Heating system for driving equipment

A technology of heating system and driving equipment, which is applied in ohmic resistance heating, cooling/ventilation/heating transformation, electric heating device, etc. The assembly process is simple, the spacing distance is increased, and the effect of promoting hot air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

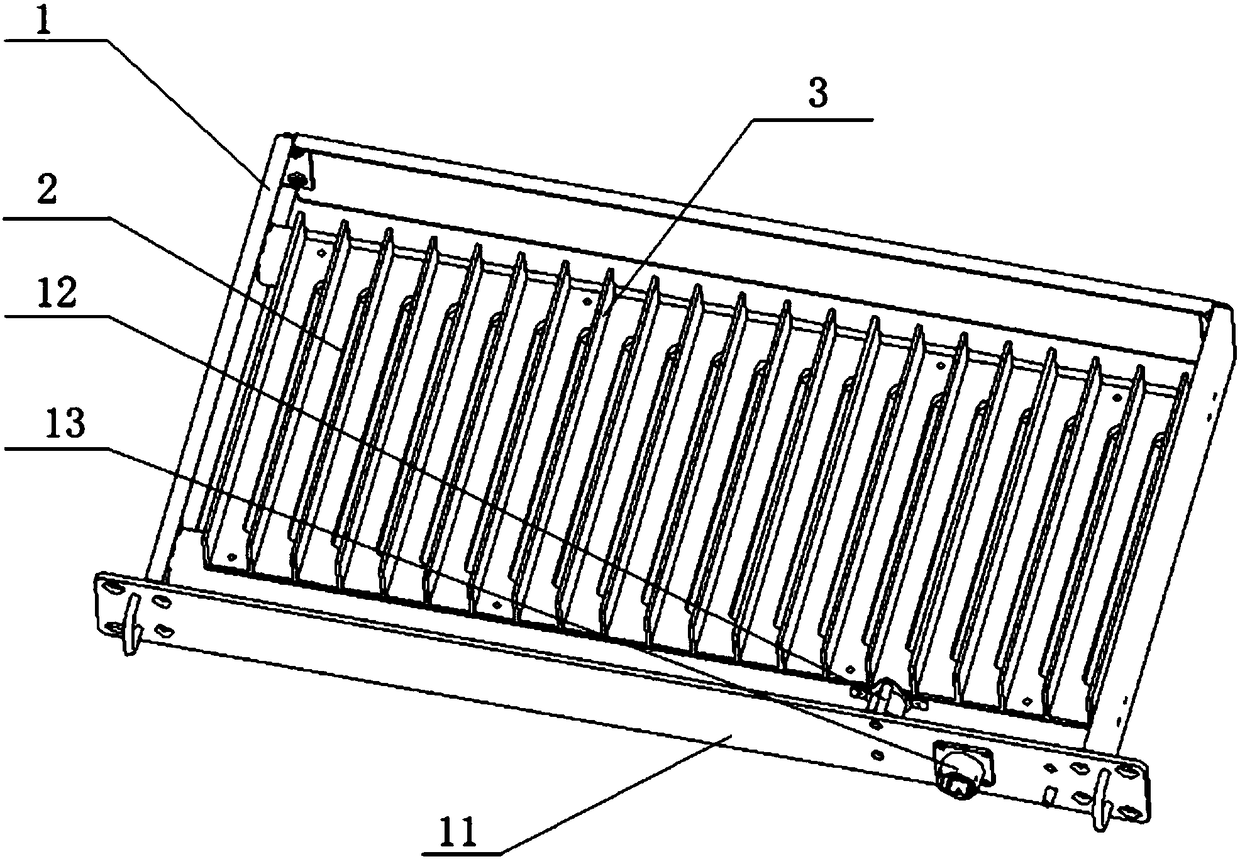

[0031] The present invention provides a heating system for driving equipment, the heating system is used to heat the cabinet, such as figure 1 As shown, the heating system includes:

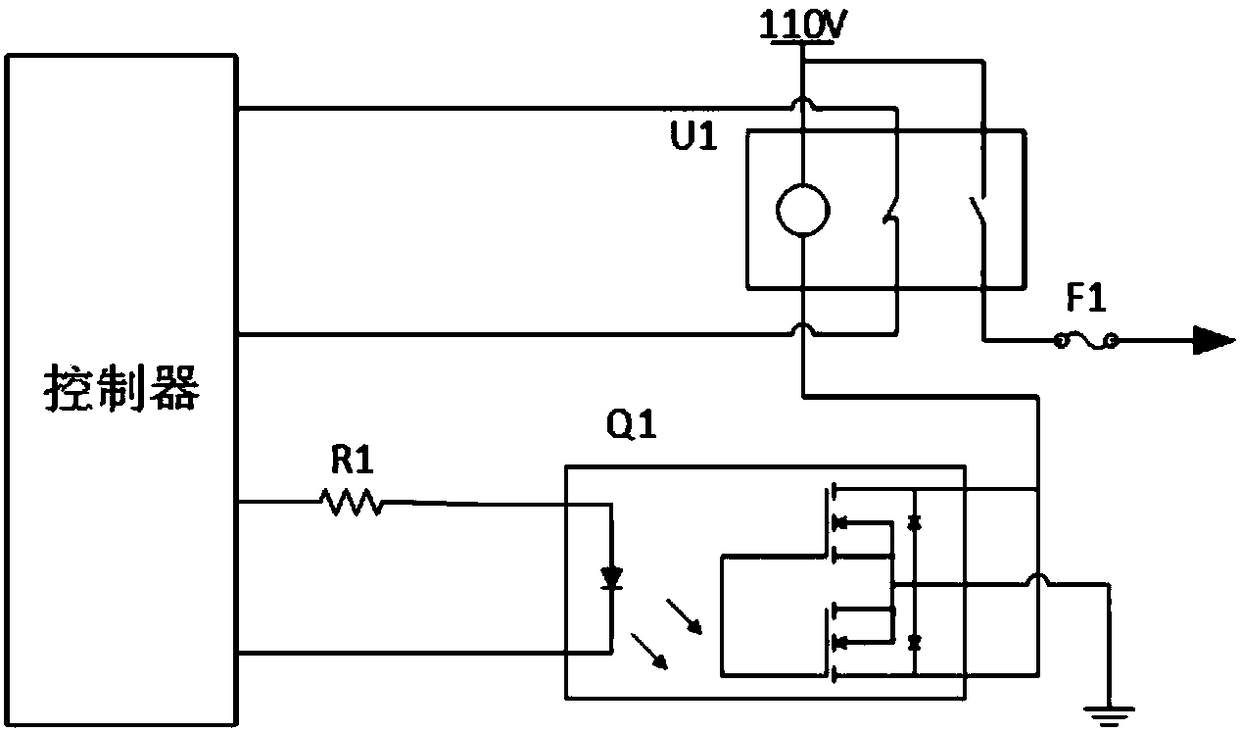

[0032] A heater, and a control board that controls the heating process of the heater, and an external temperature sensor is also connected to the control board;

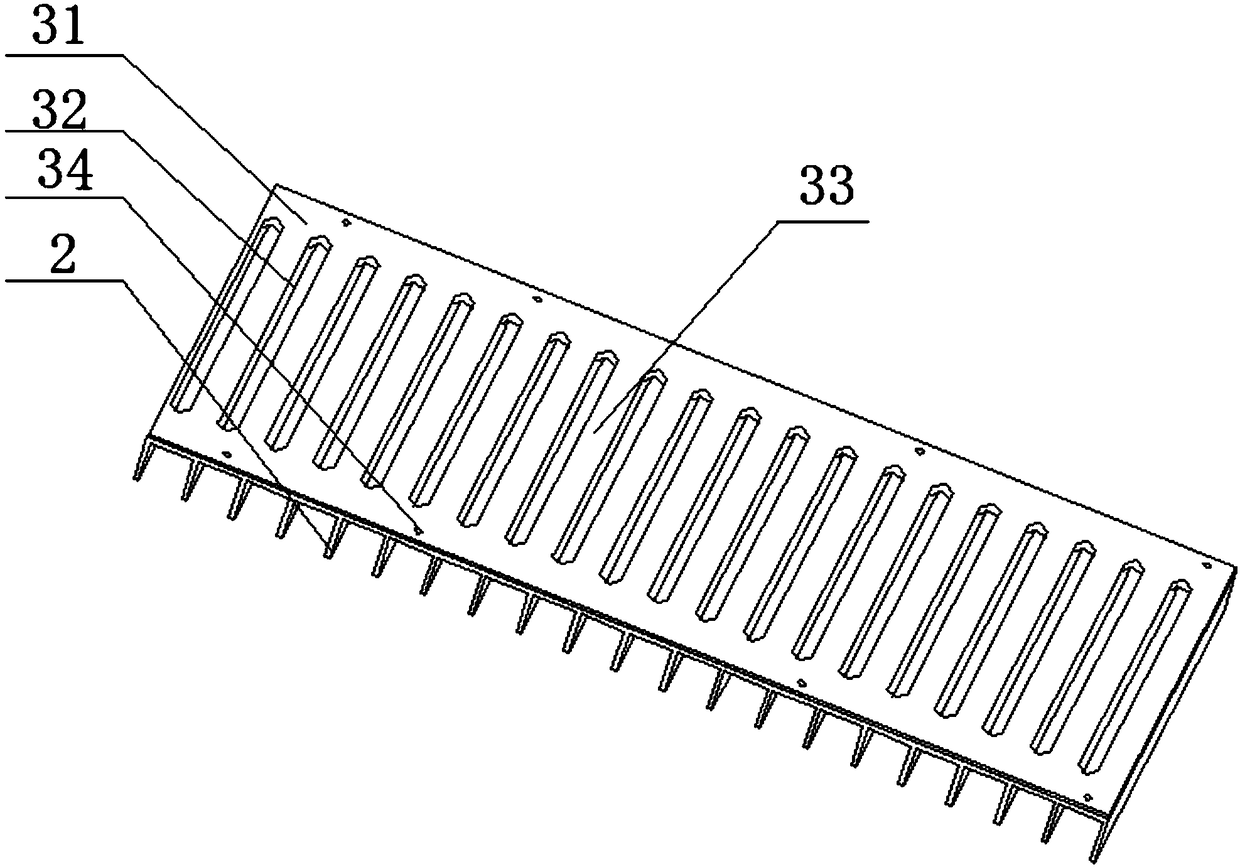

[0033] The heater includes a machine frame, and a silicone heating sheet for electric heating is fixed on the machine frame;

[0034] The temperature control switch is connected to the control board through cables.

[0035] In practice, in order to solve the various defects in the prior art of using thermistor devices to work in the driving equipment cabinet, the embodiment of the present application proposes a heating system for driving equipment, by using silica gel in the heating system to heat Compared with metal heat pipe heaters and PTC heaters, silicone heaters have the advantages of small size, simple process, convenient formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com