Smoke filtration equipment for petroleum refining process

A technology for filtering equipment and soot, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluted environment, poor equipment working flexibility, uncontrollable gas reflux reprocessing that does not meet the standard, etc. Environmental performance, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

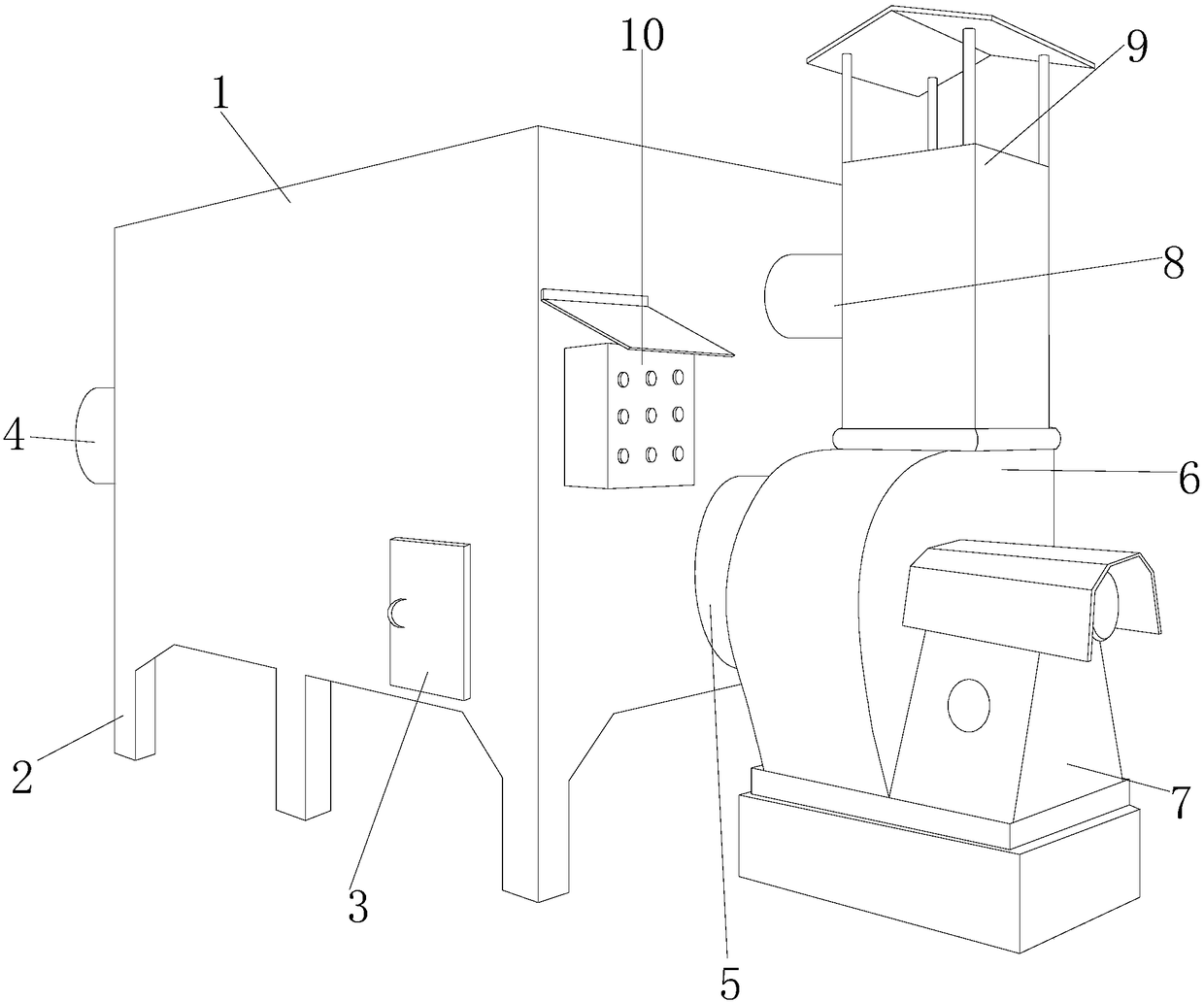

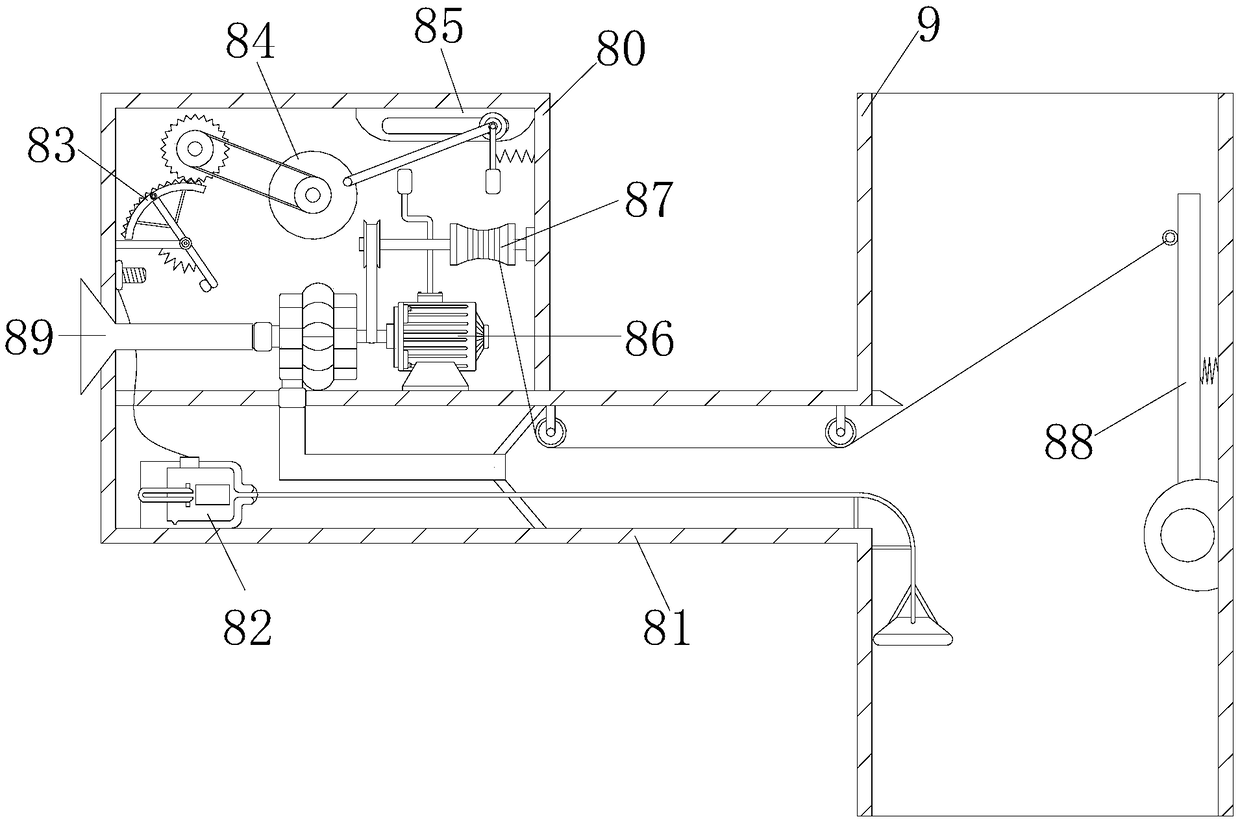

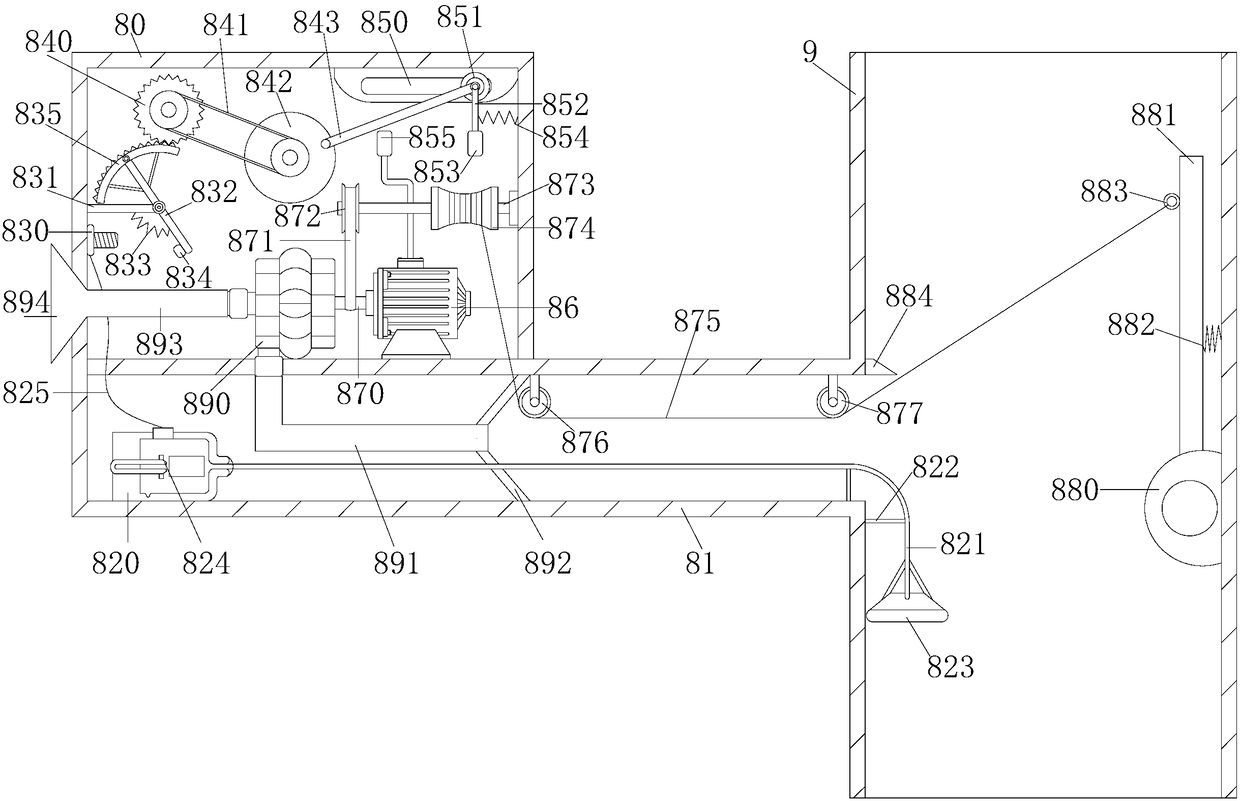

[0026] like Figure 1-Figure 4 As shown, the present invention provides a kind of technical scheme for the soot filter equipment of petroleum refining process:

[0027] A kind of soot filtering equipment used in petroleum refining process, its structure includes soot main treatment device 1, equipment stand 2, filter slag discharge port 3, soot inlet pipe 4, conveying connecting pipe 5, induced draft fan 6, induced draft fan servo motor 7. Reflow reprocessing device 8, exhaust chimney 9, electric control box 10, the main soot processing device 1 is in a rectangular structure, and the equipment tripod 2 is provided with six evenly arranged under the main soot processing device 1 and passed electric welding Vertically connected, the filter slag dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com