Method for retrieving and using technical remaining heat in petroleum refining process

A technology for petroleum refining and waste heat, which is used in household heating, heating methods, lighting and heating equipment, etc. It can solve the problem of hot water network heat recovery - low utilization rate, complicated heat consumption of heat sink users, and insufficient network flexibility, etc. To improve the hot water energy utilization process, improve flexibility and operability, and optimize hot water energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

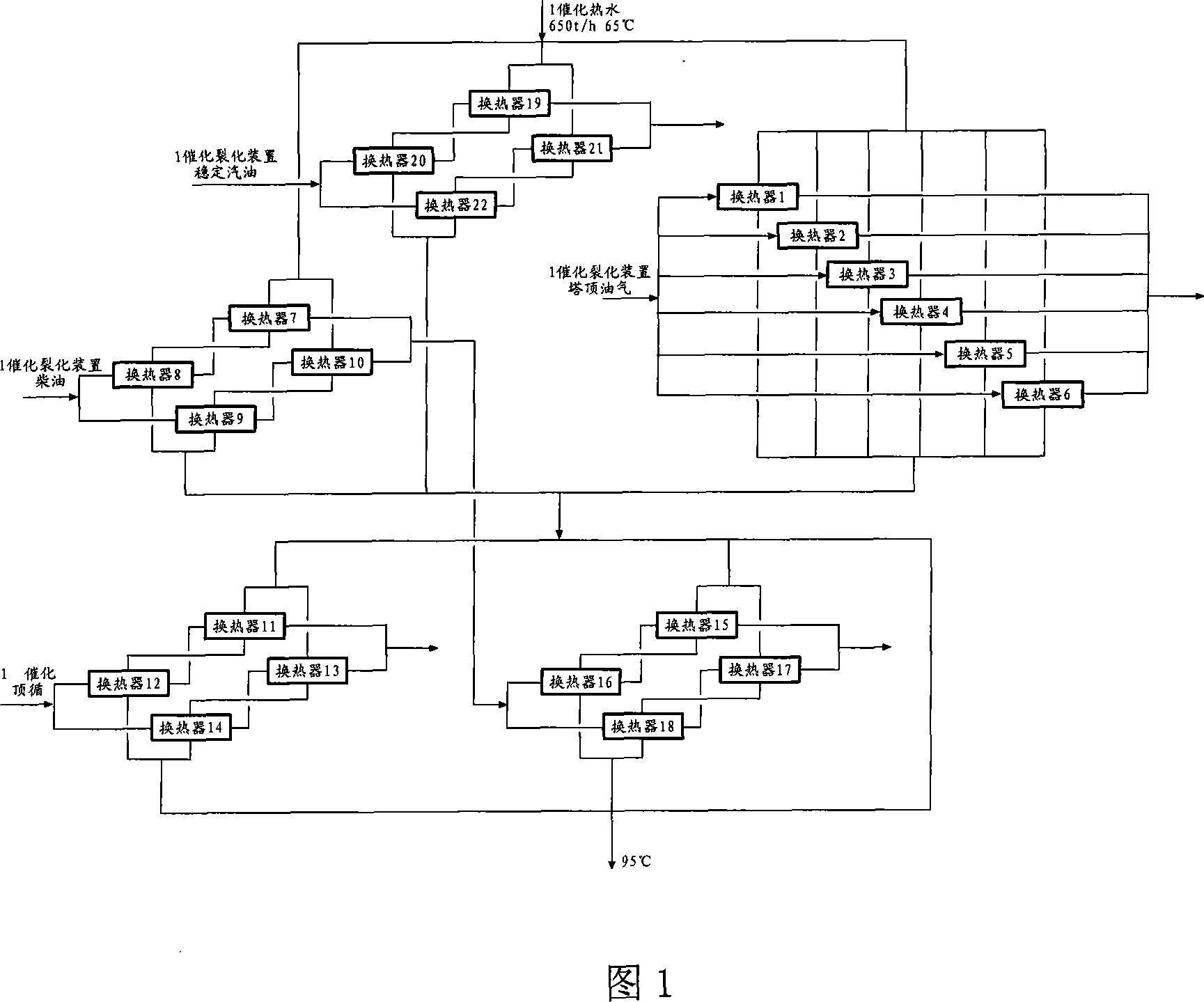

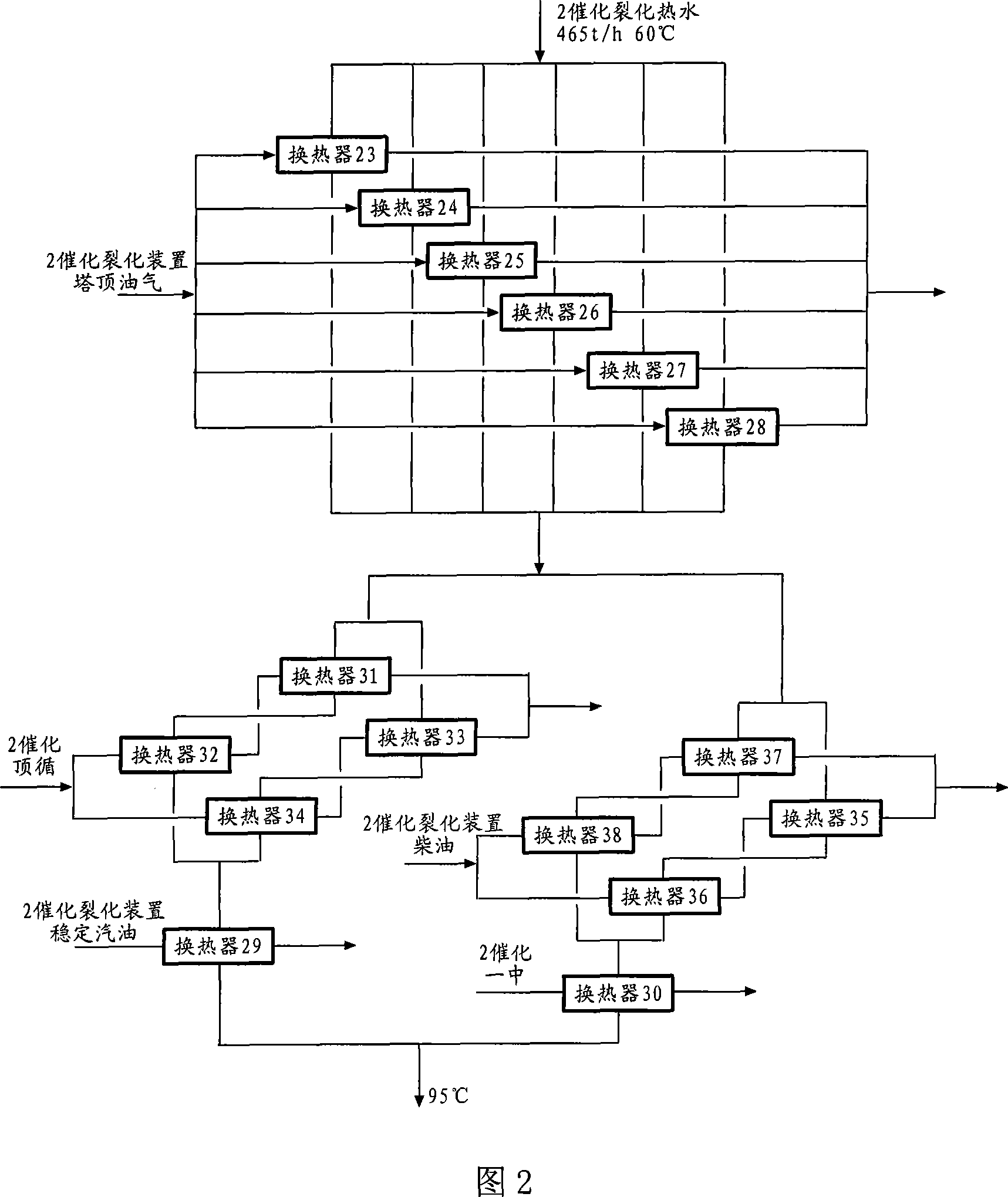

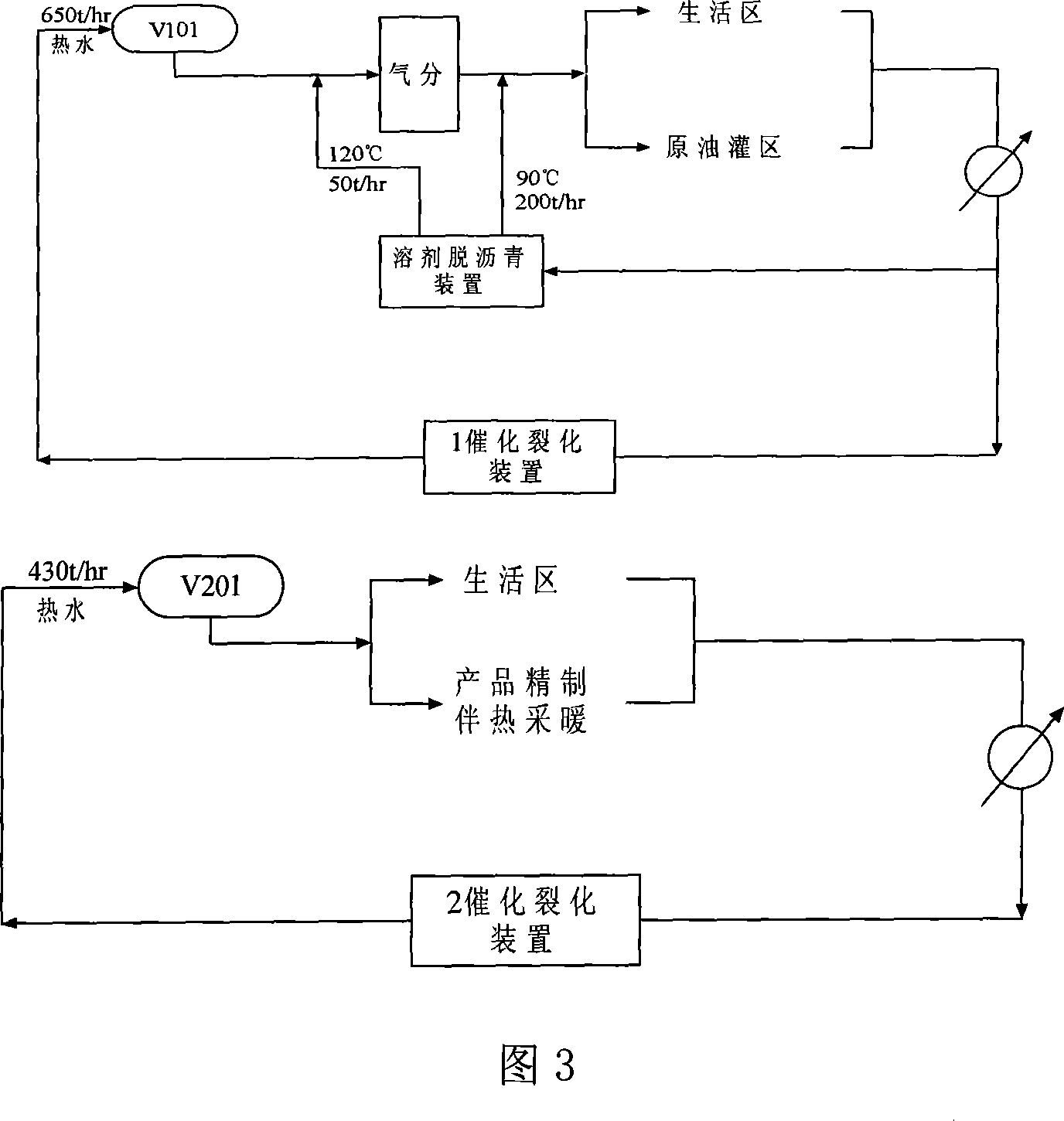

[0027] Embodiment 1 Recovery and utilization method of process waste heat of the present invention

[0028] Note: The 1 catalytic device and the 2 catalytic device described in this example are the same as the 1 catalytic device and the 2 catalytic device mentioned in the comparative example above. 1 The circulation and reflux of the main fractionation tower top of the catalytic cracking unit is referred to as 1 catalytic top circulation, 1 the circulation and reflux of the first middle section of the main fractionation tower of the catalytic cracking unit is referred to as 1 catalytic middle, 2 the circulation and reflux of the main fractionation tower top of the catalytic cracking unit is referred to as 2 catalytic top circulation, 2 The circulating reflux in the first middle section of the main fractionation tower of the catalytic cracking unit is referred to as 2 catalytic first middle.

[0029] As shown in Fig. 4, the double hot water network system of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com