System for solving ultrahigh gas temperature of dynamic wave furnace of waste acid recycling device

A technology of dynamic wave and acid recovery, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of solid particle blockage of dynamic wave circulating cooling liquid, high temperature of the outlet furnace of dynamic wave, etc., and achieve long-term benefit Safe operation, reduced inlet temperature, and improved effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

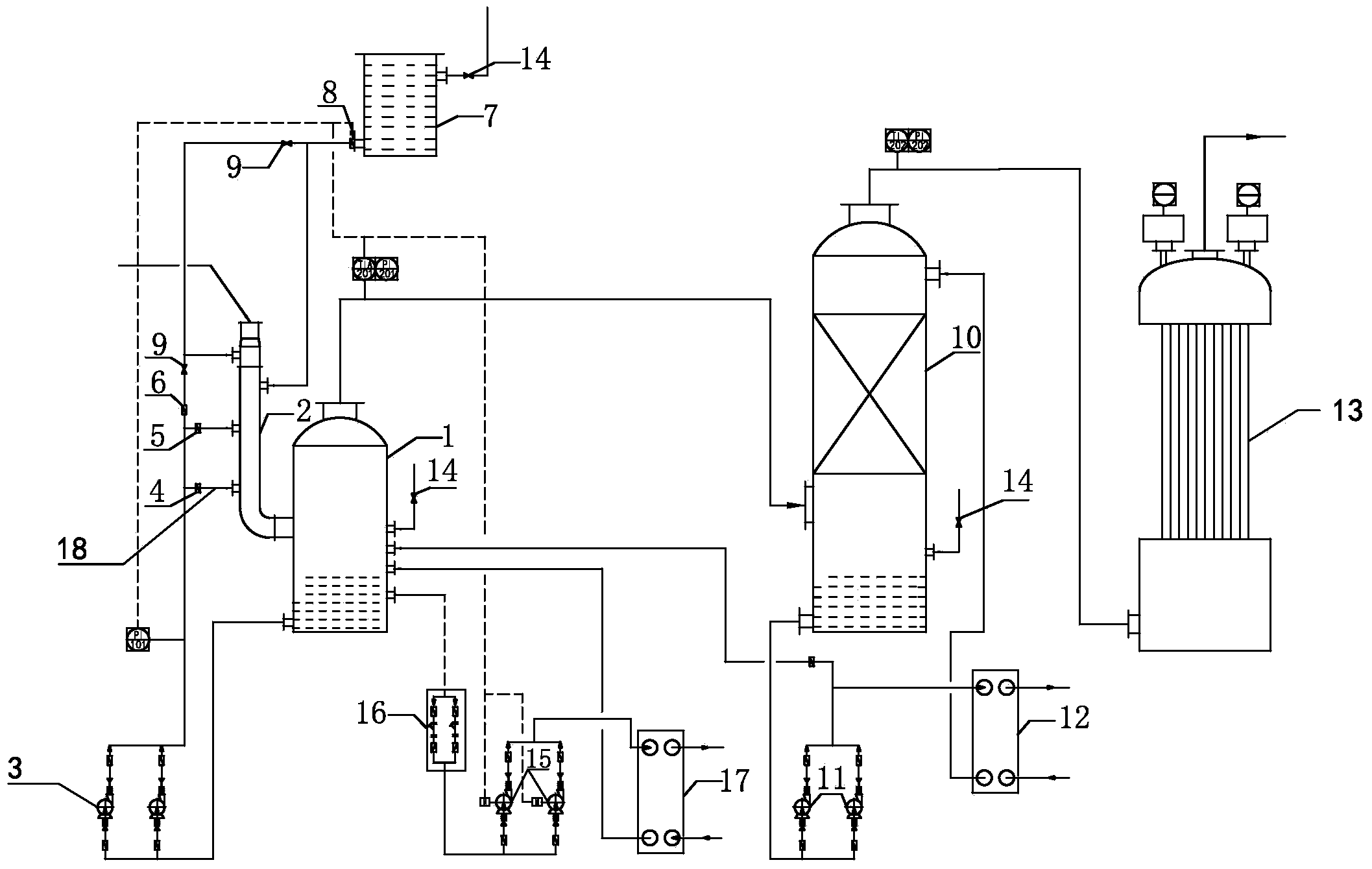

[0022] Such as figure 1 As shown, the furnace gas entering the purification section has a temperature of about 400°C, and first enters the dynamic wave exchange column 2. The dilute acid is pressurized by the dynamic wave dilute acid pump 3 and stabilized at a certain pressure head, and then sprayed by the reverse nozzle 18. The acid is in contact with the gas phase of the high-temperature furnace, and the pressure of the reverse nozzle is controlled by the first-stage nozzle control valve 4 and the second-stage nozzle control valve 5. The water in the dilute acid is quickly evaporated, and the temperature of the furnace gas is also reduced accordingly (adiabatic humidification process), The furnace gas enters the power wave gas-liquid separator 1 for gas-liquid separation, and most of the dust and other impurities in the furnace gas are removed. The furnace gas after adiabatic humidification enters the packing washing tower 10 for washing and cooling, and further removes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com