Manganese, zirconium and titanium ternary composite catalytic wet oxidation catalyst for alkaline residue wastewater as well as preparation method and application of catalyst

A technology of catalytic wet oxidation and ternary compounding, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve simple preparation methods, good practicability, and degradation efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

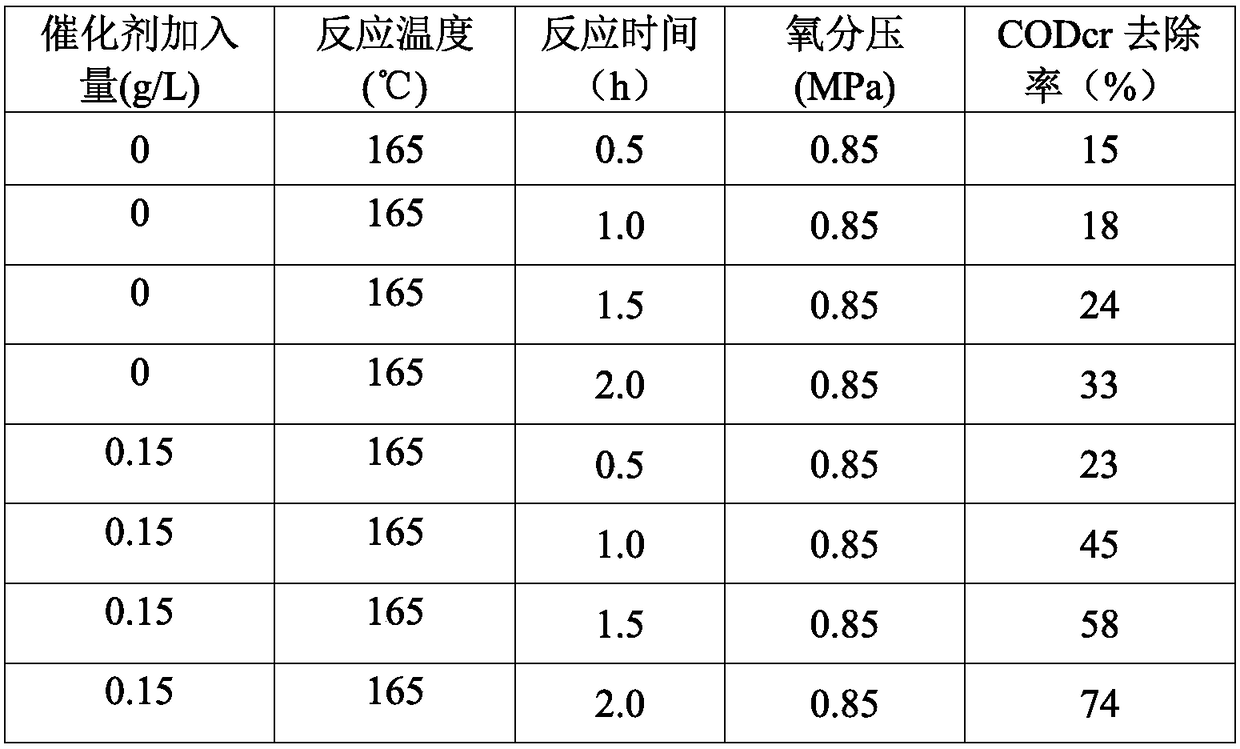

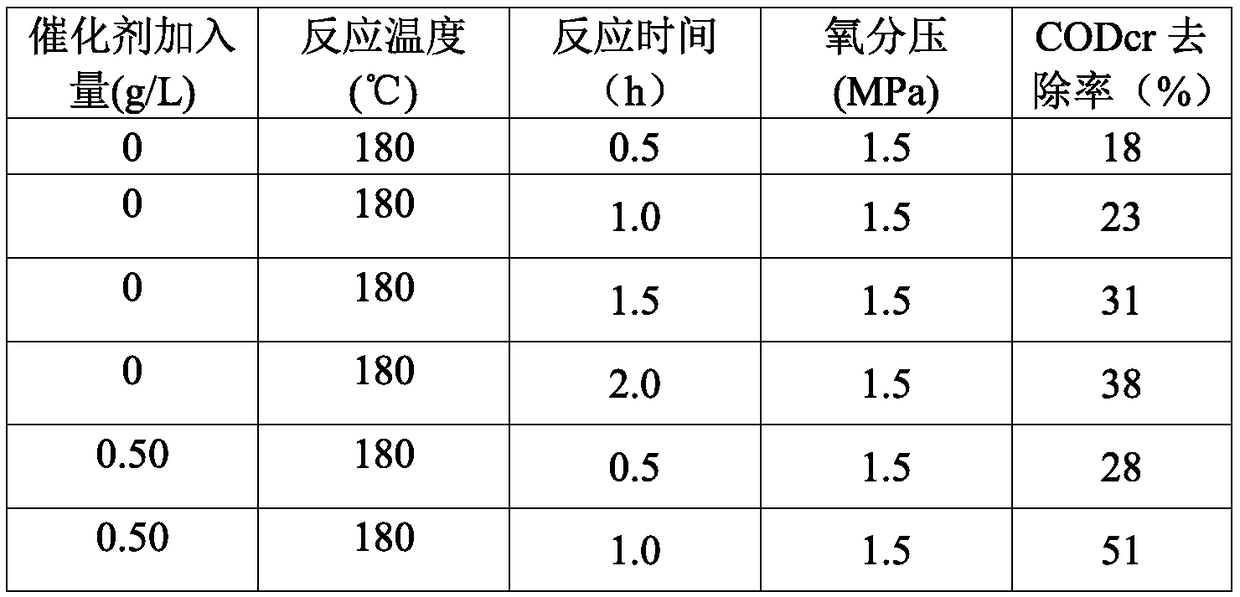

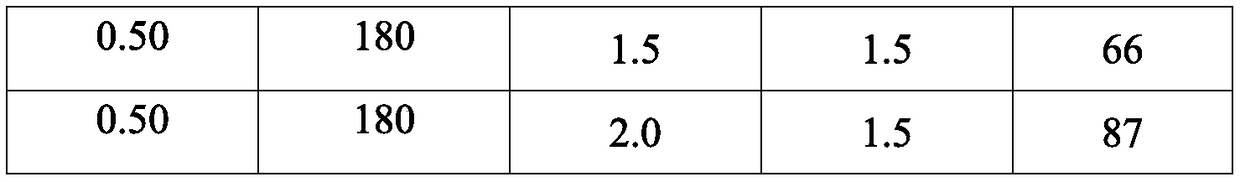

Examples

Embodiment 1

[0020] A method for preparing a manganese, zirconium, titanium ternary composite alkali slag wastewater catalytic wet oxidation catalyst, the steps are as follows:

[0021] 1) In the manganese chloride solution whose mass fraction of manganese element is 0.5%, add the nano-aluminosilicate crystal material according to the amount of adding 0.2g per liter of manganese chloride solution, dry to constant weight under vacuum condition, the temperature is 70°C. Afterwards, the prepared material was burned in a muffle furnace at 300° C. for 5 hours to obtain an intermediate product.

[0022] 2) Prepare a mixed solution of titanium sulfate and zirconium oxychloride, wherein the concentration of titanium sulfate is 0.03mol / L, the concentration of zirconium oxychloride is 0.02mol / L, and nitric acid is added therein (mass fraction concentration is 68%) , the addition of nitric acid is 0.5mL / L mixed solution of titanium sulfate and zirconium oxychloride. Use a peristaltic pump to gradua...

Embodiment 2

[0028] A method for preparing a manganese, zirconium, titanium ternary composite alkali slag wastewater catalytic wet oxidation catalyst, the steps are as follows:

[0029] 1) In the manganese chloride solution whose mass fraction of manganese element is 0.65%, add nano-aluminosilicate crystal material according to the amount of 0.35g per liter of manganese chloride solution, dry to constant weight under vacuum condition, the temperature is 70°C. Afterwards, the prepared material was burned in a muffle furnace at 350° C. for 6 hours to obtain an intermediate sample.

[0030] 2) Prepare a mixed solution of titanium sulfate and zirconium oxychloride, wherein the concentration of titanium sulfate is 0.05mol / L, the concentration of zirconium oxychloride is 0.05mol / L, and nitric acid is added therein (mass fraction concentration is 68%) , the addition of nitric acid is 0.8mL / L mixed solution of titanium sulfate and zirconium oxychloride. Use a peristaltic pump to gradually add th...

Embodiment 3

[0037] A method for preparing a manganese, zirconium, titanium ternary composite alkali slag wastewater catalytic wet oxidation catalyst, the steps are as follows:

[0038] 1) In the manganese chloride solution whose manganese element mass fraction is 0.8%, add the nano aluminosilicate crystal material according to the amount of adding 0.5g per liter of manganese chloride solution, dry to constant weight under vacuum condition, the temperature is 70°C. Afterwards, the prepared material was burned in a muffle furnace at 400° C. for 7 hours to obtain an intermediate sample.

[0039]2) Prepare a mixed solution of titanium sulfate and zirconium oxychloride, wherein the concentration of titanium sulfate is 0.07mol / L, the concentration of zirconium oxychloride is 0.08mol / L, and nitric acid is added therein (mass fraction concentration is 68%) , the addition of nitric acid is 1.2mL / L mixed solution of titanium sulfate and zirconium oxychloride. Use a peristaltic pump to gradually a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com