Patents

Literature

44 results about "Petroleum refining processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries (also referred to as oil refineries) to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

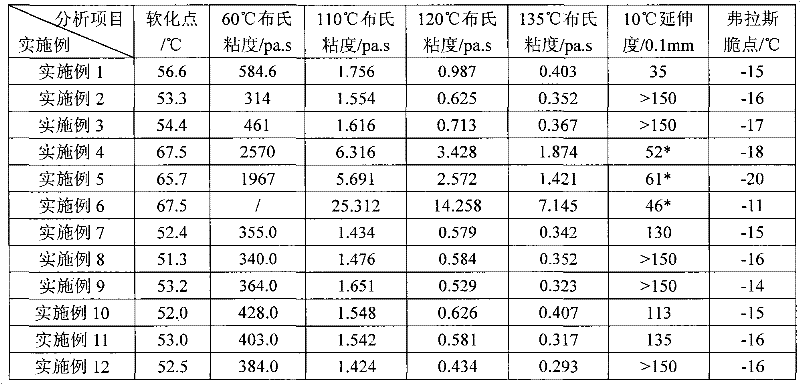

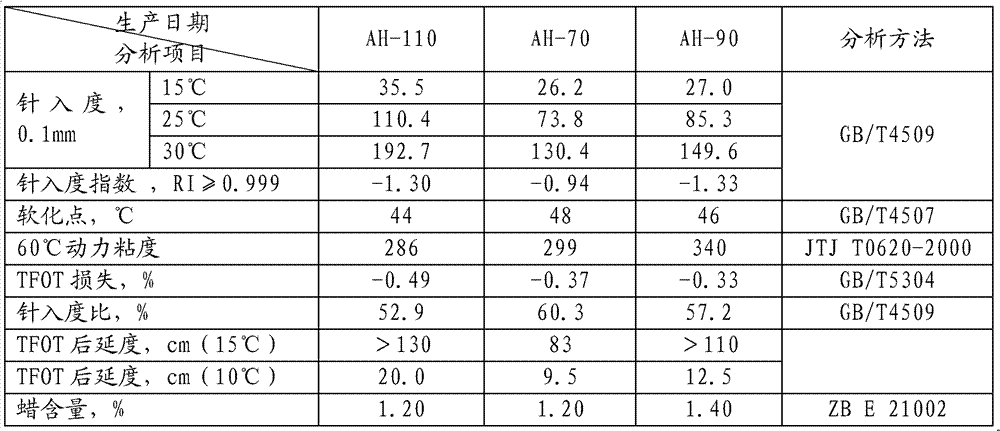

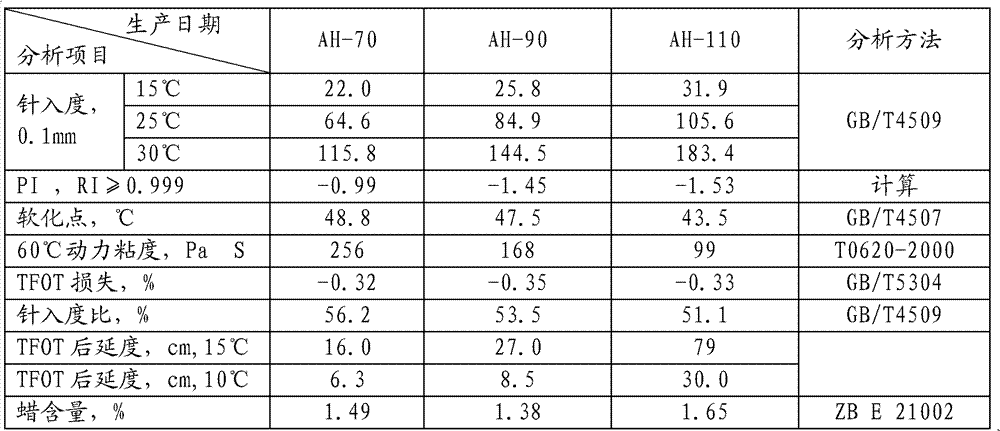

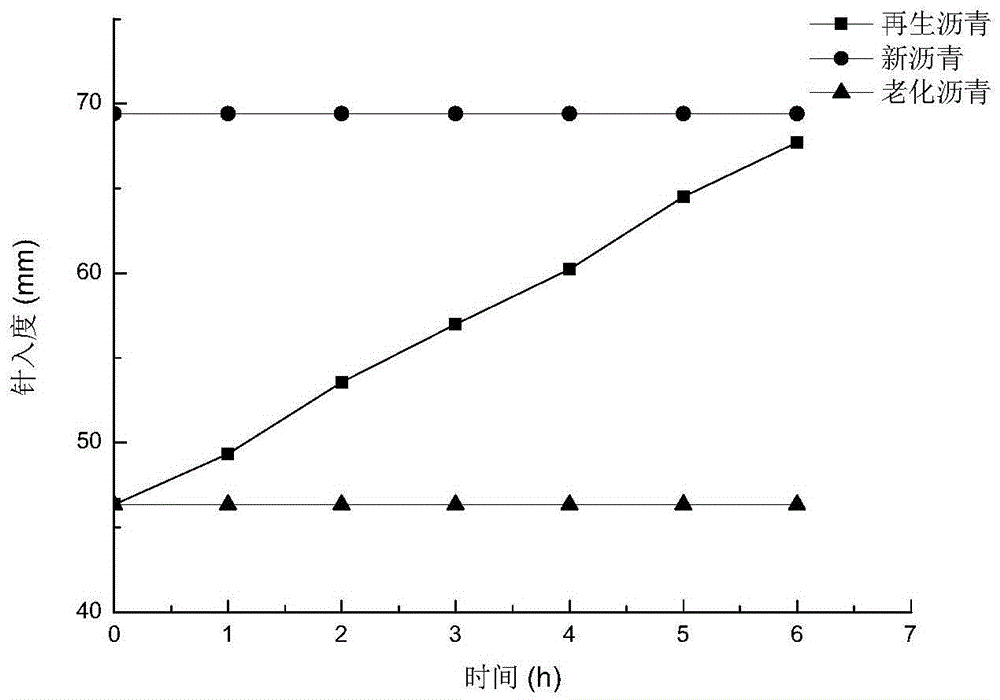

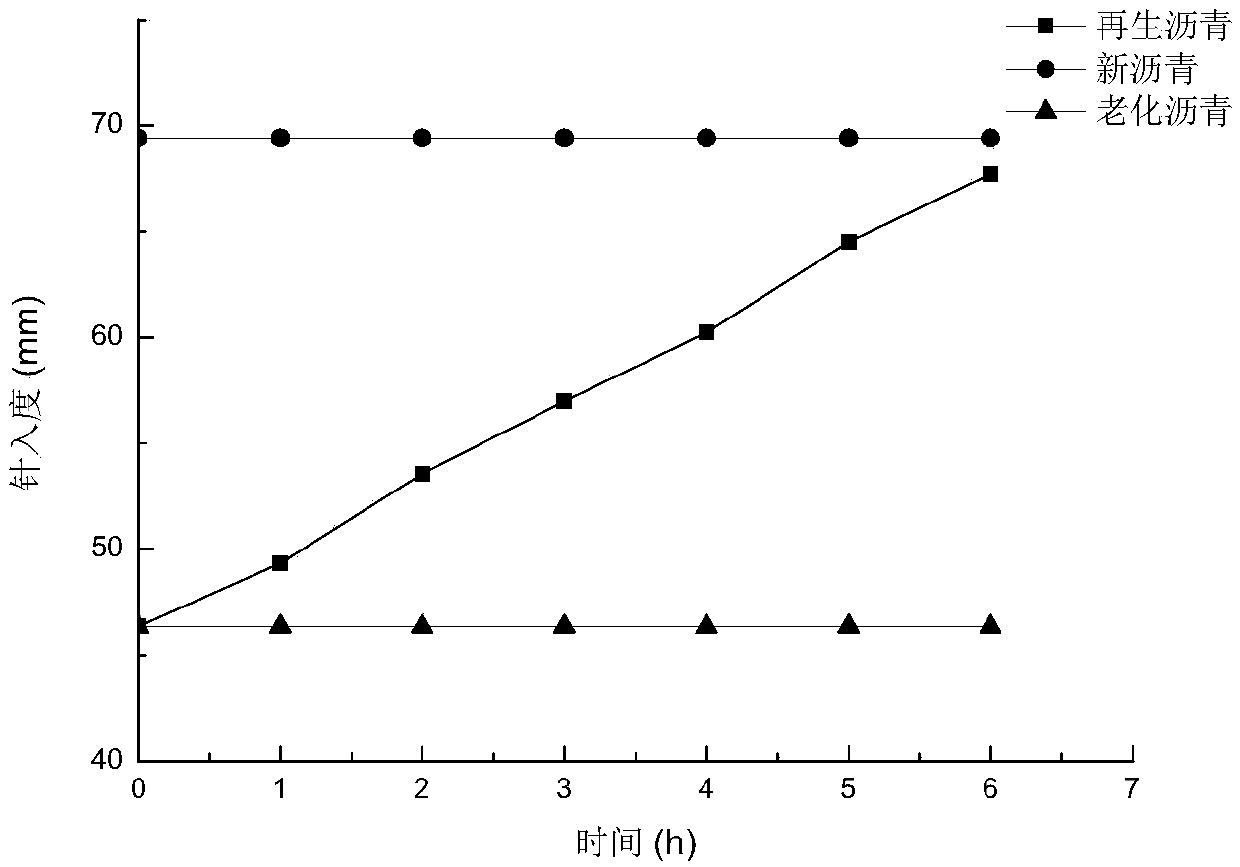

Warm mixed asphalt cement and preparation method thereof

ActiveCN102532920AWith viscosity reducing effectHas a lubricating effectIn situ pavingsClimate change adaptationEnvironmental resistanceChemical industry

Owner:PETROCHINA CO LTD +1

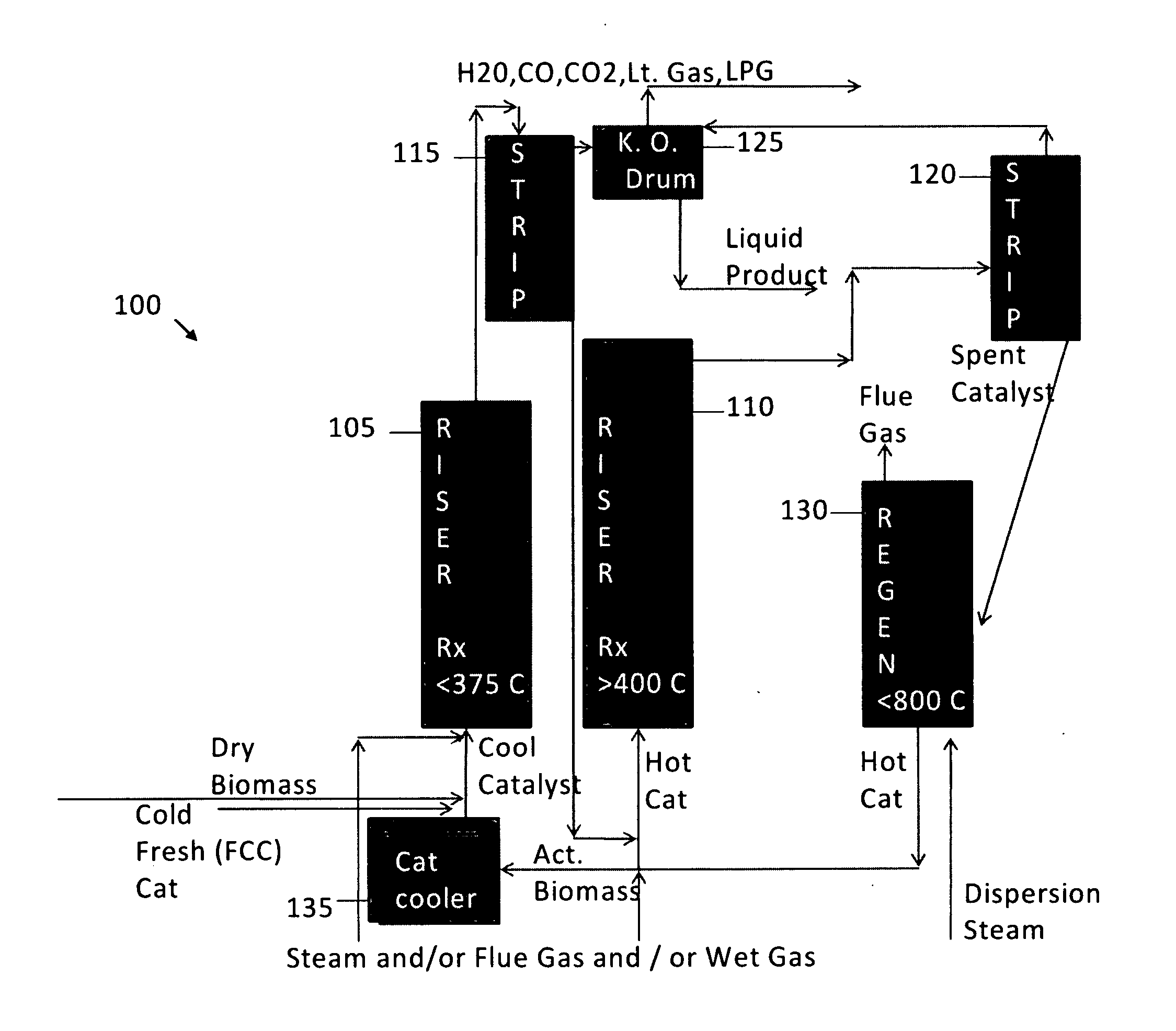

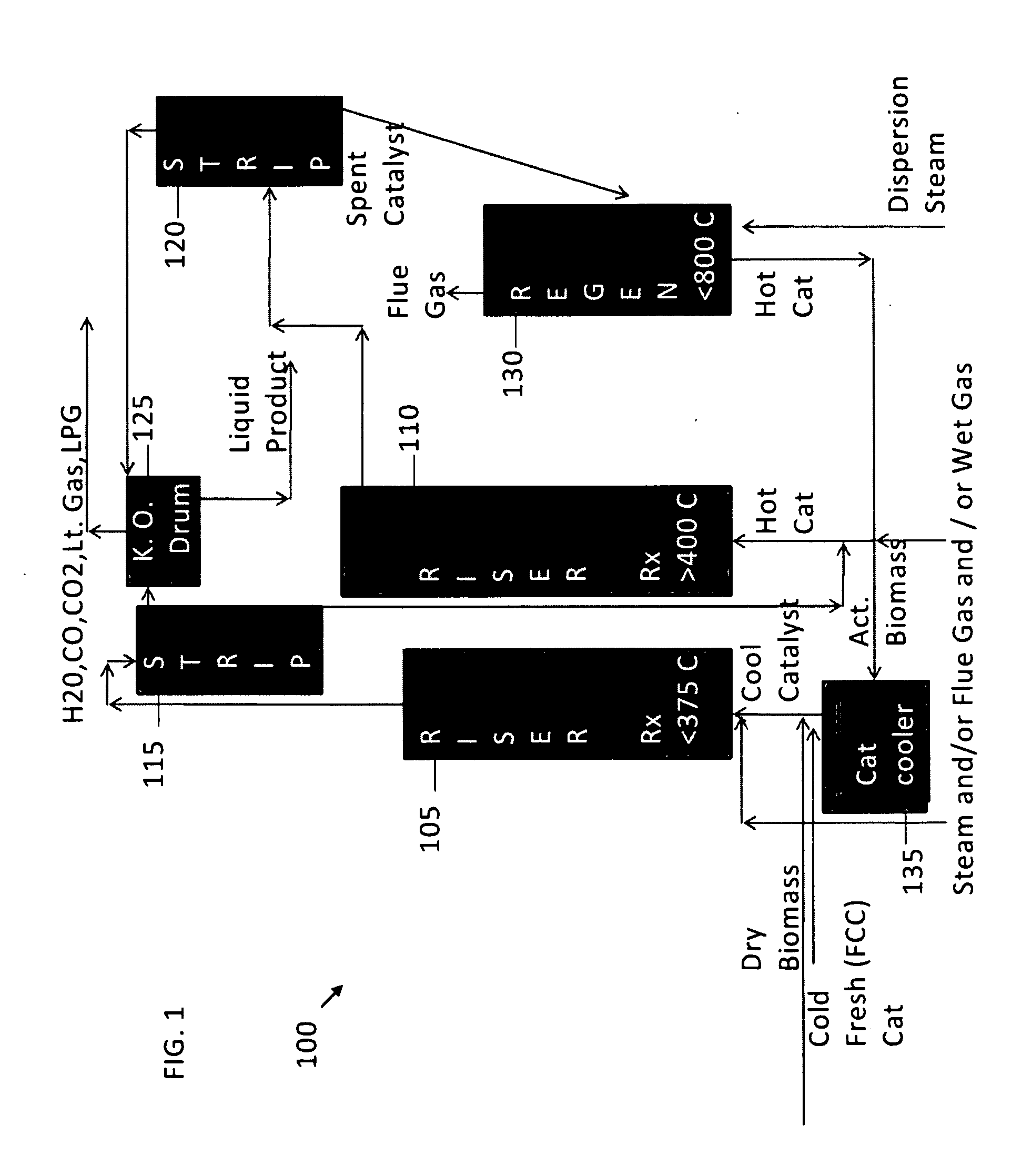

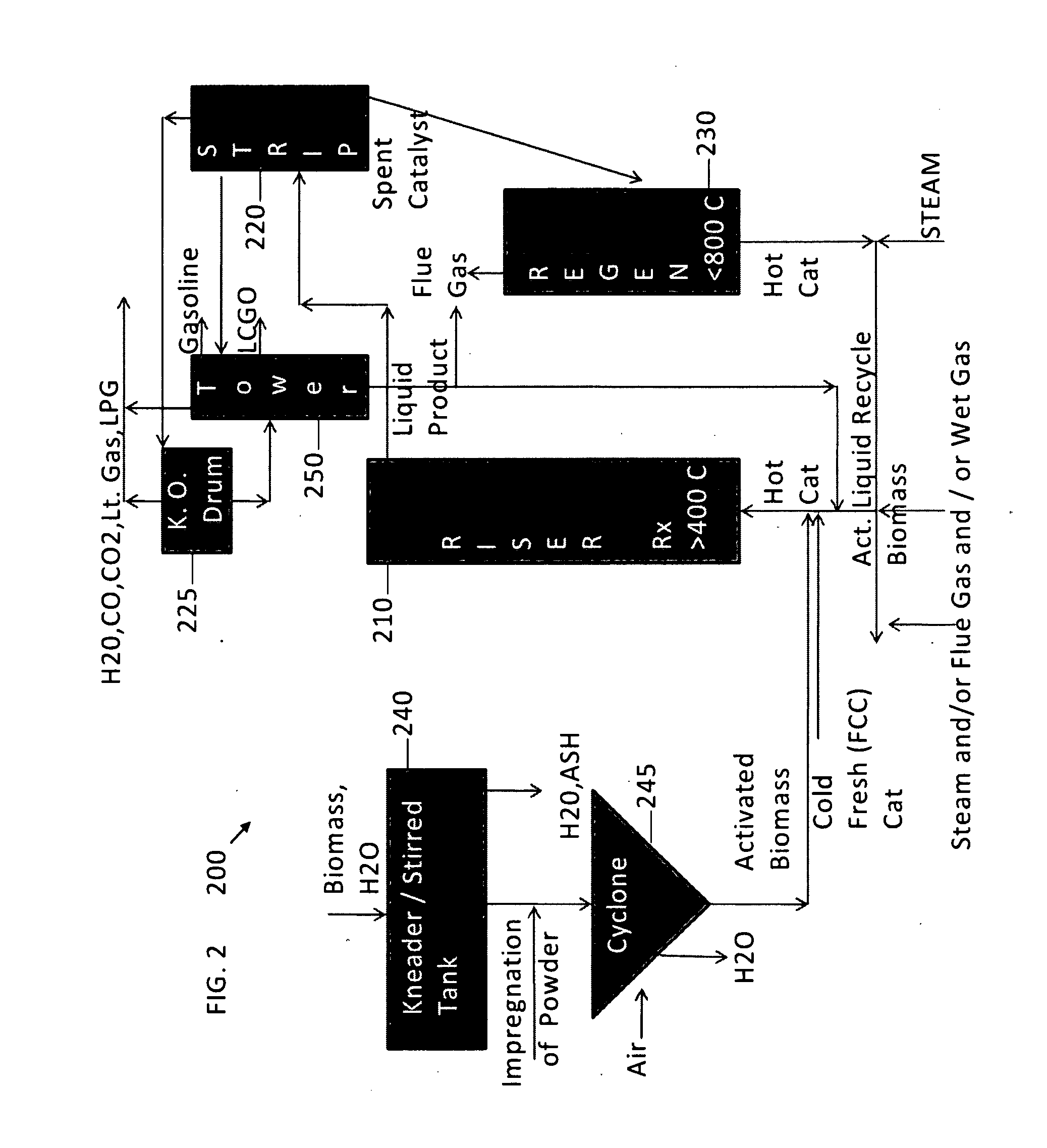

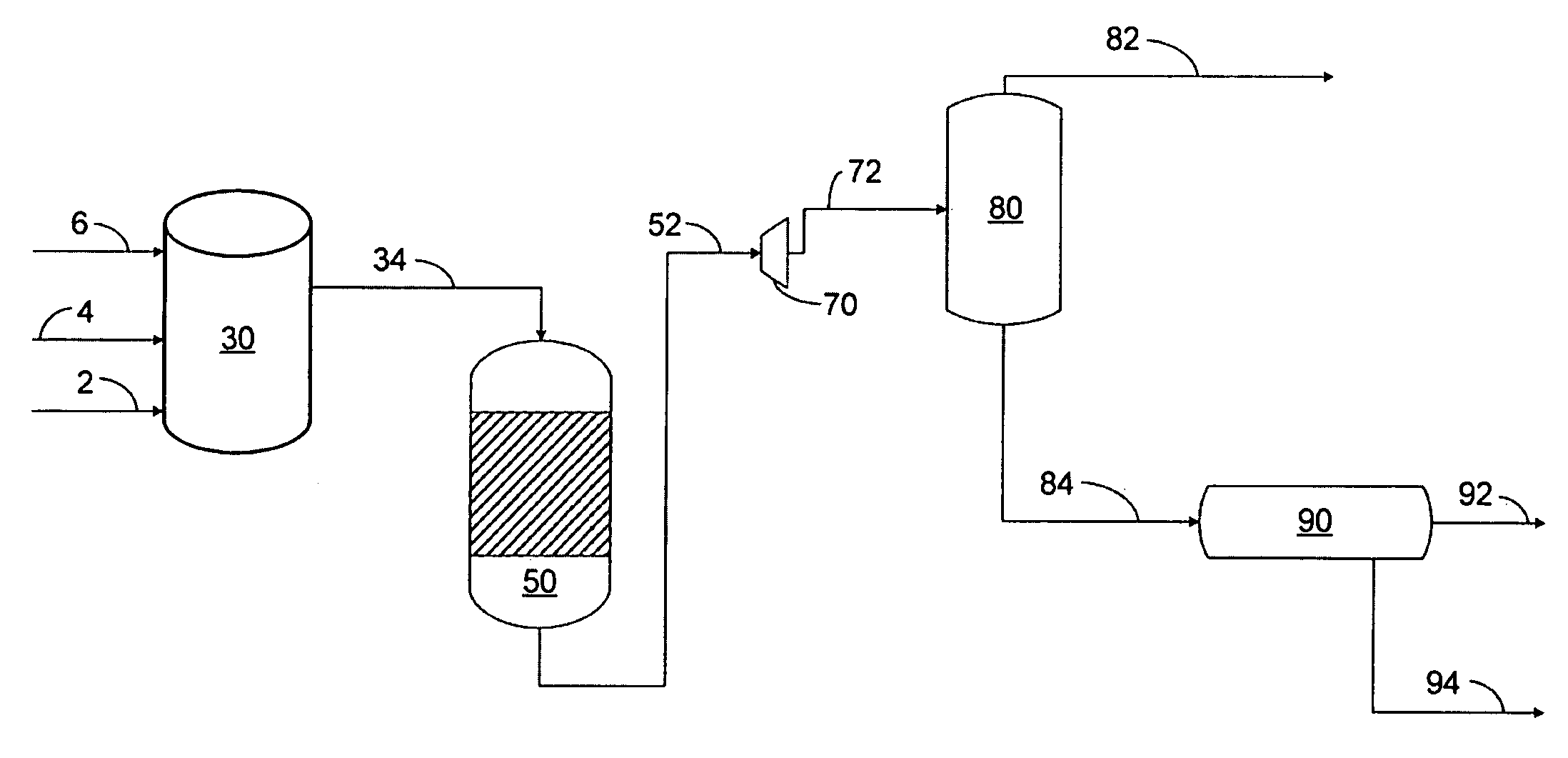

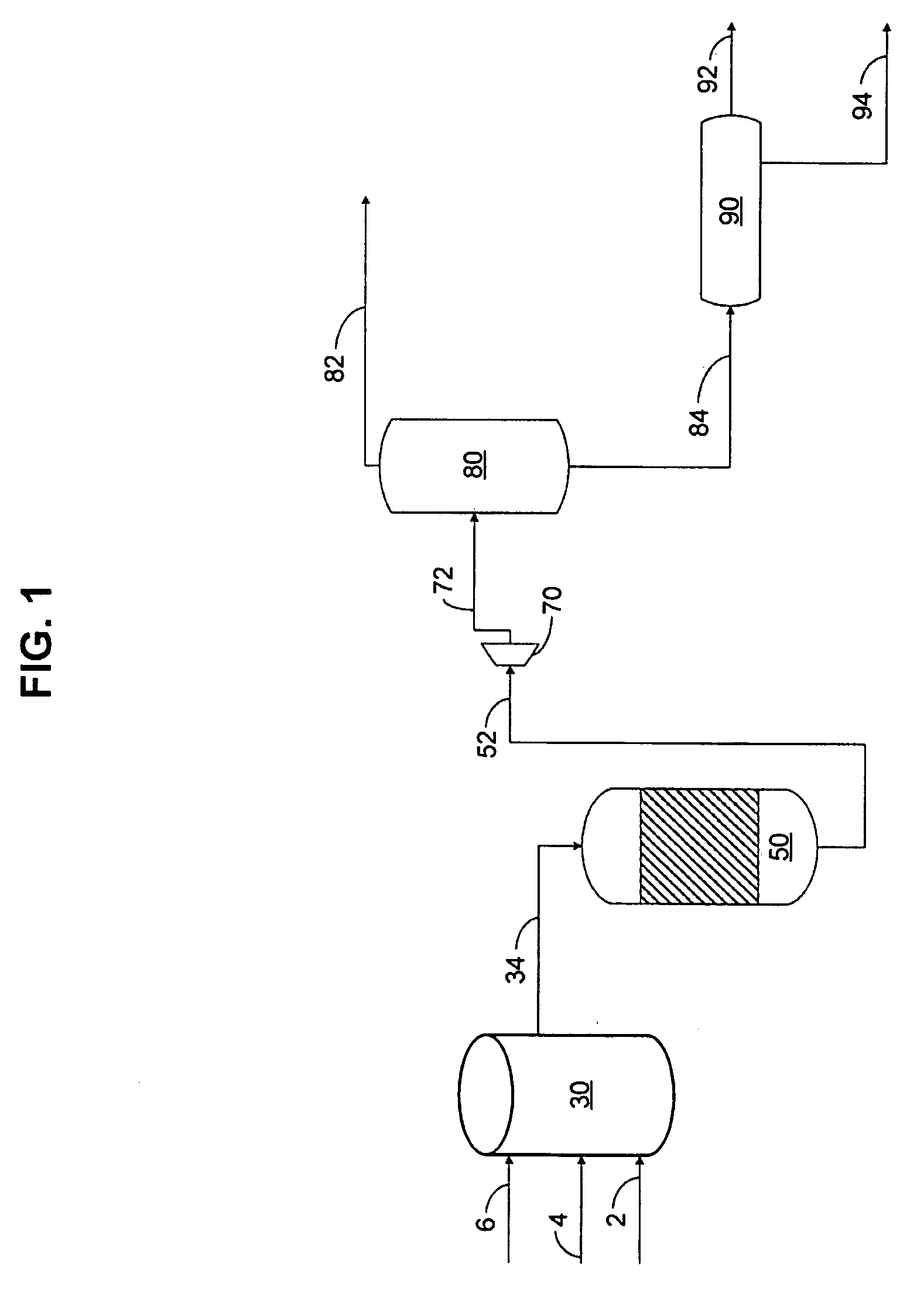

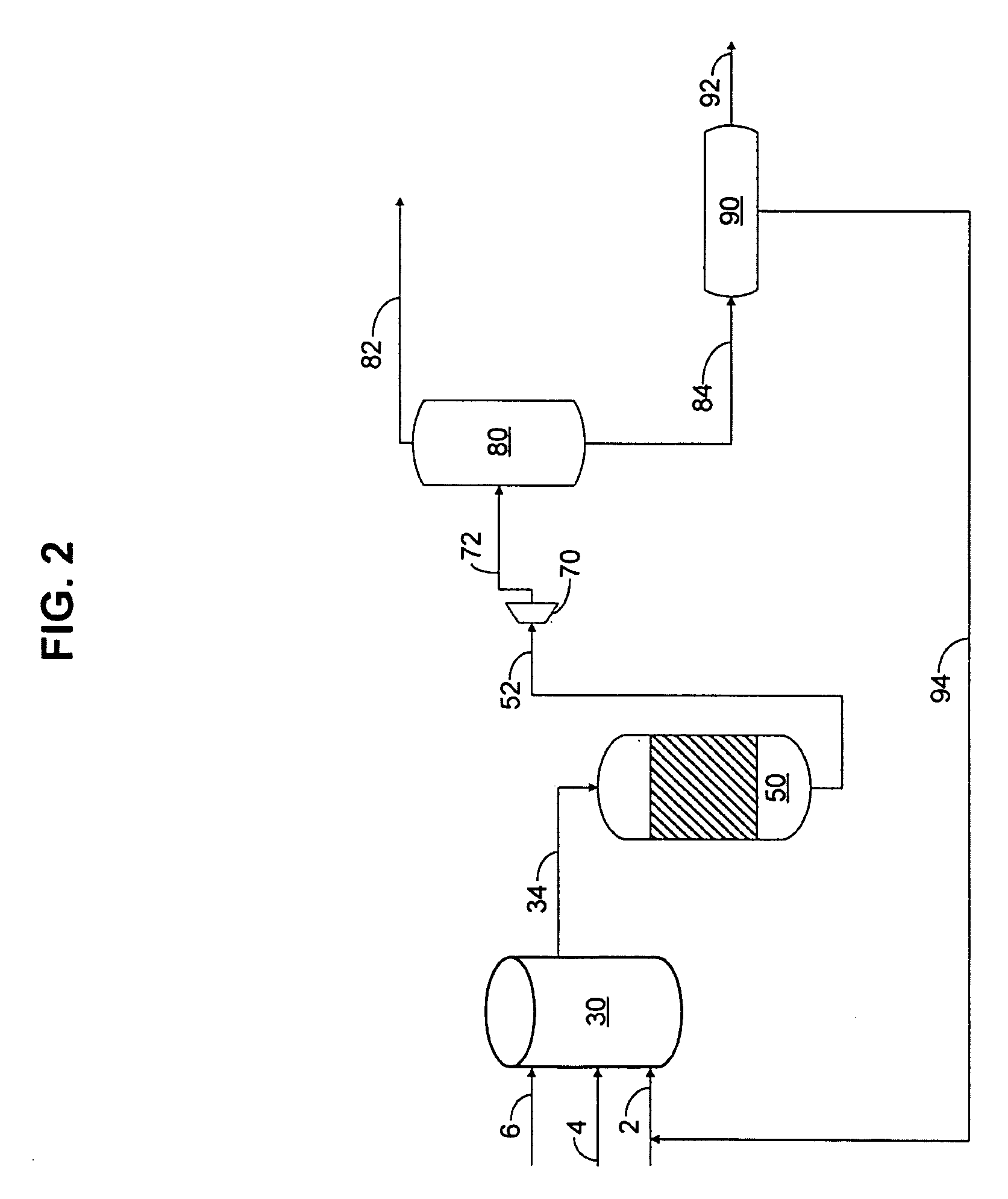

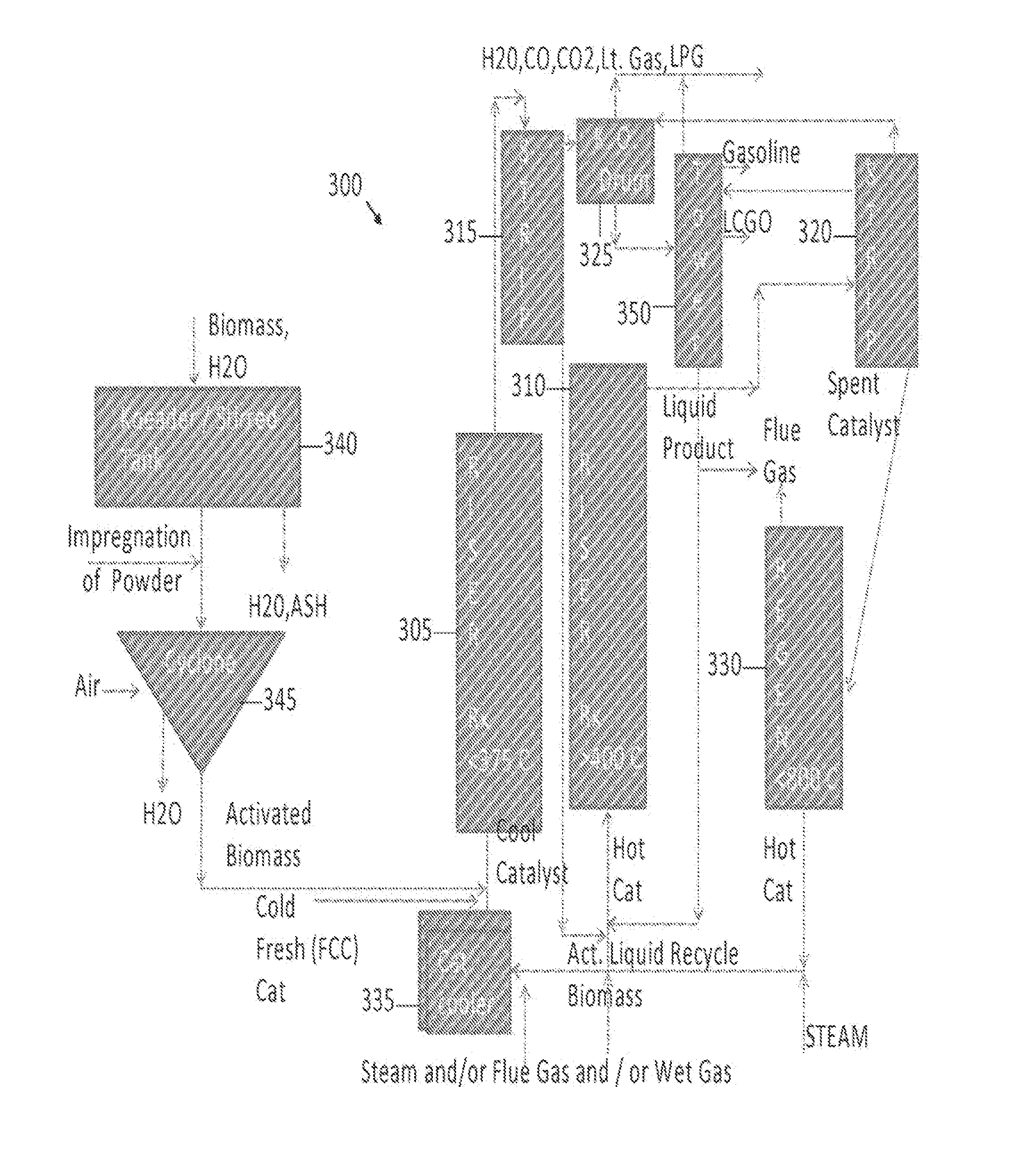

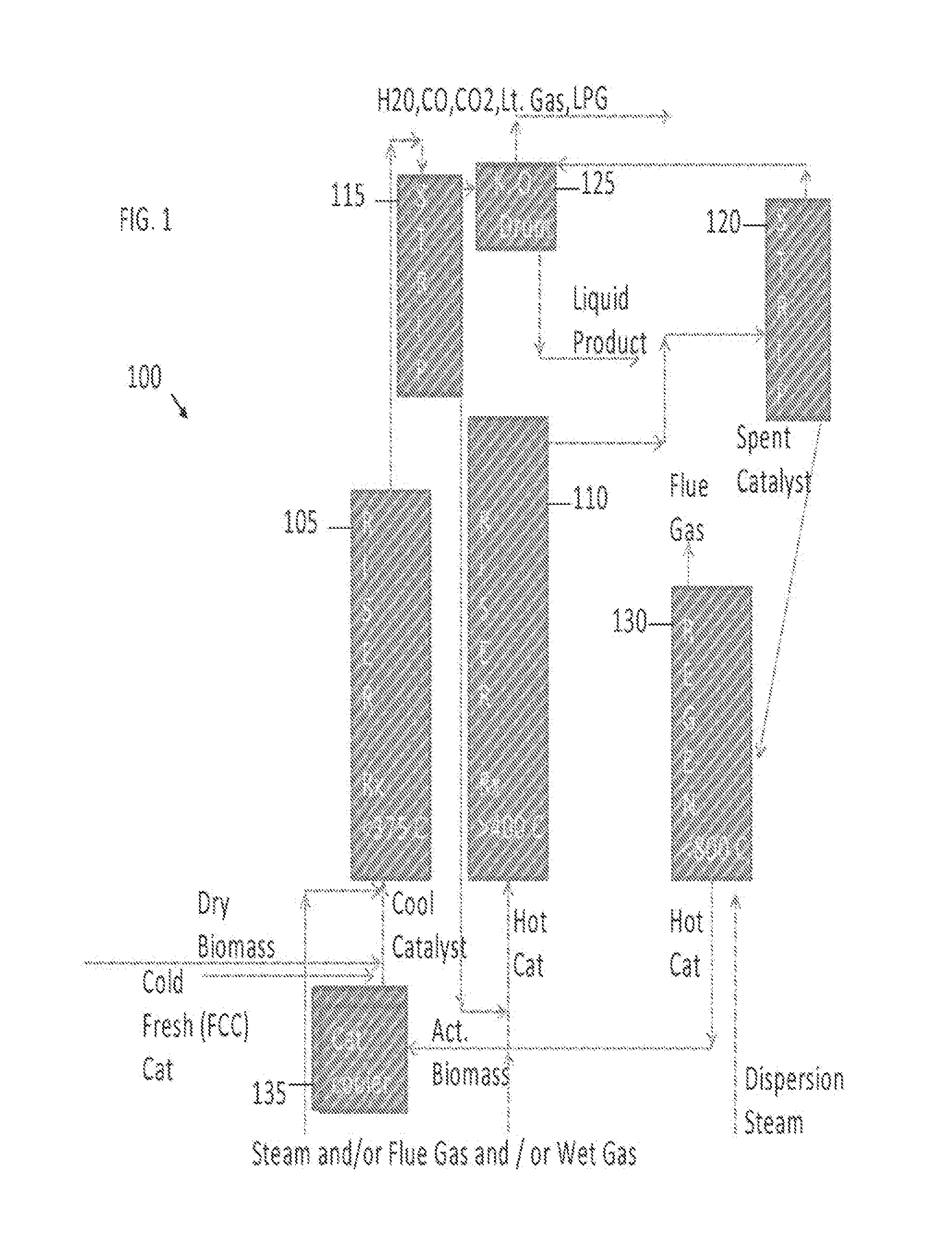

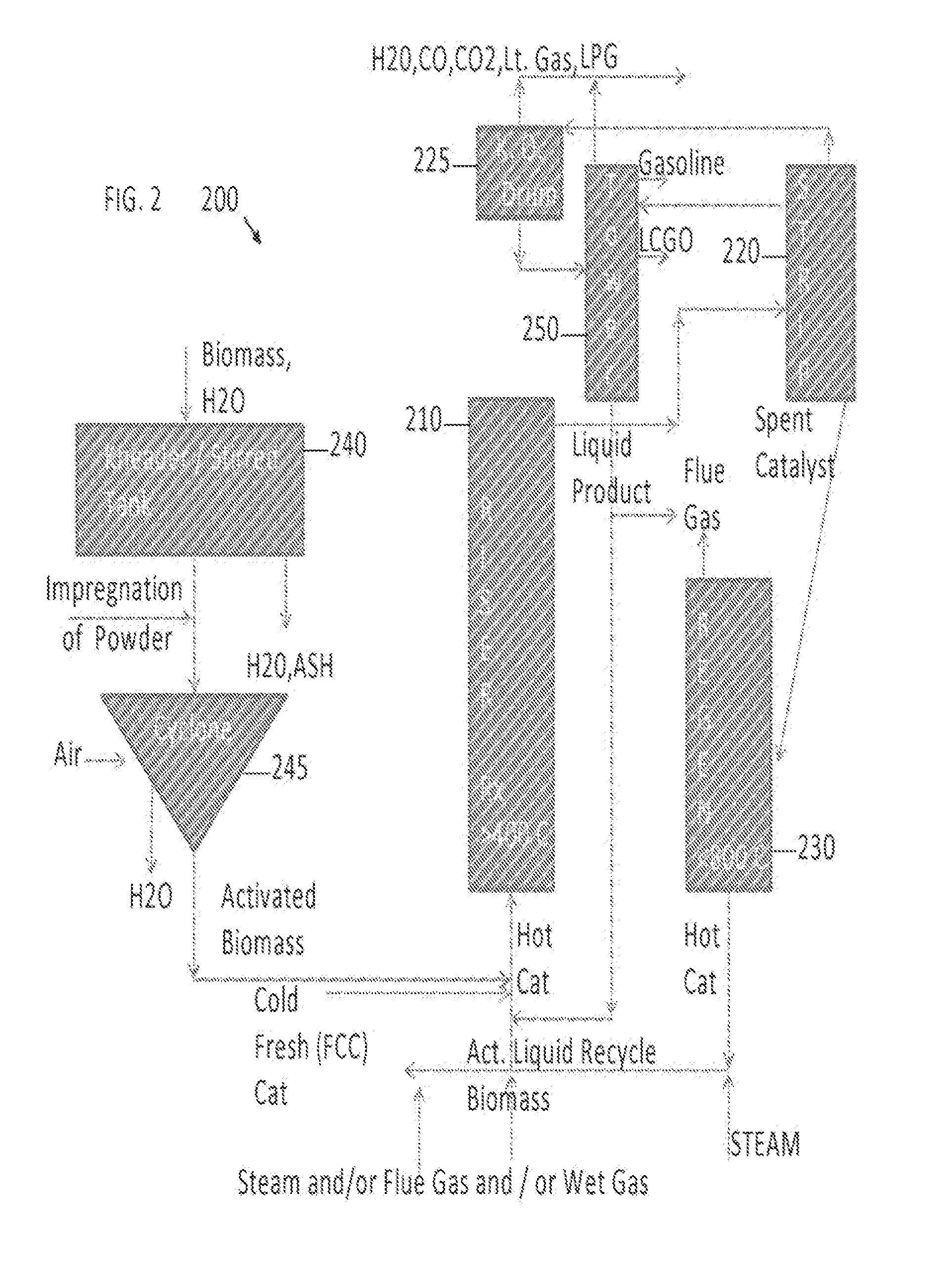

Co-processing solid biomass in a conventional petroleum refining process unit

ActiveUS20120022307A1Reduce degradationReduce energy costsCatalytic crackingOther chemical processesCo-processingPetroleum

Preparing solid biomass particles for catalytic conversion includes agitating solid biomass particles and providing a biomass-catalyst mixture to a conventional petroleum refinery process unit. The biomass-catalyst mixture includes the solid biomass particles and a catalyst. Agitating solid biomass particles includes flowing a gas to provide a velocity to at least a portion of the solid biomass particles sufficient to reduce their sizes. Co-processing a biomass feedstock and a conventional petroleum feedstock includes liquefying at least a portion of a biomass-catalyst mixture and co-processing at least a portion of the liquefied biomass feedstock and a conventional petroleum feedstock in a conventional petroleum refinery process unit. The biomass feedstock includes a plurality of solid biomass particles and a catalyst, which is liquefied to produce a liquefied biomass feedstock.

Owner:MARD INC

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

Co-processing solid biomass in a conventional petroleum refining process unit

ActiveUS8288599B2Low costReduce degradationCatalytic crackingOther chemical processesCo-processingPetroleum

Preparing solid biomass particles for catalytic conversion includes agitating solid biomass particles and providing a biomass-catalyst mixture to a conventional petroleum refinery process unit. The biomass-catalyst mixture includes the solid biomass particles and a catalyst. Agitating solid biomass particles includes flowing a gas to provide a velocity to at least a portion of the solid biomass particles sufficient to reduce their sizes. Co-processing a biomass feedstock and a conventional petroleum feedstock includes liquefying at least a portion of a biomass-catalyst mixture and co-processing at least a portion of the liquefied biomass feedstock and a conventional petroleum feedstock in a conventional petroleum refinery process unit. The biomass feedstock includes a plurality of solid biomass particles and a catalyst, which is liquefied to produce a liquefied biomass feedstock.

Owner:MARD INC

Pseudomonas sp. XQ23 capable of efficiently degrading multiple phenolic compounds

The invention discloses a pseudomonas sp. XQ23 capable of efficiently degrading multiple phenolic compounds. The strain of the pseudomonas sp. XQ23 is separated and purified from sludge which is seriously polluted by phenols. The strain has been preserved in China Center for Type Culture Collection since August 8th, 2009, and the preservation No. is CCTCC M 209175. The invention belongs to the technical field of environmental protection, and especially aims to the degradation problem of phenolic compounds in phenol-containing sewage generated in the petroleum refining process. Ten phenolic compounds, such as phenol, methyl phenol and the like, generally account for more than 97% of the total phenol content in the phenol-containing sewage. The strain is inoculated to the water body which contains one, or some or all of the ten phenolic compounds, and necessary inorganic salts are added; and while controlling the reaction temperature at 30+ / -2 DEG C and the controlling initial pH value to 7.0+ / -0.2 during degrading, the strain can completely degrade the phenolic compounds within shorter time under aerobic conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

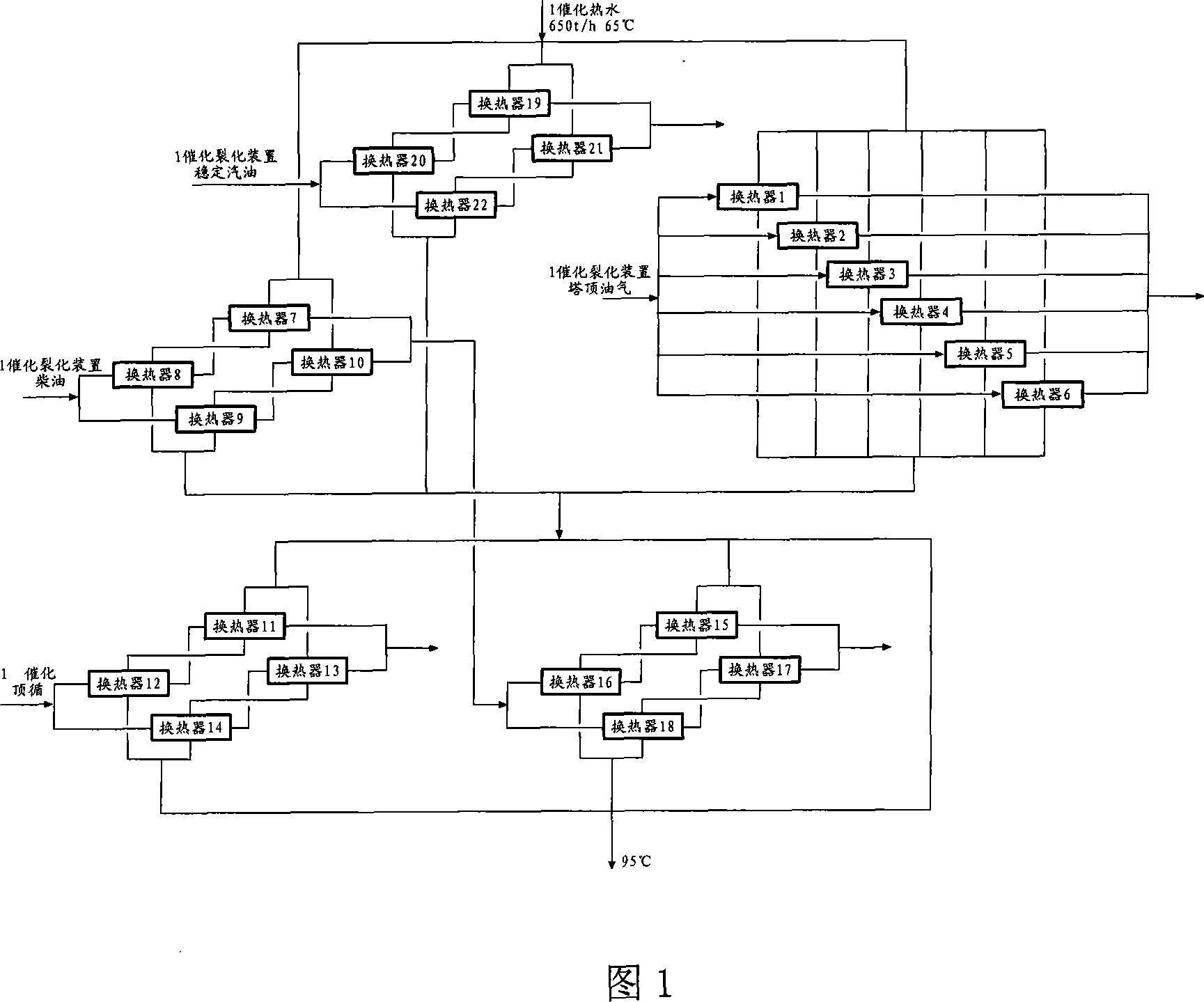

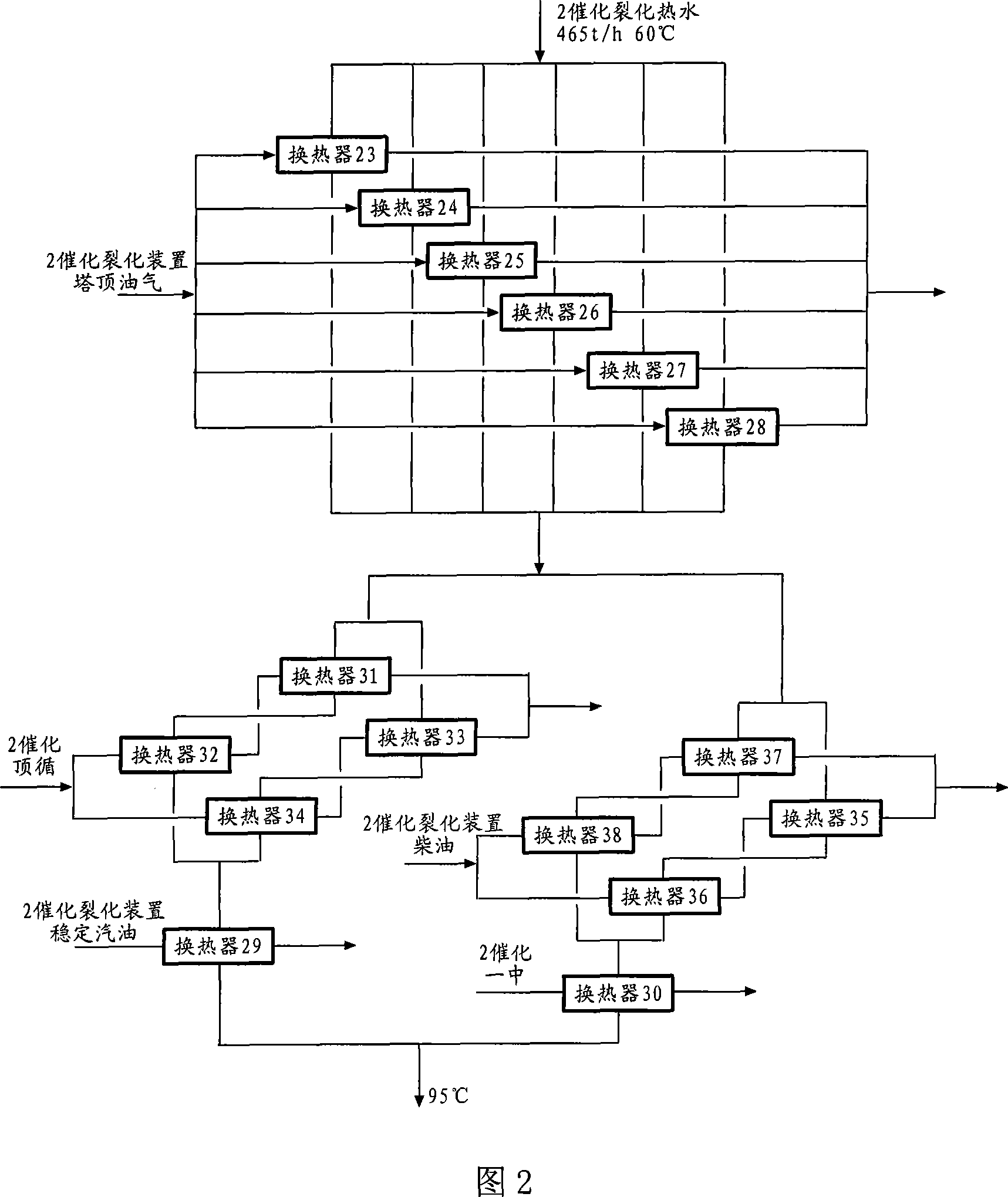

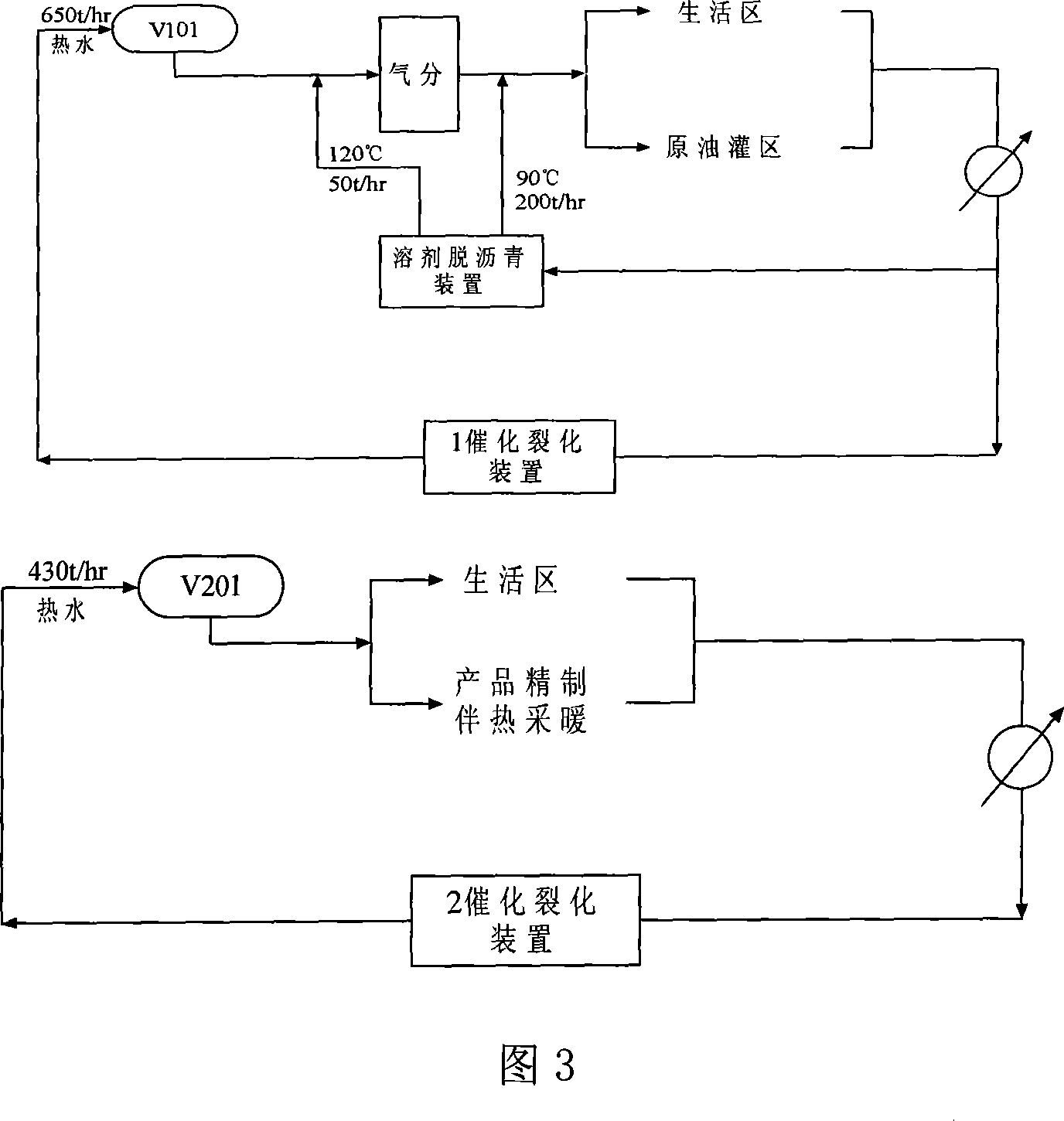

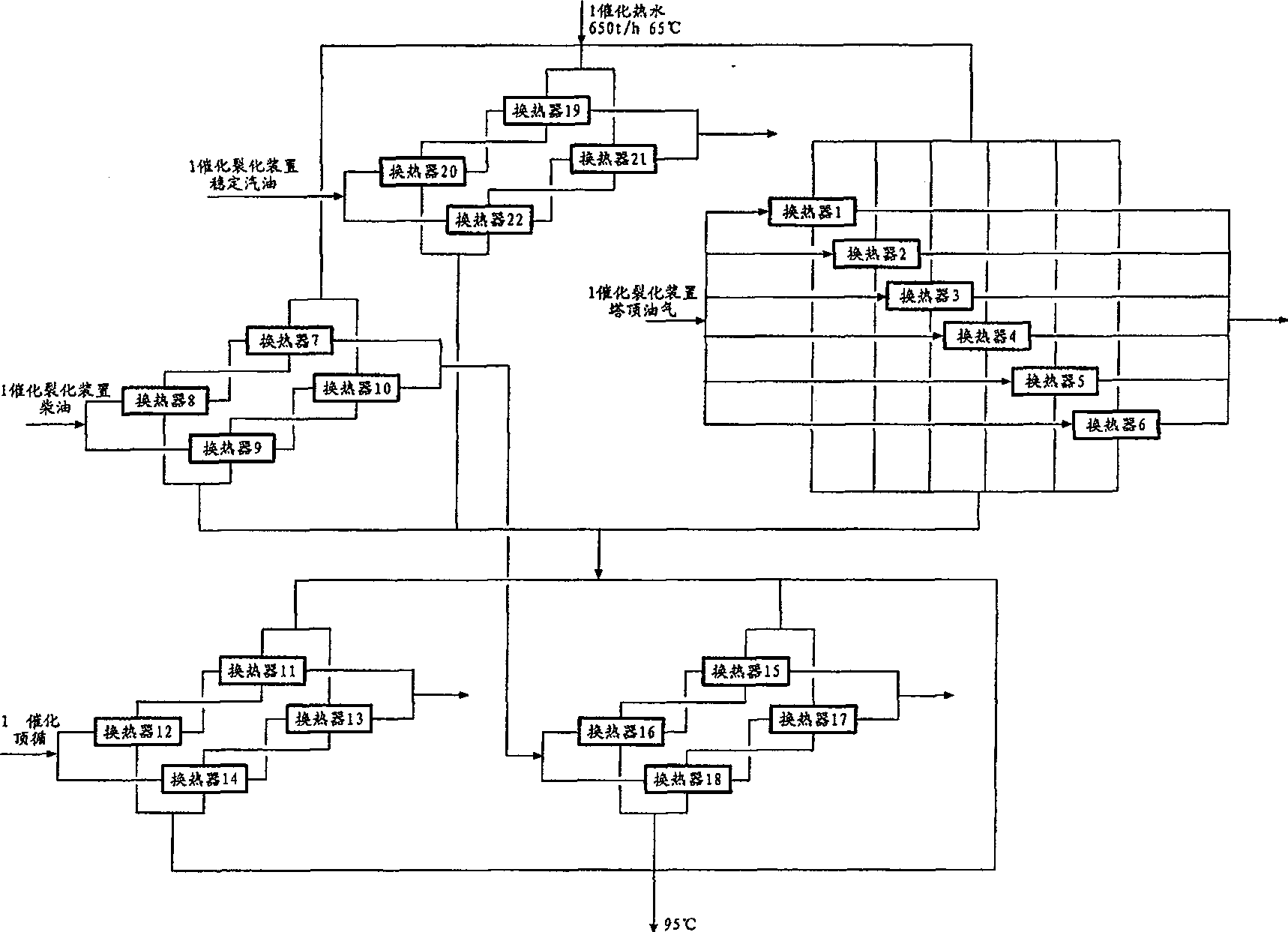

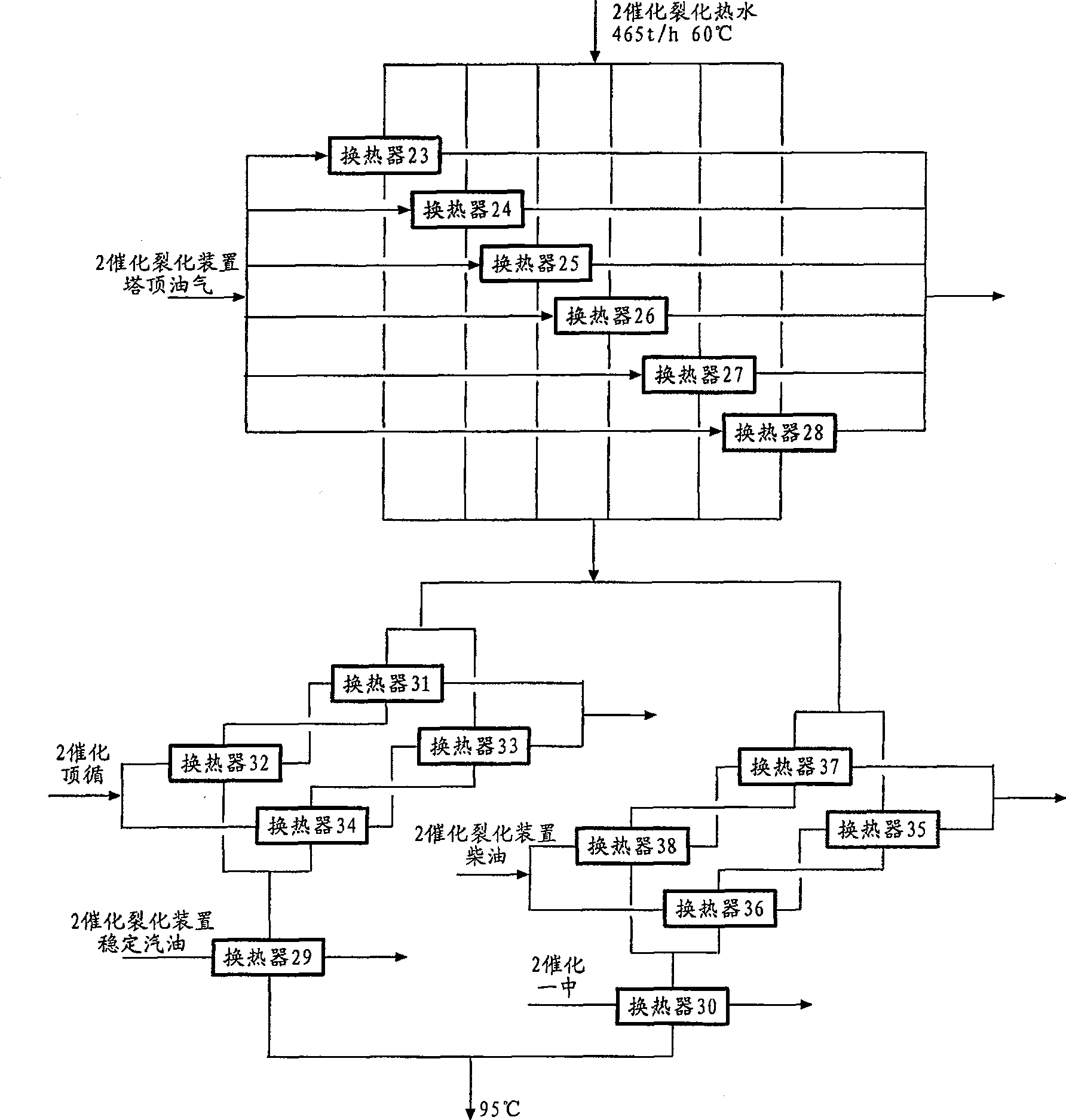

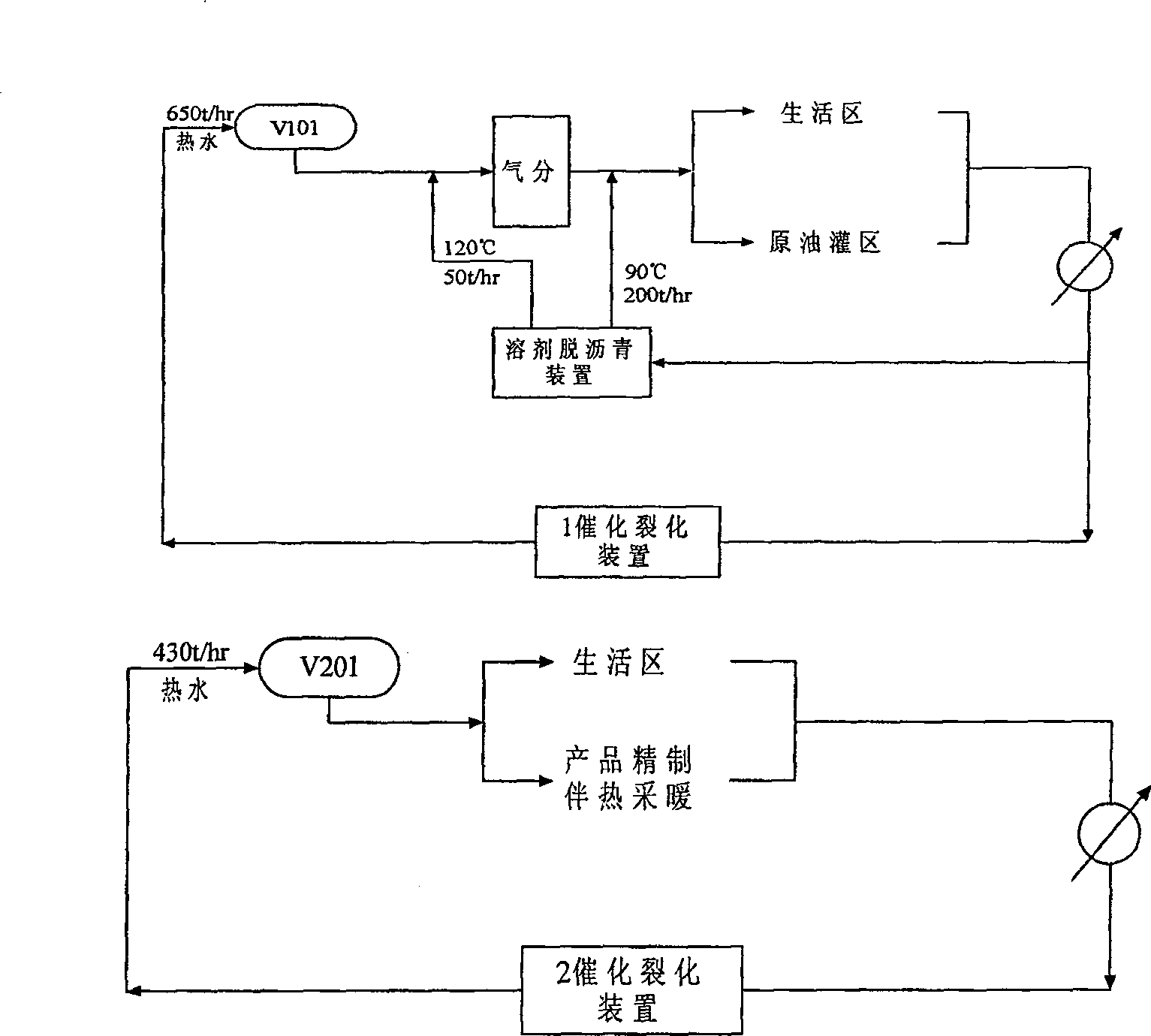

Method for retrieving and using technical remaining heat in petroleum refining process

InactiveCN101093089APerfect processEasy to recycleLighting and heating apparatusHot-water central heatingProcess engineeringThermal water

This invention relates to a method for recovering and utilizing waste heat in oil refining including: 1, a high temperature hot water system recovers waste heat of all high temperature level and part of low temperature level and a low temperature hot water system recovers residual low temperature waste heat at a source part, 2, a heat trap part is divided into a stable part and an unstable part, the stable trap is taken as the main part of the high temperature hot water system and the unstable one is taken as the main part of the low temperature hot water system, 3, hot water is cooled to a stipulated temperature by a cooling system then sent to the source part to collect heat before returning to the source part.

Owner:SOUTH CHINA UNIV OF TECH

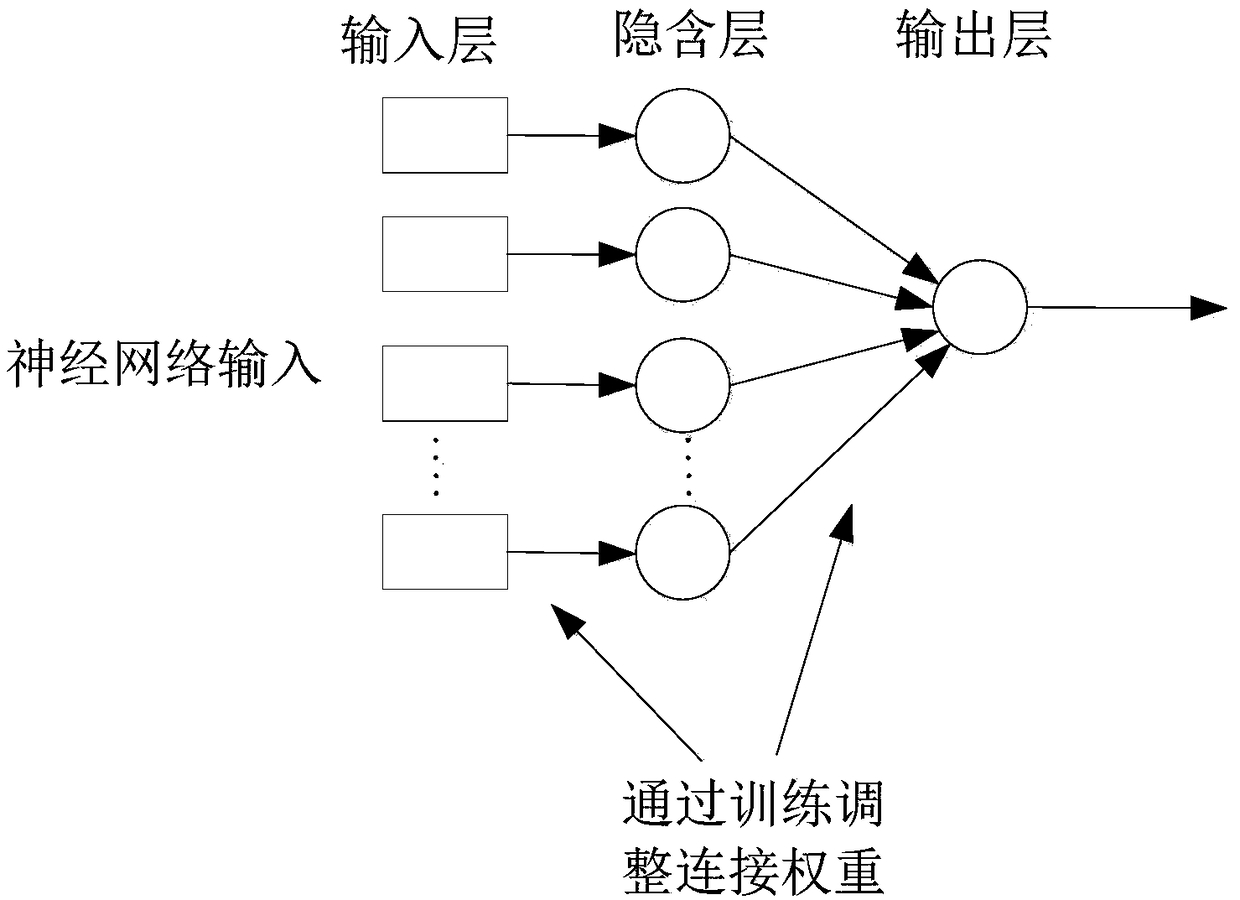

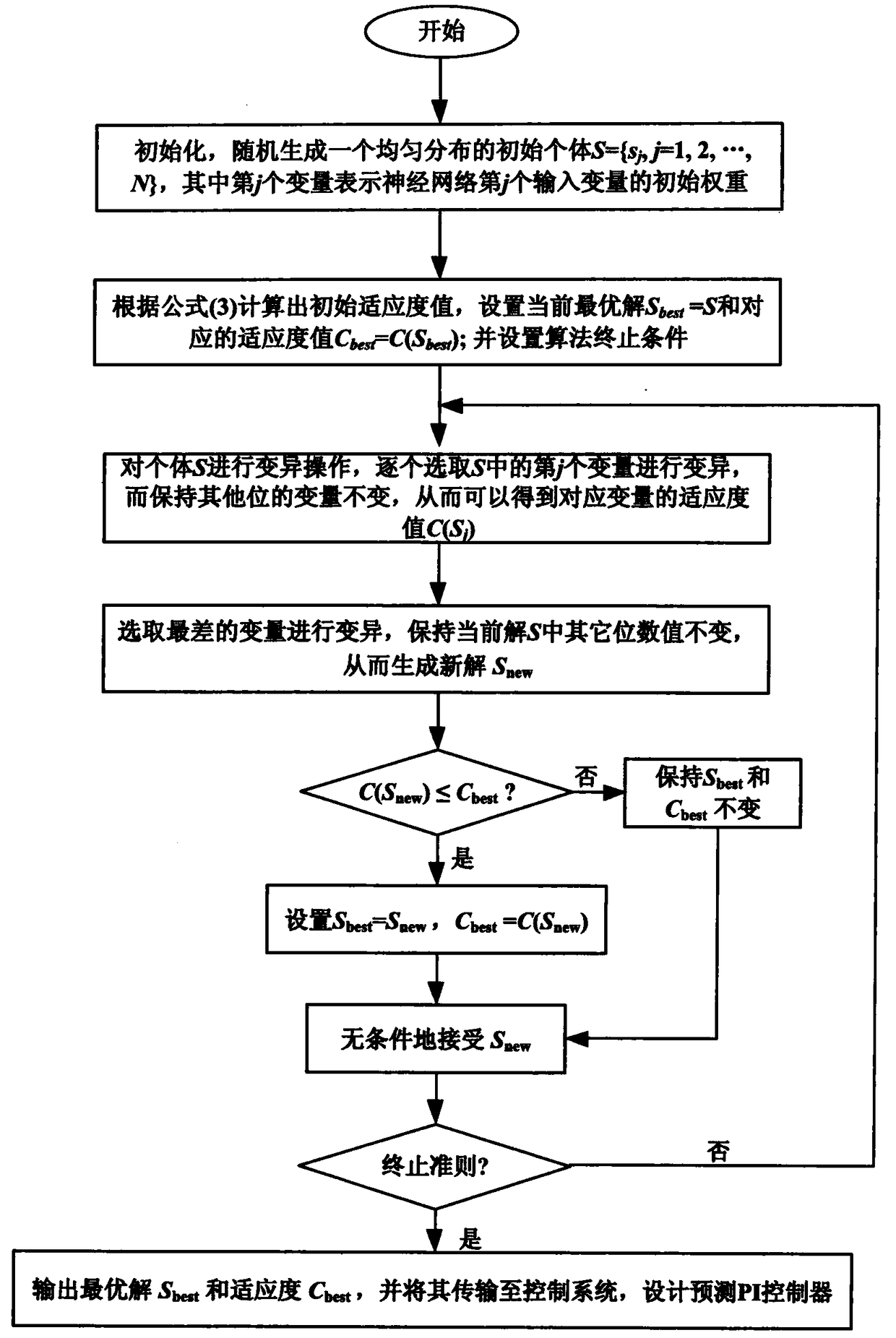

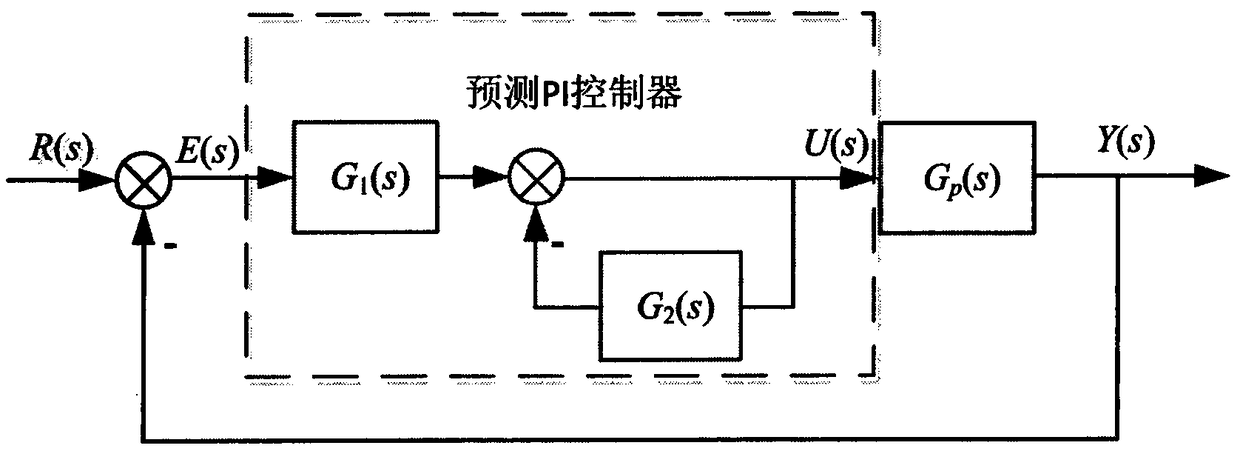

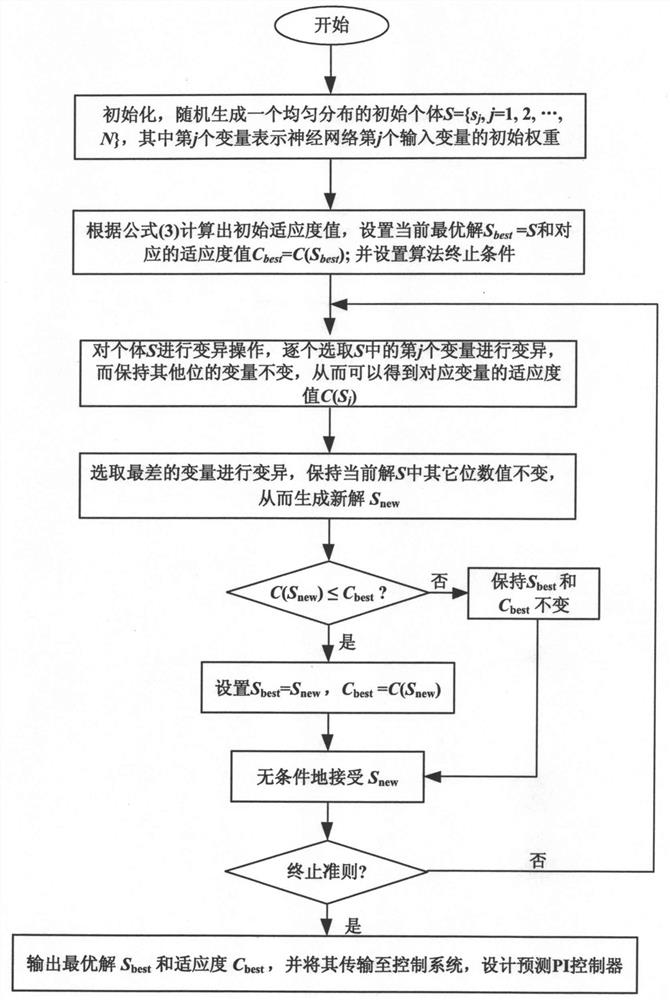

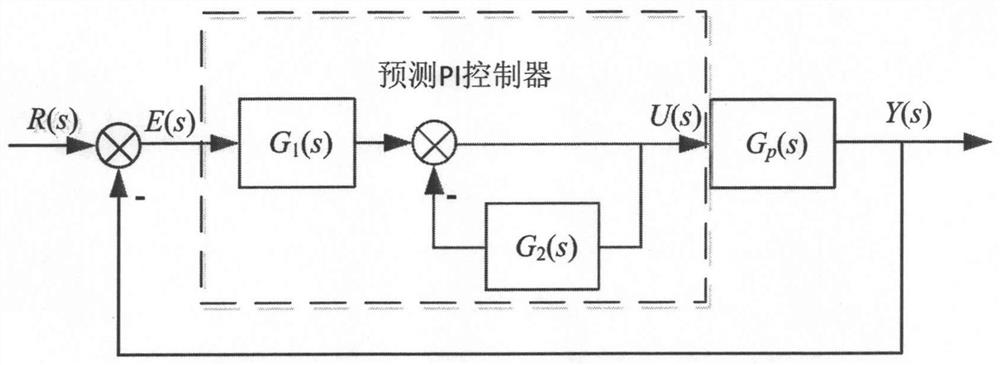

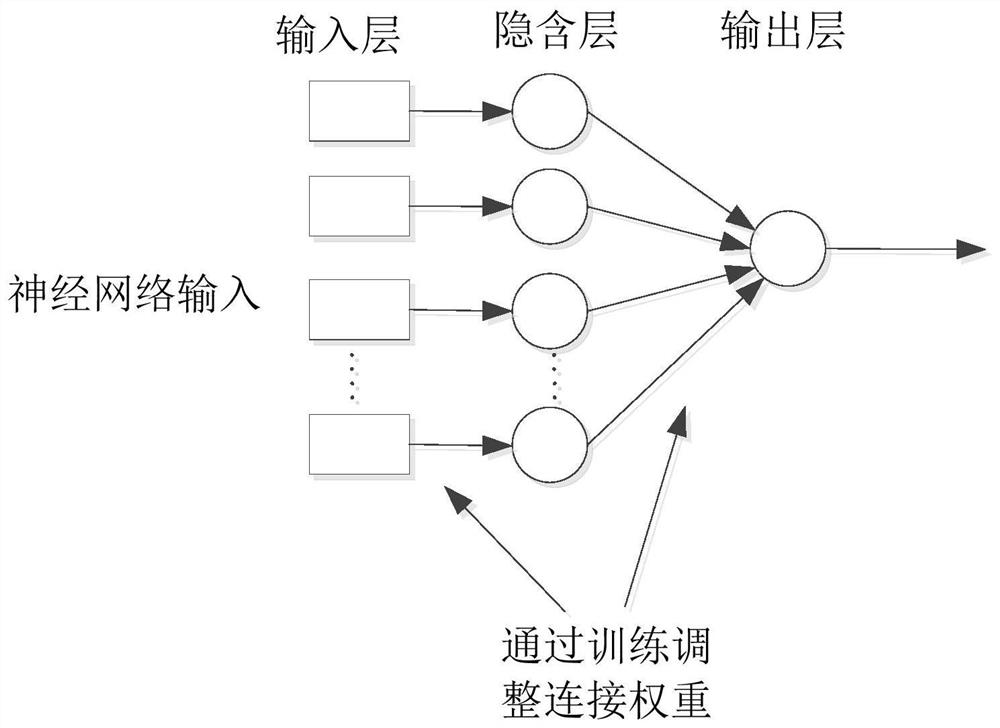

Fractionating tower liquid level adaptive control method in petroleum refining process

ActiveCN109143853AImprove learning abilityImprove anti-interference abilityLevel controlAdaptive controlCollection systemData acquisition

The invention discloses a fractionating tower liquid level adaptive control method in a petroleum refining process. In the method, a reverse error neural network and an extreme value optimization method are adopted as adaptive tools, and the input and output quantities of an actual operation process are combined to design a predictive PI control strategy. A data acquisition device is firstly usedto collect the past input and output quantities of the system, and then an extreme value optimization algorithm is designed as a solver to adjust a neural network weight in an online mode so as to train the neural network high-efficiently and accurately. After a set error constraint is satisfied, the trained neural network weight is taken as the identification parameter of the system, a system model that is close to an actual situation is established, and finally, predictive PI control is designed to control the fractionating tower liquid level of in the petroleum refining process. By using the method, the interference of a model mismatch system can be effectively alleviated, control performance is increased, and simultaneously, the application of advanced control in industrial process control is promoted.

Owner:DONGHUA UNIV

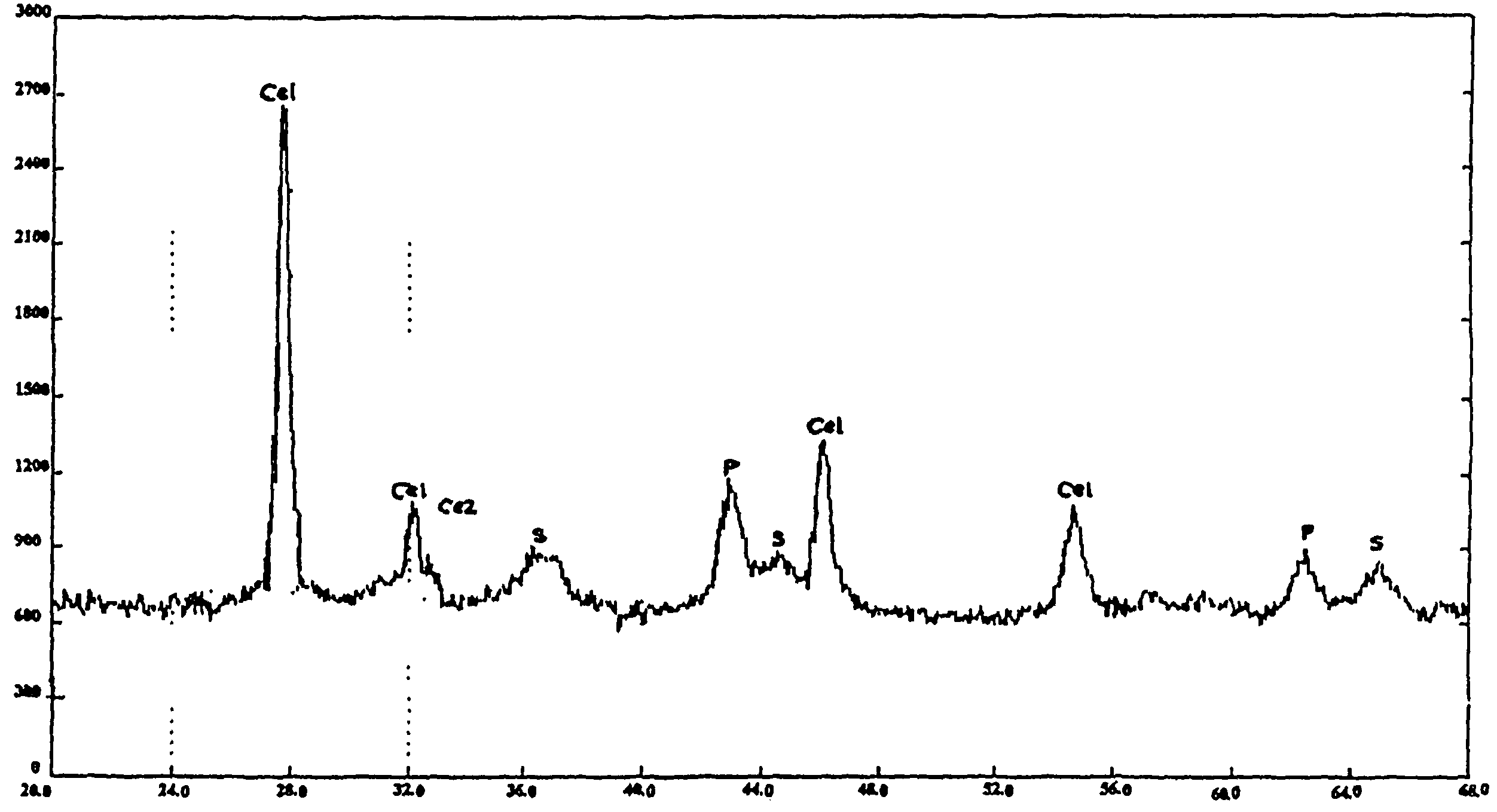

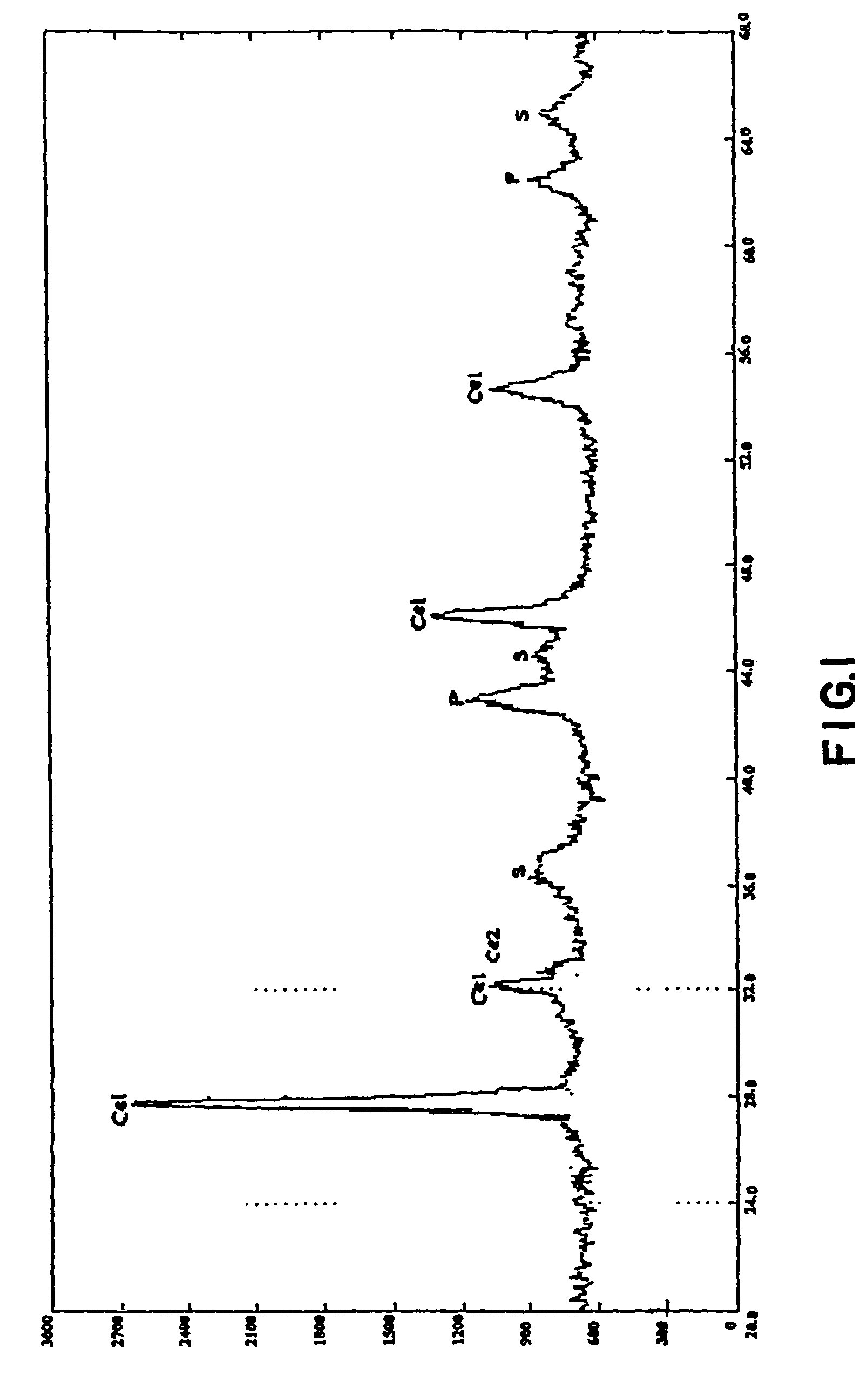

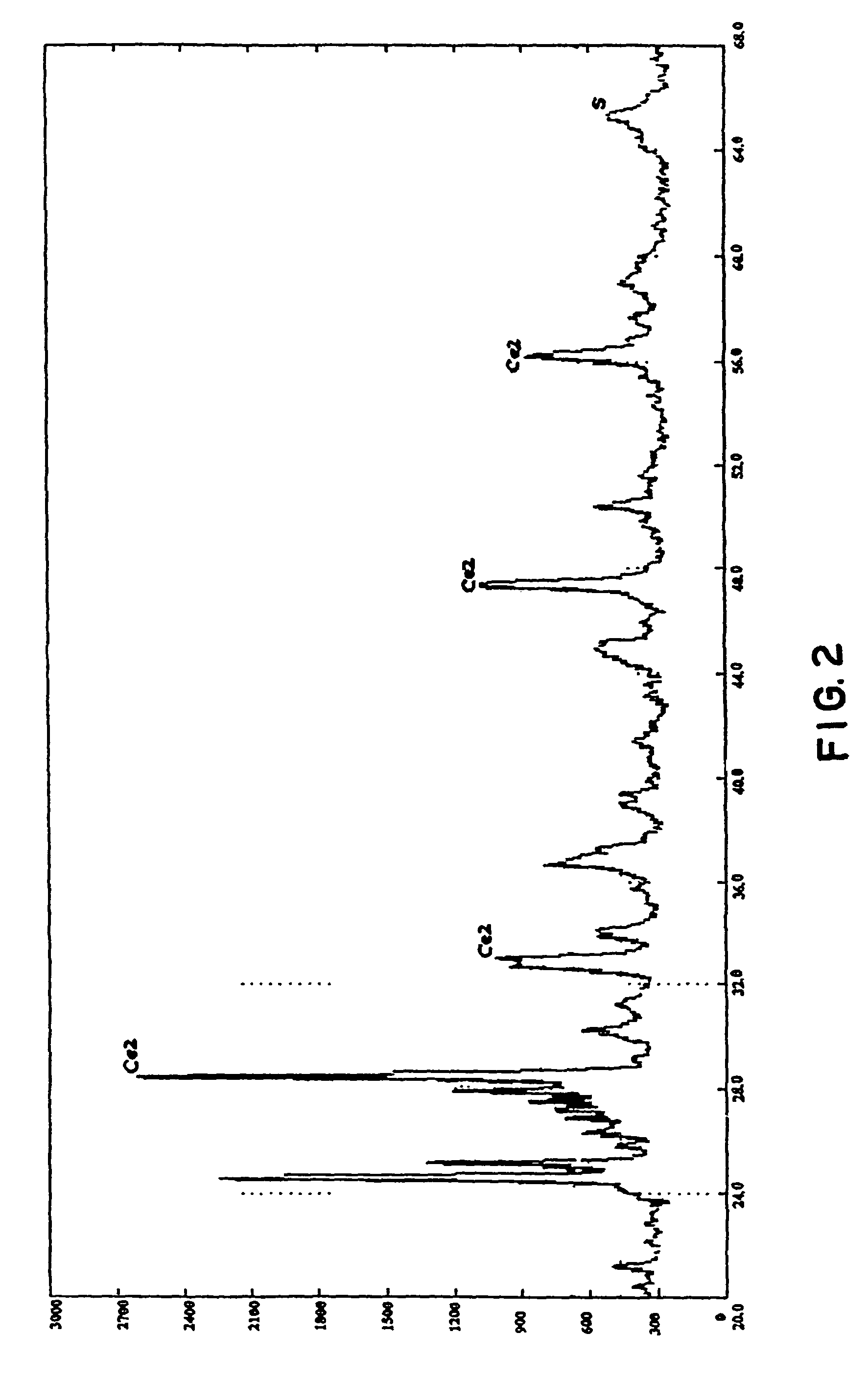

Trifunctional catalyst for sulphur transfer, denitrogenation and combustion promoting and a method for preparing the same

InactiveUS7754650B2Low costImprove abilitiesCatalytic crackingOxide/hydroxide preparationDesorptionCerium

The present invention relates to a trifunctional catalyst used in catalytic cracking device in petroleum refining industry and a method for preparing the same. The trifunctional catalyst of the invention comprises absorbent, cerium dioxide and vanadium pentoxide acting as oxidative catalyst and cerium oxyfluoride acting as structural promoter. The oxidative catalyst and structural promoter are dispersed over the absorbent. The absorbent is spinel-based composite oxides having a general formula of MgAl2-xFexO4.yMgO, where the x is 0.01-0.5 and y is 0.2-1.2. In the trifunctional catalyst, the raw material for forming the chemical compound containing rare-earth cerium is hamartite powder. The method for preparing the trifunctional catalyst of the invention is shown as follows: the components relating to the preparation of the finished product are dissolved or dispersed into liquid materials; then the trifunctional catalyst is obtained after the mixing, drying and calcining of such liquid materials. The trifunctional catalyst of the invention is used for highly efficient absorption and desorption of sulfoxides contained in the catalytic cracking flue gas regenerated in the process of petroleum refining, the combustion promoting of carbon monoxide and the reduction of nitrogen oxides. Furthermore, the method for preparing such trifunctional catalyst is featured for its lower cost.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

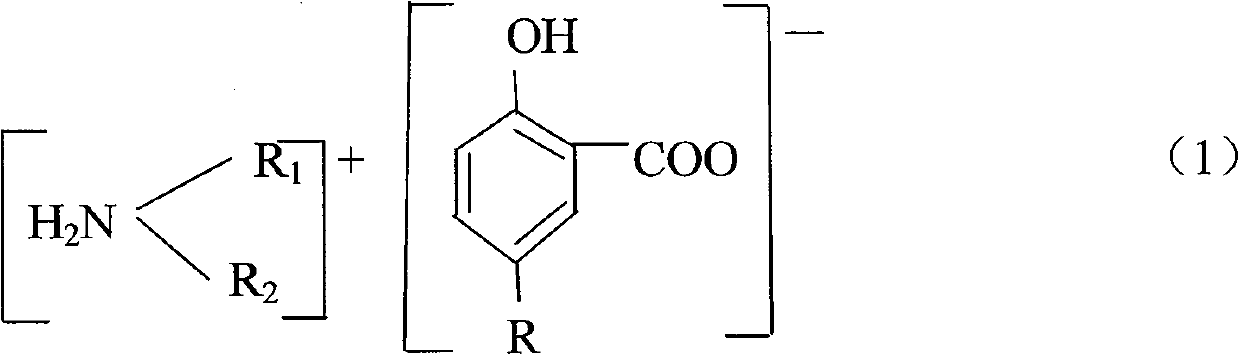

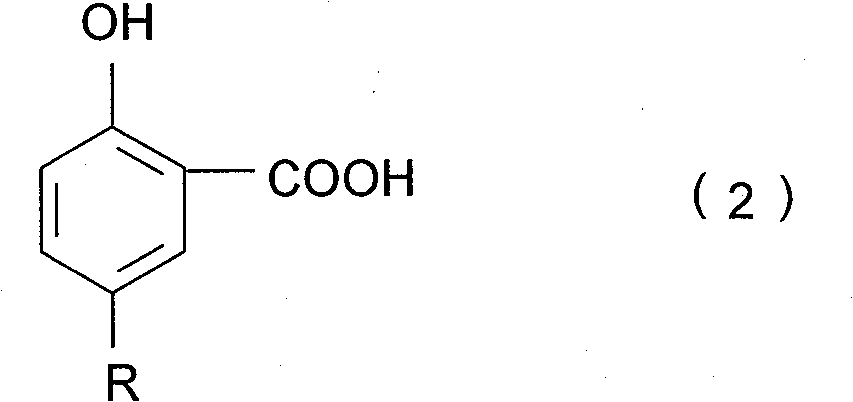

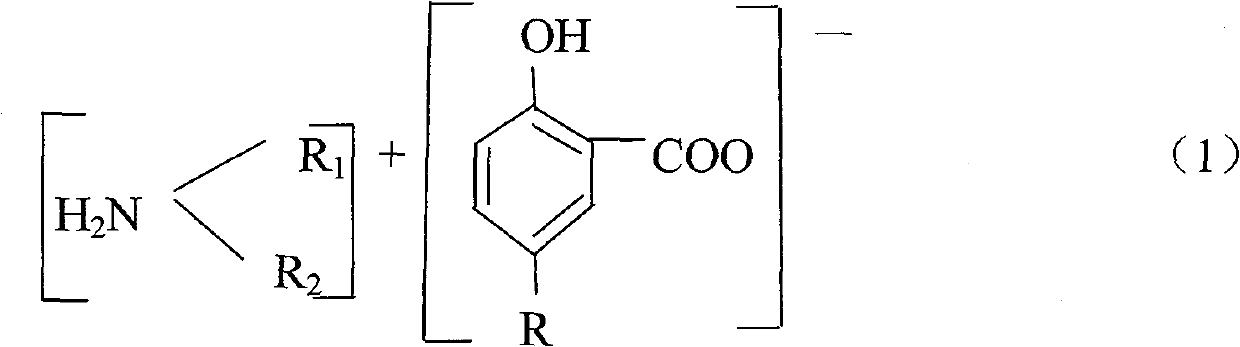

Anti-scaling agent used for hydrogenation plant and its preparation method and application

ActiveCN101265418BInhibition formationLarge poresTreatment apparatus corrosion/fouling inhibitionRefining to eliminate hetero atomsArylHeating furnace

The present invention discloses a descaling agent used for a hydrogenation device and the preparation method and the application thereof, and solves the coking and scale deposition of the relevant equipment during the petroleum refining process, such as a hydrogenation device reactor, a heating furnace, and a heat exchanger. The general formula of the hydrogenation descaling agent is shown as the formula (1), wherein, R is C8-C20 alkyl; R2 is H, R1 is C1-C24 alkyl, alkoxy or aryl; or both R1 and R2 are C1-C15 alkyl, alkoxy or aryl. Through adopting the descaling agent of the invention, notonly the coking and scale deposition can be inhibited, but also the production is simple and easy, and the descaling agent is harmless to the environment.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

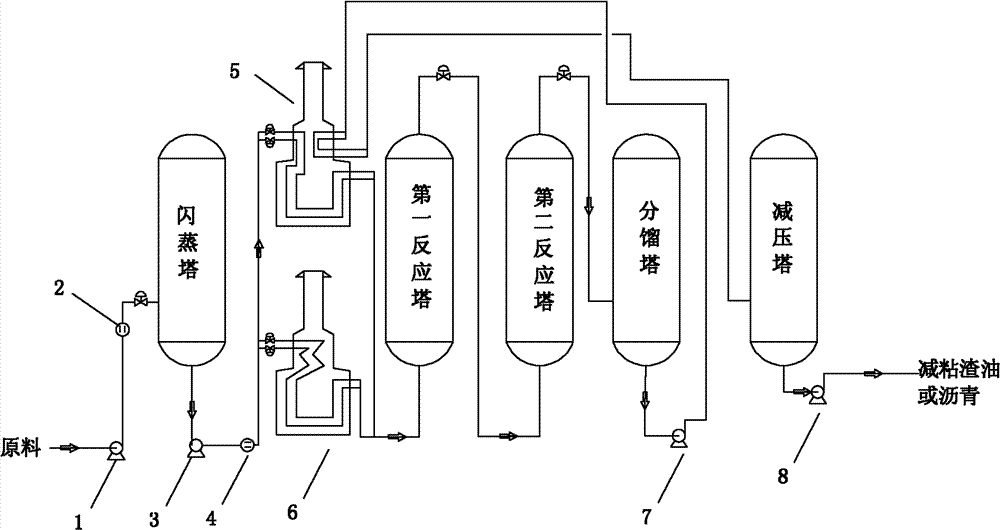

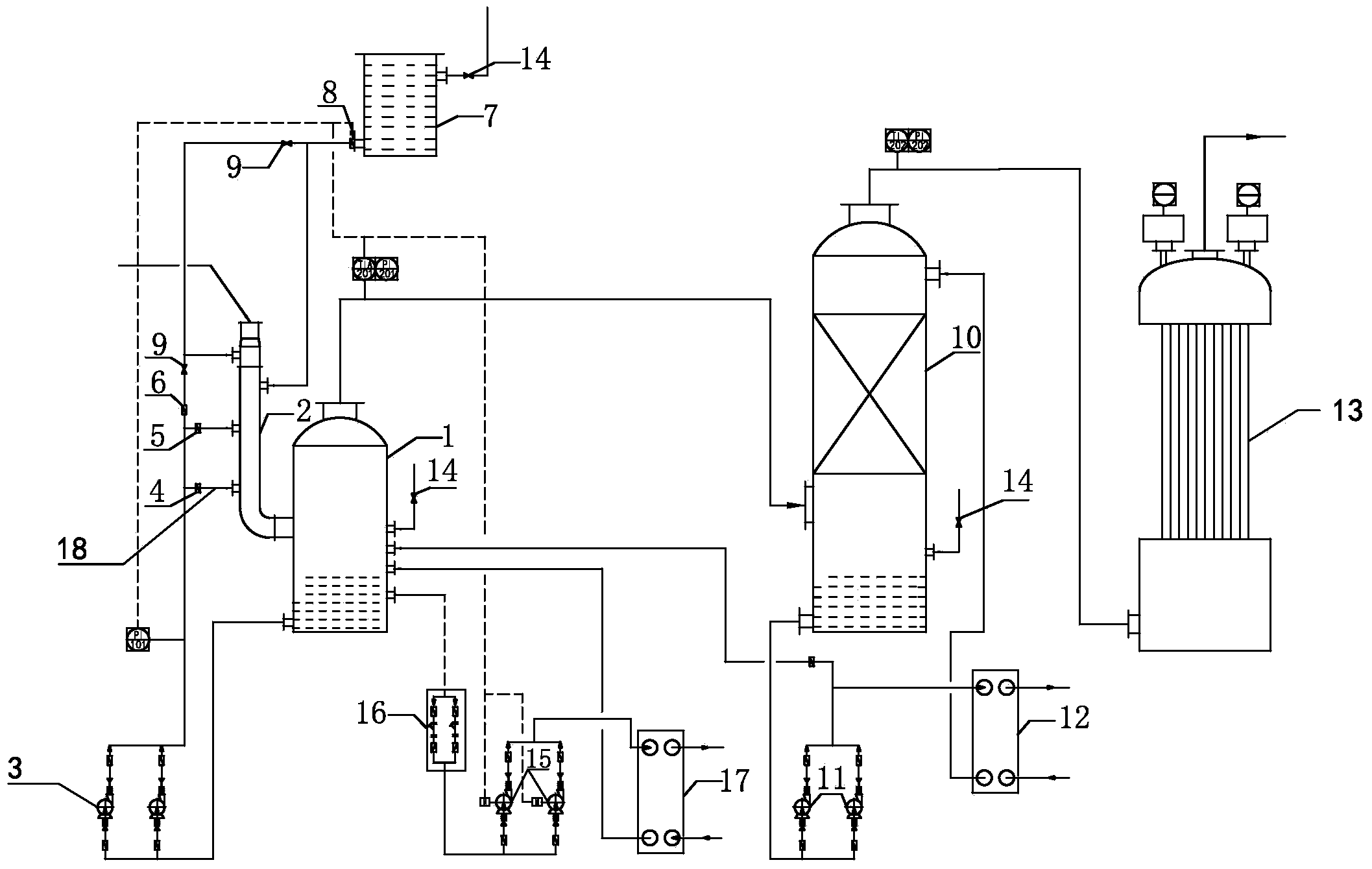

Apparatus and method for producing road petroleum asphalt from ultra heavy oil

InactiveCN102776026AViscosity reduction achievedImprove performanceTreatment with plural serial stages onlyResidual oilHeating furnace

The invention discloses an apparatus and a method for producing road petroleum asphalt from ultra heavy oil, and belongs to the field of petroleum refining process. The apparatus comprises a first heat exchanger, wherein one end of the first heat exchanger is connected with a raw-material pump; the other end of the first heat exchanger is connected with a flashing tower, wherein the tower bottom of the flash tower is connected with a flash bottom pump; the flash bottom pump is connected with a second heat exchanger; the second heat exchanger is connected with a heating furnace; the heating furnace is connected with the bottom of a reaction tower; the top of the reaction tower is connected with a fractionating tower; the bottom of the fractionating tower is connected with a tower bottom pump; the tower bottom pump is connected with the heating furnace; the heating furnace is connected with a vacuum tower; and the vacuum tower is connected with a residual oil pump. Visbreaking of the ultra heavy oil can be realized and heavy traffic paving asphalt with good performance can be produced through process combination of visbreaking and vacuum distillation.

Owner:PETROCHINA CO LTD

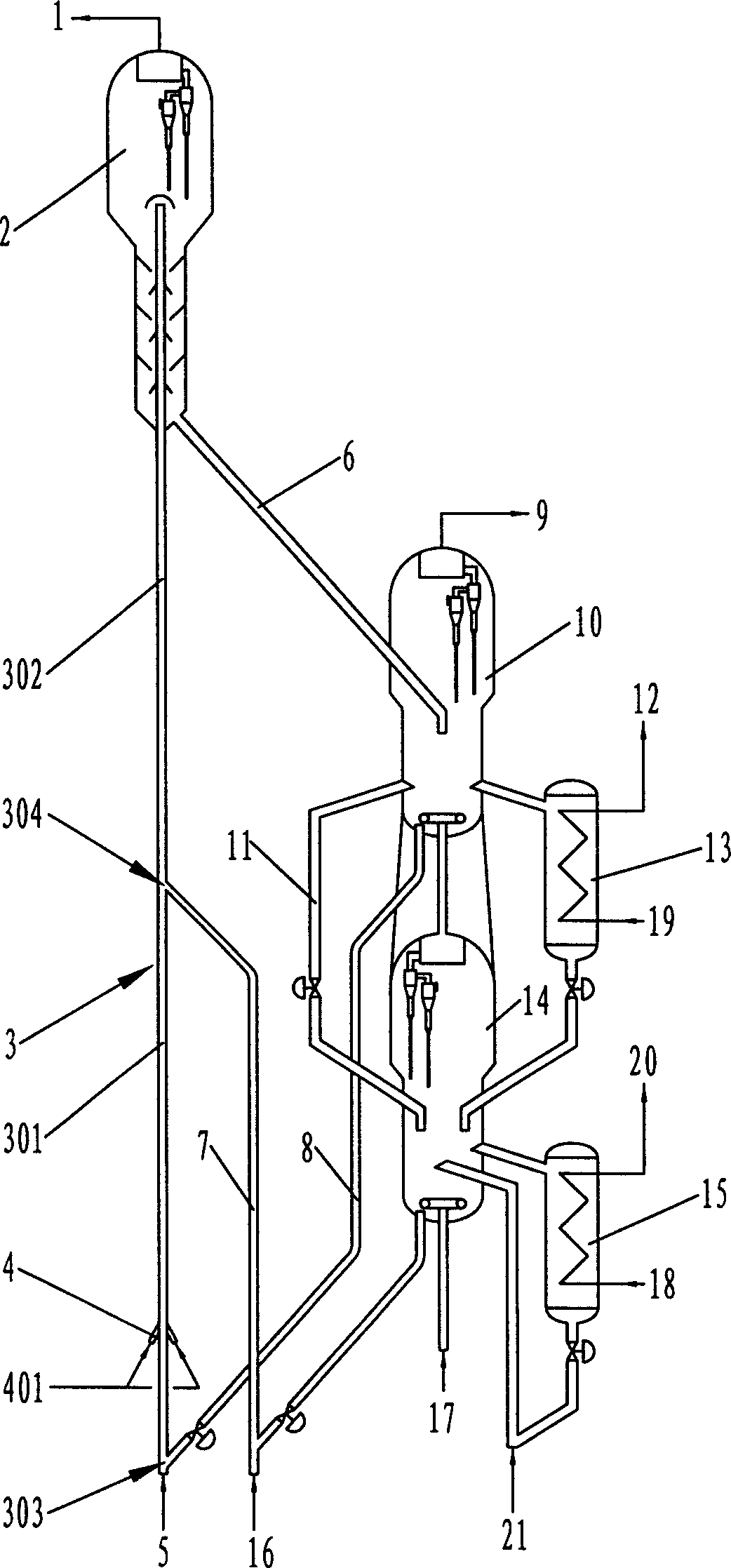

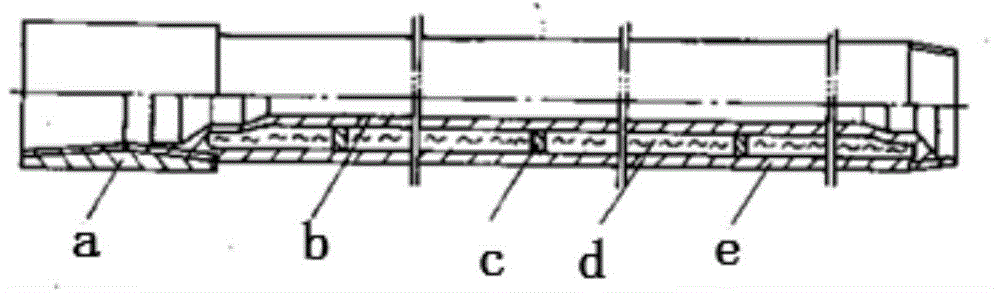

Lift pipe catalytic cracking method and device

The invention discloses a method and a device for catalytic cracking of a riser in a petroleum refining process, which are mainly used to solve the problems of poor catalytic effect in the second half of the existing riser reactor, intensified thermal cracking reaction, and the like. The present invention adopts a two-stage riser reactor, the semi-regenerated catalyst and raw oil (401) with higher temperature from the first regenerator (10) enter the bottom of the riser reactor (3), and along the first reaction section (301) carry out catalytic cracking reaction upward; Introduce the regenerated catalyst from the lower temperature of the second regenerator (14) through the catalyst inlet (304) in the middle of the riser reactor (3), and from the first reaction section (301) The upward catalyst is mixed with oil and gas, enters the second reaction section (302) and continues upward to carry out the catalytic cracking reaction. The invention is mainly used for catalytic cracking processing of petroleum heavy distillates to improve the distribution of cracked products and the quality of cracked gasoline in catalytic cracking units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

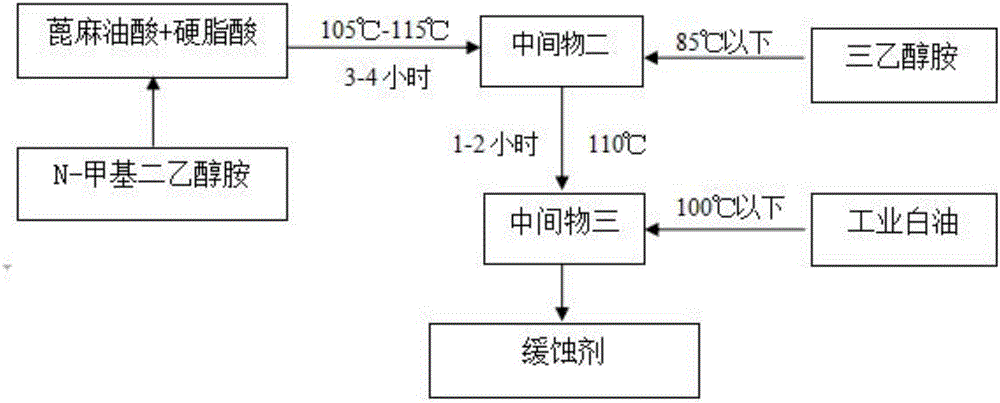

High-temperature corrosion inhibitor for oilfield exploitation and petroleum refining process and preparation method of high-temperature corrosion inhibitor

ActiveCN106433781ASafe and Reliable ProductivitySafe and reliable operabilityDrilling compositionBorehole/well accessoriesPetrochemicalStearic acid

The invention belongs to the technical field of petrochemical equipment and particularly provides a high-temperature corrosion inhibitor for oilfield exploitation and a petroleum refining process. The high-temperature corrosion inhibitor is prepared from raw materials in parts by weight as follows: a raw material group A: 6-8 parts of ricinolic acid and 2-4 parts of stearic acid; a raw material group B: N-methyldiethanolamine, triethanolamine and industrial white oil, wherein the weight of N-methyldiethanolamine is 0.18-0.2 times that of the raw material group A, the weight of triethanolamine is 0.06-0.08 times that of the raw material group A, and the weight of the industrial white oil is 0.35-0.4 times that of the raw material group A. The high-temperature corrosion inhibitor has the corrosion inhibition rate of about 97% and has the advantages of being good in corrosion inhibiting effect, non-irritant, safe, reliable, safe and stable in the production use operation process, environment-friendly and the like. According to the preparation method, performance of the raw materials is comprehensively considered, and the high-temperature corrosion inhibitor with more stable performance and more excellent corrosion inhibition effects can be obtained.

Owner:徐文忠 +1

System for solving ultrahigh gas temperature of dynamic wave furnace of waste acid recycling device

The invention relates to the field of alkylation assorted waste acid recycling devices in the petroleum refining process and in particular relates to a system for solving ultrahigh gas temperature of a dynamic wave furnace of a waste acid recycling device. The system comprises a dynamic wave gas-liquid separator, a filler washing tower and an electric defogger which are connected through a pipeline; the system is characterized in that furnace gas firstly enter a dynamic wave exchange column; the dynamic wave exchange column is connected with one or more reversed injection pipes; a nozzle control valve is arranged on each reversed injection pipe and used for controlling the pressure of the reversed injection pipe; the reversed injection pipes are connected with the dynamic wave gas-liquid separator through a dynamic wave dilute acid pump; the furnace gas enters the dynamic wave gas-liquid separator and carries out gas-liquid separation, then the furnace gas enters the filler washing tower to be washed and cooled, finally the furnace gas enters the electric defogger and removes the residual acid fog. The system is capable of reducing the temperature of a furnace gas outlet of a dynamic wave scrubber, facilitating long-period and safe operation of the device, improving the treatment capacity of the device, reducing the dilute acid treatment capacity and reducing sewage treatment load and cost.

Owner:SHANDONG JINCHENG HEAVY OIL RES INST OFCHEM TECH

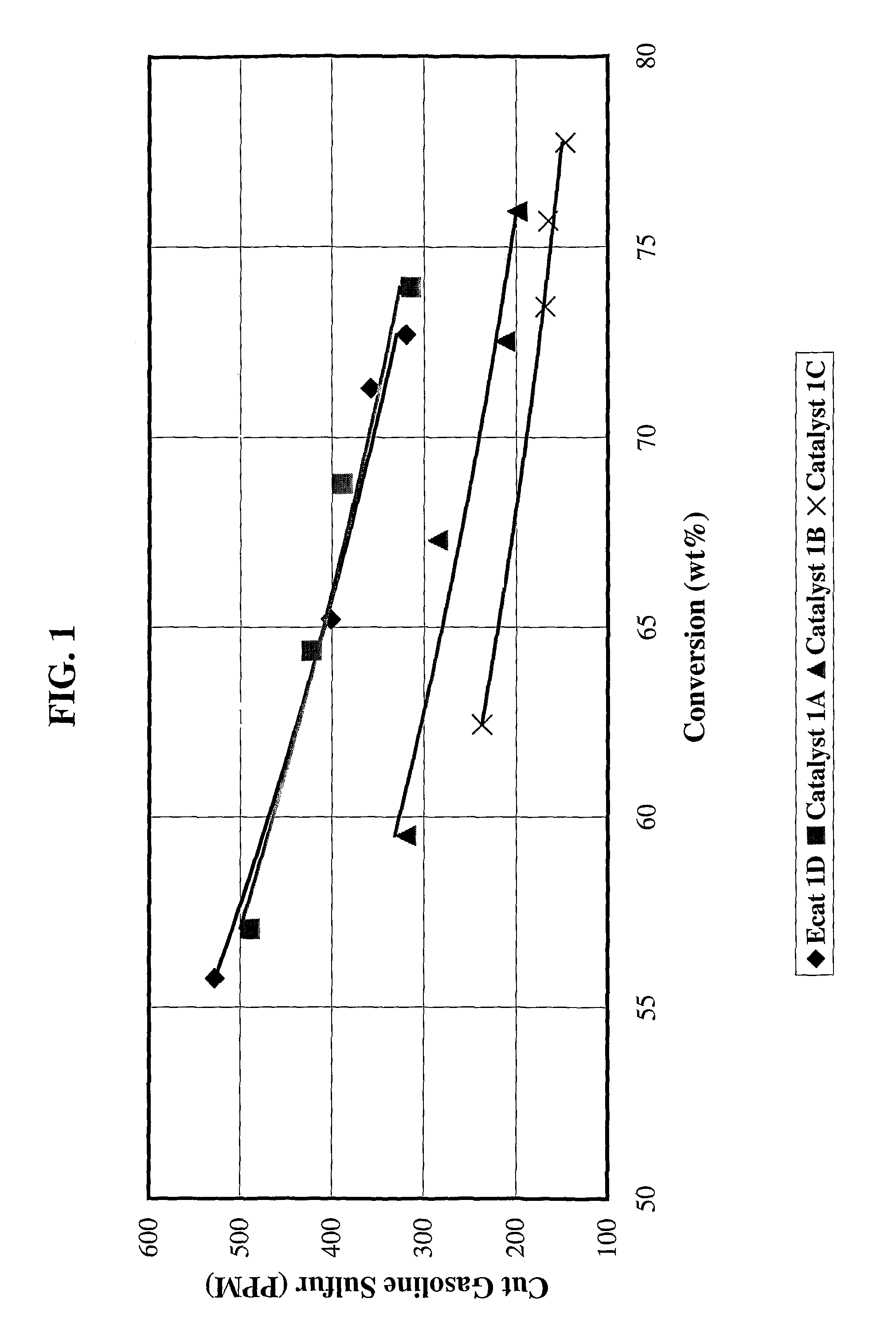

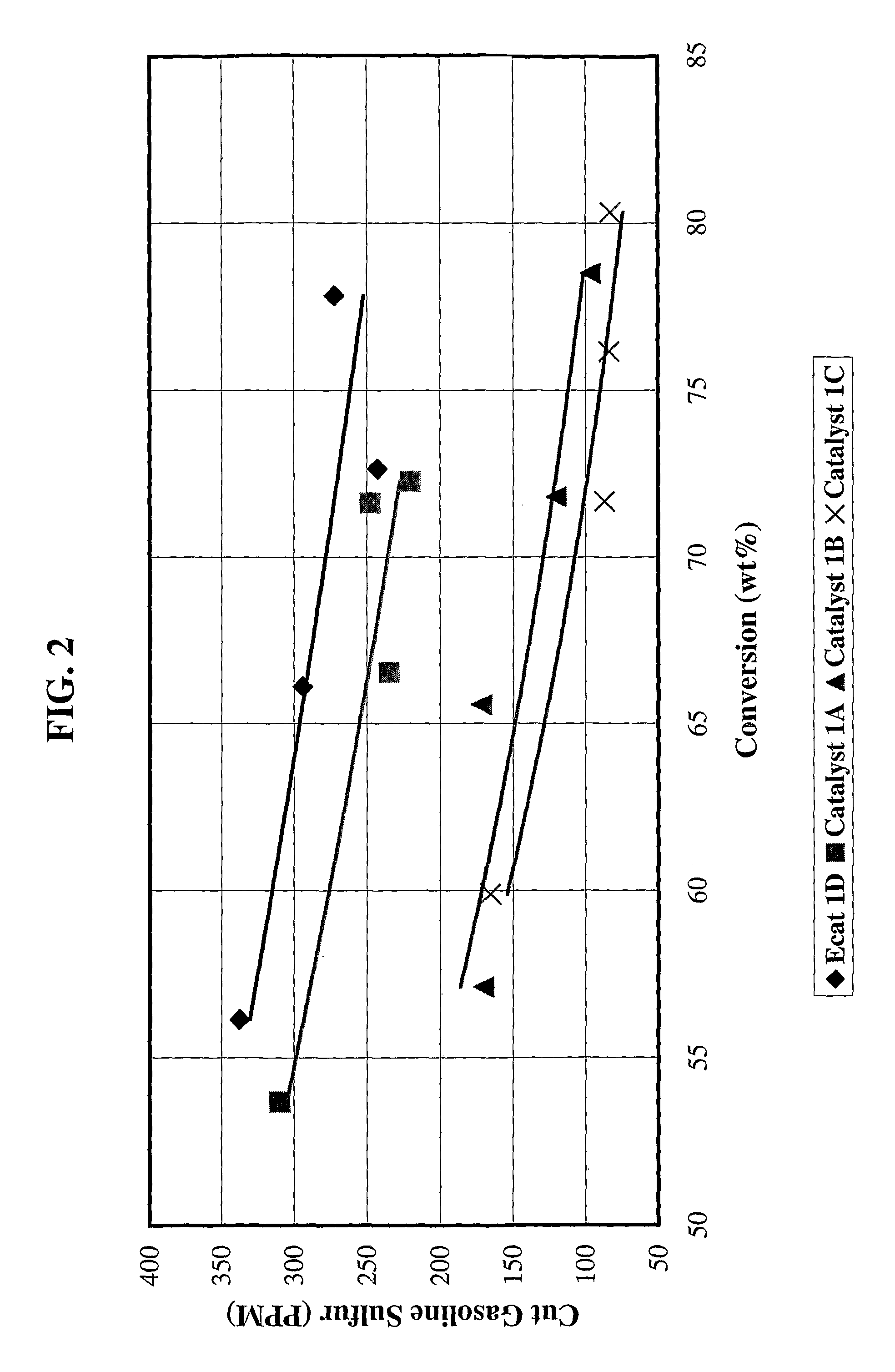

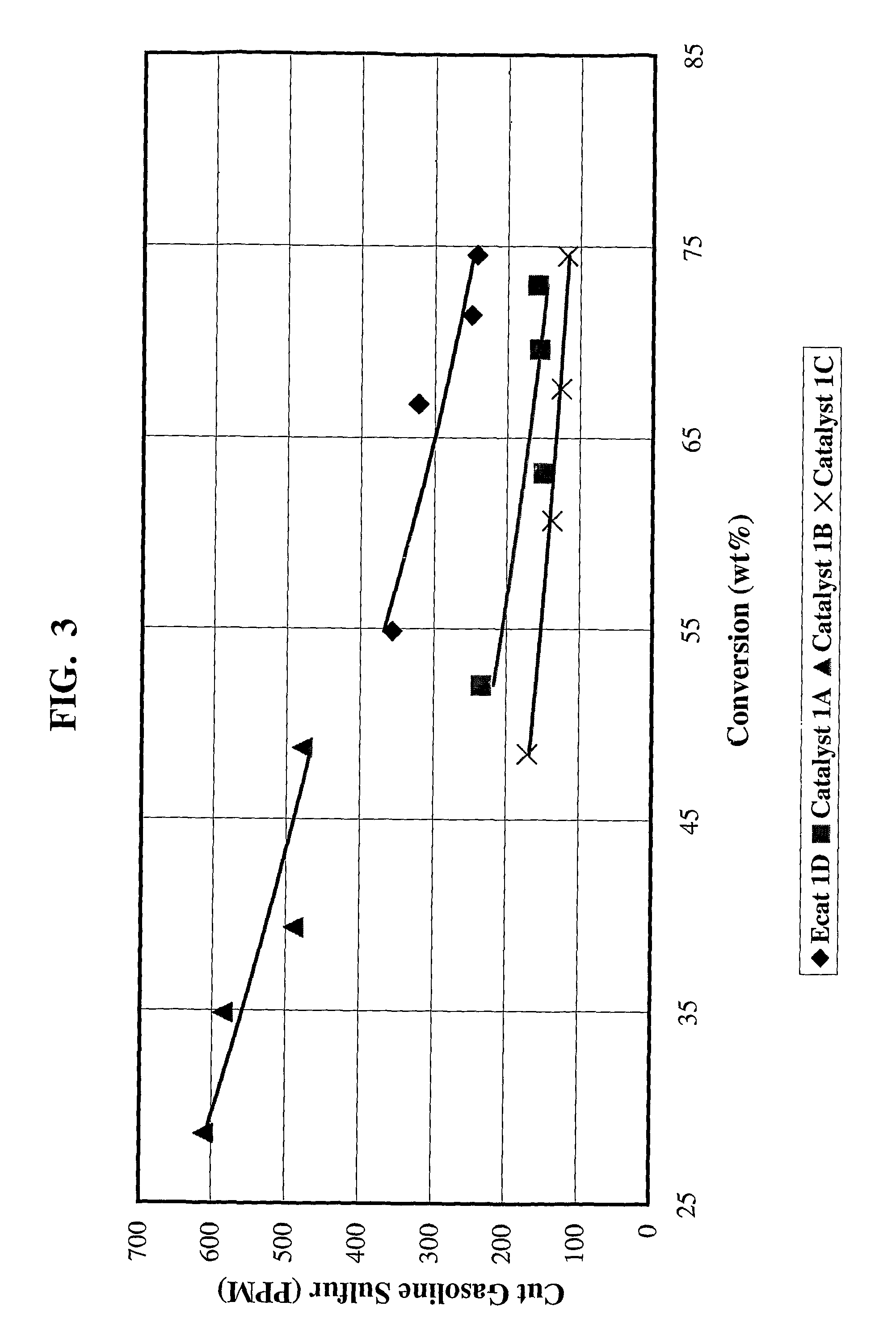

Gasoline sulfur reduction catalyst for fluid catalytic cracking process

InactiveUS7902106B2Easy to crackReduce sulfur contentCatalytic crackingMolecular sieve catalystsSulfurManganese

The invention is a composition that is suitable for reducing sulfur species from products produced by petroleum refining processes, especially gasoline products produced by fluidized catalytic cracking (FCC) processes. The composition comprises zeolite, yttrium, and at least one element selected from the group consisting of zinc, magnesium and manganese, wherein the yttrium and element are present as cations. The yttrium and zinc are preferably present as cations that have been exchanged onto the zeolite. The zeolite is preferably a zeolite Y.

Owner:WR GRACE & CO

Process for improving absorption stability in petroleum refining process

InactiveCN107760372AEffective absorptionAvoid reactionLiquid hydrocarbon mixture recoveryTreatment with hydrotreatment processesDesorptionFractionation

The invention discloses a process based on improving absorption stability in the petroleum refining process, comprising the following steps: compressed rich gas cooling process, absorption process, reabsorption process, desorption process, gasoline stabilization process, and light and heavy gasoline separation process. This process can efficiently absorb the fractionated components, avoid the reaction caused by contact with each other, make the components stable and convenient for subsequent use, and solve the unreasonable design of the absorption process for the fractionated components in the existing refining process. The absorption effect is poor, and it is extremely unstable, which can easily lead to reactions between components, resulting in the problem of composition confusion.

Owner:陈飞

Quick-dry fog sealing layer material, and preparation method and application thereof

The invention relates to a quick-dry fog sealing layer material, which is formed by the following components: 20wt percent to 40wt percent of asphalt-recycling agent, and 5wt percent to 25wt percent of complex solubilizer, wherein the asphalt-recycling agent is formed by deasphalted oil, heavy aromatic oil and additives; the additives are selected from at least one of the following compounds: dibutyl phthalate, epoxidized soybean oil, chlorinated methoxy fatty acid ester and parabens; the mass ratio of the deasphalted oil to the heavy aromatic oil to the additives is 1:0.1 to 1:0.05 to 0.5. The invention also relates to a preparation method and application of the quick-dry fog sealing layer material. According to the quick-dry fog sealing layer material, the heavy aromatic oil and the like during the petroleum refining process are utilized to form the asphalt-recycling agent so as to obtain the fog sealing layer material with high additional value, so that the quick-dry fog sealing layer material can play a role in preventing aging and regenerating on aged asphalt pavements. In addition, according to the quick-dry fog sealing layer material provided by the invention, the maintenance time at low temperature is only 2 to 4h, which is shortened by over half the time for sealing and maintaining of the existing fog sealing layer material.

Owner:EAST CHINA UNIV OF SCI & TECH

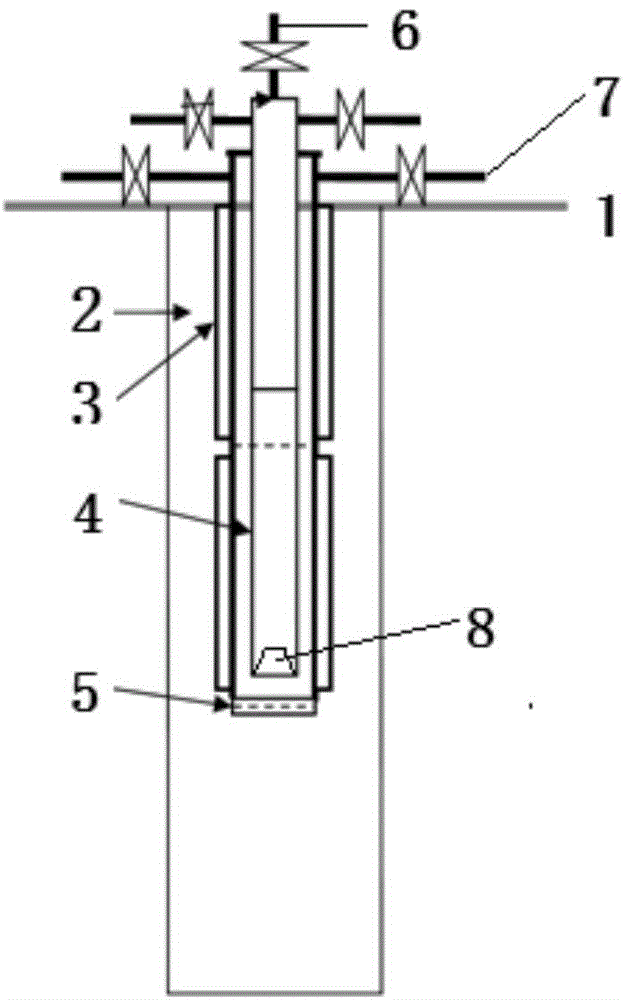

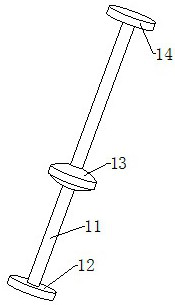

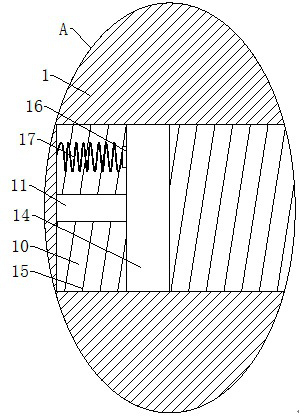

Underground heat insulation air-suspended bed reactor

ActiveCN105013411AProtect the environmentImprove securityChemical/physical processesChemical reactionProcess engineering

The invention provides an underground heat insulation air-suspended bed reactor which is suitable for a heavy oil hydrogenation lightweighting technology, a hydrogenation direct liquidation technology for coal and biomass and a mixing coprocessing lightweighting machining technology for coal, biomass and heavy oil in a petroleum refining process and a high-temperature and high-pressure chemical reaction process of other fluid materials.

Owner:仲兴行(上海)商务服务有限公司

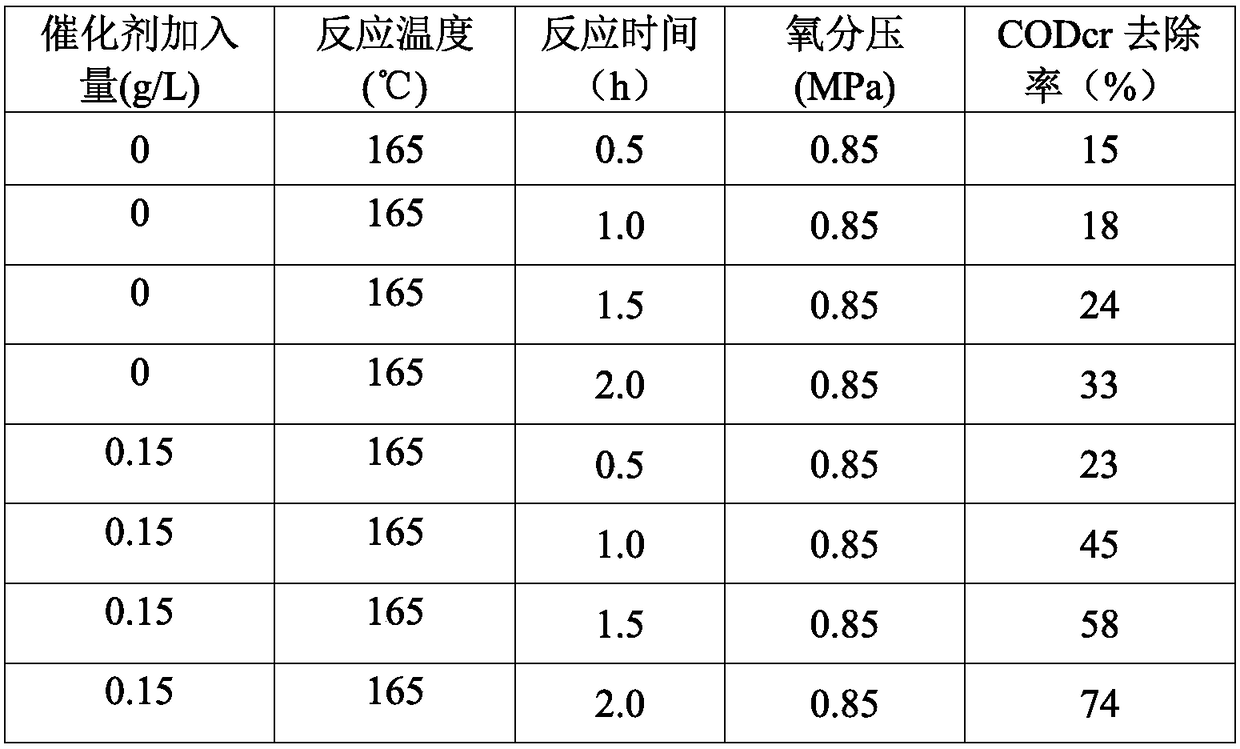

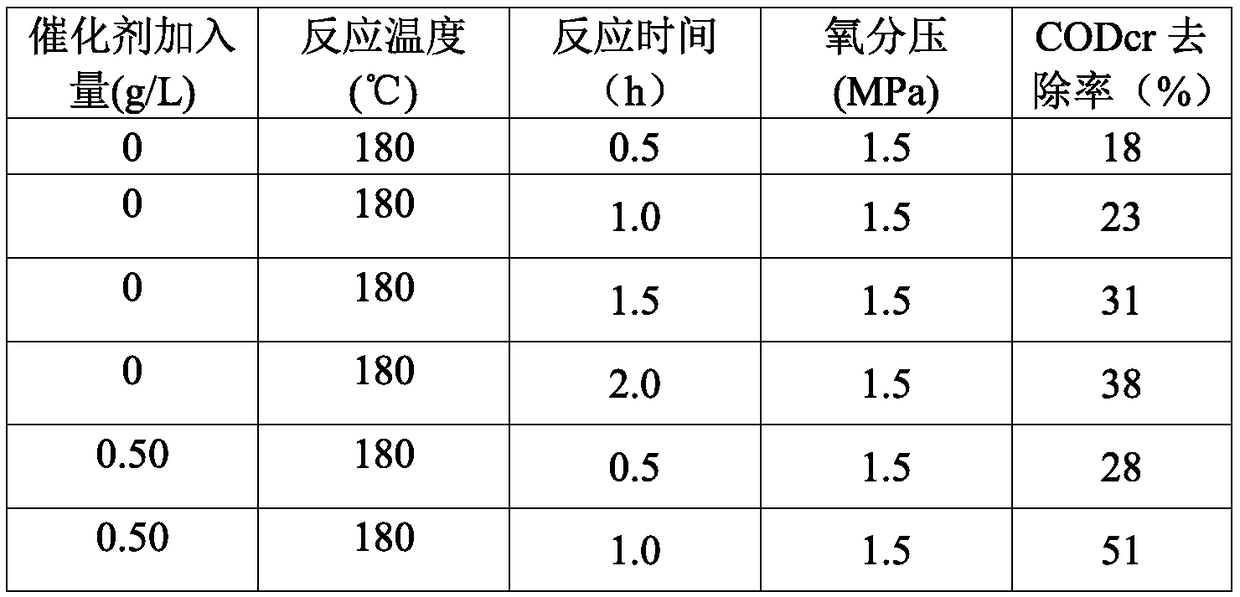

Manganese, zirconium and titanium ternary composite catalytic wet oxidation catalyst for alkaline residue wastewater as well as preparation method and application of catalyst

PendingCN108745343AEasy to prepareEasy to implementWater contaminantsNature of treatment waterHigh concentrationManganese

The invention discloses a manganese, zirconium and titanium ternary composite catalytic wet oxidation catalyst for alkaline residue wastewater as well as a preparation method and an application of thecatalyst. The ternary composite catalyst is formed by supporting ruthenium, zirconium and titanium ternary composite metal on nano aluminosilicate crystals as a carrier. The preparation method of themanganese, zirconium and titanium ternary composite catalytic wet oxidation catalyst for alkaline residue wastewater is simple and easy to implement, the obtained manganese, zirconium and titanium ternary composite catalytic material has good catalytic action on catalytic wet oxidation treatment of high-concentration and refractory alkaline residue wastewater produced in the petroleum refining process, tests prove that the degradation efficiency is remarkably improved, the CODcr removal rate of the alkaline residue wastewater is increased by 41% or above as compared with the wet oxidation degradation effect without the catalyst under the same condition, and the catalyst has very good practicability.

Owner:JIANGSU OPEN UNIV

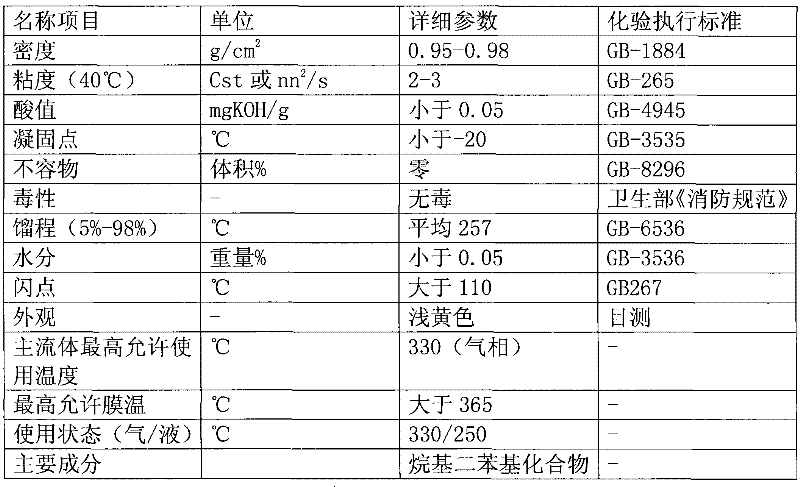

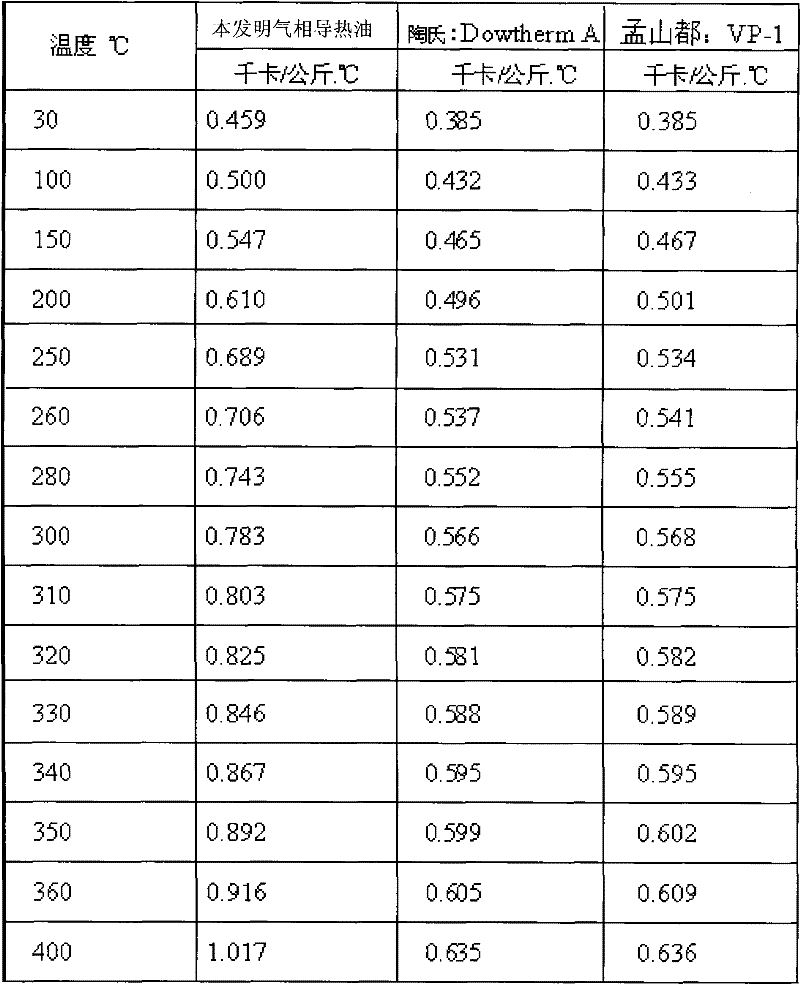

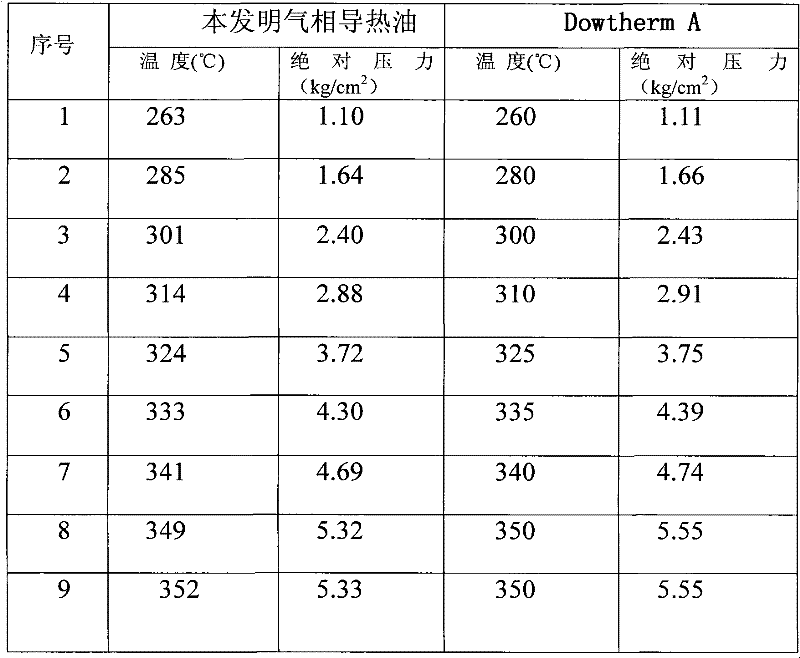

Vapor phase heat transfer oil and its preparation process

InactiveCN102268237AEasy industrial upgradeReduce consumptionTreatment with hydrotreatment processesHeat-exchange elementsPolyesterCatalytic reforming

The invention discloses a gas-phase heat-conducting oil and a preparation process thereof. The gas-phase heat-conducting oil contains alkyl diphenyl and its isomer compounds. The preparation process of gas-phase heat transfer oil includes the following steps: 1. Raw material selection. The raw material selected in this step is the tower bottom material after the catalytic reforming unit in the petroleum refining process or the polyester production raw material p-xylene plant tower bottom material or pyrolysis production Hydrogenation feedstock for ethylene by-products. 2. Extraction of aromatics. In this step, chemical products such as benzene and xylene are obtained, and the remaining products are the primary raw materials for gas-phase heat transfer oil. 3. Precision rectification and purification. In this step, the preliminary raw materials obtained in step 2 are purified, and the fraction at 240°C-270°C is selected, and then the above fraction is sent to a high-efficiency precision rectification tower for further rectification, and the fraction at 252°C-258°C is cut. Narrow cut, ie the final vapor phase heat transfer oil product. This vapor phase heat transfer oil product can completely replace the existing but biphenyl-diphenyl ether products (for example: vp-1, DowthermA, ThermS, ThermS-300 and other foreign vapor phase heat transfer oils).

Owner:北京燕通石油化工有限公司

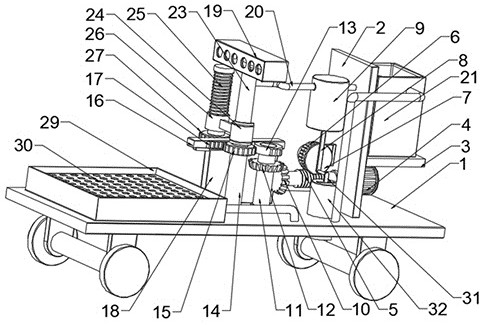

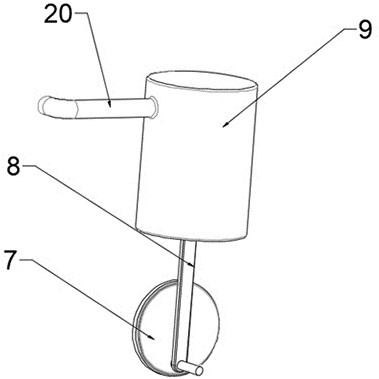

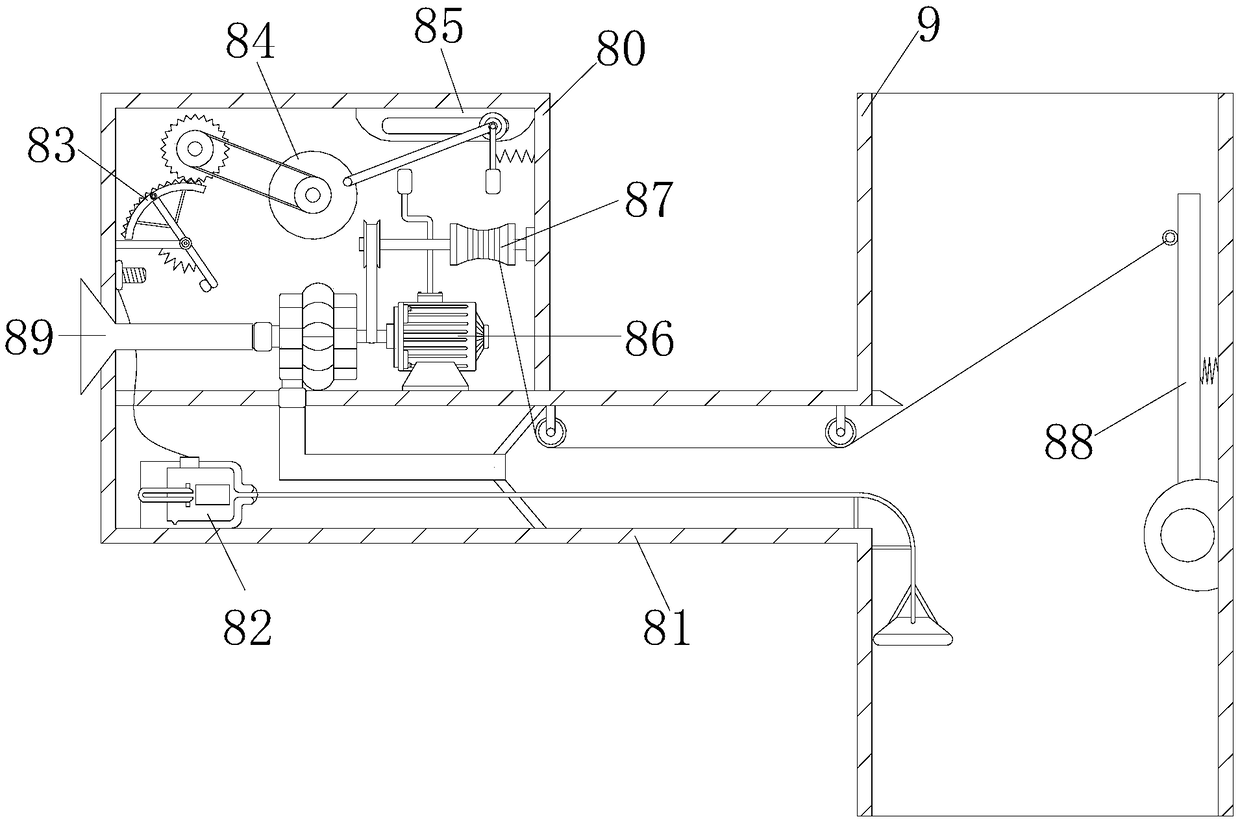

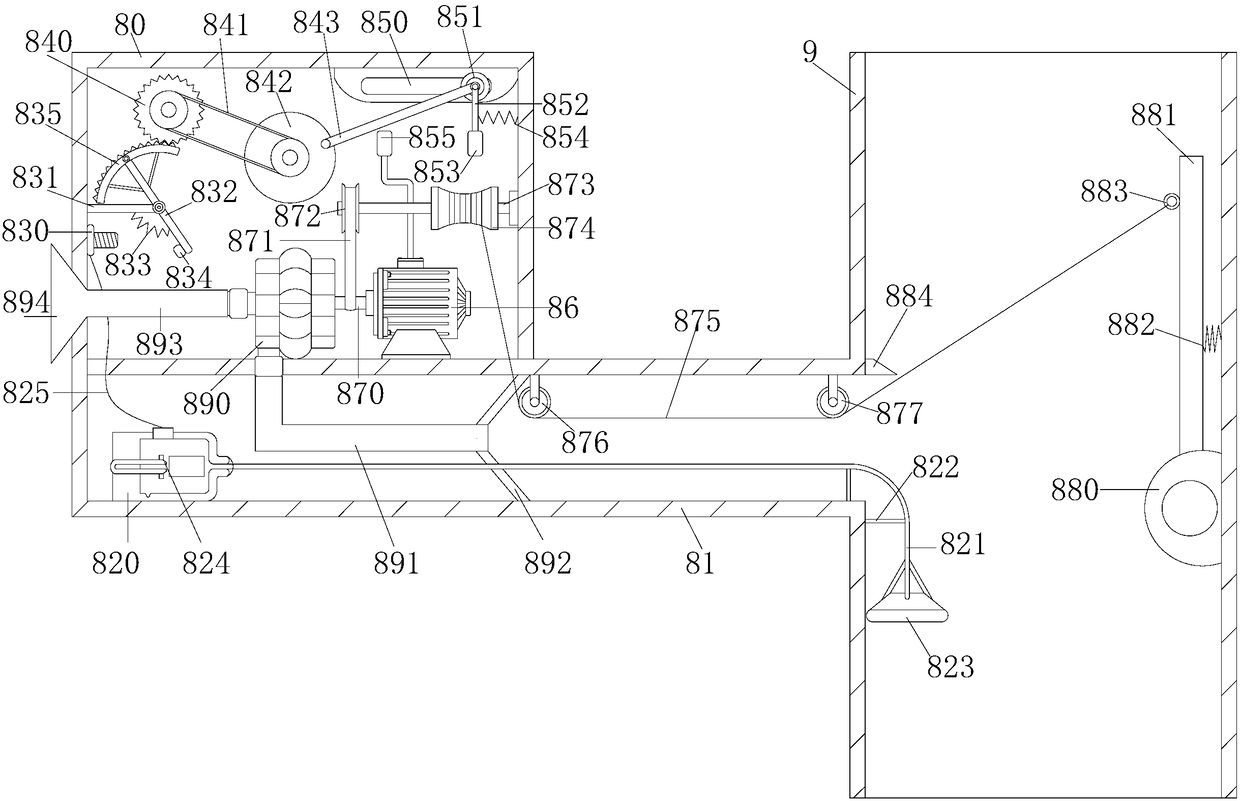

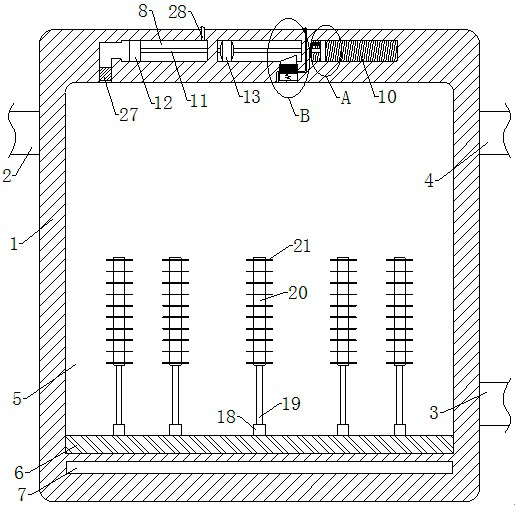

Wet-type purification equipment for petroleum refining

ActiveCN113521932AExpand the spraying rangeEfficient purificationUsing liquid separation agentSeparation devicesProcess engineeringPetrochemical

The invention relates to the technical field of petrochemical production equipment, and discloses wet purification equipment for petroleum refining. According to the technical scheme, the wet-type purification equipment for petroleum refining comprises a bottom plate and a fixing plate fixedly installed on the bottom plate, and a transverse plate parallel to the bottom plate is fixedly installed on the fixing plate. The wet-type purification equipment for petroleum refining further comprises: a spray head, wherein the spray head is movably arranged on the bottom plate; a reciprocating mechanism which is movably arranged on the bottom plate and is connected with the spray head; a lifting assembly which is connected with the reciprocating mechanism and is movably mounted on the bottom plate; and a driving mechanism which is connected with the reciprocating mechanism. Polluted gas generated in the petroleum refining process is efficiently purified, purification liquid and dust in the purification process can be automatically screened, the purification liquid can be recycled, the cost is greatly reduced, and safety and environment friendliness are achieved.

Owner:东营思达石油化工有限公司

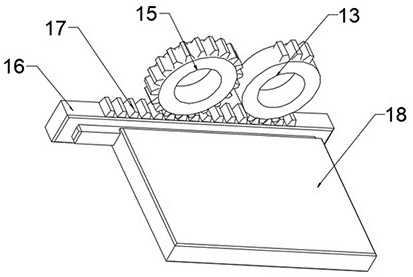

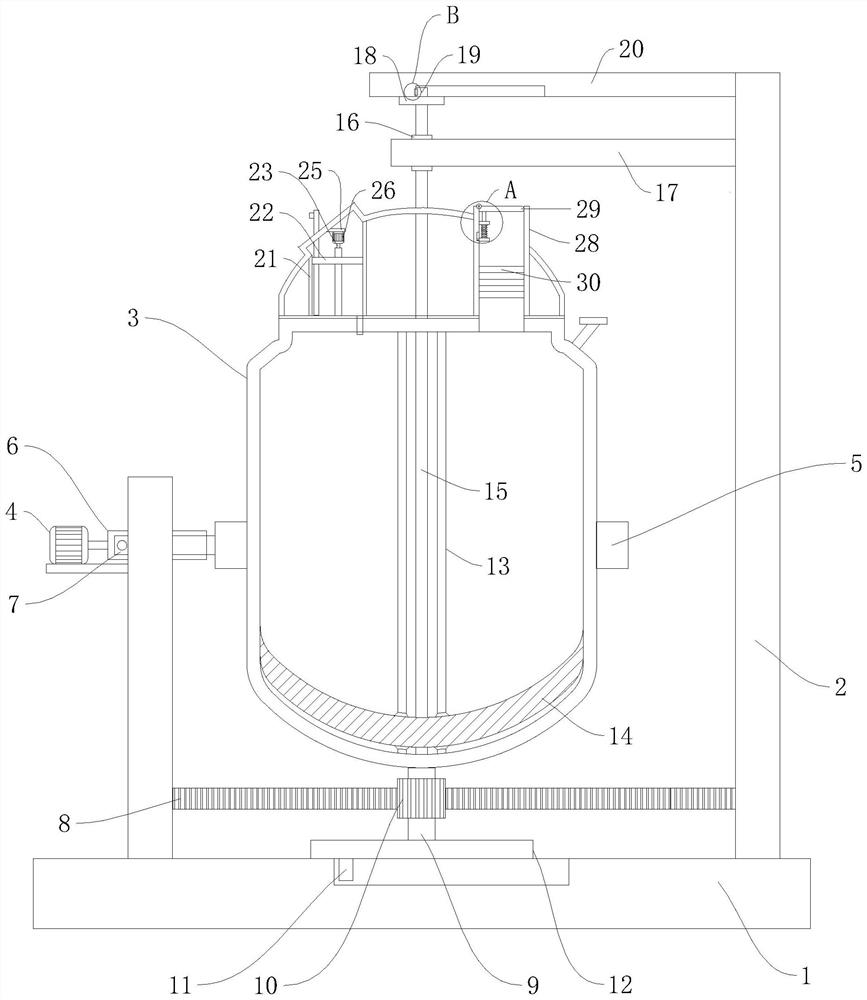

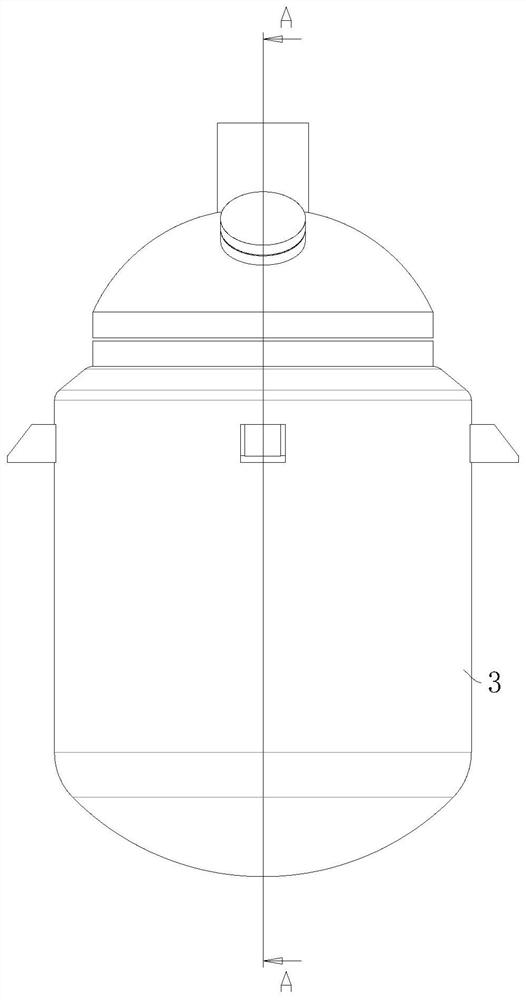

Anti-coking reaction kettle for petroleum refining

PendingCN114522659AImprove liquidityUniform refiningProcess control/regulationFeed devicesPhysical chemistryElectric machinery

The invention relates to the technical field of reaction kettles, in particular to an anti-coking reaction kettle for petroleum refining, which comprises a bottom plate, and the top of the bottom plate is fixedly connected with two vertical plates for supporting and fixing; the reaction kettle body is used for refining petroleum; the motor is used for providing driving force; a shaking mechanism for improving the mobility of petroleum is mounted on the outer side of the reaction kettle body. When the reaction kettle works, the reaction kettle moves left and right to shake, so that the mobility of petroleum can be effectively improved; when the reaction kettle works, the reaction kettle rotates, so that petroleum in the reaction kettle can be uniformly refined; when the reaction kettle works, cokes on the inner wall of the reaction kettle can be cleaned in the petroleum refining process of the reaction kettle, so that normal petroleum refining can be effectively ensured.

Owner:姬雅妮

A method for self-adaptive control of fractionation tower liquid level in petroleum refining process

ActiveCN109143853BImprove learning abilityImprove anti-interference abilityLevel controlAdaptive controlData acquisitionFractionating column

The invention discloses an adaptive control method for the liquid level of a fractionation tower in the petroleum refining process. In this method, the reverse error neural network and extreme value optimization method are used as adaptive tools, and the predictive PI control strategy is designed in combination with the input and output of the actual operation process. The present invention first uses the data acquisition device to collect the past input and output of the system, and then designs an extreme value optimization algorithm as a solver to adjust the weight of the neural network online, thereby efficiently and accurately training the neural network; after satisfying the set error constraints, The trained neural network weight is used as the identification parameter of the system, and a system model close to the actual situation is established. Finally, the predictive PI control is designed to control the liquid level of the fractionation tower in the process of petroleum refining. By adopting the method of the invention, the interference of model mismatch to the system can be effectively relieved, the control performance is improved, and the application of advanced control in industrial process control is also promoted.

Owner:DONGHUA UNIV

A kind of quick-drying mist sealing layer material and its preparation method and application

The invention relates to a quick-dry fog sealing layer material, which is formed by the following components: 20wt percent to 40wt percent of asphalt-recycling agent, and 5wt percent to 25wt percent of complex solubilizer, wherein the asphalt-recycling agent is formed by deasphalted oil, heavy aromatic oil and additives; the additives are selected from at least one of the following compounds: dibutyl phthalate, epoxidized soybean oil, chlorinated methoxy fatty acid ester and parabens; the mass ratio of the deasphalted oil to the heavy aromatic oil to the additives is 1:0.1 to 1:0.05 to 0.5. The invention also relates to a preparation method and application of the quick-dry fog sealing layer material. According to the quick-dry fog sealing layer material, the heavy aromatic oil and the like during the petroleum refining process are utilized to form the asphalt-recycling agent so as to obtain the fog sealing layer material with high additional value, so that the quick-dry fog sealing layer material can play a role in preventing aging and regenerating on aged asphalt pavements. In addition, according to the quick-dry fog sealing layer material provided by the invention, the maintenance time at low temperature is only 2 to 4h, which is shortened by over half the time for sealing and maintaining of the existing fog sealing layer material.

Owner:EAST CHINA UNIV OF SCI & TECH

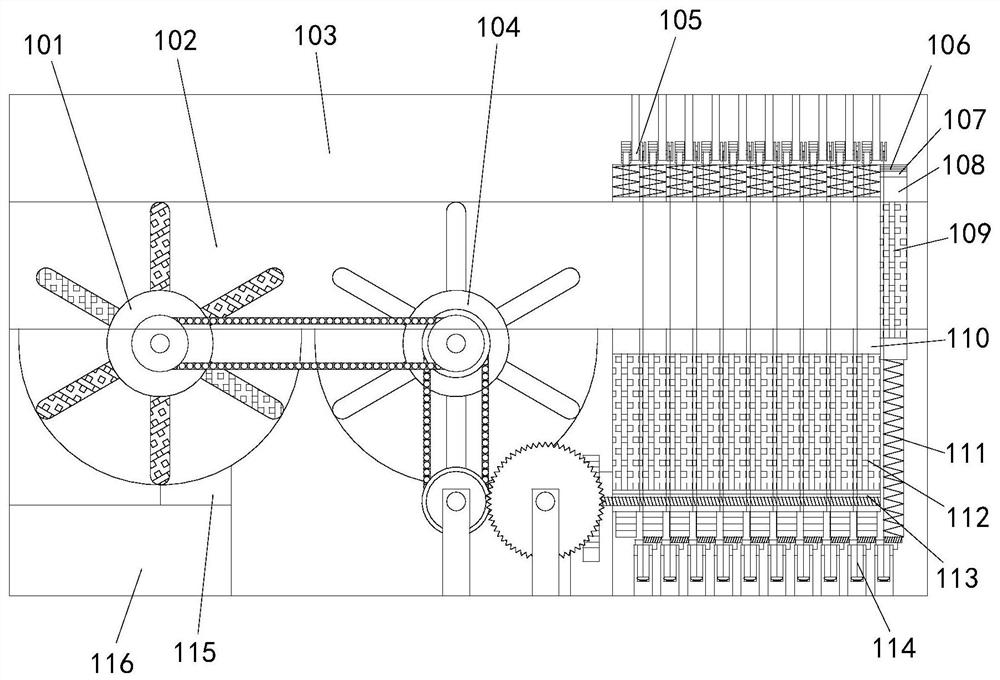

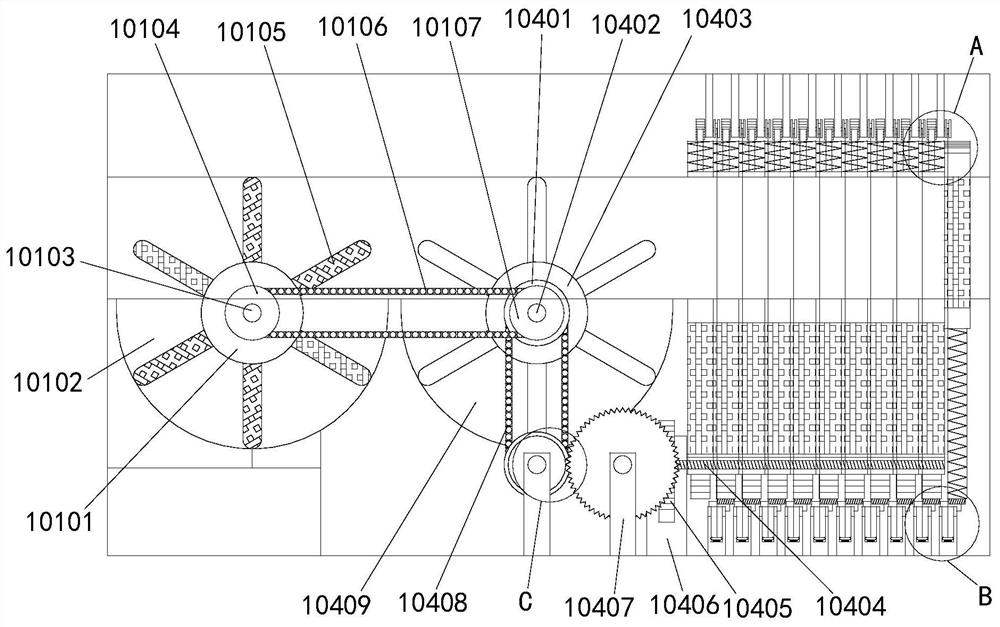

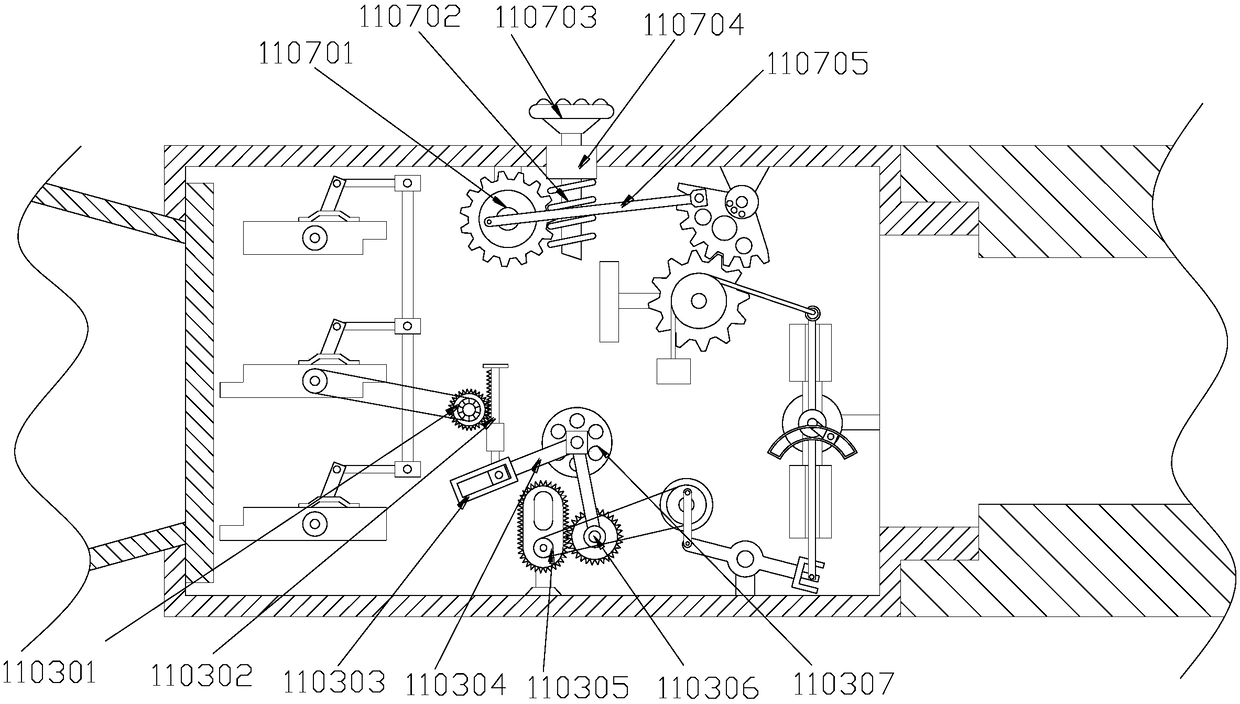

A kind of soot filter equipment used in petroleum refining process

ActiveCN108654228BTo prevent the problem of serious decline in filtering effectReduce ventilationDispersed particle filtrationTransportation and packagingFlue gasGear wheel

The invention discloses a smoke filter equipment used in petroleum refining process. Its structure includes a filter body, a filter plate assembly cover plate, a power on and off controller, a support base plate, and a miscellaneous box. The filter body is a cuboid, and the right side of the front end is inlaid The filter plate assembly cover is fastened, and the support bottom plate is welded on the front and rear sides of the bottom. The mechanism composed of springs, gears, chains, electromagnets, etc. enables the equipment to automatically switch between multiple spare filter plates at regular intervals, and can automatically lower and retract the front filter plates when switching to use, so that when the equipment is in use It can better prevent the filter drop, clogging and flue gas recirculation caused by the long-term use of the filter plate. It can also replace and clean the filter plate during work, and can perform secondary filtration, and can filter the impurities in the secondary filter. Automatic collection for ease of use.

Owner:江苏鹏威重工股份有限公司

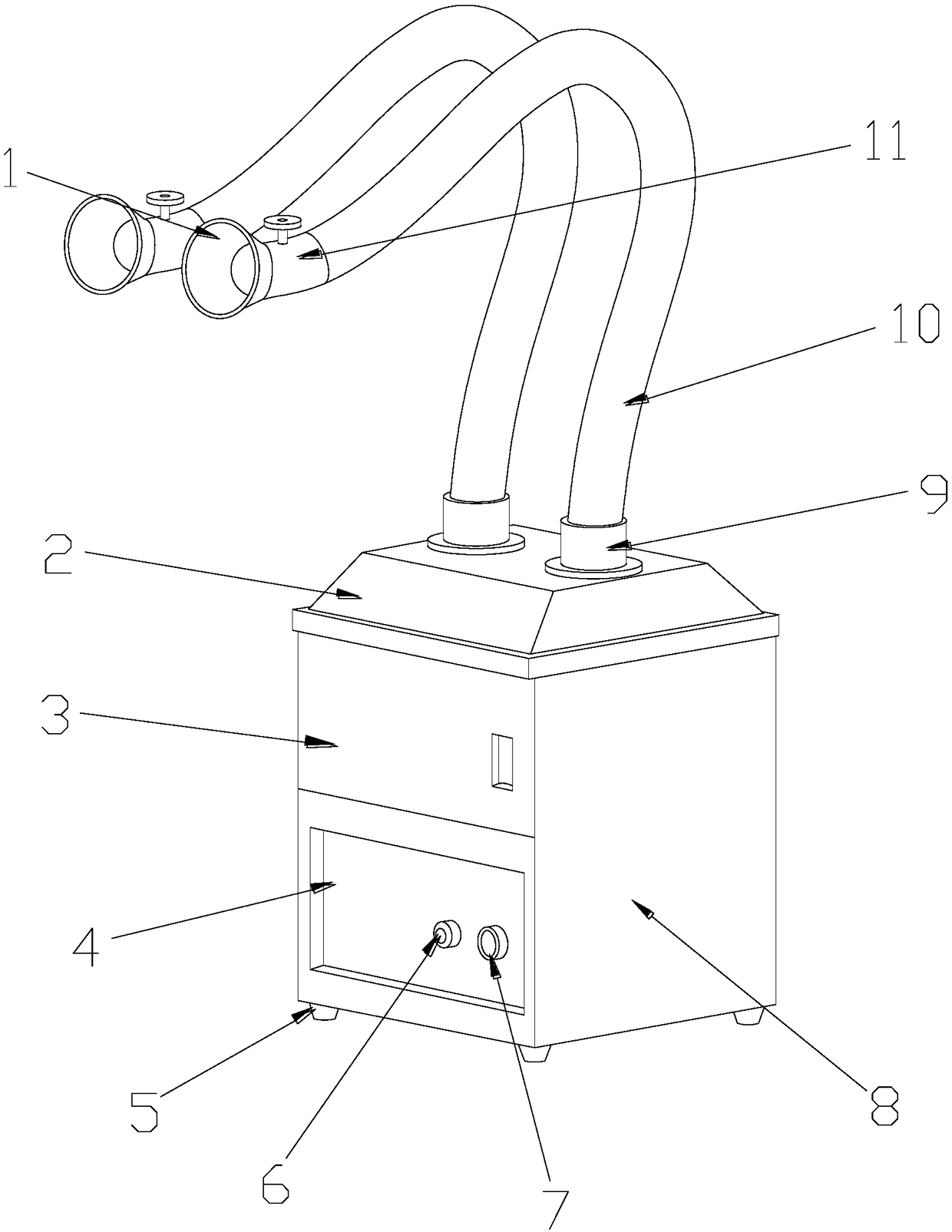

Smoke dust purification device for petroleum refining process

InactiveCN108526181ATo achieve the effect of adjusting the air intakeAvoid enteringDirt cleaningAir volumePetroleum

The invention discloses a smoke dust purification device for a petroleum refining process. A structure of the smoke dust purification device for the petroleum refining process comprises an air suctioncover, a device sealing cover, a smoke dust purification chassis, a control panel, anti-slip supporting legs, a control button, a power indicator light, a purification device shell, a fixing flange,a universal suction arm, and an air volume adjusting valve. The smoke dust purification device for the petroleum refining process realizes that the smoke dust purification device for the petroleum refining process is provided with the air volume adjusting valve, and smoke dust purification device for the petroleum refining process can adjust air inlet amount of the suction arm when being used, avoids excessive smoke entering the device to reduce purification quality, avoid impurities entering the inside of the device through the suction arm when not in use, effectively prolongs the service life of the device, and improves the practicality of the device.

Owner:谢云琼

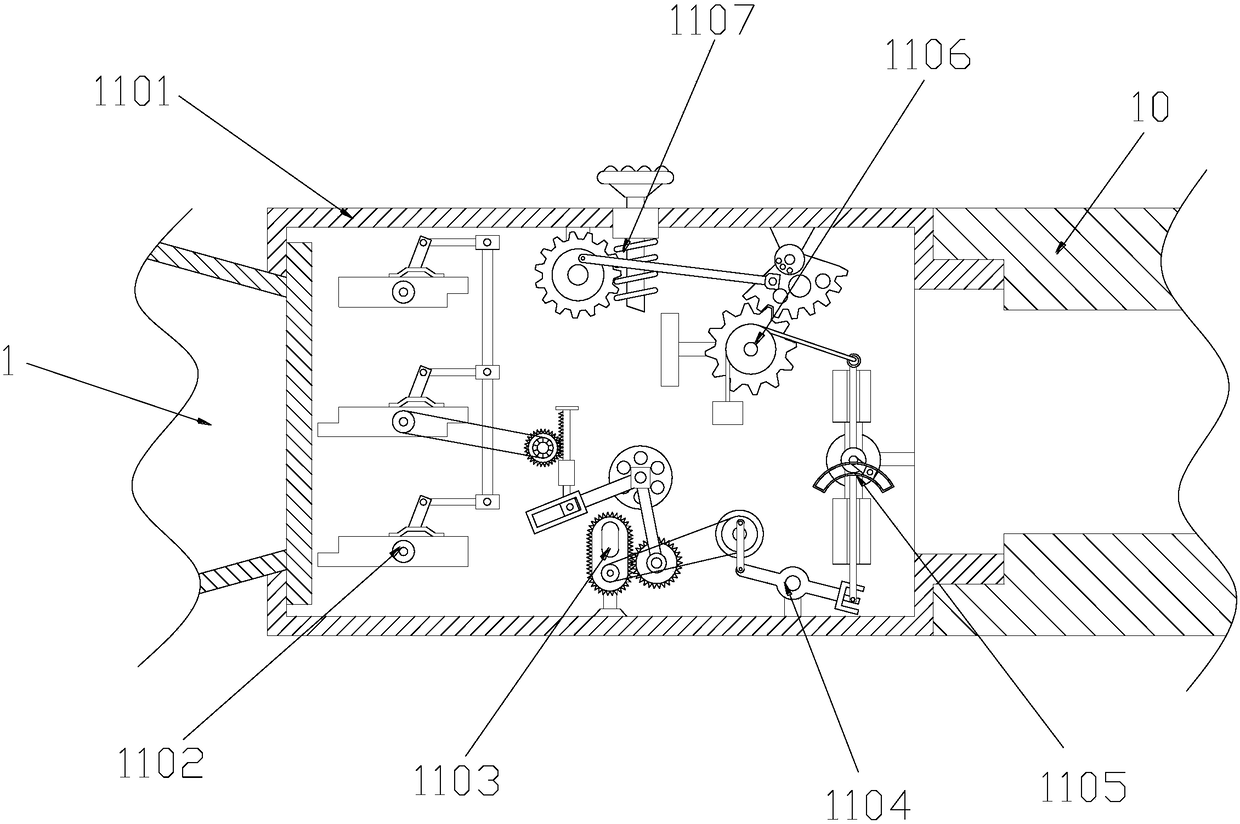

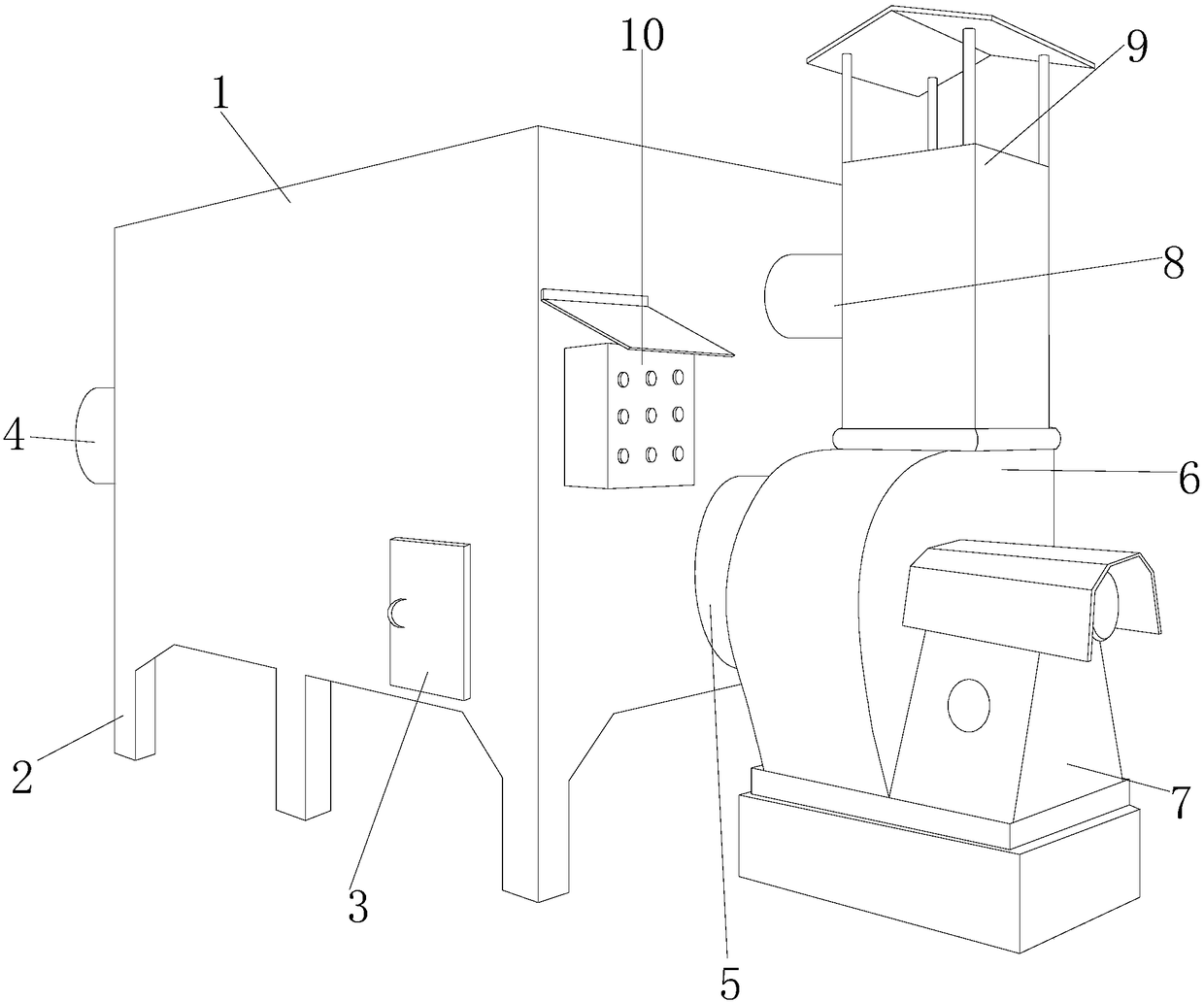

Smoke filtration equipment for petroleum refining process

InactiveCN108543378AImprove environmental performanceCombination devicesDispersed particle filtrationAtmospheric airFiltration

The invention discloses smoke filtration equipment for a petroleum refining process. The smoke filtration equipment structurally comprises a main smoke treatment device, equipment scaffolds, a filterresidue outlet, a smoke inlet pipe, a conveying and connecting pipe, an induced draft fan, an induced draft fan servo motor, a reflux retreatment device, an exhaust chimney and an electric control cabinet; the six equipment scaffolds are arranged below the main smoke treatment device and is vertically connected by electrowelding; the filter residue outlet is formed below the right of the front surface of the main smoke treatment device; and the smoke inlet pipe is arranged in the center of the left side of the main smoke treatment device and is vertically connected by electrowelding. Due to the arrangement of the reflux retreatment device, the treated smoke is detected, and smoke treated not to reach the standard can be automatically subjected to reflux retreatment, so that dust dischargedinto the atmospheric environment is kept to be gases reaching the standard, the environment is protected, and the environment friendliness of the smoke filtration equipment for a petroleum refining process is effectively improved.

Owner:南安冠玲工业设计有限公司

Method for retrieving and using technical remaining heat in petroleum refining process

InactiveCN100480587CPerfect processEasy to recycleLighting and heating apparatusHot-water central heatingProcess engineeringThermal water

This invention relates to a method for recovering and utilizing waste heat in oil refining including: 1, a high temperature hot water system recovers waste heat of all high temperature level and part of low temperature level and a low temperature hot water system recovers residual low temperature waste heat at a source part, 2, a heat trap part is divided into a stable part and an unstable part, the stable trap is taken as the main part of the high temperature hot water system and the unstable one is taken as the main part of the low temperature hot water system, 3, hot water is cooled to a stipulated temperature by a cooling system then sent to the source part to collect heat before returning to the source part.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving reaction and generation efficiency in petroleum refining

InactiveCN107760367AIncrease profitQuality improvementCatalytic crackingTreatment with plural serial stages onlySlurryRecuperator

The invention discloses a method based on improving the recovery efficiency of the petroleum refining process. The mixed wax oil and the atmospheric residual oil are respectively sent from the raw material tank of the tank farm to the static mixer in the device and mixed evenly, then enter the raw material buffer tank, and then Pump it out with a raw material pump, pass through the flow control valve, return to exchange heat, and then exchange heat with oil slurry to 170-220°C, and enter the static mixer together with the refined oil to mix evenly. Together, they enter the riser through six feed nozzles, contact with the high-temperature regenerated catalyst from the second secondary, and immediately vaporize, crack into light products and generate oil slurry, dry gas and coke. The process strictly controls the reaction and regeneration process, so that the obtained product meets the quality, improves the precision of refining, and improves the utilization rate of oil.

Owner:郭莉

A Boiler Internal Pressure Control System for Petroleum Processing

ActiveCN114413485BIncrease temperatureLow calorific valueControl of fluid heatersThermodynamicsControl system

The invention relates to the technical field of boilers, in particular to a boiler internal pressure control system for petroleum processing, which includes a boiler body and a feed pipe fixedly installed on the upper side of the boiler body for feeding raw materials into the boiler body and discharging materials. The pipe is fixedly installed at the lower end of the boiler body for discharging processed waste materials, and the distribution pipe is fixedly installed at the other side of the upper end of the boiler body for taking out different types of products produced during the petroleum refining process. A cavity is opened inside the boiler body, a metal plate is fixedly installed inside the cavity, and an electromagnetic heating device body is also installed at the bottom of the boiler body. In the present invention, after the pressure inside the boiler body increases, the controller will control the power of the electromagnetic heating device body to decrease, thereby reducing the calorific value of the metal plate, thereby preventing the temperature inside the cavity from continuing to rise.

Owner:东营市特种设备检验研究院

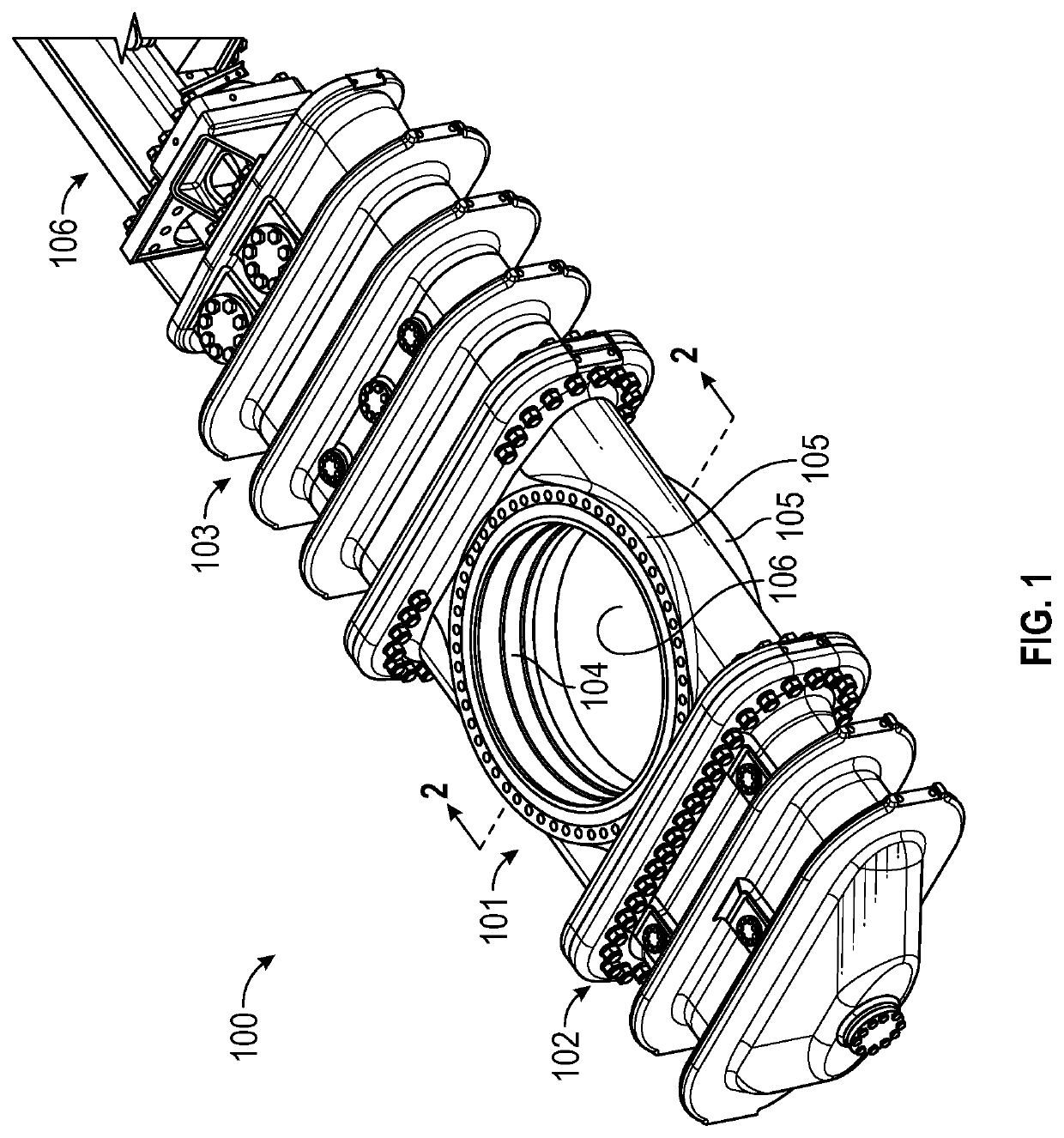

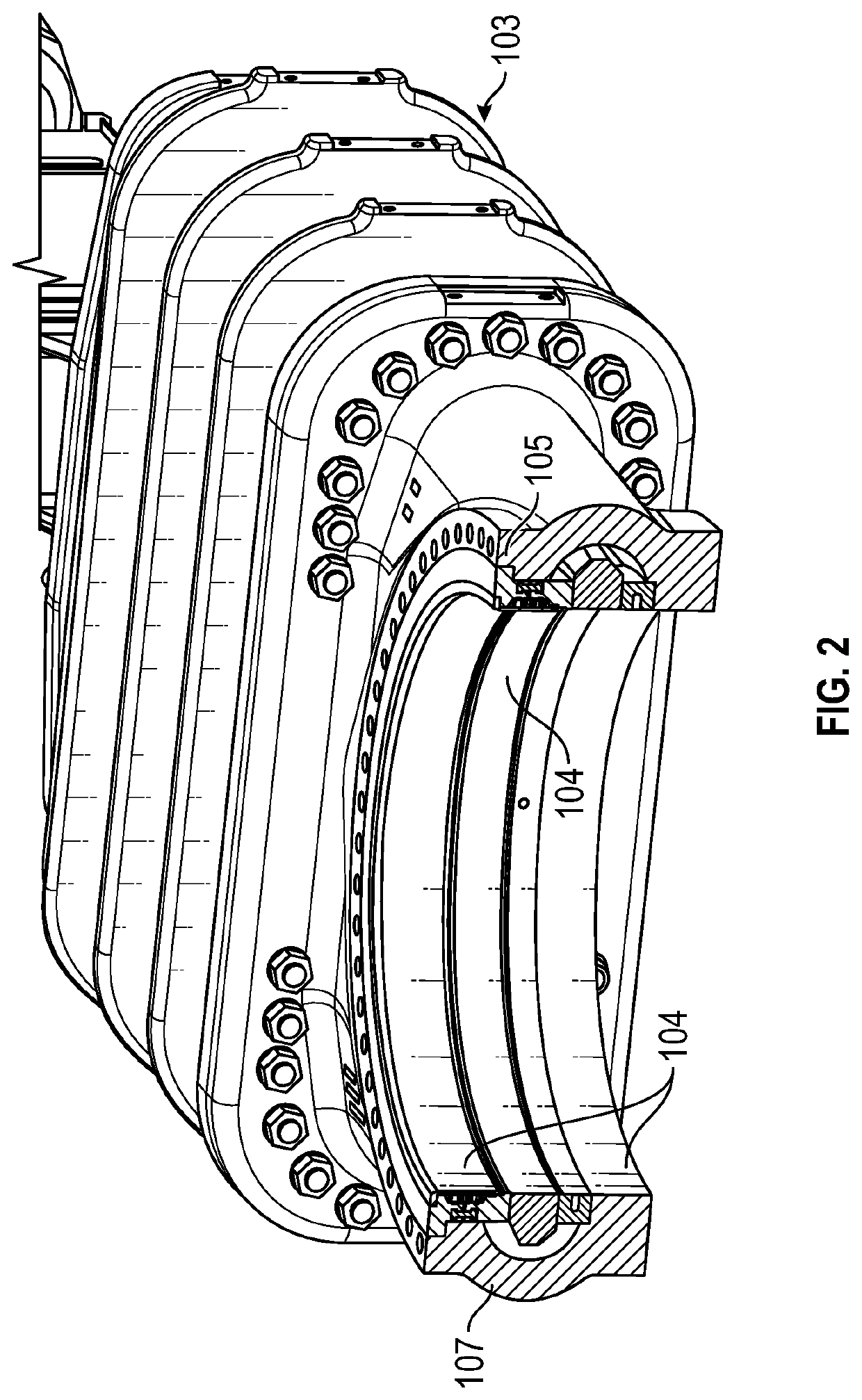

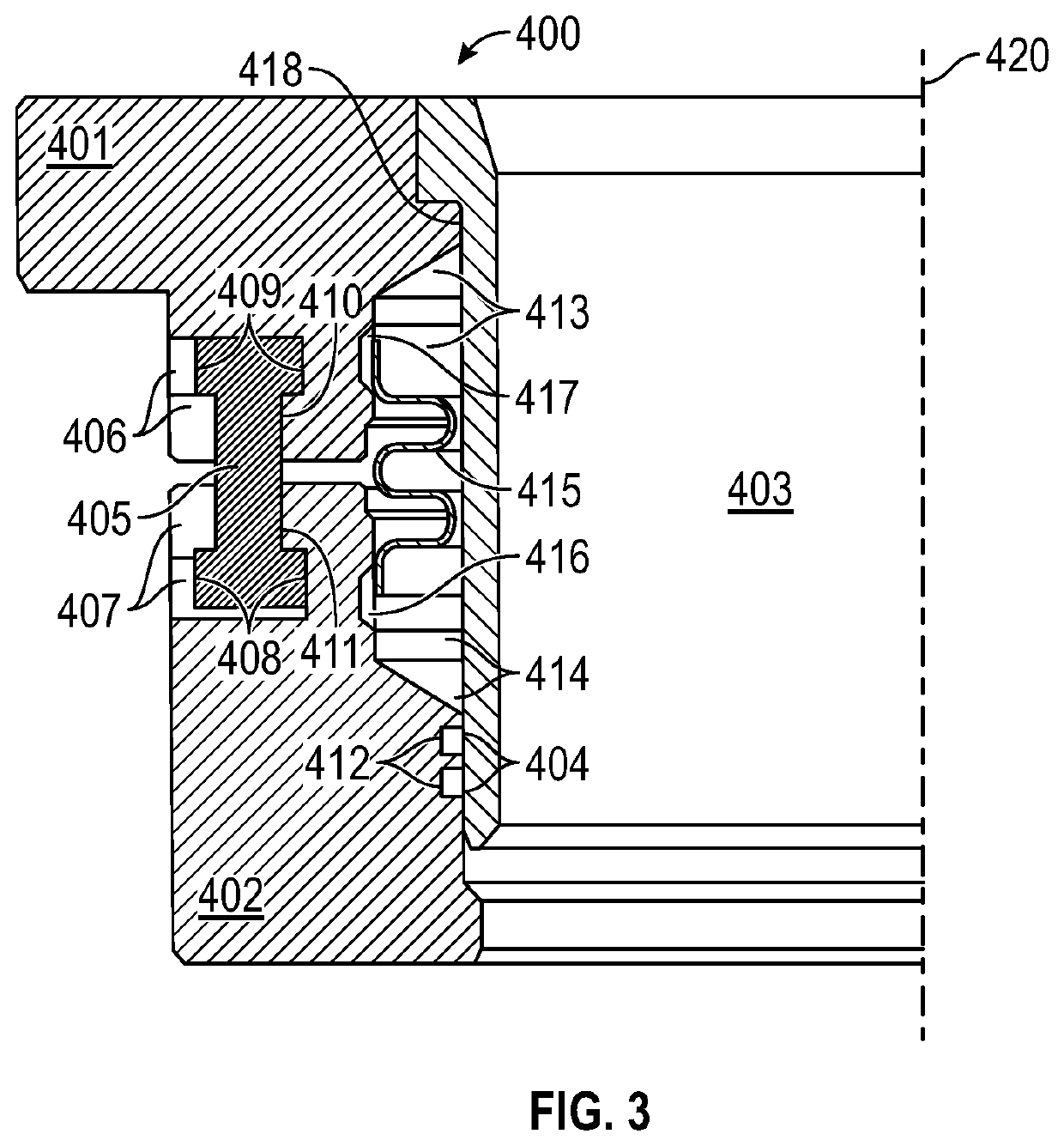

Systems and Methods for Valve Sealing

ActiveUS20200157431A1Preventing steam lossesPrevent leakageCoke quenchingSlide valveIsolation valveVALVE PORT

A system for sealing an unheading or isolation valve in a petroleum refining process. Some aspects relate to a bellows seal for preventing leakage of petroleum product and steam within the valve. Some aspects relate to a restrictor for restricting the motion of a dynamic seat relative to a seat base structure.

Owner:DELTAVALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com