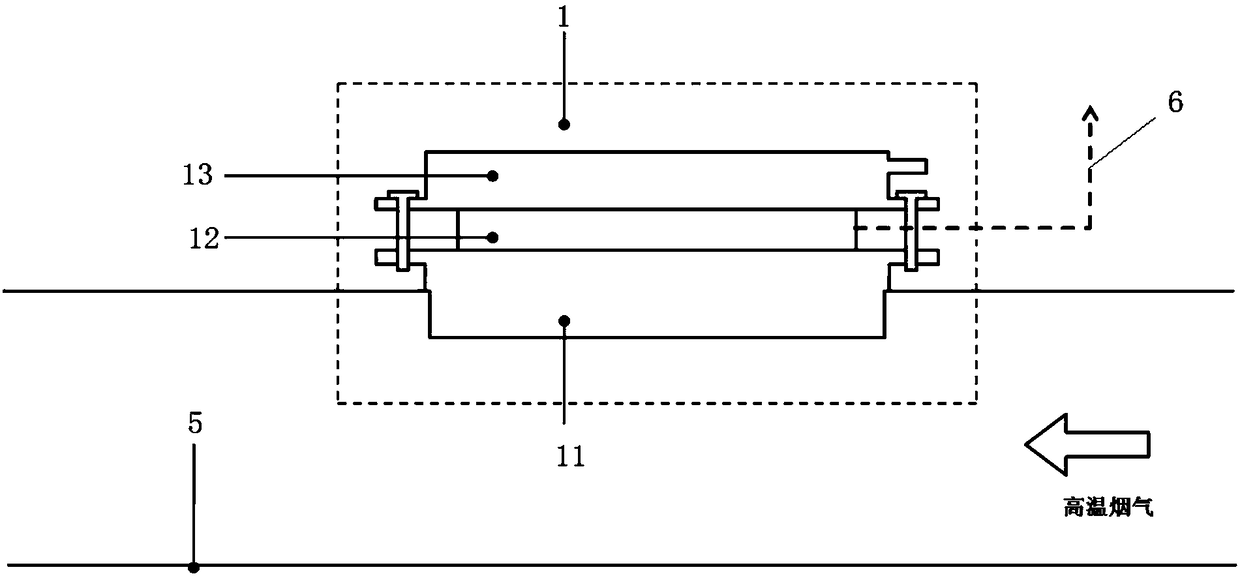

[0026] Such as Figure 1~4 As shown, a low-temperature electrostatic precipitator system based on thermoelectric power generation includes a heat recovery device 1 , a low-temperature electrostatic precipitator 2 , an absorption tower 3 and a reheater 4 .

[0027] The heat recovery device 1 is a thermoelectric power generation heat recovery device, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com