Vapor phase heat transfer oil and its preparation process

A preparation process and technology of heat conduction oil, which is applied in the field of heat conduction, can solve the problems of high cost of biphenyl-biphenyl ether mixture, increase of factory cost, etc., and achieve the effect of convenient industrial upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

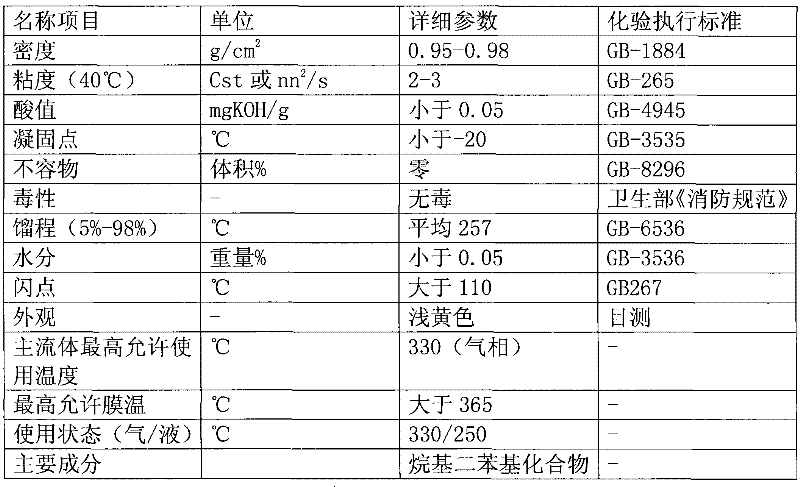

[0040] The gas-phase heat-conducting oil provided by the present invention includes alkyl diphenyl and its isomer compounds.

[0041] The preparation process of the vapor phase heat transfer oil comprises the following steps:

[0042] 1. Raw material selection. The raw material selected in this step is the bottom material of the catalytic reforming unit in the petroleum refining process or the bottom material of the p-xylene plant of the polyester production raw material or the hydrogenation raw material for the production of ethylene by-products by pyrolysis. The above raw materials contain a large amount of aromatics.

[0043] 2. Extraction of aromatics. In this step, chemical products such as benzene and xylene are obtained, and the remaining products are the primary raw materials for gas-phase heat transfer oil.

[0044] 3. Precision rectification and purification. In this step, the preliminary raw materials obtained in step 2 are purified, and the fraction at 240°C-270°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com